Impact of CO2-water-coal on enhanced coalbed methane recovery by CO2 injection in Huainan coalfield

-

摘要:

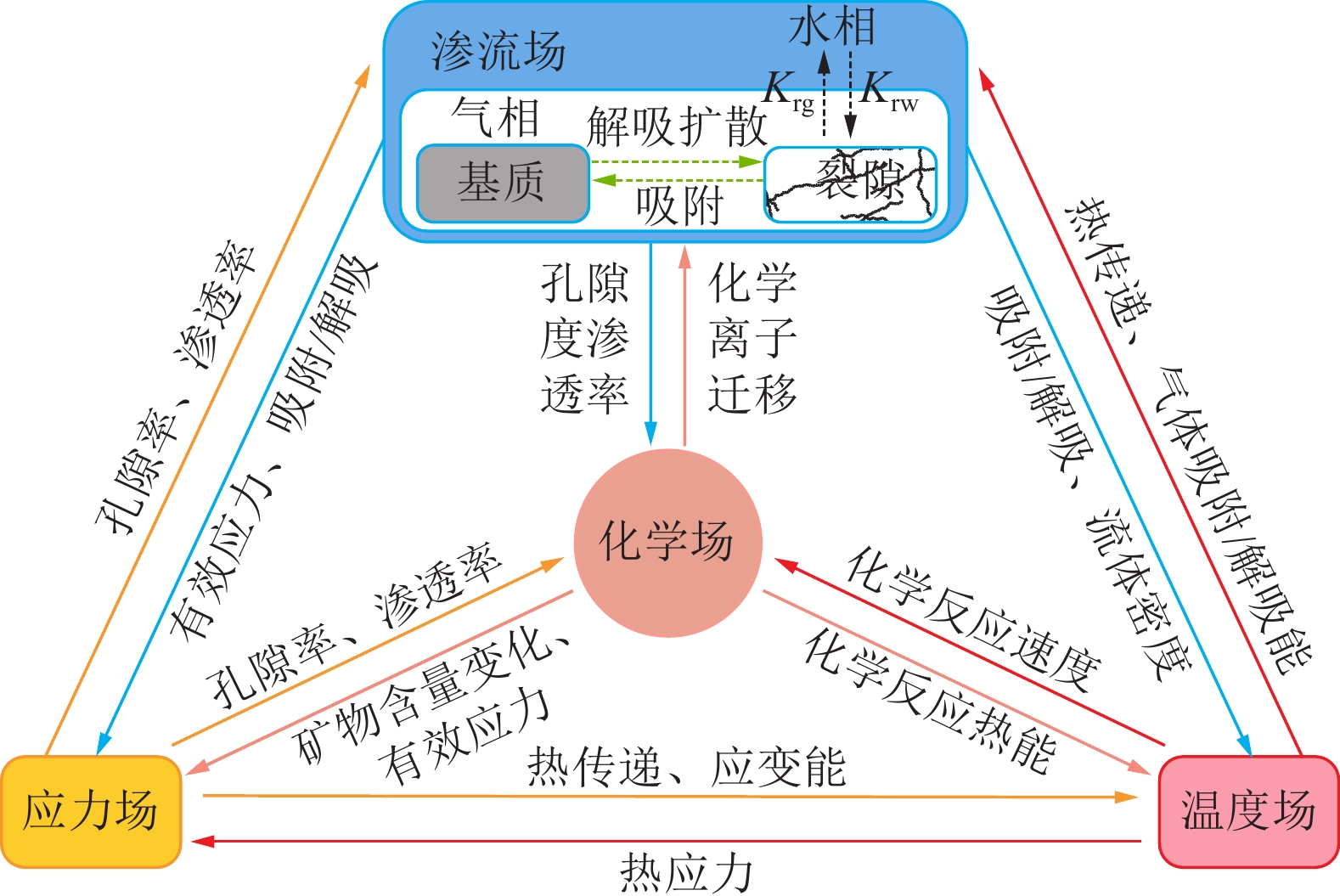

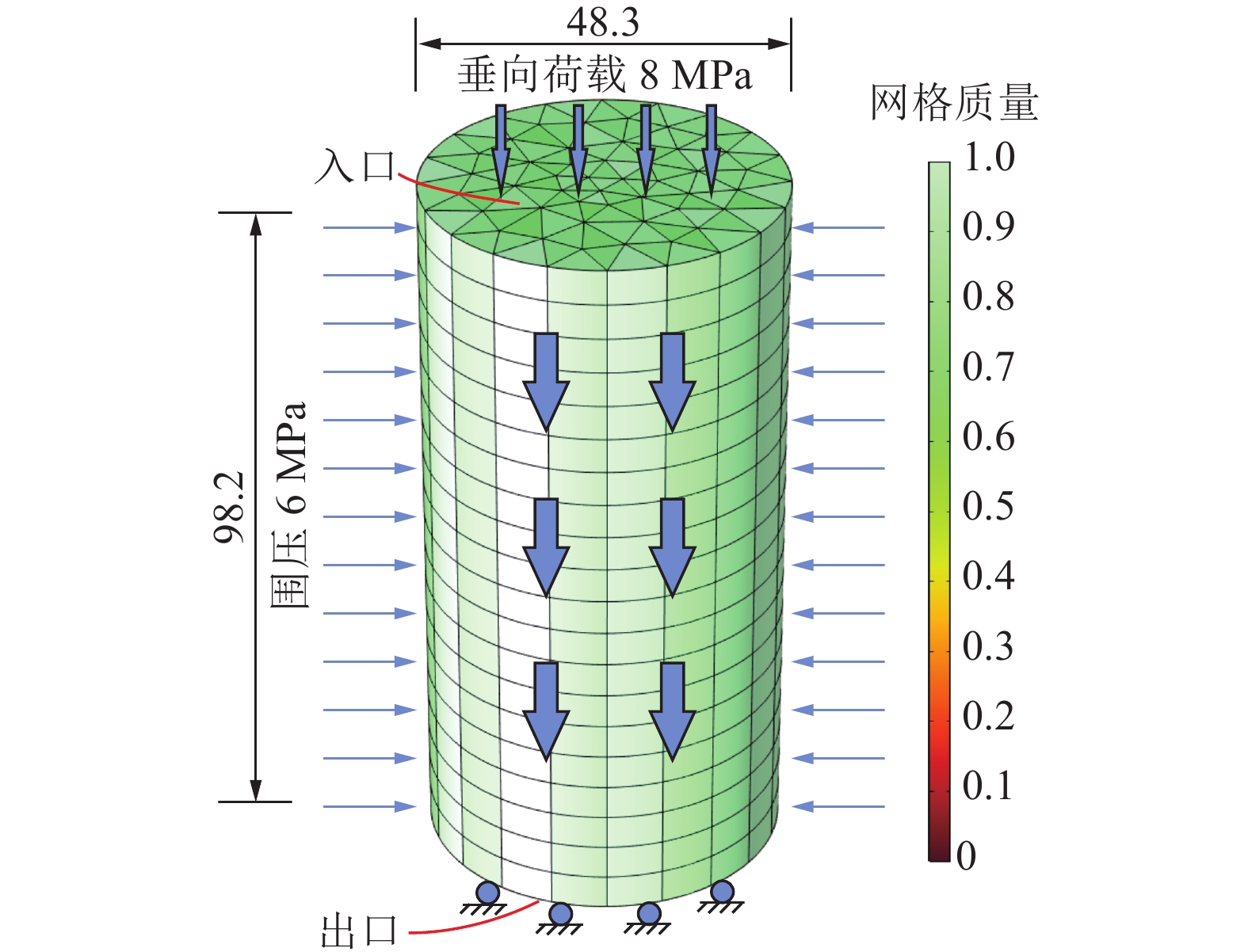

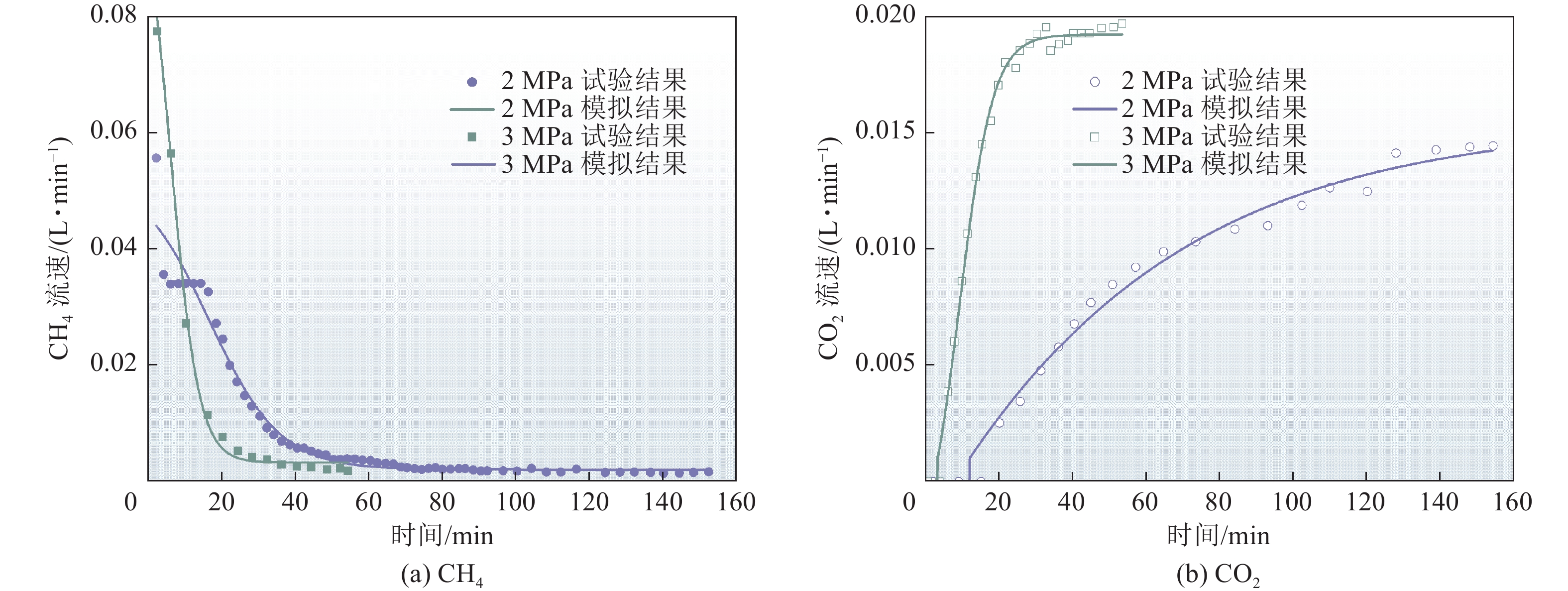

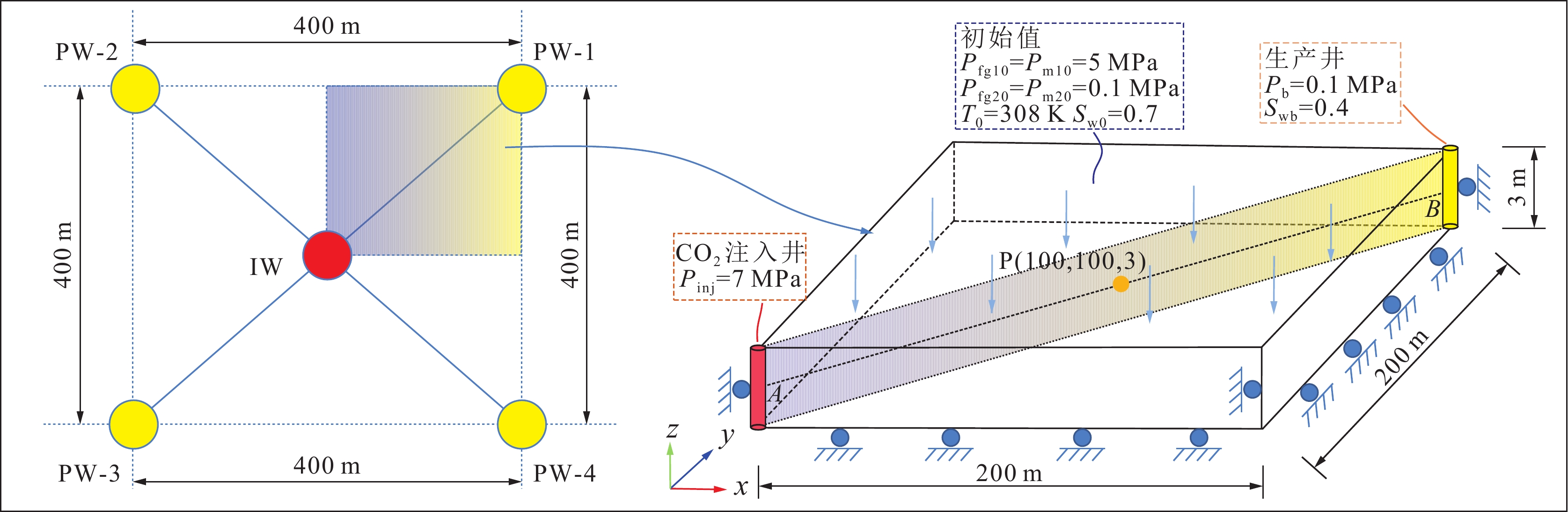

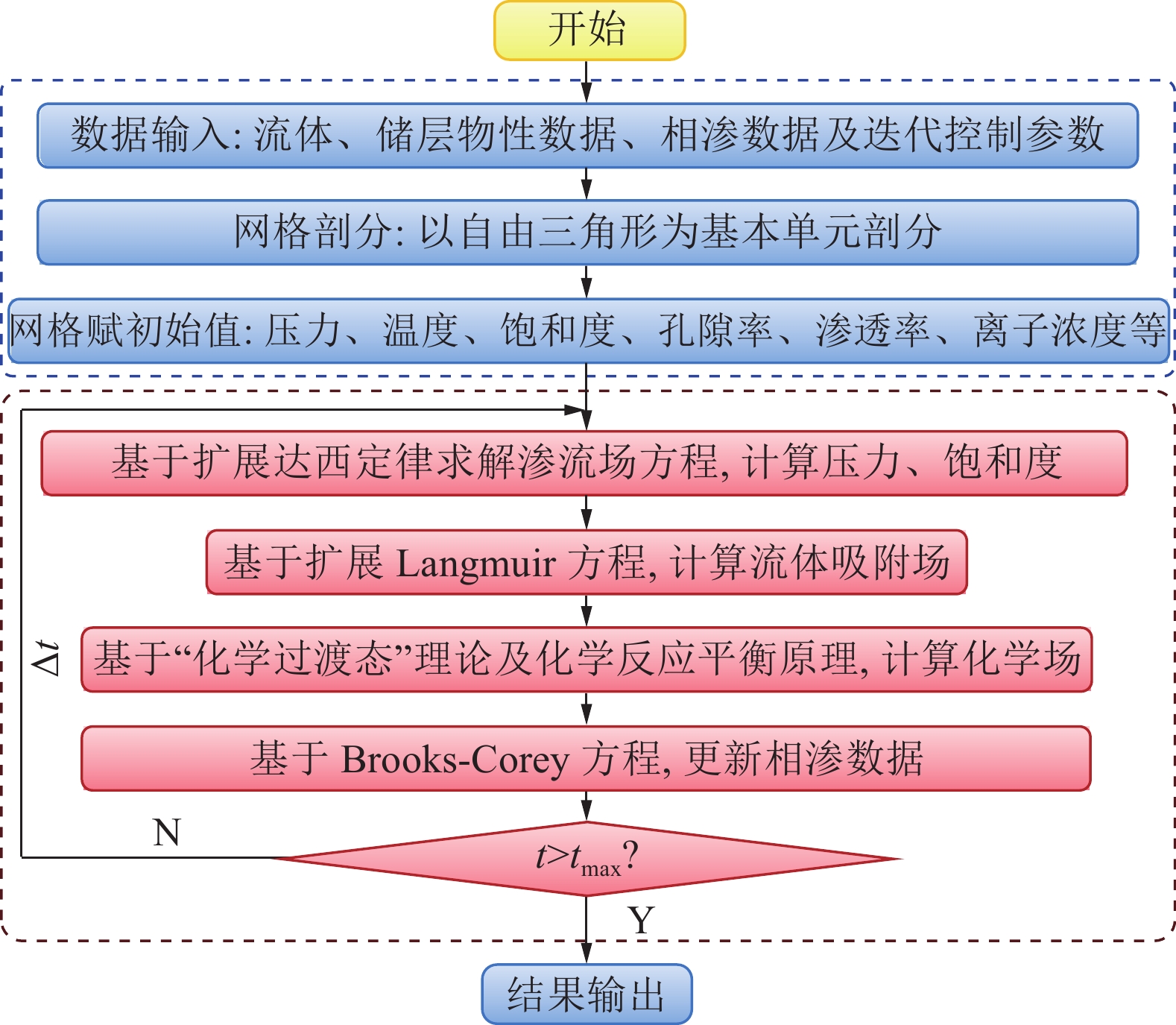

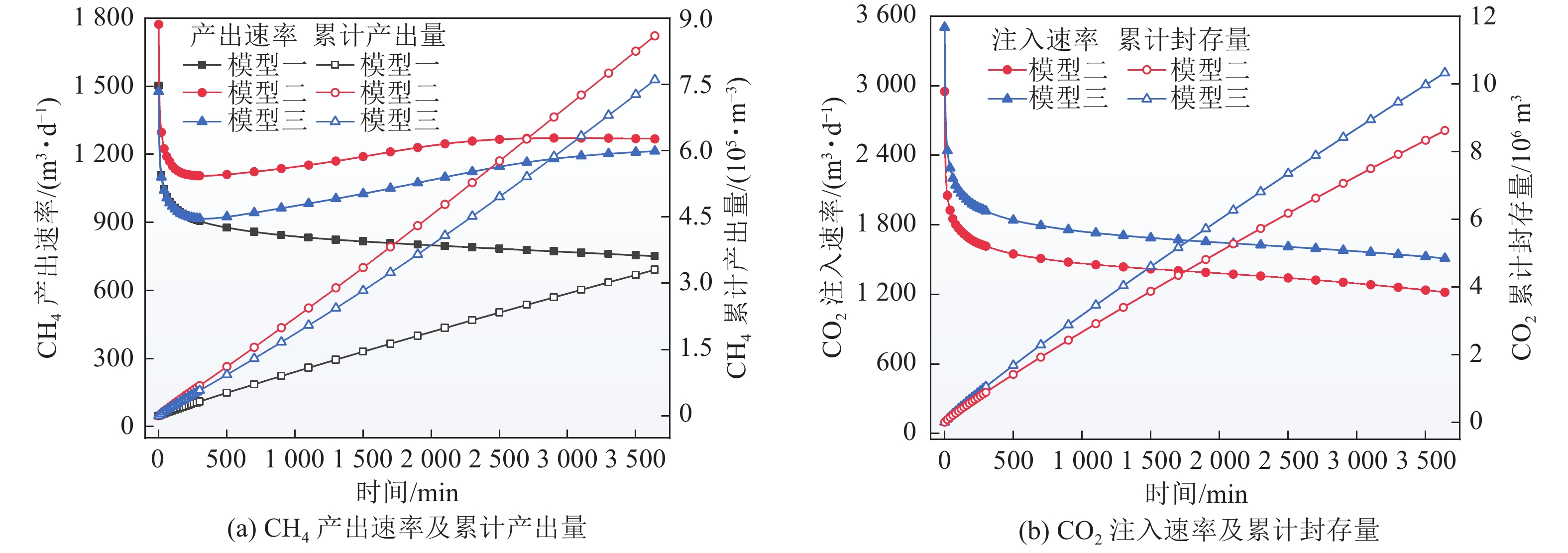

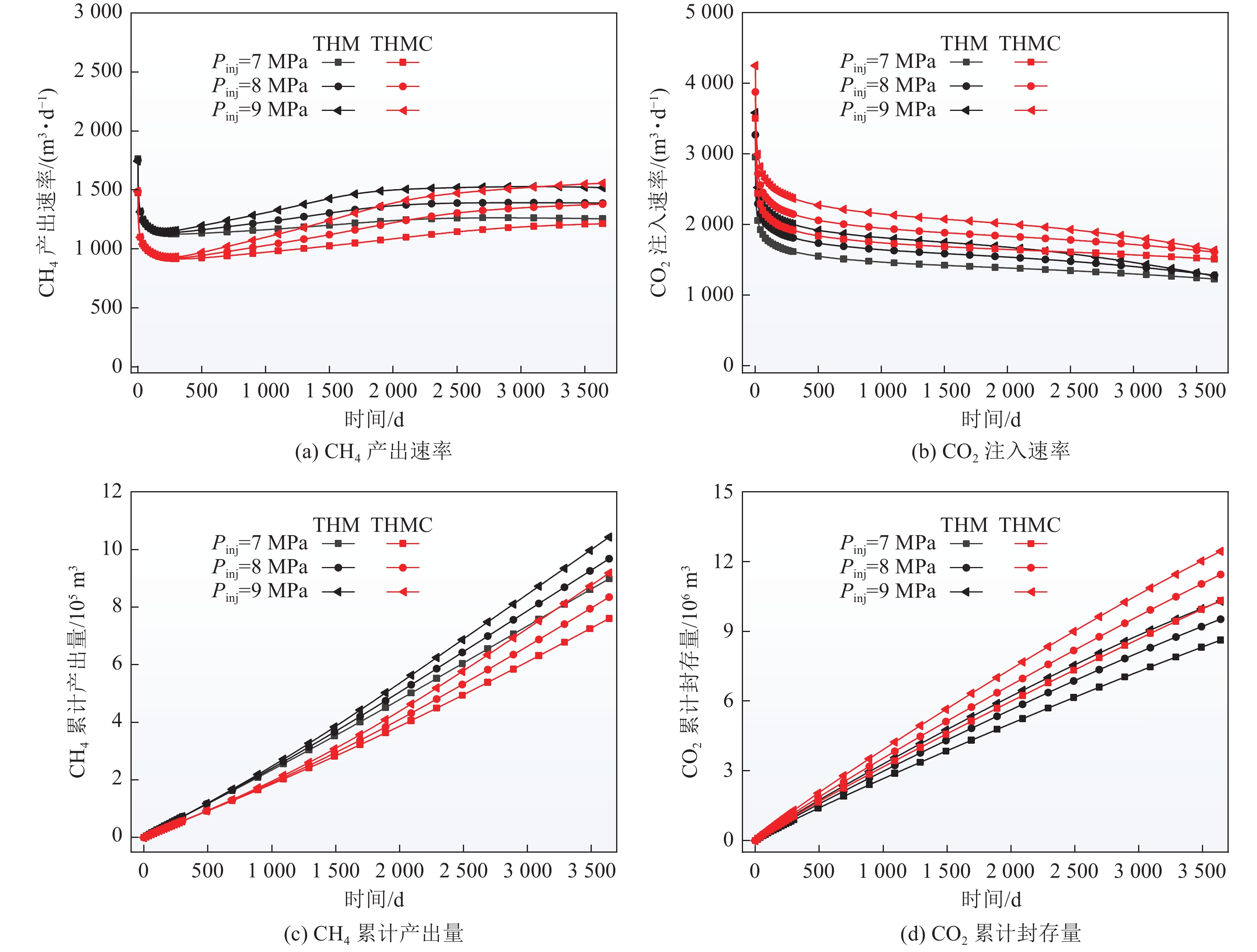

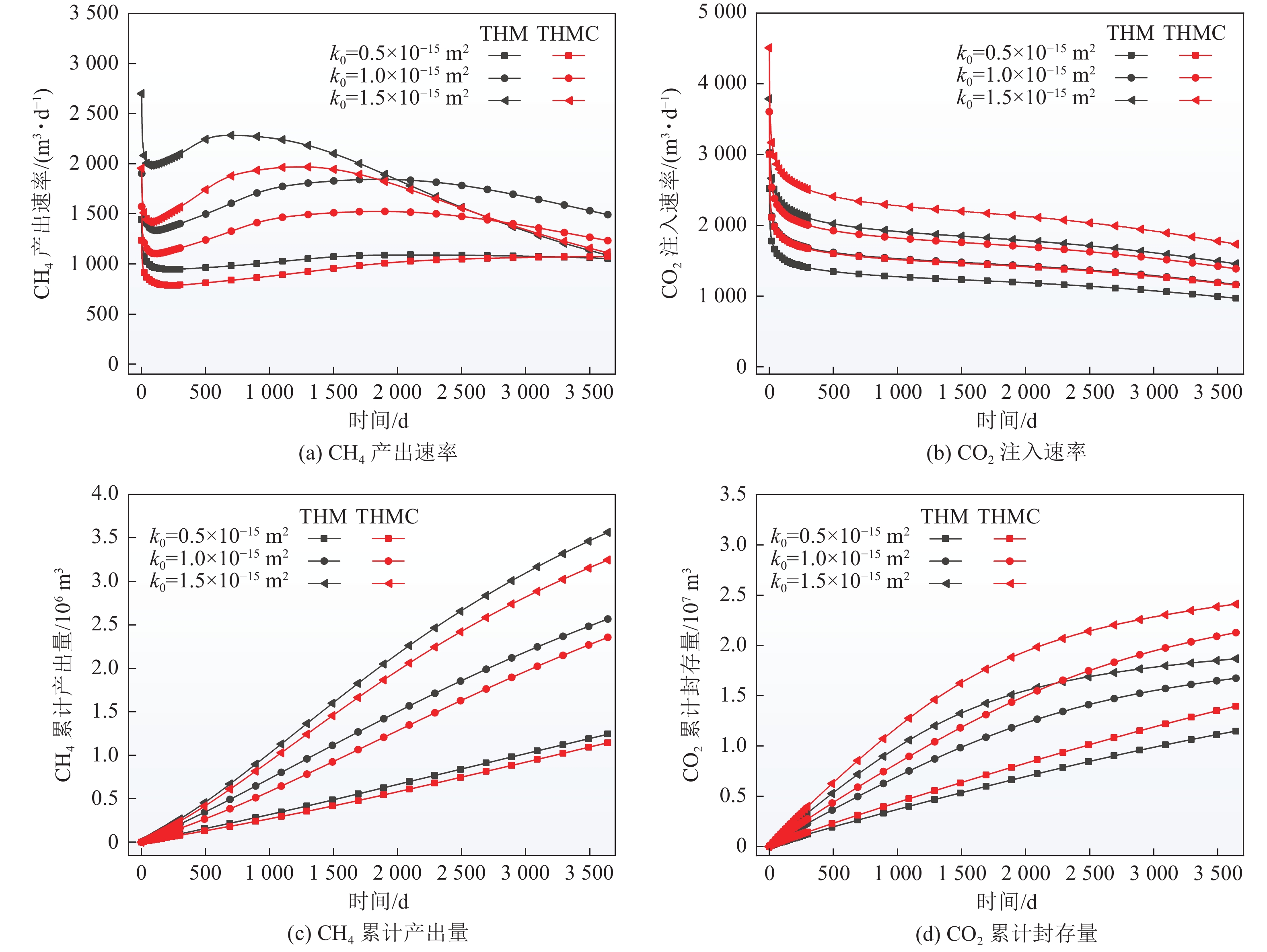

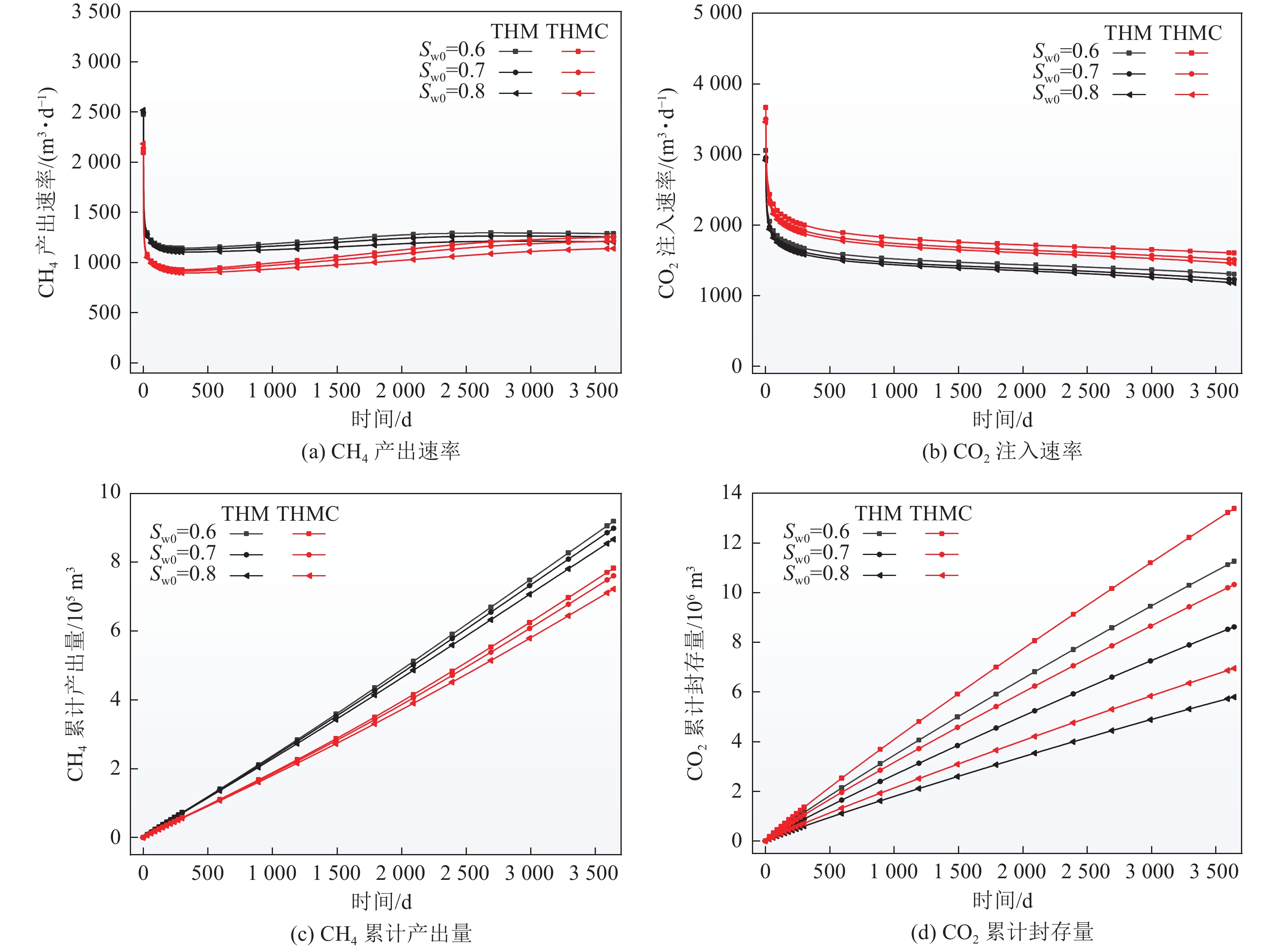

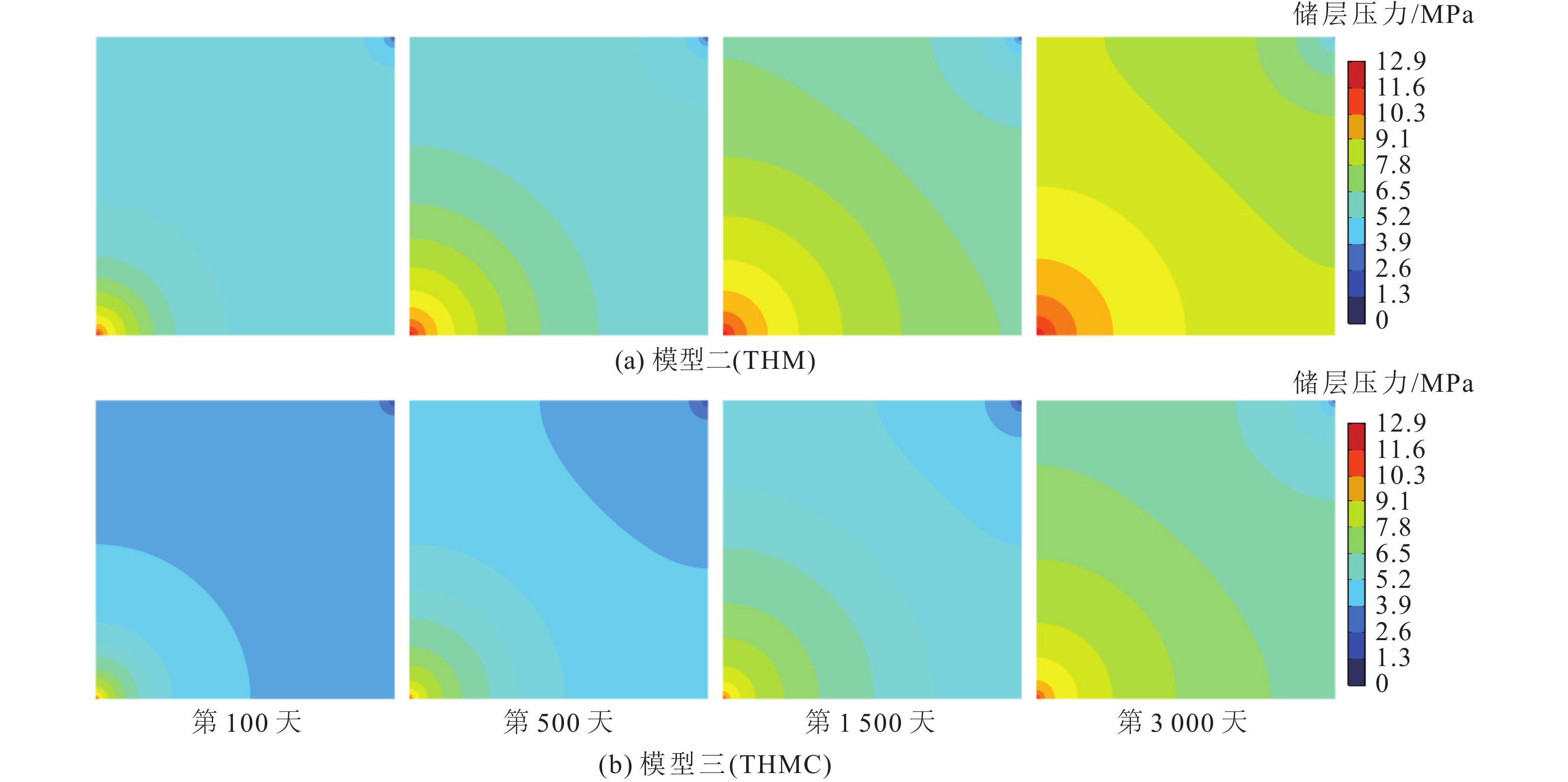

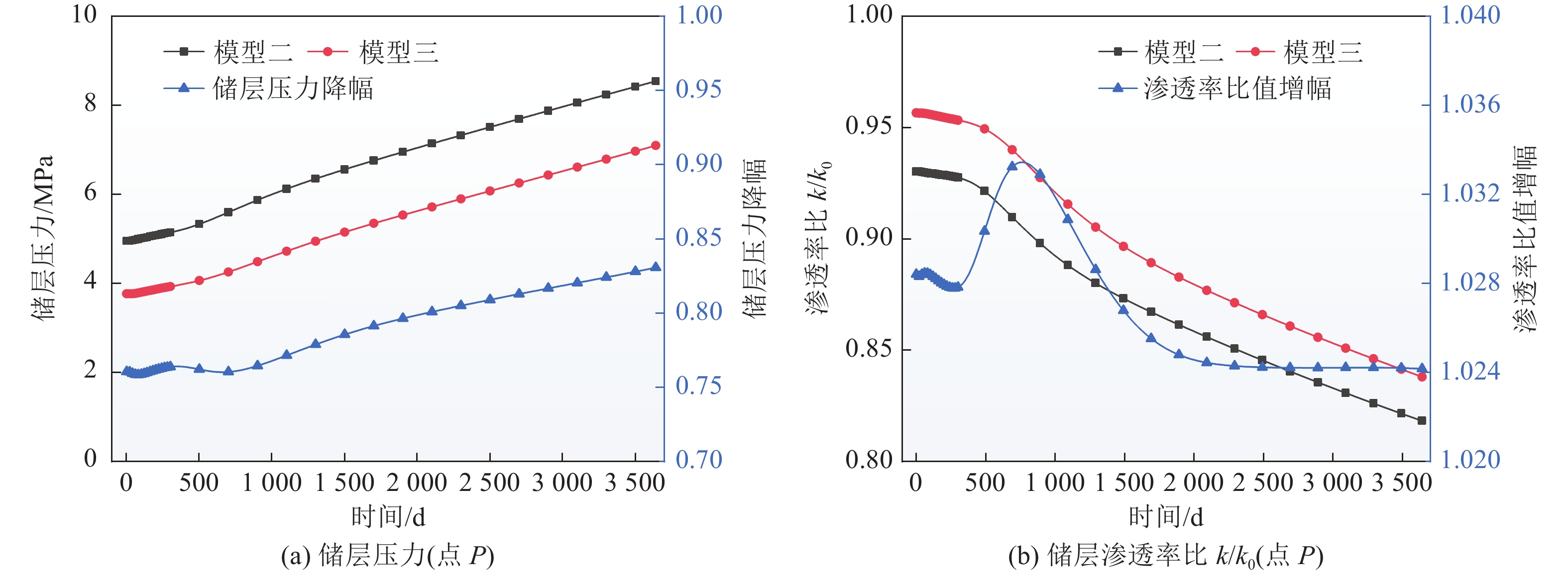

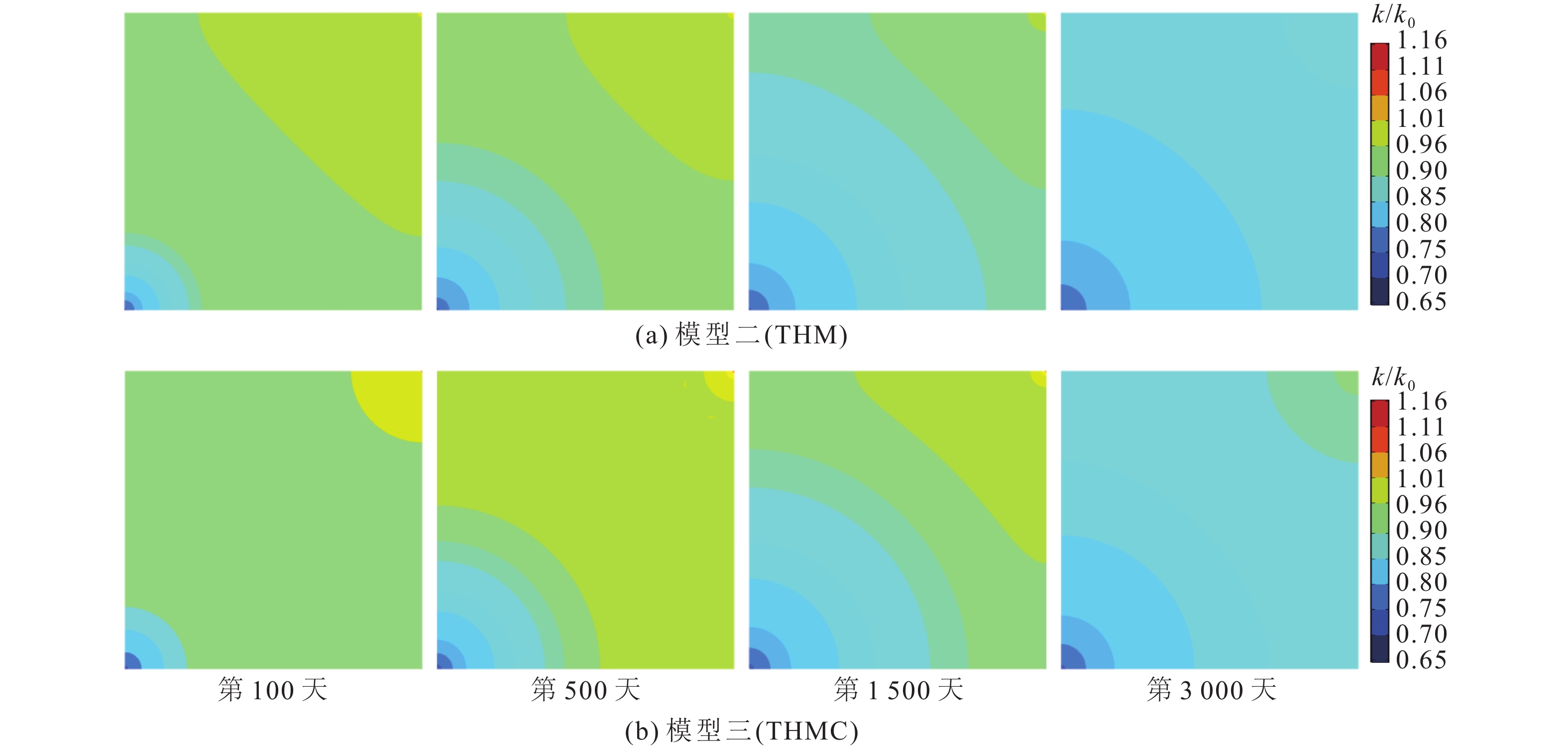

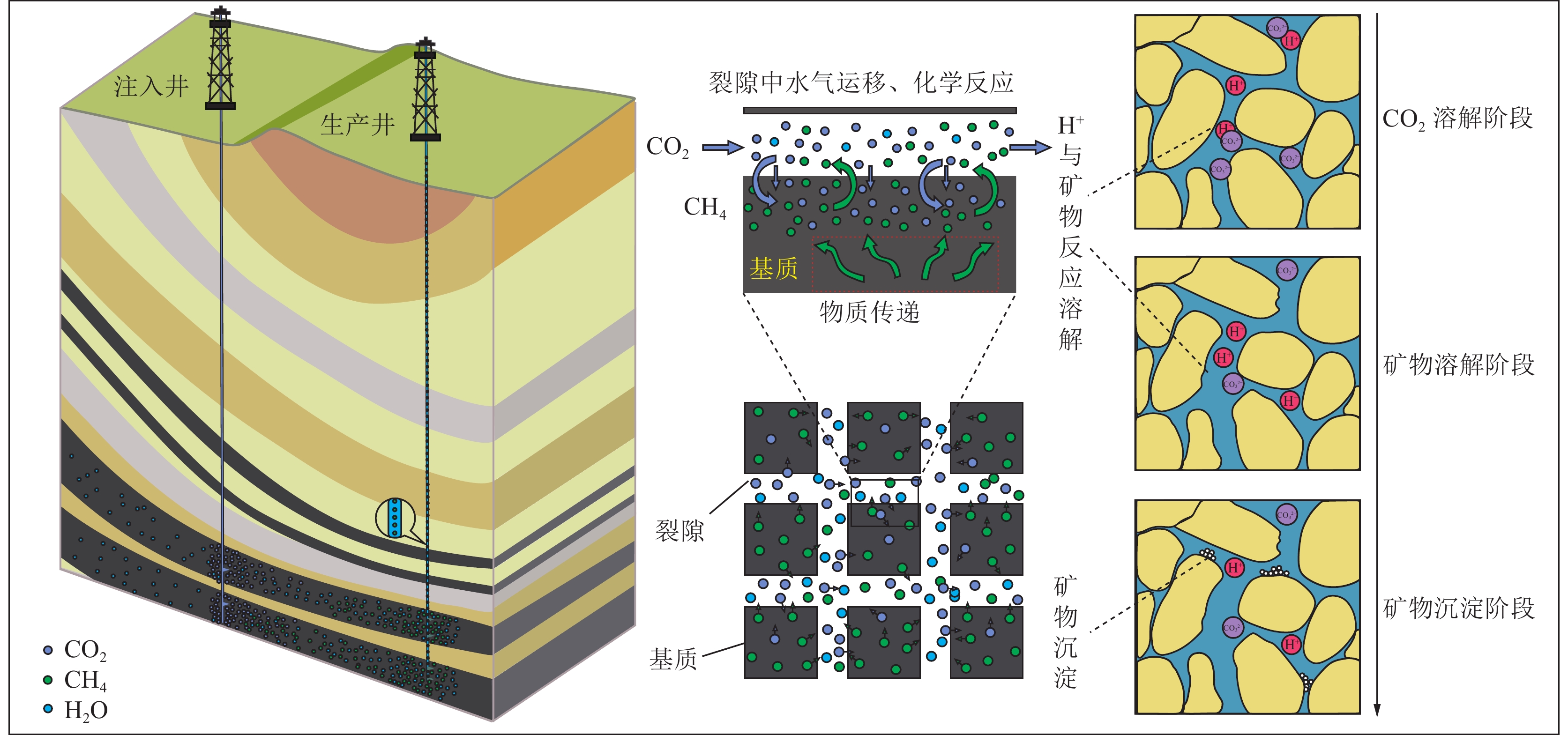

CO2驱煤层气封存(CO2-ECBM)是重要的CO2地质利用与地质封存方式,有望破解以淮南煤田为代表的松软、低渗、难抽采煤层煤层气开发效果差、产量衰减快等难题,提高煤层气产量和采收率。CO2注入煤层与煤中无机矿物的地球化学作用可导致煤层孔裂隙结构和渗透性的变化,对煤层CO2封存能力和煤层气增产效果具有显著影响。为此,考虑有效应力、温度及地球化学效应影响下的CO2与CH4竞争吸附、扩散与渗流作用、CO2−水−煤地球化学作用及其影响的煤层孔隙率与渗透率动态演化特征,建立了CO2注入煤储层渗流场−应力场−温度场−化学场全耦合数学模型,开展了淮南煤田CO2-ECBM工程数值模拟研究,分析了地球化学作用条件下,CO2注入煤层增产CH4效果,以及CO2注入压力、初始渗透率和含水饱和度等对CH4增产、CO2封存的影响。结果表明:数学模型与试验结果吻合度较高,CH4、CO2混合气体体积分数及产出速率平均误差为1%~10%;相较于未考虑地球化学作用的情况,模拟周期内CH4累计产量降低11%,CO2累计封存量提升19.8%,表明忽略CO2−水−煤地球化学作用会高估CH4增产效果和低估CO2封存量;注入压力和煤储层初始渗透率越大,CH4增产效果越显著,CO2封存量越大;而高含水饱和度对CH4增产和CO2封存产生不利影响,指示了CO2驱煤层气封存应结合储层性质,优选目标层位,并通过合理设计注入工艺最大化CH4增产和CO2封存效果;CO2−水−煤地球化学作用能够缓解CO2注入导致的储层压力升高,降低裂隙中自由态CO2含量,进而抑制应力−应变效应造成的煤储层渗透率下降,促进渗透率的回升,渗透率回升幅度达2.4%~3.3%,而渗透率回升进一步促进了储层压力传导和CO2吸附、CH4解吸与扩散,从而提升CH4增产和CO2封存效果。

Abstract:CO2-enhanced coalbed methane recovery (CO2-ECBM) is a key method for CO2 geological utilization and sequestration. It holds promise for addressing challenges such as soft, low-permeability coal seams with difficult gas extraction, poor development performance, rapid production decline, and low recovery rates, as exemplified by the Huainan coalfield. The geochemical interactions of CO2 injection into coal seams and inorganic minerals in coal can alter the pore-fracture structure and permeability of the coal, significantly influencing CO2 sequestration capacity and methane production enhancement. Therefore, considering the effects of effective stress, temperature, and geochemical interactions—including competitive adsorption, diffusion, seepage of CO2 and CH4, and CO2-water-coal geochemical interactions, as well as their impact on the dynamic evolution of coal seam porosity and permeability—a fully coupled Thermo-Hydro-Mechanical-Chemical mathematical model was developed for the seepage-stress-temperature-chemical interactions in CO2-injected coal reservoirs. Numerical simulation studies on CO2-ECBM were conducted for the Huainan coalfield to analyze the effect of geochemical interactions on CH4 production enhancement during CO2 injection, as well as the influence of injection pressure, initial permeability, and water saturation on CH4 production and CO2 sequestration. The results showed a high degree of consistency between the mathematical model and experimental outcomes, with the average error range for CH4 and CO2 mixture volumetric fractions and production rates falling within 1%−10%. Compared to scenarios ignoring CO2-water-coal geochemical interactions, the cumulative CH4 production decreased by 11%, while cumulative CO2 storage increased by 19.8%, indicating that neglecting geochemical interactions could lead to an overestimation of CH4 production and underestimation of CO2 storage capacity. Higher injection pressures and initial permeability of coal reservoirs resulted in more significant CH4 production enhancement and CO2 sequestration, whereas high water saturation adversely affected both processes. These findings suggest that CO2-ECBM should be tailored to reservoir properties, optimizing target layers and injection strategies to maximize CH4 production and CO2 storage. Geochemical interactions were found to alleviate the reservoir pressure increase caused by CO2 injection, reduce the free-state CO2 content in fractures. This, in turn, mitigated permeability decline due to stress-strain effects, promoting permeability recovery by 2.4%−3.3%. The permeability recovery further facilitated pressure transmission, CO2 adsorption, and CH4 desorption/diffusion, ultimately enhancing CH4 production and CO2 sequestration efficiency.

-

-

参数 数值 参数 数值 基质孔隙率 0.06 初始渗透率/m2 1.2×10−17 裂隙孔隙率 0.01 CH4朗格缪尔体积/(m3·t−1) 20 CH4动力黏度/(Pa·s) 1.03×10−5 CH4朗格缪尔压力/MPa 2.07 CO2动力黏度/(Pa·s) 1.38×10−5 CO2朗格缪尔体积/(m3·t−1) 31.4 水动力黏度/(Pa·s) 1.01×10−3 CO2朗格缪尔压力/MPa 1.38 初始水饱和度 0.6 CH4应变系数 0.0128 残余水饱和度 0.42 CO2应变系数 0.0237 表 2 数值模拟核心参数

Table 2 Key parameters for numerical simulation

参数 数值 参数 数值 煤体密度ρc/(kg·m−3) 1.47×103 标况下CH4密度ρs1/(kg·m−3) 0.717 初始基质孔隙率ϕm0 0.065 标况下CO2密度ρs2/(kg·m−3) 1.977 初始裂隙孔隙率ϕf0 0.025 初始渗透率k0/m2 3.5×10−16 CH4动力黏度μ1/(Pa·s) 1.34×10−5 CH4朗格缪尔体积常数VL1/(m3·t−1) 25.6 CO2动力黏度μ2/(Pa·s) 1.84×10−5 CH4朗格缪尔压力常数PL1/MPa 2.07 水动力黏度μw/(Pa·s) 1.01×10−3 CO2朗格缪尔体积常数VL2/(m3·t−1) 20.4 CO2溶解热eg2/(kJ·mol−1) 14.12 CO2朗格缪尔压力常数PL2/MPa 1.73 CH4吸附热qst1/(kJ·mol−1) 16.4 CH4朗格缪尔应变系数εL1 0.0128 CO2吸附热qst2/(kJ·mol−1) 19.2 CO2朗格缪尔应变系数εL2 0.0237 煤层初始温度T0/K 308 初始水饱和度sw0 0.7 煤层弹性模量E/GPa 3.033 残余水饱和度swr 0.2 煤骨架弹性模量Es/GPa 5.733 残余气饱和度sgr 0.05 裂隙刚度Kf/(MPa·m−1) 2 800 克林伯格因子bk/MPa 0.76 泊松比ν 0.37 裂隙初始CO2压力pfg20/MPa 0.1 煤比热容Cs/(J·kg−1·K−1) 1350 基质初始CO2压力pmg20/MPa 0.1 水比热容Cw/(J·kg−1·K−1) 4187 裂隙初始CH4压力pfg10/MPa 5 CH4比热容Cg1/(J·kg−1·K−1) 2220 基质初始CH4压力pmg10/MPa 5 CO2比热容Cg2/(J·kg−1·K−1) 844 CH4吸附时间τ1/d 0.221 热膨胀系数αT/K−1 2.4×10−5 CO2吸附时间τ2/d 0.334 温度系数d1/K−1 2.10×10−2 煤体导热系数λs/(W·m−1·K−1) 0.1913 压力系数d2/MPa−1 7.10×10−2 CH4导热系数λg1/(W·m−1·K−1) 0.0301 参考温度Tr/K 300 CO2导热系数λg2/(W·m−1·K−1) 0.0137 CO2亨利系数H2 0.0347 水导热系数λw/(W·m−1·K−1) 0.5987 表 3 储层中溶液组分初始质量摩尔浓度

Table 3 Initial concentrations of solution components in the reservoir

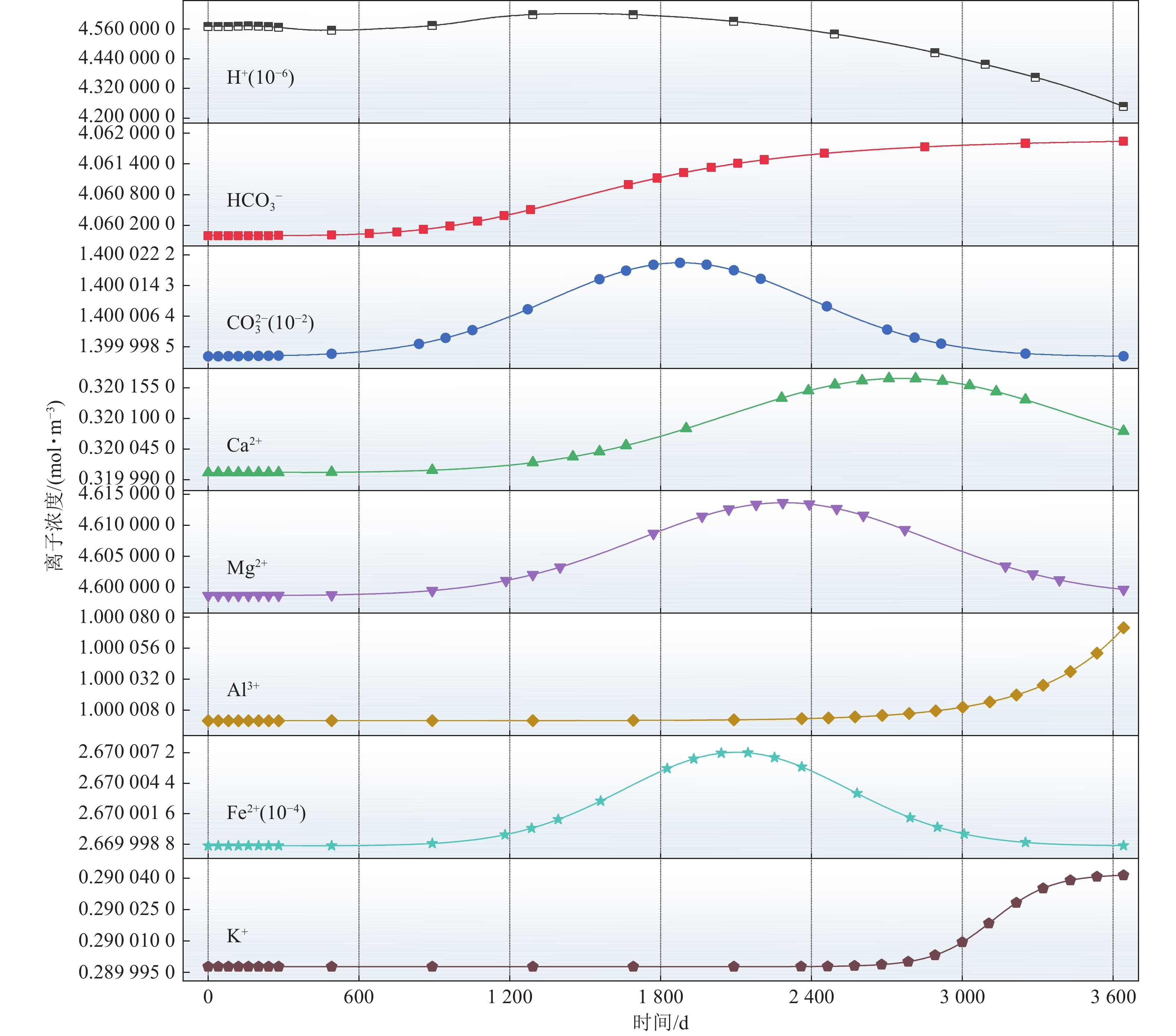

离子组分 质量摩尔浓度/(mmol·kg−1) 离子组分 质量摩尔浓度/(mmol·kg−1) H+ 4.57×10−6 K+ 0.29 ${\mathrm{HCO}}_3^- $ 4.06 Al3+ 1 ${\mathrm{CO}}_3^{2-} $ 1.40×10−2 Fe2+ 2.67×10−4 Ca2+ 0.32 Mg2+ 4.6 表 4 储层中初始矿物体积分数

Table 4 Initial volume fractions of minerals in the reservoir

矿物类型 化学式 体积分数 方解石(Calcite) CaCO3 0.171 高岭石(Kaolinite) Al2Si2O5(OH)4 0.089 伊利石(Illite) K0.6Mg0.25Al1.8(Al0.5Si3.5O10)(OH)2 0.012 绿泥石(Chlorite) Mg2.5Fe2.5Al2Si3O10(OH)8 0.016 其他 — 0.712 表 5 数值模拟具体方案

Table 5 Specific plan for numerical simulation

方案 模型 耦合方式 影响因素 A 模型1:CBM T-H-M 地球化学作用 模型2:CO2-ECBM T-H-M 模型3:CO2-ECBM T-H-M-C B 模型4:注入压力7 MPa T-H-M-C 注入压力 模型5:注入压力8 MPa T-H-M-C 模型6:注入压力9 MPa T-H-M-C C 模型7:初始渗透率0.5×10−15 m2 T-H-M-C 初始渗透率 模型8:初始渗透率1×10−15 m2 T-H-M-C 模型9:初始渗透率1.5×10−15 m2 T-H-M-C D 模型10:初始含水饱和度0.6 T-H-M-C 初始含水饱和度 模型11:初始含水饱和度0.7 T-H-M-C 模型12:初始含水饱和度0.8 T-H-M-C -

[1] 桑树勋. 二氧化碳地质存储与煤层气强化开发有效性研究述评[J]. 煤田地质与勘探,2018,46(5):1−9. doi: 10.3969/j.issn.1001-1986.2018.05.001 SANG Shuxun. Research review on technical effectiveness of CO2 geological storage and enhanced coalbed methane recovery[J]. Coal Geology & Exploration,2018,46(5):1−9. doi: 10.3969/j.issn.1001-1986.2018.05.001

[2] 杜艺,桑树勋,王文峰. 超临界CO2注入煤岩地球化学效应研究评述[J]. 煤炭科学技术,2018,46(3):10−18. DU Yi,SANG Shuxun,WANG Wenfeng. Study and review on geochemical effect of coal and rock injected with super-critical CO2[J]. Coal Science and Technology,2018,46(3):10−18.

[3] 刘世奇,皇凡生,杜瑞斌,等. CO2地质封存与利用示范工程进展及典型案例分析[J]. 煤田地质与勘探,2023,51(2):158−174. doi: 10.12363/issn.1001-1986.22.12.0998 LlU Shiqi,HUANG Fansheng,DU Ruibin,et al. Progress and typical case analysis of demonstration projects of the geological sequestration and utilization of CO2[J]. Coal Geology & Exploration,2023,51(2):158−174. doi: 10.12363/issn.1001-1986.22.12.0998

[4] 申建,秦勇,张春杰,等. 沁水盆地深煤层注入CO2提高煤层气采收率可行性分析[J]. 煤炭学报,2016,41(1):156−161. SHEN Jian,QIN Yong,ZHANG Chunjie,et al. Feasibility of enhanced coalbed methane recovery by CO2 sequestration into deep coalbed of Qinshui Basin[J]. Joural of China Coal Society,2016,41(1):156−161.

[5] 王赞惟,孟尚志,张松航,等. 沁水盆地柿庄北深部煤层水平井CO2注入参数研究[J]. 煤田地质与勘探,2018,46(5):188−192. doi: 10.3969/j.issn.1001-1986.2018.05.029 WANG Zanwei,MENG Shangzhi,ZHANG Songhang,et al. CO2 injection parameters in horizontal well of deep coalbed in north Shizhuang block of Qinshui basin[J]. Coal Geology & Exploration,2018,46(5):188−192. doi: 10.3969/j.issn.1001-1986.2018.05.029

[6] 叶建平,张兵,韩学婷,等. 深煤层井组CO2注入提高采收率关键参数模拟和试验[J]. 煤炭学报,2016,41(1):149−155. YE Jianping,ZHANG Bing,HAN Xueting,et al. Well group carbon dioxide injection for enhanced coalbed methane recovery and key parameter of the numerical simulation and application in deep coalbed methane[J]. Journal of China Coal Society,2016,41(1):149−155.

[7] 刘世奇,方辉煌,桑树勋,等. 基于多物理场耦合求解的煤层CO2-ECBM数值模拟研究[J]. 煤炭科学技术,2019,47(9):51−59. LIU Shiqi,FANG Huihuang,SANG Shuxun,et al. Numerical simulation study on coal seam CO2-ECBM based on multi-physics fields coupling solution[J]. Coal Science and Technology,2019,47(9):51−59.

[8] 杜艺. ScCO2注入煤层矿物地球化学及其储层结构响应的实验研究[D]. 徐州:中国矿业大学,2018. DU Yi. Experimental study on mineral geochemical reaction and its inducing the reservoir structure response with the injection of ScCO2 into the coal seam[D]. Xuzhou:China University of Mining and Technology,2018.

[9] 刘旭东. 沁水盆地柿庄南示范工程二氧化碳驱煤层气地质封存数值模拟研究[D]. 徐州:中国矿业大学,2023. LIU Xudong. Study on numerical simulation of CO2-ECBM for Shizhuangnan demonstration project in Qinshui Basin[D]. Xuzhou:China University of Mining and Technology,2023.

[10] WEN Hu,LI Zhenbao,Deng Jun,et al. Influence on coal pore structure during liquid CO2-ECBM process for CO2 utilization[J]. Journal of CO2 Utilization,2017,21:543−552. doi: 10.1016/j.jcou.2017.09.002

[11] LIU Guoxiang,Andrei V. Smirnov. Modeling of carbon sequestration in coal-beds:A variable saturated simulation[J]. Energy Conversion and Management,2008,49:2849−2858. doi: 10.1016/j.enconman.2008.03.007

[12] Dawson G. K. W.,Golding S. D.,Biddle D.,et al. Mobilisation of elements from coal due to batch reactor experiments with CO2 and water at 40 ℃ and 9.5 MPa[J]. International Journal of Coal Geology,2015,140:63−70.

[13] WANG Wenxing,HUANG Weiyu,ZHU Wancheng,et al. Biogeochemical changes during supercritical CO2–H2O-coal-microorganism interaction[J]. Gas Science and Engineering,2024,128:205391. doi: 10.1016/j.jgsce.2024.205391

[14] CHENG Xiaojiao,WEN Hu,FAN Shixing,et al. Evolution law of the pore structure of CO2-H2O-coal in liquid CO2-ECBM[J]. Journal of CO2 Utilization,2024,89:102971. doi: 10.1016/j.jcou.2024.102971

[15] Mwakipunda,WANG Yuting,Mgimba M M,et al. Recent advances in carbon dioxide sequestration in deep unmineable coal seams using CO2-ECBM technology:experimental studies,simulation,and field applications[J]. Energy & Fuels,2023,37(22):17161−17186.

[16] 张松航,唐书恒,张守仁,等. 不同排采程度煤储层注CO2驱煤层气模拟评价[J]. 煤炭学报,2022,47(3):1275−1285. ZHANG Songhang,TANG Shuheng,ZHANG Shouren,et al. Simulation and evaluation of enhanced coalbed methane recovery by CO2 storage in coal reservoirs with different drainage and production levels[J]. Journal of China Coal Society,2022,47(3):1275−1285.

[17] 王开然. 煤层系统CO2−水−煤(岩)地球化学作用及其对盖层封闭性演化的影响[D]. 长春:吉林大学,2016. WANG Kairan. CO2-H2O-coal(rock) geochemical interaction in coalseam and its effects on the evolution of caprock sealing ability[D]. Changchun:Jilin University,2016.

[18] FANG Huihuang,YU Shua,ZHANG Shiwen,et al. Coupling mechanism of THMC fields in crushed soft coal with low permeability after CO2 injection and its application in CO2-ECBM technology[J]. Energy & Fuels,2024,38(8):6891−6911.

[19] 刘旭东,桑树勋,周效志,等. 基于煤储层三维非均质地质模型的CO2-ECBM数值模拟研究[J]. 煤炭学报,2023,48(3):2773−2790. LIU Xudong,SANG Shuxun,ZHOU Xiaozhi,et al. Numerical simulation of CO2-ECBM based on 3D heterogeneous geological model[J]. Journal of China Coal Society,2023,48(3):2773−2790.

[20] 袁亮. 淮南矿区现代采矿关键技术[J]. 煤炭学报,2007,32(1):8−12. doi: 10.3321/j.issn:0253-9993.2007.01.002 YUAN Liang. Key technolgy for modern mining Huainan coal area[J]. Journal of China Coal Society,2007,32(1):8−12. doi: 10.3321/j.issn:0253-9993.2007.01.002

[21] FAN Chaojun,ELSWORTH D,LI Sheng,et al. Themo-hydro-mechanical-chemical couplings controlling CH4 production and CO2 sequestration in enhanced coalbed methane recovery[J]. Energy,2019,173:1054−1077. doi: 10.1016/j.energy.2019.02.126

[22] 方辉煌. 基于数字岩石物理技术的无烟煤储层CO2-ECBM流体连续过程数值模拟研究[D]. 徐州:中国矿业大学,2020. FANG Huihuang. Numerical simulation of the CO2-ECBM fluid continuous process in anthracite reservoirs based on digital petrophysical technology[D]. Xuzhou:China University of Mining and Technology,2020.

[23] LIU Xudong,SANG Shuxun,ZHOU Xiaozhi,et al. Coupled adsorption-hydro-thermo-mechanical-chemical modeling for CO2 sequestration and well production during CO2-ECBM[J]. Energy,2023,262:125306. doi: 10.1016/j.energy.2022.125306

[24] FAN Yongpeng,Deng Cunbao,ZHANG Xu,et al. Numerical study of CO2-enhanced coalbed methane recovery[J]. International Journal of Greenhouse Gas Control,2018,76:12−23. doi: 10.1016/j.ijggc.2018.06.016

[25] 范超军,李胜,罗明坤,等. 基于流−固−热耦合的深部煤层气抽采数值模拟[J]. 煤炭学报,2016,41(12):3076−3085. FAN Chaojun,Li Sheng,Luo Mingkun,et al. Deep CBM extraction numerical simulation based on hydraulic-mechanical-thermal coupled model[J]. Journal of China Coal Society,2016,41(12):3076−3085.

[26] Addisalem B. Mitiku,D. Li,S. Bauer,et al. Geochemical modelling of CO2-water-rock interactions in a potential storage formation of the North German sedimentary basin[J]. Applied Geochemistry,2013(36):168−186.

[27] 崔国栋,张亮,任韶然,等. 油藏CO2驱及封存过程中地化反应特征及埋存效率[J]. 中国石油大学学报(自然科学版),2017,41(6):123−131. doi: 10.3969/j.issn.1673-5005.2017.06.015 CUI Guodong,ZHANG Liang,REN Shaoran,et al. Geochemical reactions and CO2 storage efficiency during CO2-EOR process and subsequent storage[J]. Journal of China University of Petroleum,2017,41(6):123−131. doi: 10.3969/j.issn.1673-5005.2017.06.015

[28] 杨志杰. 二氧化碳增强咸水开采工程中储层压力管控和布井方案优化研究[D]. 长春:吉林大学,2019. YANG Zhijie. The study on the reservoir pressure control strategies and optimization of well pattern for a CO2-enhanced water recovery project[D]. Changchun:Jilin University,2019.

[29] 田海龙. CO2-咸水-岩相互作用对盖层封闭性影响研究[D]. 长春:吉林大学,2014. TIAN Hailong. Impacts of CO2-brine-rock interaction on the caprock sealing efficiency[D]. Changchun: Jilin University,2014.

[30] 李全中,倪小明,王延斌,等. CO2分压条件下煤中矿物质溶解度数值模拟[J]. 煤田地质与勘探,2013,41(6):19−21,42. doi: 10.3969/j.issn.1001-1986.2013.06.05 LI Quanzhong,NI Xiaoming,WANG Yanbin,et al. Numerical simulation of coal mineral solubility under CO2 partial pressure[J]. Coal Geology & Exploration,2013,41(6):19−21,42. doi: 10.3969/j.issn.1001-1986.2013.06.05

[31] 于志超,杨思玉,刘立,等. 饱和CO2地层水驱过程中的水-岩相互作用实验[J]. 石油学报,2012,33(6):1032−1042. doi: 10.7623/syxb201206016 YU Zhichao,YANG Siyu,LIU Li,et al. An experimental study on water-rock interaction during water flooding in formations saturated with CO2[J]. Acta Petrolei Sinica,2012,33(6):1032−1042. doi: 10.7623/syxb201206016

[32] FANG Huihuang,LI Ang,SANG Shuxun,et al. Numerical analysis of permeability rebound and recovery evolution with THM multi-physical field models during CBM extraction in crushed soft coal with low permeability and its indicative significance to CO2 geological sequestration[J]. Energy,2023,262:125395. doi: 10.1016/j.energy.2022.125395

[33] 凡永鹏,霍中刚,王永. 基于流−固−热耦合的CO2−ECBM数值模拟研究[J]. 煤矿安全,2022,53(2):162−169. FAN Yongpeng,HUO Zhonggang,WANG Yong. Numerical simulation of CO2-ECBM based on fluid-solid-thermal coupled model[J]. Safety in Coal Mines,2022,53(2):162−169.

[34] LI Ziwen,YU Hongjin,BAI Yansong,et al. Analysis of reservoir permeability evolution and influencing factors during CO2-Enhanced coalbed methane recovery[J]. Energy,2024,304:132045. doi: 10.1016/j.energy.2024.132045

[35] 张林峰,杨艳国,穆永亮,等. 基于气−水两相流的注热CO2增产CH4数值模拟研究[J]. 煤炭科学技术,2024,52(3):115−128. doi: 10.12438/cst.2023-0690 ZHANG Linfeng,YANG Yanguo,MU Yoneliang,et al. Numerical study of heat iniection CO2 to increase CH4 production based on gas-water two-phase flow[J]. Coal Science and Technology,2024,52(3):115−128. doi: 10.12438/cst.2023-0690

-

期刊类型引用(56)

1. 蔡高彬, 种梦祥, 葛蔓. 基于小波包分解和LOF-LVQ-PNN网络的煤岩识别. 煤矿现代化. 2025(05)  百度学术

百度学术

2. 任金伟,魏迎春,李慧茹,王平,刘子亮,王安民,曹代勇. 超声波解堵煤粉堵塞筛管的数值模拟研究. 煤矿安全. 2025(02): 93-101 .  百度学术

百度学术

3. 李富强. 基于深度卷积神经网络与多源信号的煤岩识别研究. 煤炭技术. 2025(03): 233-238 .  百度学术

百度学术

4. 栾恒杰,杨玉晴,刘建康,蒋宇静,刘建荣,马德良,张孙豪. 基于优化的U-net网络掘进工作面煤岩识别方法研究. 采矿与岩层控制工程学报. 2025(01): 98-112 .  百度学术

百度学术

5. 王忠宾,李福涛,司垒,魏东,戴嘉良,张森. 采煤机自适应截割技术研究进展及发展趋势. 煤炭科学技术. 2025(01): 296-311 .  本站查看

本站查看

6. 张闯,张超力,崔涛,武国旺,王志红. 煤矿智能化开采技术现状及展望. 能源与节能. 2024(01): 186-189 .  百度学术

百度学术

7. 柳圆,司垒,王忠宾,魏东,顾进恒. 基于电磁波的煤岩识别技术研究进展. 工矿自动化. 2024(01): 42-48+65 .  百度学术

百度学术

8. 卢才武,宋义良,江松,章赛,王懋,纪凡. 基于改进U-net的少样本煤岩界面图像分割方法. 金属矿山. 2024(01): 149-157 .  百度学术

百度学术

9. 齐爱玲,王雨,马宏伟. 基于改进门控循环神经网络的采煤机滚筒调高量预测. 工矿自动化. 2024(02): 116-123 .  百度学术

百度学术

10. 王洪磊,郭鑫,张亦凡,张俊升. 煤质煤量全面在线检测技术发展现状及应用进展. 煤炭科学技术. 2024(02): 219-237 .  本站查看

本站查看

11. 张强,刘伟,王聪,苏金鹏,刘峻铭,顾颉颖,张润鑫. 刮板输送机多永磁电机串联驱动新模式及关键技术. 煤炭科学技术. 2024(02): 238-252 .  本站查看

本站查看

12. 王虹,陈明军,张小峰. 我国煤矿快速掘进20a发展与展望. 煤炭学报. 2024(02): 1199-1213 .  百度学术

百度学术

13. 李嘉豪,司垒,王忠宾,魏东,顾进恒. 综放工作面煤矸识别技术及其应用. 仪器仪表学报. 2024(01): 1-15 .  百度学术

百度学术

14. 汪进超,韩增强,王益腾,王超,张国华. 基于像素空间信息的孔内低照度图像孔隙结构量化方法研究. 岩石力学与工程学报. 2024(S1): 3175-3186 .  百度学术

百度学术

15. 宋国利,赵云飞,曹宁宁. 薄煤层综采工作面智能化关键技术与应用. 煤炭工程. 2024(05): 84-88 .  百度学术

百度学术

16. 邹云兴,李标. 煤矿采煤机自动拖缆装置及控制方法研究. 工矿自动化. 2024(S1): 179-182 .  百度学术

百度学术

17. 张锦旺,王逢辰. 表面活性剂辅助的煤矸识别教学实验设计. 实验技术与管理. 2024(05): 188-194 .  百度学术

百度学术

18. 李敏,王婷,王晓红,周嘉林,韩征,张诗檬,许飞青,周捷铭. 北京市密云东庄铁矿区岩浆岩断面结晶度特征信息提取方法研究. 城市地质. 2024(02): 267-273 .  百度学术

百度学术

19. 李敏,王婷,王晓红,栾英波,周嘉林. 基于小波变换的北京密云沙厂区域相关岩群断面图像特征仿真研究. 矿产勘查. 2024(06): 1049-1056 .  百度学术

百度学术

20. 张云,童亮,来兴平,曹胜根,闫保旭,刘永孜,孙浩强,杨彦斌,何伟. 基于机器视觉的煤尘环境下掘进空间煤岩界面感知与精准识别. 煤炭学报. 2024(07): 3276-3290 .  百度学术

百度学术

21. 韦小龙,王方田,何东升,刘超,徐大连. 基于CSPNet-YOLOv7目标检测算法的煤矸图像识别模型. 煤炭科学技术. 2024(S1): 238-248 .  本站查看

本站查看

22. 武强,王显辉,曾一凡,刘春生. 基于EWOA-VMD的钻孔弹性波处理与煤岩识别方法. 中国矿业大学学报. 2024(05): 857-871 .  百度学术

百度学术

23. 许吉禅,阮大志,马天兵,杨孝筱. 基于PSO优化的悬臂式掘进机自适应控制研究. 煤矿机械. 2024(11): 150-153 .  百度学术

百度学术

24. 陈鹏飞,翟伟,王李进,陈智星. 基于DeeplabV3的煤岩界面识别方法. 山西焦煤科技. 2024(09): 51-53 .  百度学术

百度学术

25. 赵一鸣,相志,张农,戴京辰. 雷达探测中煤岩介质相对介电常数变化特征. 采矿与安全工程学报. 2024(06): 1222-1229 .  百度学术

百度学术

26. 张传伟,何正伟,路正雄,李林岳,龚凌霄,张刚强,潘巧娜. 基于MRU-Net++的极薄煤层综采面煤岩界面图像识别. 煤炭科学技术. 2024(11): 103-116 .  本站查看

本站查看

27. 尹玉玺,周常飞,许志鹏,史春祥,胡文渊. 基于改进1DCNN的煤岩识别模型研究. 工矿自动化. 2023(01): 116-122 .  百度学术

百度学术

28. 邢望,姚克,王龙鹏,翁寅生. 煤矿坑道钻机电液控制方法综述. 煤矿机械. 2023(02): 131-133 .  百度学术

百度学术

29. 刘闯,李化敏,常发展,鲁智豪,刘超月. 微波照射-红外探测主动式煤矸识别方法. 矿业研究与开发. 2023(02): 184-188 .  百度学术

百度学术

30. 秦涛,王乐清,韩偲. 基于二维伽马函数的煤岩图像照度校正. 黑龙江科技大学学报. 2023(01): 24-31 .  百度学术

百度学术

31. 袁亮,张平松. 煤矿透明地质模型动态重构的关键技术与路径思考. 煤炭学报. 2023(01): 1-14 .  百度学术

百度学术

32. 葛世荣,胡而已,李允旺. 煤矿机器人技术新进展及新方向. 煤炭学报. 2023(01): 54-73 .  百度学术

百度学术

33. 王科平,连凯海,杨艺,费树岷. 基于改进YOLOv4的综采工作面目标检测. 工矿自动化. 2023(02): 70-76 .  百度学术

百度学术

34. 张明星. 采煤机智能截割控制系统的应用研究. 机械管理开发. 2023(03): 196-197+202 .  百度学术

百度学术

35. 王国法,张建中,薛国华,刘再斌,刘清,李梅,刘军锋,程健,张学亮. 煤矿回采工作面智能地质保障技术进展与思考. 煤田地质与勘探. 2023(02): 12-26 .  百度学术

百度学术

36. 李梅,毛善君,赵明军. 煤矿智能地质保障系统研究进展与展望. 煤炭科学技术. 2023(02): 334-348 .  本站查看

本站查看

37. 张磊,王浩盛,雷伟强,王斌,林建功. 基于YOLOv5s-SDE的带式输送机煤矸目标检测. 工矿自动化. 2023(04): 106-112 .  百度学术

百度学术

38. 巩师鑫,赵国瑞,王飞. 机器视觉感知理论与技术在煤炭工业领域应用进展综述. 工矿自动化. 2023(05): 7-21 .  百度学术

百度学术

39. 翟小伟,张羽琛,罗金雷. 不同应力对煤自然氧化的影响规律试验研究. 煤矿安全. 2023(05): 199-204 .  百度学术

百度学术

40. 崔耀,叶壮. 基于5G+云边端协同技术的采煤机智能调高调速控制系统设计与应用. 煤炭科学技术. 2023(06): 205-216 .  本站查看

本站查看

41. 张意,康正明,冯宏,李飞,李新,韩雪. 方位电磁波仪器PeriScope水平井煤岩边界探测特性研究. 煤炭科学技术. 2023(06): 158-167 .  本站查看

本站查看

42. 余华婷,徐连满,李玮哲,周禹含. 地表开采沉陷监测技术研究. 科技创新与应用. 2023(20): 183-186 .  百度学术

百度学术

43. 张扬. 国产采煤机自动截割技术现状及展望. 煤矿机械. 2023(10): 70-72 .  百度学术

百度学术

44. 赵杰,赵浩,徐晗. 基于改进U-NET模型的煤岩图像识别算法研究. 中国新技术新产品. 2023(16): 6-8 .  百度学术

百度学术

45. 姜子超,杨春花,孟田华,姜晓云. 探地雷达在煤岩界面识别中的应用. 山西大同大学学报(自然科学版). 2023(05): 89-93 .  百度学术

百度学术

46. 闫志蕊,王宏伟,耿毅德. 基于改进DeeplabV3+和迁移学习的煤岩界面图像识别方法. 煤炭科学技术. 2023(S1): 429-439 .  本站查看

本站查看

47. 吴卫东,蔡树文,徐威,周兴平. 融合声音的采煤机煤岩状态识别. 煤炭技术. 2023(12): 220-223 .  百度学术

百度学术

48. 杨恩,王世博,宣统. 融合近红外光谱的煤岩界面分布感知研究. 工矿自动化. 2022(07): 22-31+42 .  百度学术

百度学术

49. 许献磊,彭苏萍,马正,朱鹏桥,王一丹. 基于空气耦合雷达的矿井煤岩界面随采动态探测原理及关键技术. 煤炭学报. 2022(08): 2961-2977 .  百度学术

百度学术

50. 丁光彬. 大型煤炭企业年度煤炭生产计划编制要点浅析. 能源技术与管理. 2022(05): 199-201 .  百度学术

百度学术

51. 张礼才. 基于倒频谱分析的矿用重型减速器故障诊断研究. 机电产品开发与创新. 2022(05): 85-87 .  百度学术

百度学术

52. 郭永红,刘道园,杨云博. 基于人工智能技术的矿用远程识别系统设计. 工矿自动化. 2022(S1): 105-107 .  百度学术

百度学术

53. 刘波,刘道园,杨云博. 矿用5G多频段融合组网应用研究. 工矿自动化. 2022(S1): 108-111 .  百度学术

百度学术

54. 李彦明,孙利海. 基于多源异构信息耦合的煤岩界面识别技术研究. 矿业安全与环保. 2022(05): 6-10 .  百度学术

百度学术

55. 杨建辉,黄子洋,汪梅,符立梅,刘安强,李远成,于振华,王征,董立红. 机器视觉灰度化金字塔卷积模型的煤流异物识别. 煤炭科学技术. 2022(11): 194-201 .  本站查看

本站查看

56. 许志鹏,刘振坚,庄德玉,尹玉玺. 基于振动信号的采矿机截割负载分类. 工矿自动化. 2022(12): 137-143 .  百度学术

百度学术

其他类型引用(28)

下载:

下载: