摘要:

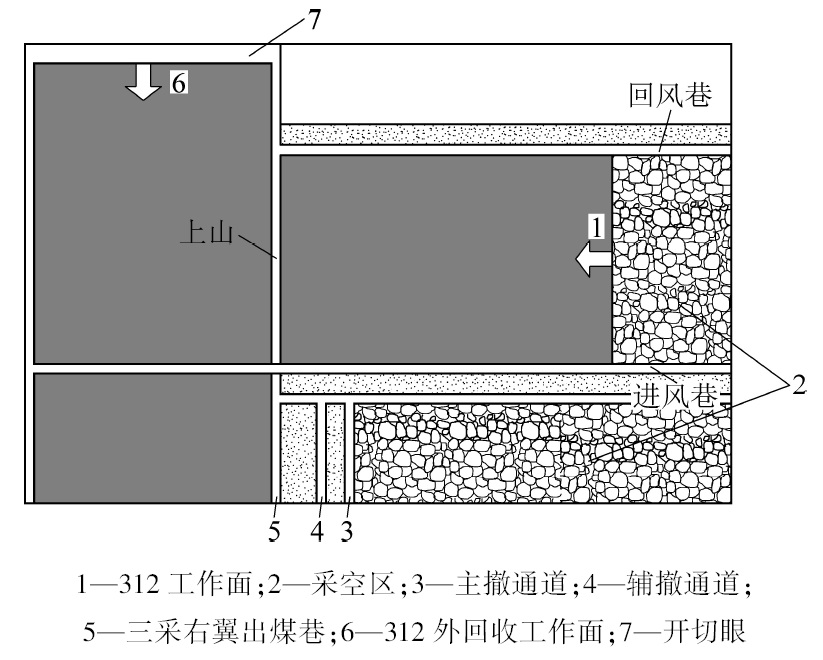

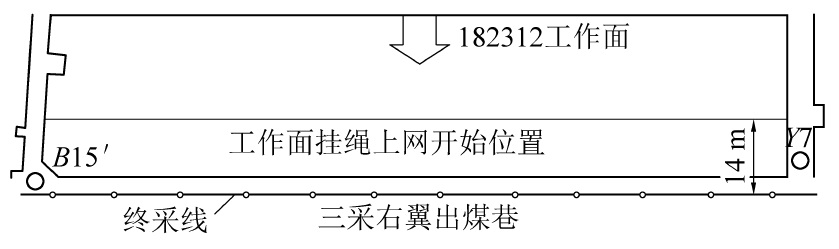

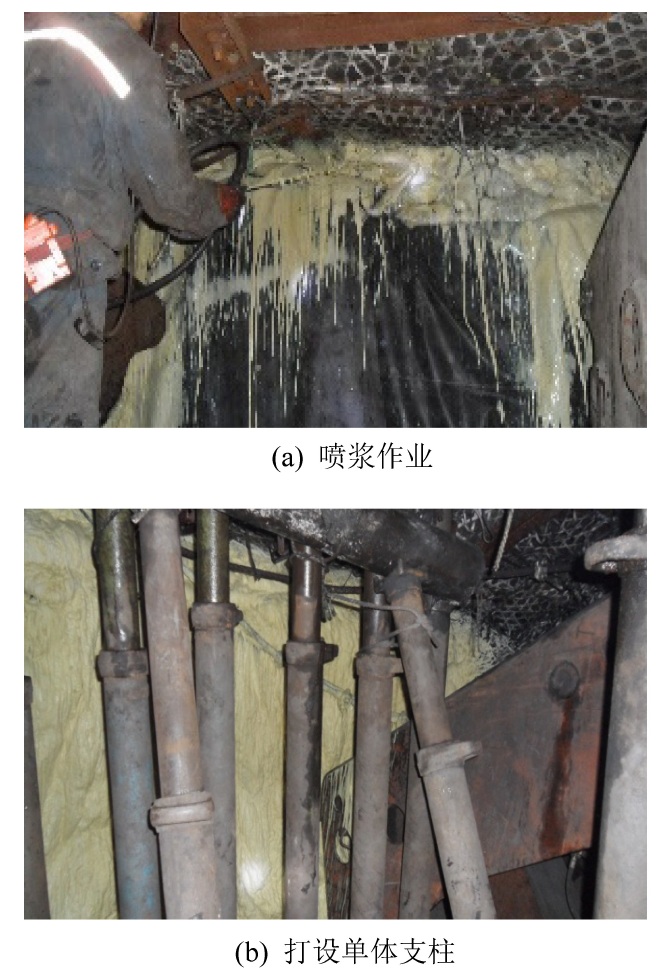

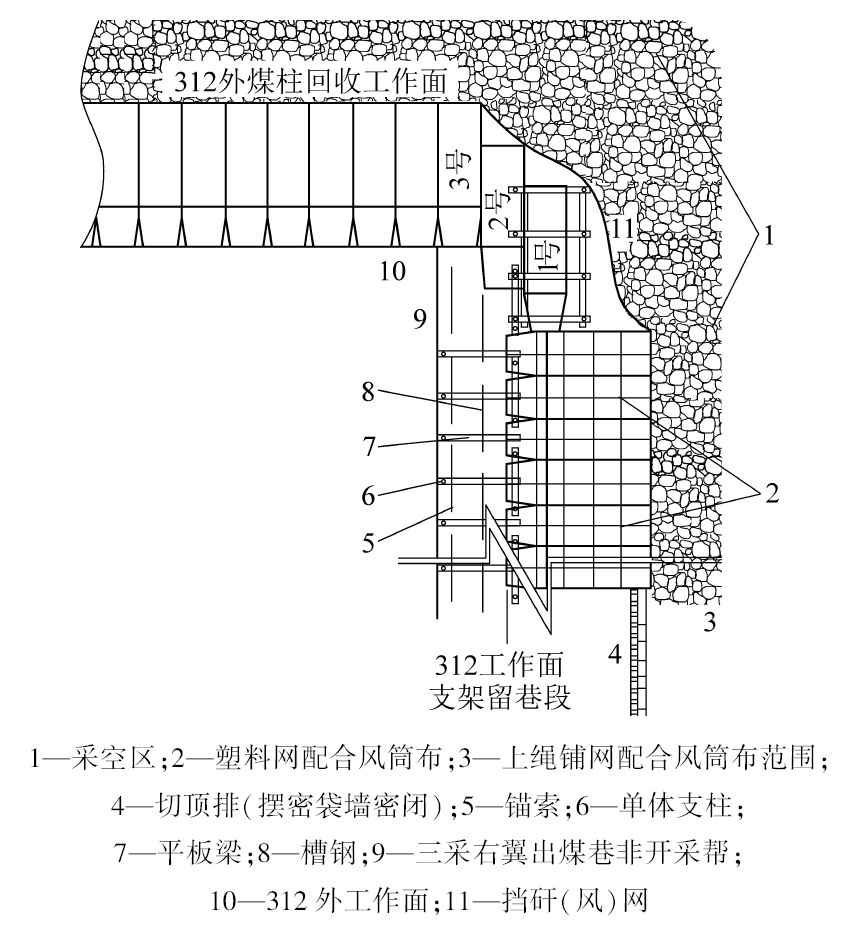

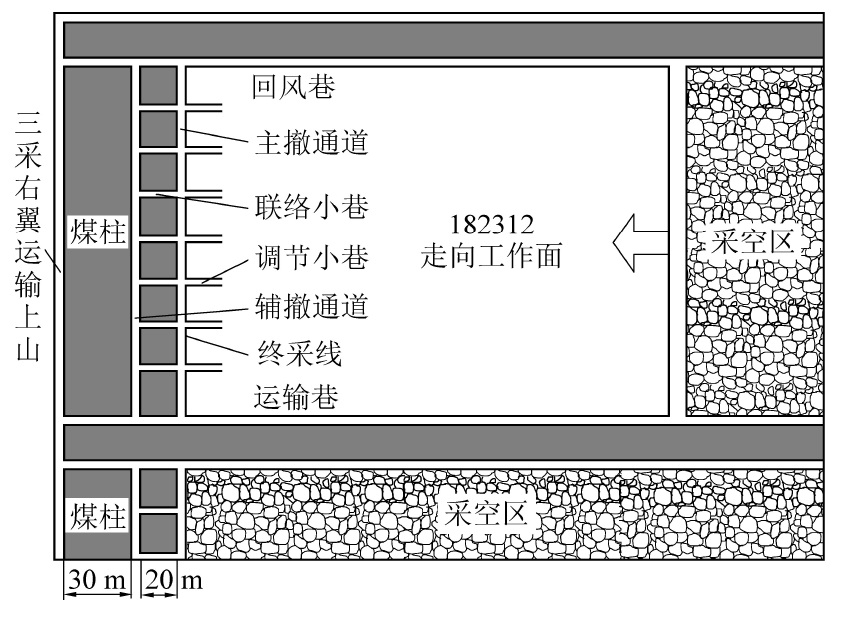

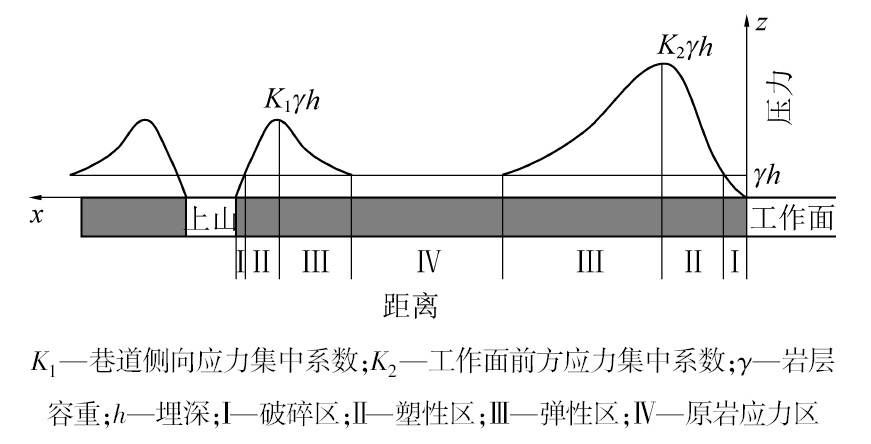

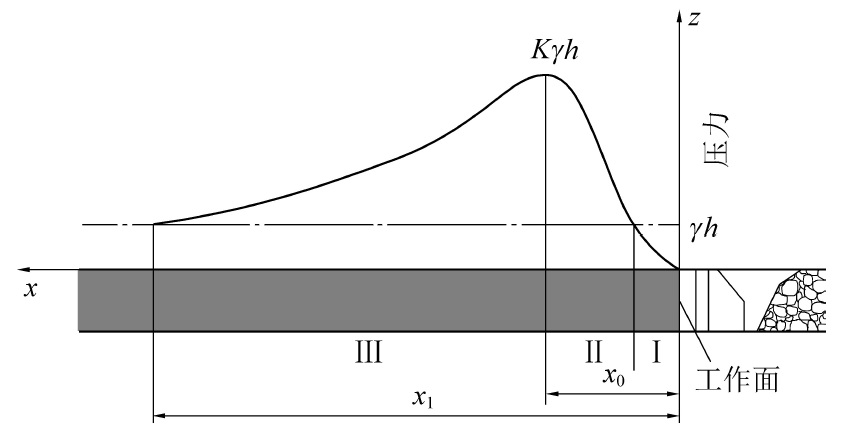

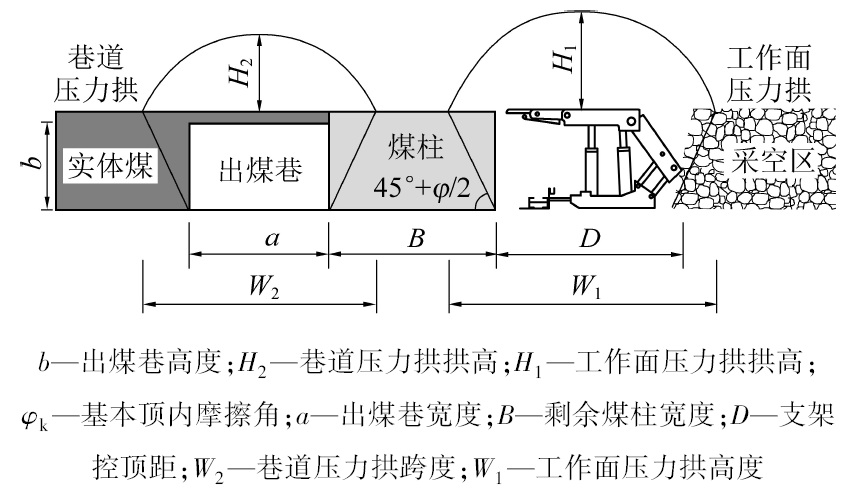

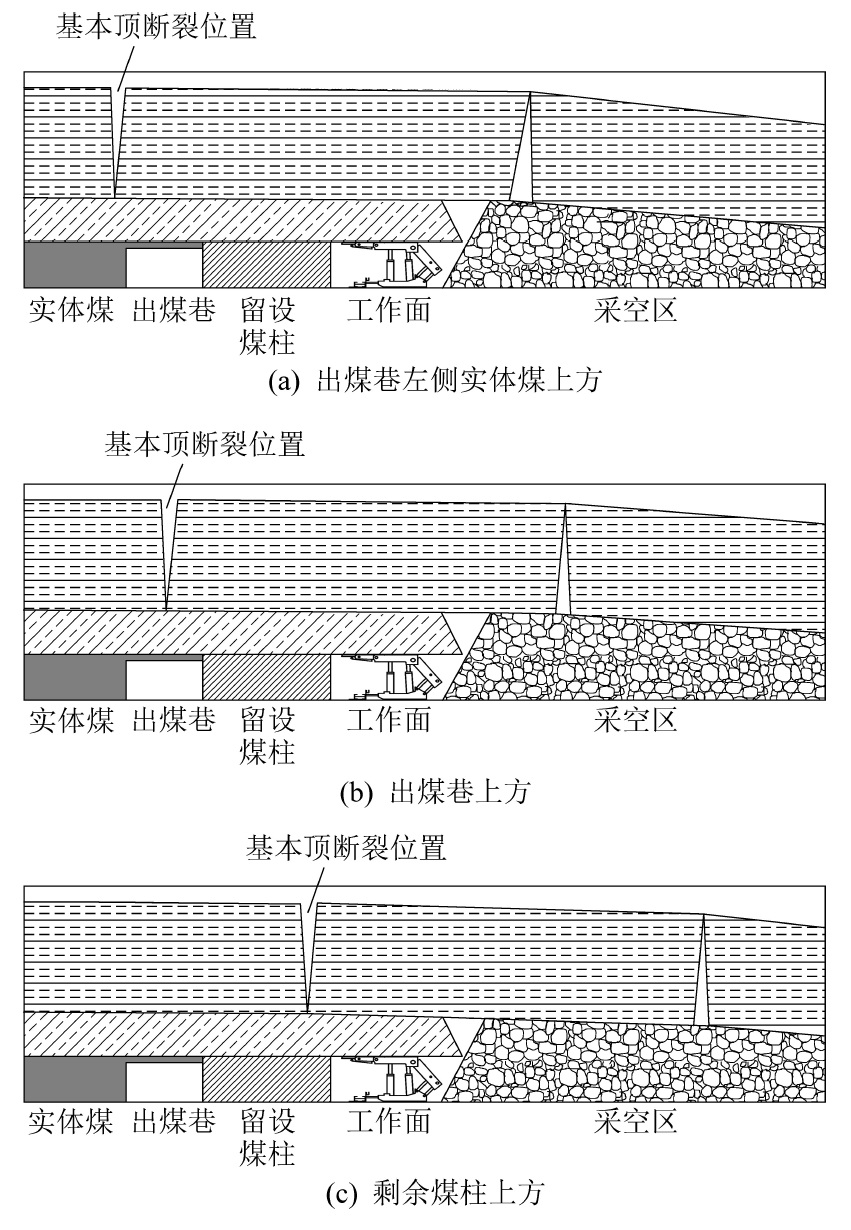

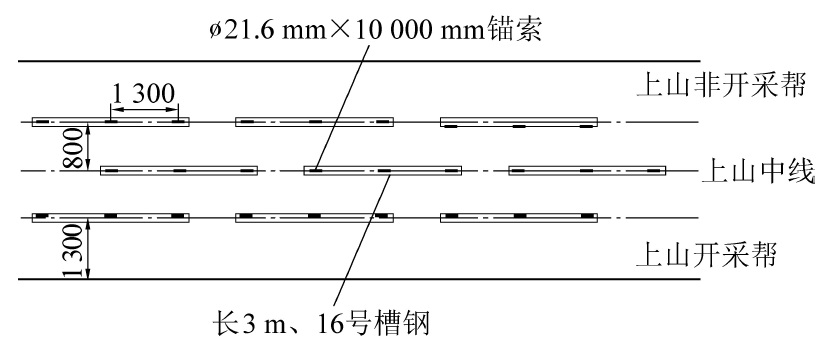

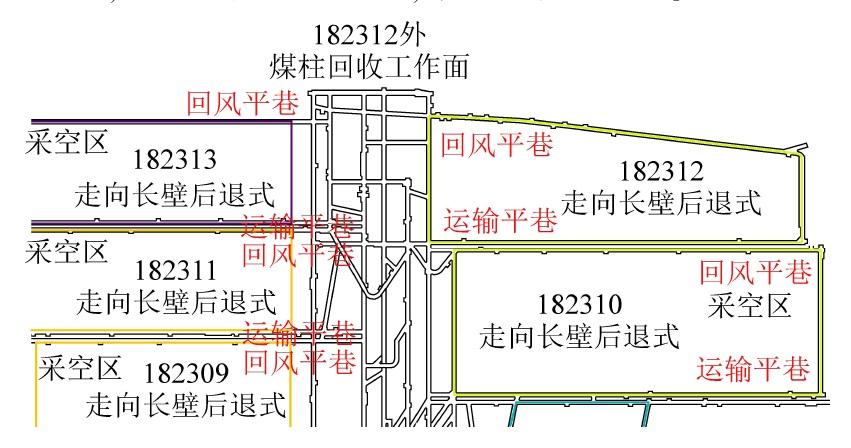

基于现有采区最后1个走向工作面与煤柱采出工作面开采衔接时间长、工艺复杂、煤炭采出率低以及支架回撤巷道掘进工程量大等问题,结合梧桐庄矿2号煤层三采区182312(简称312)走向工作面及182312外(简称312外)煤柱采出工作面地质生产情况,采用理论分析、工业性试验等研究方法,提出了工作面回采与支架回撤协同作业新技术:在312工作面回采过程中完成312外工作面生产系统,312工作面贯通三采右翼出煤巷,利用支架对出煤巷进行留巷,在312外工作面推至支架留巷段,边推进工作面边回撤支架。研究表明:由极限平衡区公式计算得支承应力峰值叠加区宽度为7.2 m,在压力拱载荷作用下,由不同支架控顶距计算得煤柱宽度为6.6~7.7 m,最终确定了贯通前让压煤柱宽度为8 m;分析了312工作面在贯通出煤巷前基本顶不同断裂形式及其让压调节机理,计算分析得基本顶预断裂位置超前合理断裂位置1.4 m,因此采用支架高阻力停采等压16 h;在312工作面距出煤巷50 m前完成了巷内补强支护;312工作面距终采线14 m进行挂绳铺网,并在距终采线2.4~13.0 m铺设风筒布;312工作面贯通出煤巷后,制定了支架留巷工艺;支架留巷完成后,开始回采312外工作面,在312外工作面推至支架留巷段,采用“掩护式迈步台阶支架拆除法”边推进工作面边回撤支架。此技术实现了出煤巷的“一巷三用”,提高了煤炭回收率,简化了工作面衔接及支架回撤工艺,节省了巷道工程量及支护费用,最终实现了工作面回采与支架回撤的协同作业。

Abstract:

Based on the problems that long times mining connection, complicated process, low coal recovery rate between the last longwall working face and the coal pillar recovery working face of the existing mining area, and large amount of engineering in support withdrawal, combined with the geological and production conditions of No.182312 (abbreviated as No.312) longwall working face and No.182312 outer (referred to as No.312 outer)coal pillar recovery working face in the third mining area of No.2 coal seam in Wutongzhuang Coal Mine, theoretical analysis and industrial test and other research methods was used, the new technology of collaborative work between face mining and bracket withdrawal was put forward:the No.312 outer working surface production system was completed during the No.312 working face recovery process, the No.312 working face passed through the uphill without coal pillars and uphill was retained with support.When the No.312 outer working face was pushed on to the gob-side entry retaining section, the bracket was retracted while pushing the No.312 outer working face.The results have showed:abutment pressure peak superposition area was calculated 7.2 m by limit equilibrium zone formula; the width of the coal pillar is calculated 6.6~7.7 m from different bracket roof-control area under the pressure arch load; it was finally determined that the coal pillar was 8 m before the No.312 working face passed through uphill.Analyzed different fracture modes of basic top and their pressure regulation mechanism, calculated and analyzed that the basic top pre-fracture position was advanced the reasonable fracture position 1.4 m, therefore, stopped mining for 16 h and the bracket was with high resistance.Reinforcement support measures in the uphill was completed before the No.312 working face was 50 m away from uphill; started lanyard and paving when No.312 working face was 14 m away from stopping line; and the air duct cloth was laying within the range of 13~2.4 m from the stopping line; the process of gob-side entry retaining with bracket was formulated after the No.312 working face passed through the uphill.Began recovering the coal pillars after the completion of gob-side entry retaining; when the No.312 outer working face was pushed to the gob-side entry retaining section, the bracket was retracted while pushing the No.312 outer working face with the method of shielding type stepping bracket withdrawal.This technology realized that the uphill has three functions.The coal recovery rate and work efficiency have been improved, the process of working face connection and bracket retraction have been simplified, the amount of roadway engineering and maintenance costs have been saved.Finally, the collaborative work of working face recovery and bracket withdrawal was realized.

百度学术

百度学术

百度学术

百度学术

百度学术

百度学术

本站查看

本站查看

百度学术

百度学术

百度学术

百度学术

百度学术

百度学术

百度学术

百度学术

百度学术

百度学术

百度学术

百度学术

本站查看

本站查看

本站查看

本站查看

百度学术

百度学术

百度学术

百度学术

本站查看

本站查看

本站查看

本站查看

百度学术

百度学术

下载:

下载: