摘要:

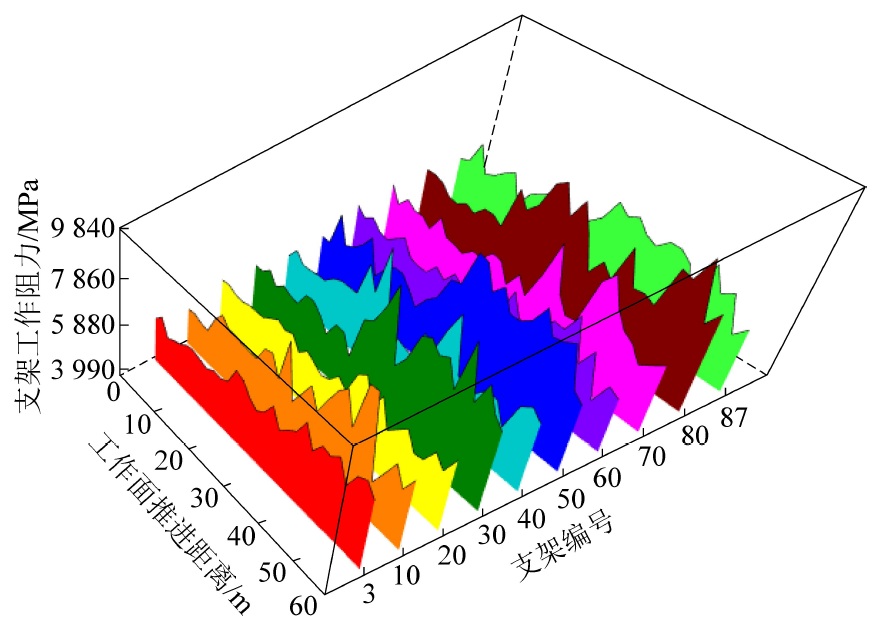

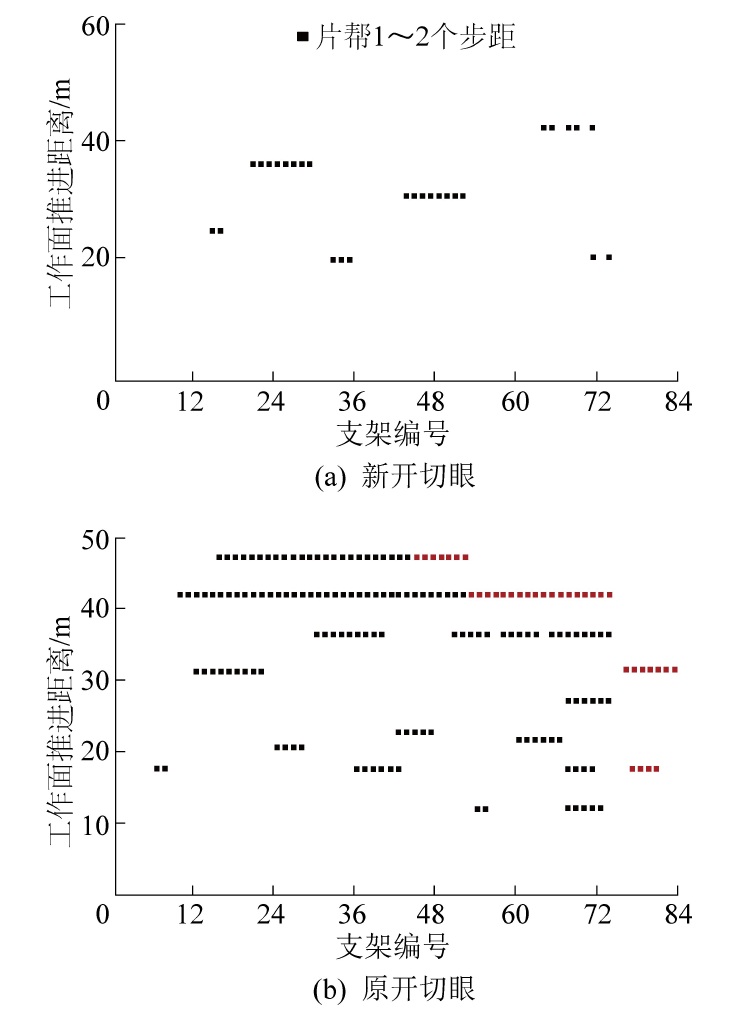

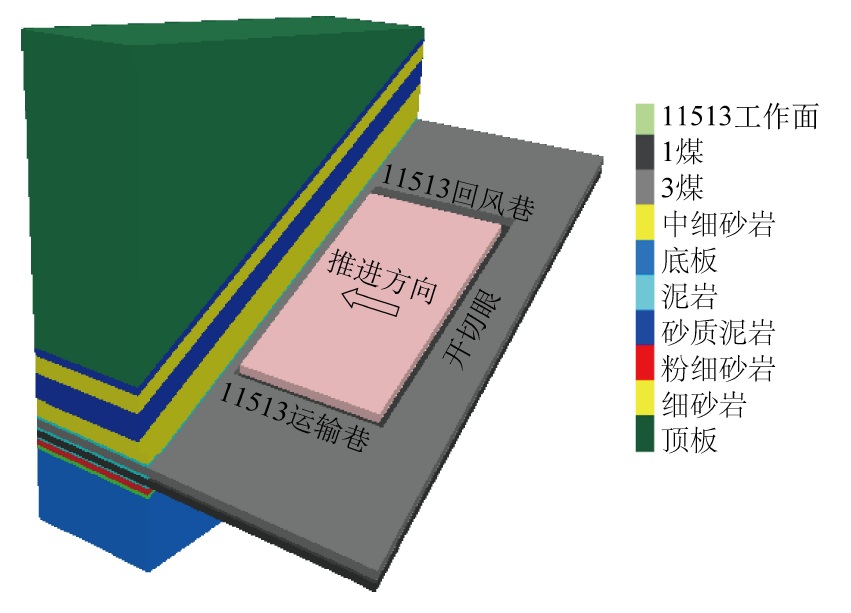

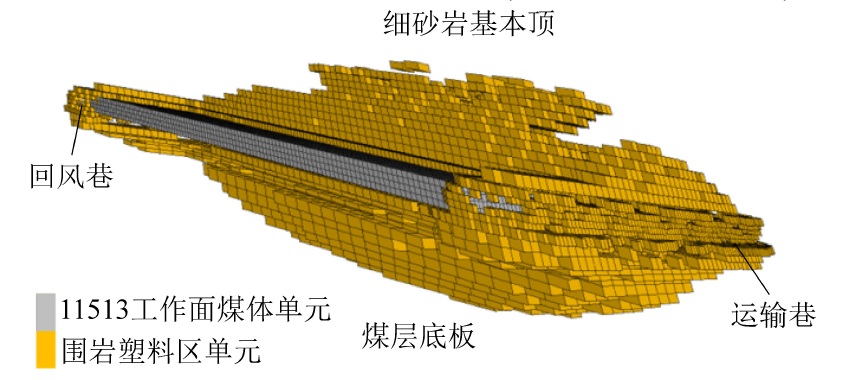

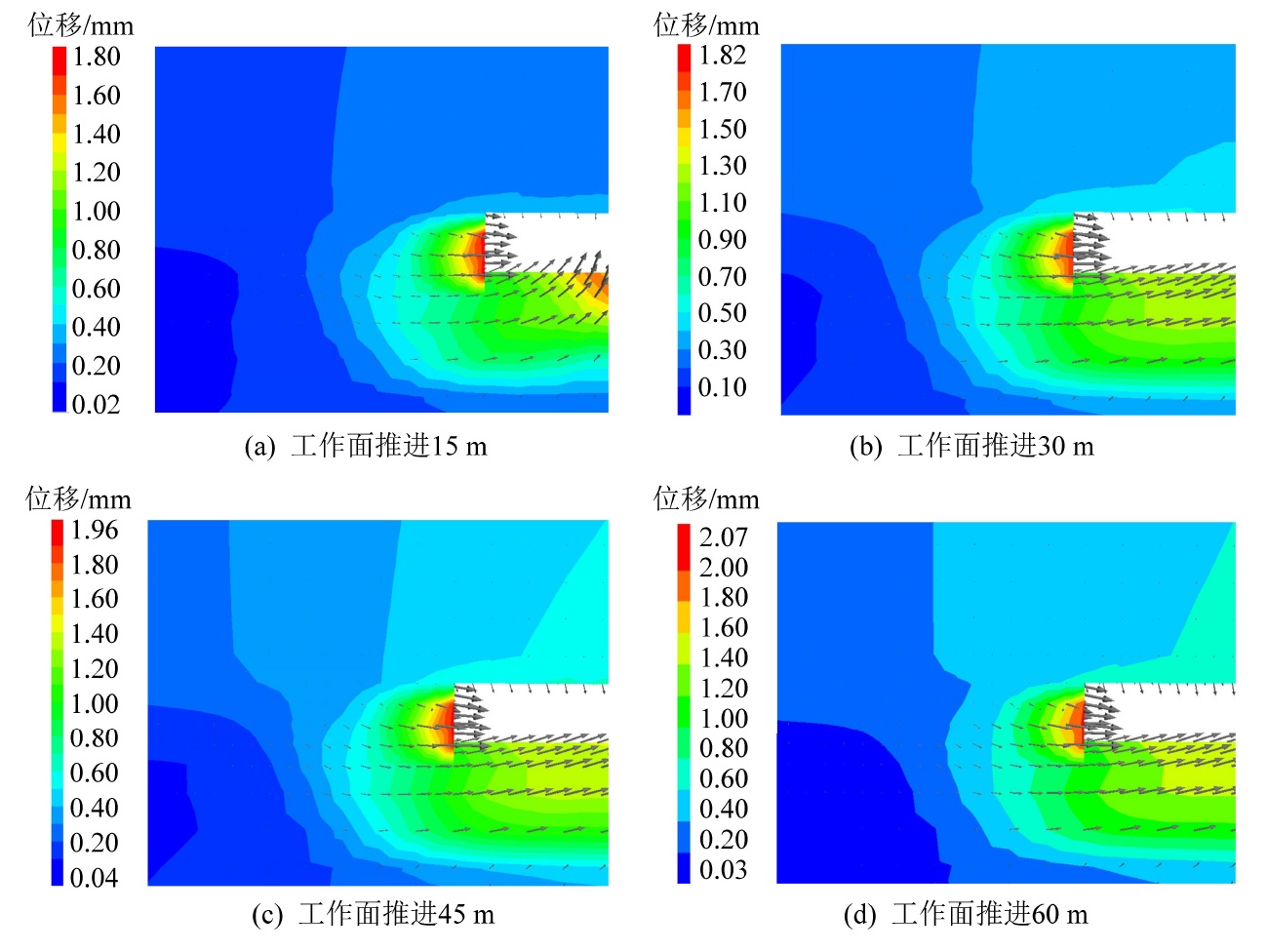

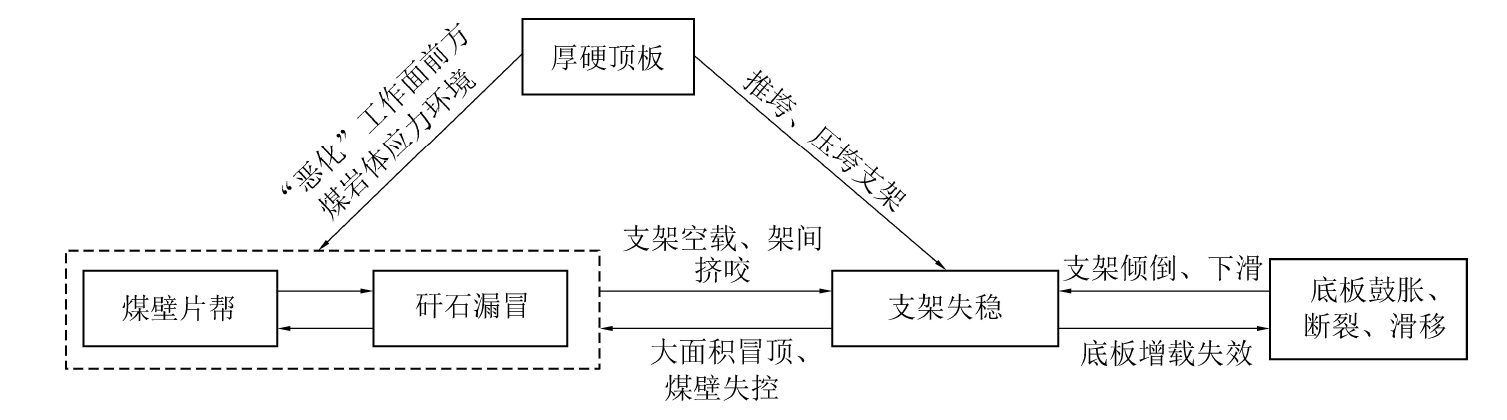

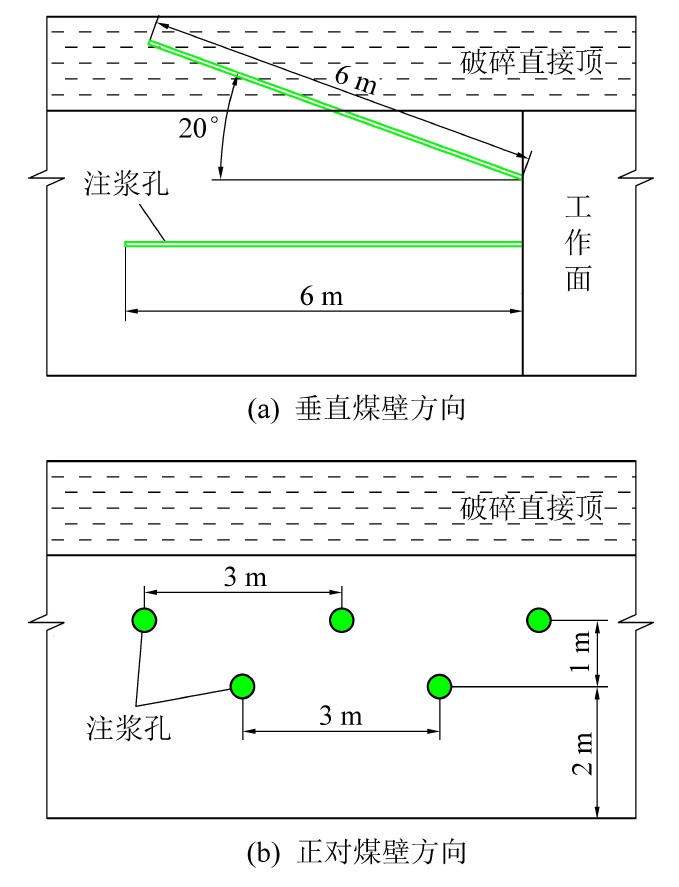

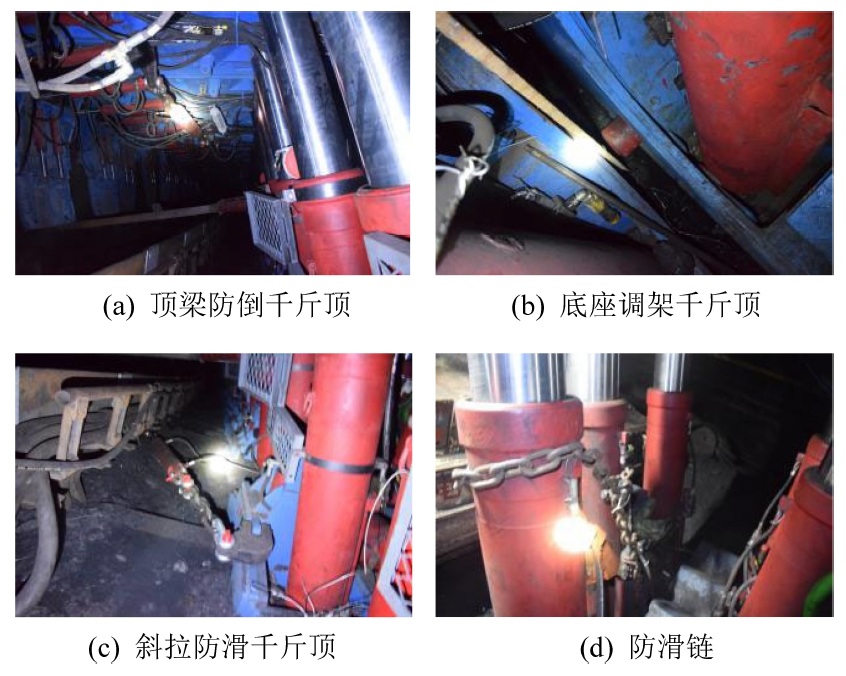

针对潘四东煤矿11513大倾角工作面煤壁片帮、支架滑移倾倒和顶板大面积来压问题,通过理论分析、数值模拟和现场实测的研究方法对厚硬顶板下大倾角软煤开采的灾变机制和防控技术开展研究。研究结果表明:在厚硬顶板下大倾角软煤开采初期,围岩塑性破坏主要集中在煤壁和底板岩层;邻近工作面区域煤岩体位移表现出煤壁挤出位移量>底板鼓起位移量>顶板下沉位移量的特征;由于厚硬顶板的存在,随工作面推进距离的增大,煤壁挤出位移量逐渐增大,煤壁片帮失稳的概率倍增。根据厚硬顶板下大倾角软煤开采围岩位移和变形破坏特征,结合现场观测提出厚硬顶板下大倾角软煤开采2种灾害模式,一是以“片帮-冒顶”为主导,诱发“支架-围岩”系统发生大范围失稳的动态互馈的时发性灾害,二是厚硬砂岩破断诱发冲击动力显现的瞬发性灾害。基于厚硬顶板下大倾角软煤开采灾变机制,采用厚硬顶板深孔预裂爆破初次放顶技术,控制厚硬顶板运动;采取煤壁注浆加固、支架防倒防滑以及“铺金属网+工字钢”辅助液压支架管理破碎直接顶等措施,防治煤壁片帮和破碎顶板漏冒,保证“支架-围岩”系统的稳态工作。通过对支架工作阻力和煤壁片帮统计分析发现,11513工作面采取系列防治措施后,煤壁得到有效控制,初次来压时,支架工作阻力较为富裕,安全阀开启较少且支架无明显倾倒滑移现象,实现了厚硬顶板下大倾角软煤的安全高效开采。

Abstract:

Aiming at the problems of rib spalling, sliding and tipping of supports and large area roof pressure of No.11513 steep dipping working face of Pansidong Coal Mine, the catastrophic mechanism and prevention technology of soft steep dipping coal seam mining under thick and hard roof were studied by means of theoretical analysis, numerical simulation and field observation. The research results show that in the initial stage of large-incline soft coal mining under the thick and hard roof, the surrounding rock damage are mainly concentrated in the coal wall and floor rock. The displacement of coal and rock mass in the adjacent working face area show that the extrusion displacement of coal wall >floor heave displacement >roof subsidence displacement.Due to the existence of thick and hard roof, as the ad vance distance of the working face increases, the displacement of the coal wall gradually increases and the instability probability of coal wall is increased gradually. According to the characteristics of rock deformation and field observations, two disaster modes of large-incline soft coal mining under thick and hard roof were proposed. One is a time-occurring disaster dominated by rib spalling and roof caving, which induces large area instability of the supporting and surrounding rock system. Another is the instantaneous disaster caused by the breakage of thick hard sandstone. Based on the catastrophic mechanism of large inclination soft coal mining under the thick and hard roof, deep hole pre-crack blasting of thick and hard roof have been adopted to control the movement of thick and hard roof. In order to ensure the stable operation of the supporting and surrounding rock system, measures are taken to reinforce the coal wall, prevent the support from falling or slipping and manage the crushing direct roof by laying metal mesh and I-steel auxiliary support. The statistical analysis of the working resistance of the support and the rib spalling showed that the rib spalling was effectively controlled after a series of prevention measures were taken at the 11513 working face.When the pressure is first applied, the working resistance of the support is relatively rich, the safety valve is less open and the supportdoes not fall significantly, which realizesthe safe and efficient mining of soft coal with large inclination under the thick and hard roof.

百度学术

百度学术

本站查看

本站查看

百度学术

百度学术

百度学术

百度学术

百度学术

百度学术

百度学术

百度学术

本站查看

本站查看

百度学术

百度学术

本站查看

本站查看

百度学术

百度学术

百度学术

百度学术

百度学术

百度学术

下载:

下载: