摘要:

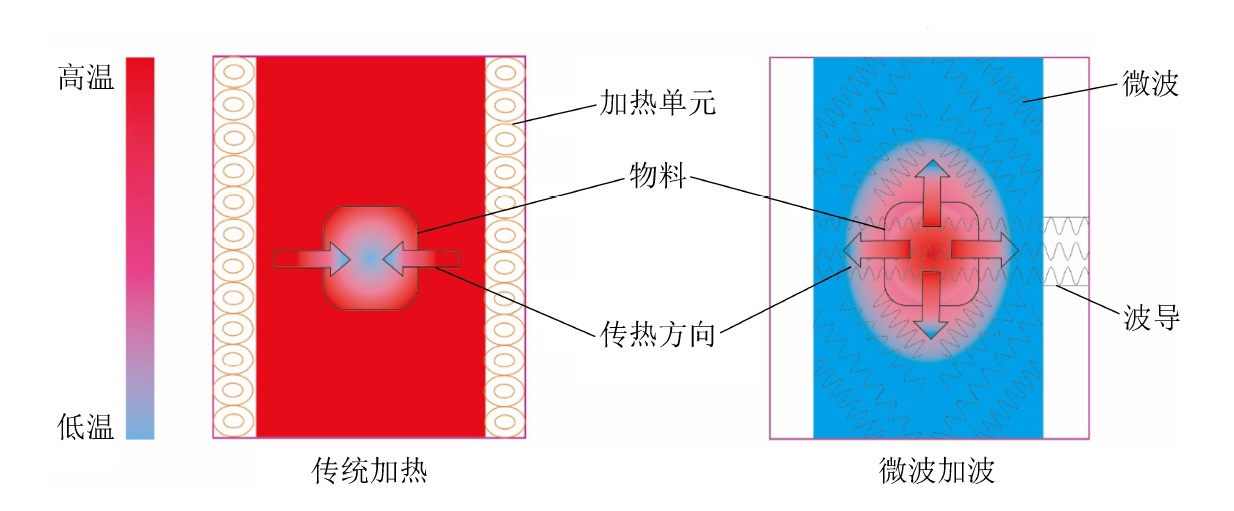

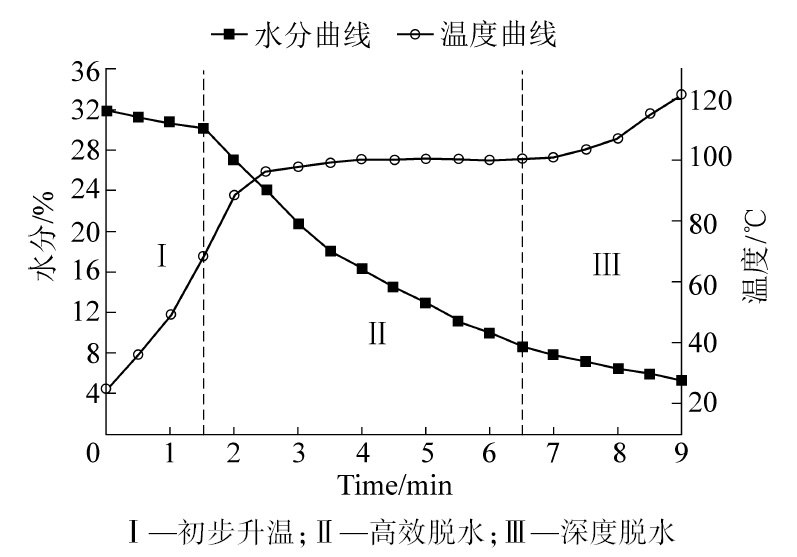

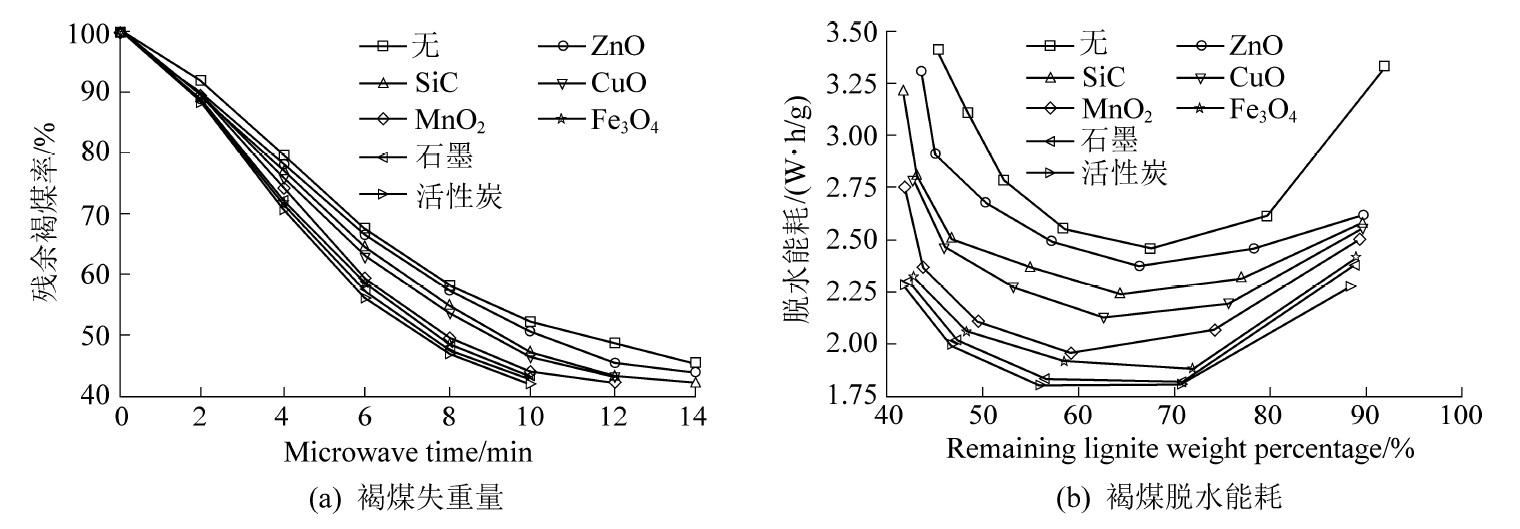

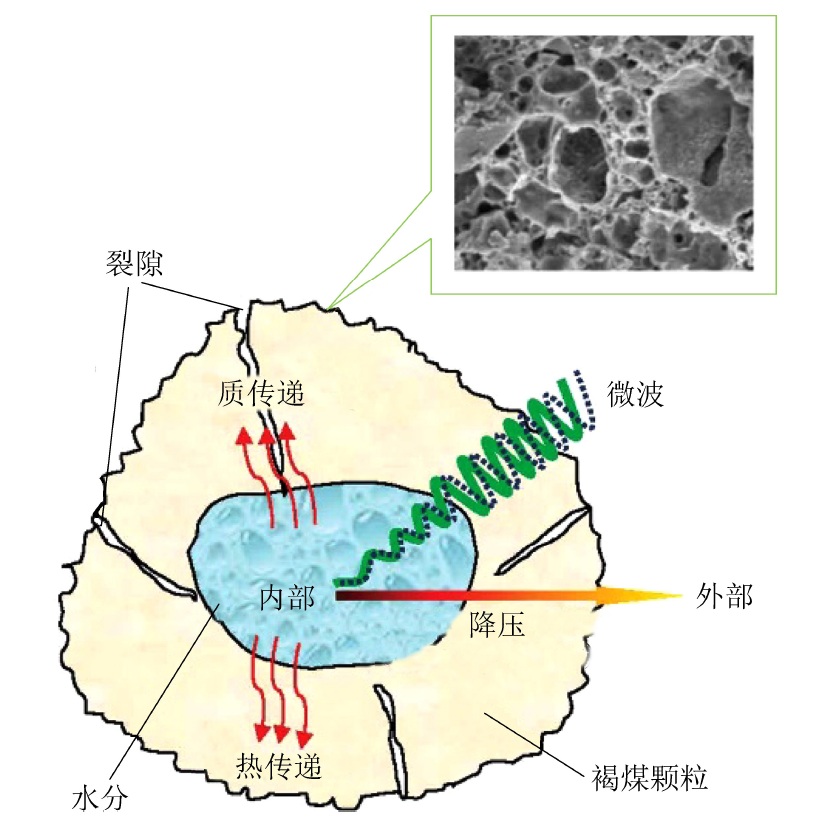

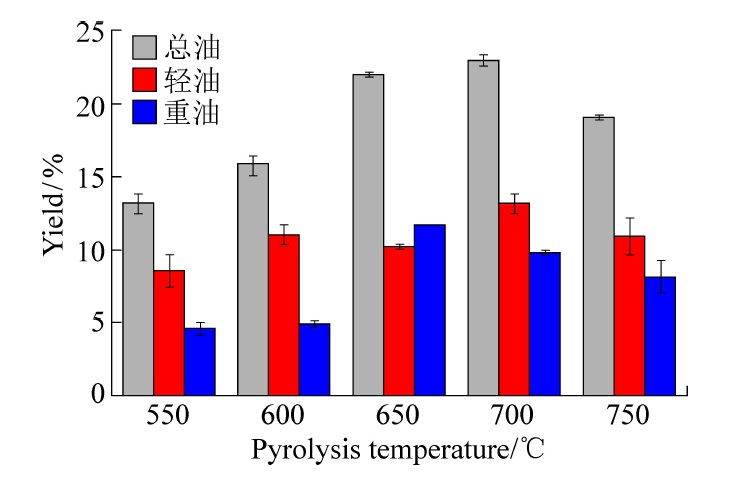

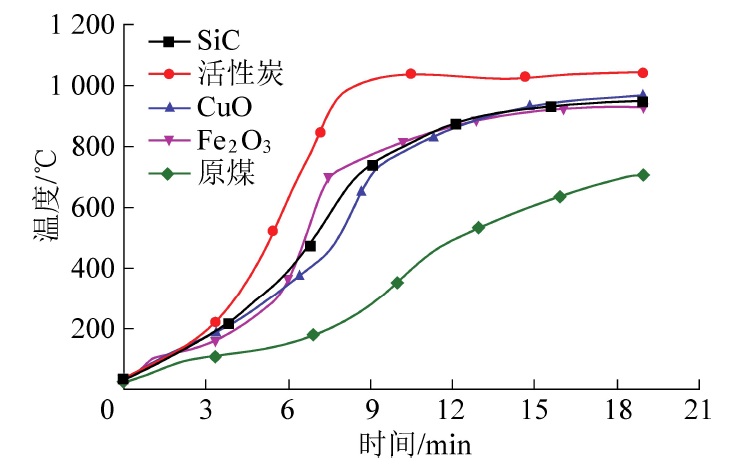

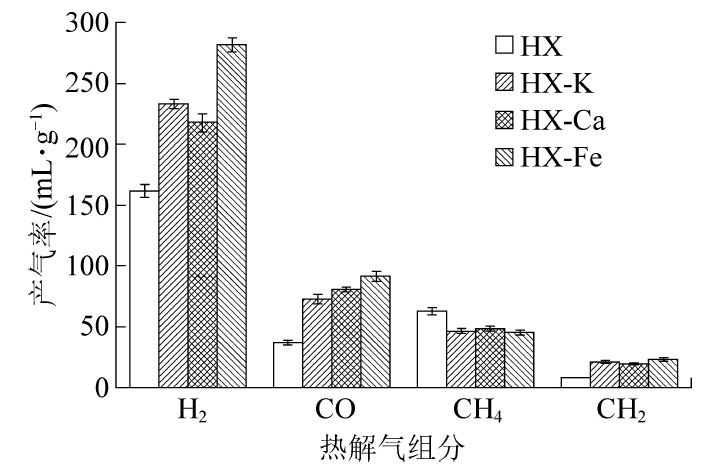

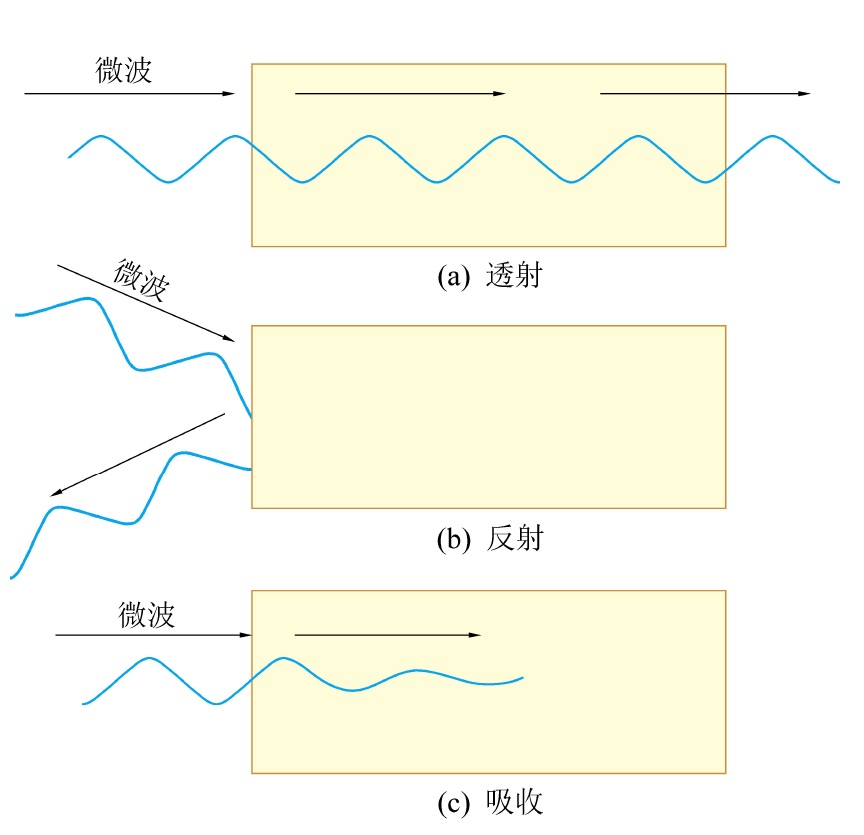

微波热处理技术具有快速均匀、选择性加热和操作灵活、安全环保的优势,为实现低阶煤的清洁高效利用提供了新途径。从低阶煤的微波辅助干燥提质和热解提质出发,综述了低阶煤对微波的介电响应特性,梳理了影响低阶煤微波干燥提质过程的因素,阐述了微波干燥提质对低阶煤品质和理化性质的作用规律,不同工艺条件对低阶煤微波热解提质的影响以及引入吸波剂和催化剂对强化低阶煤微波热解提质的作用特性。结果表明:低阶煤中的水分和矿物含量是影响其介电损耗能力的主要因素,内在水分对微波的快速响应有利于实现微波对低阶煤的快速干燥提质。微波加热干燥有效提升了低阶煤固定碳含量和燃烧热值,内在水分被优先加热发生快速迁移可促进孔隙结构形成进而增强了其可磨性,极性含氧官能团在微波诱导下易发生分解有助于抑制低阶煤的自燃倾向。相比常规热解,微波辅助低阶煤热解提质表现出加热速率快、热解效率高、焦油轻质组分丰富以及合成气产量高的优势。微波功率、辐射时间、热解终温和反应气氛是影响低阶煤微波热解提质的主要因素,基于目标导向的热解工艺参数优化是实现低阶煤高效分级分质利用的核心。利用吸波剂和催化剂充分强化低阶煤微波热解提质,有利于提高微波能利用率、加深煤热解程度、定向调控产物分布以及改善热解产物品质。此外,微波辅助低阶煤和生物质、油页岩和废塑料等富氢物质进行共热解,能够增强焦油向轻质化的转变以及提升有效气体收率,是实现低阶煤清洁高效梯级利用的重要发展方向。

Abstract:

Microwave heating technology possesses the unique advantages of rapid and uniform heating, selective heating, flexible operation, safety and environmental protection, which offers a new way to achieve the clean and high-efficient utilization of low-rank coal. Based on the upgrading technology of microwave drying and pyrolysis of low-rank coal, the dielectric response characteristics of low-rank coal towards microwave were analyzed, and the factors influencing the microwave drying upgradation process of low-rank coal were summarized. Furthermore, the effect rules of microwave drying upgradation on the quality and physicochemical properties of low-rank coal were expounded, the impact of various process conditions on the microwave pyrolysis upgrading of low-rank coal are emphatically reviewed. Additionally, the characteristics of the introduction of microwave absorbers and catalysts on enhancing the microwave pyrolysis upgrading of low-rank coal are analyzed in detail. The results show that the moisture and mineral content of low-rank coal are the key factors of affecting its dielectric loss ability, and the rapid dielectric response of internal moisture towards microwave is beneficial to achieve the rapid drying and quality improvement of low-rank coal under microwave irradiation. Microwave drying can effectively improve the fixed carbon content and combustion calorific value of low- rank coal,and the internal moisture can be preferentially heated for rapid migration with microwave radiation, which is conducive to promoting the development of pore structure and the enhancement of grindability of low- rank coal. The oxygen-containing functional groups with polarity are easy to be decomposed under microwave induction, which is beneficial for inhibiting the spontaneous combustion of low-rank coal. Compared with conventional pyrolysis, microwave-assisted pyrolysis upgrading of low-rank coal shows numerous unique advantages involving fast heating rate, high pyrolysis efficiency, abundant light tar components, and high syngas production. Microwave power, radiation time, final pyrolysis temperature and reaction atmosphere are the main factors that affect the microwave pyrolysis process of low-rank coal. Target-oriented optimization of pyrolysis process parameters is the core for achieving the clean and high-efficient utilization of low-rank coal. The introduction of microwave absorbers and catalysts to fully strengthen the microwave pyrolysis process of low-rank coal is an effective way to increase the utilization rate of microwave energy, enhance the pyrolysis efficiency of coal, directional control of product distribution and improve the quality of pyrolysis products. In addition, microwave-assisted co-pyrolysis of low-rank coal and hydrogen-rich materials such as biomass, oil shale and waste plastics can enhance the production of light tar components and increase the yield the effective gas, which is the crucial development direction to realize the clean and high-efficient utilization of low-rank coal

百度学术

百度学术

百度学术

百度学术

百度学术

百度学术

本站查看

本站查看

百度学术

百度学术

百度学术

百度学术

百度学术

百度学术

百度学术

百度学术

本站查看

本站查看

百度学术

百度学术

百度学术

百度学术

百度学术

百度学术

百度学术

百度学术

下载:

下载: