煤矿智能化开采新进展

New development of intelligent mining in coal mines

-

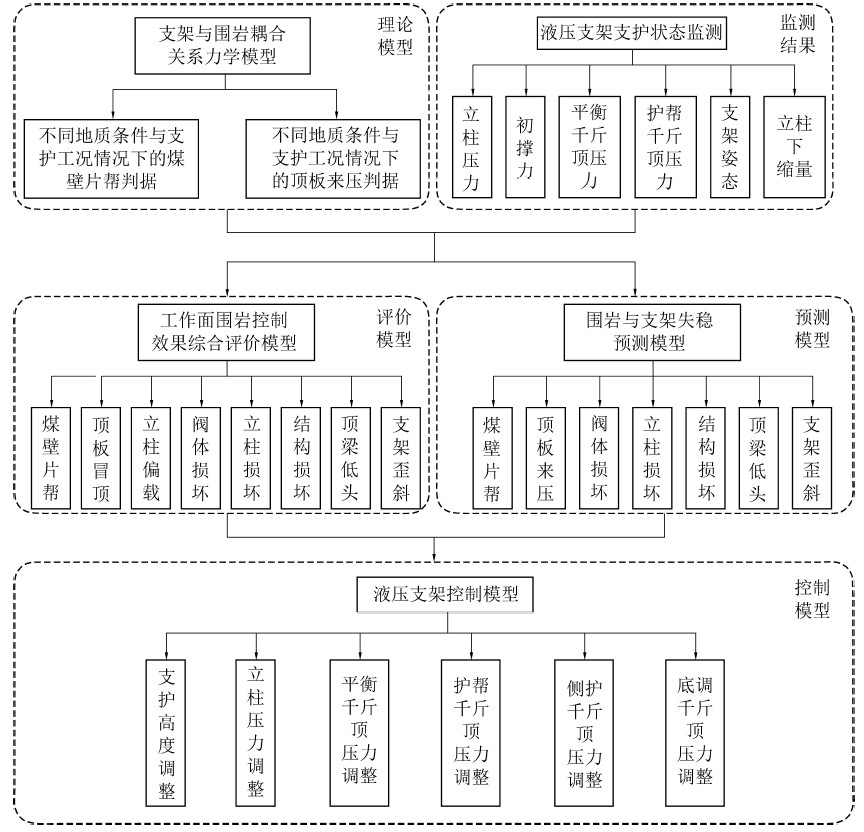

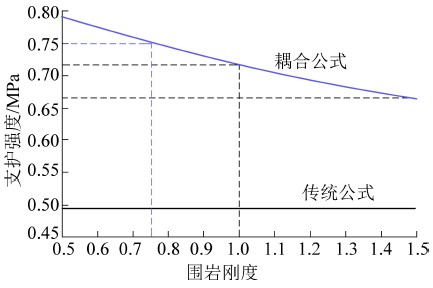

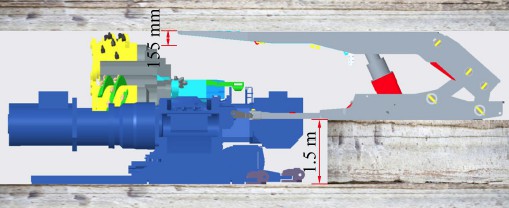

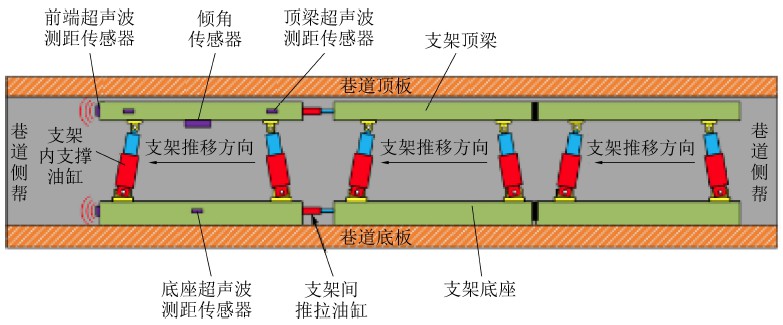

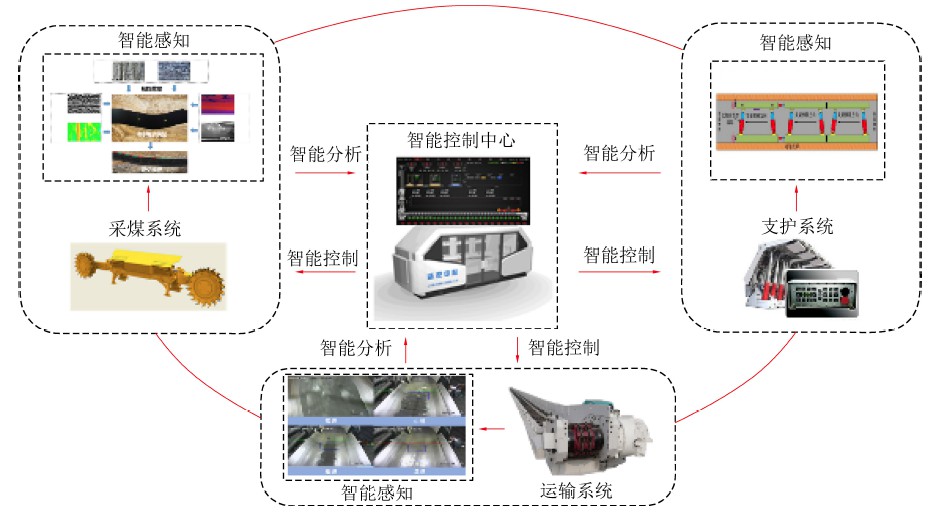

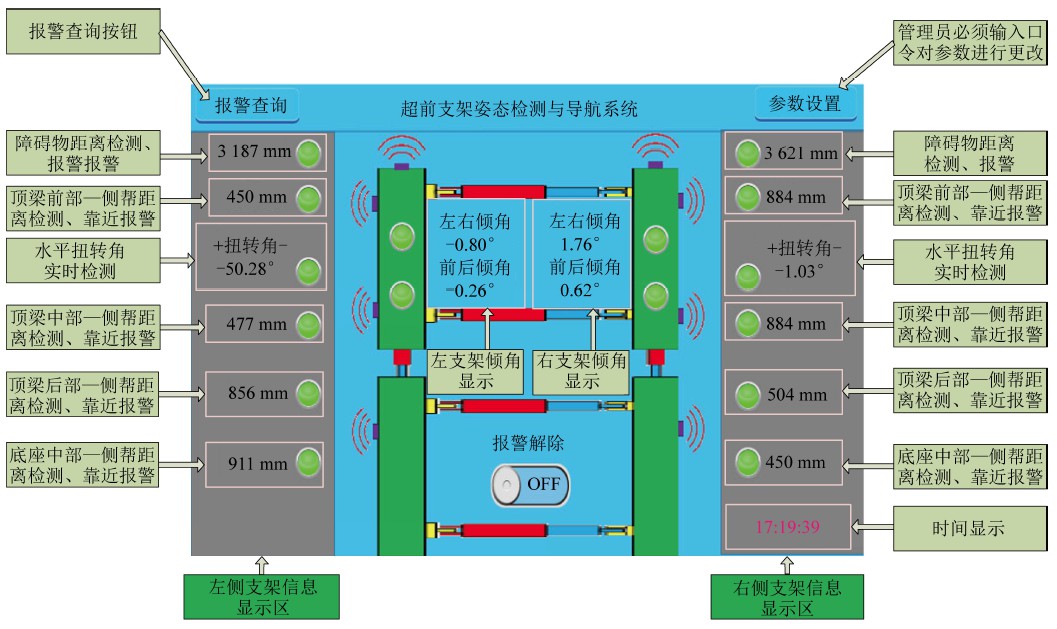

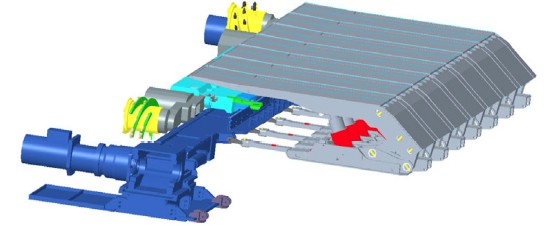

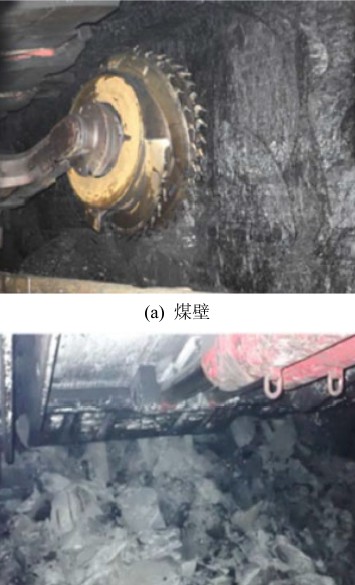

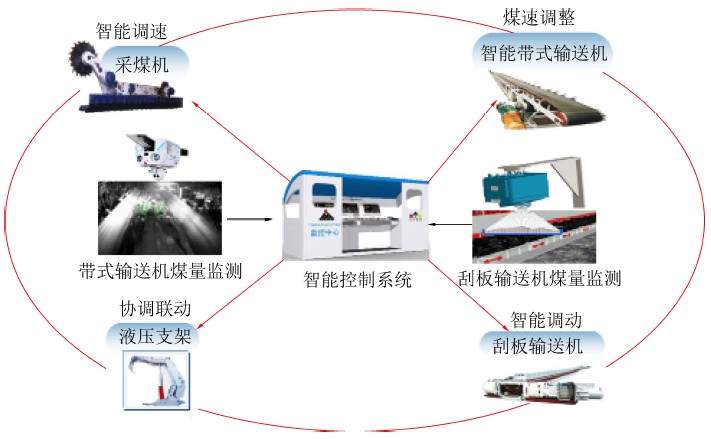

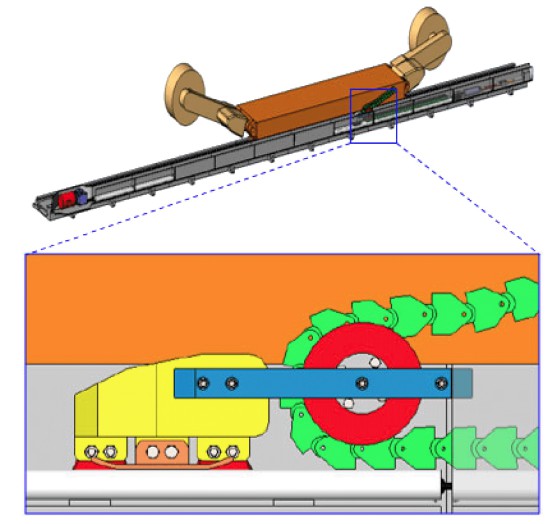

摘要: 智能化开采是煤炭工业高质量发展的核心技术支撑。经过多年发展,我国智能化开采形成了薄煤层和中厚煤层智能化无人操作,大采高煤层人-机-环智能耦合高效综采,综放工作面智能化操控与人工干预辅助放煤,复杂条件智能化+机械化4种智能化开采模式。为了解决工作面综机装备智能决策难题,研发了工作面智能协同控制系统,实现采煤机自适应割煤与自主感知防碰撞,基于煤流量智能感知的采煤机、液压支架、刮板输送机等综采装备的协同联动,工作面综采装备与端头和超前支架的联动控制。上述研究成果在陕北侏罗纪1.1m 硬煤薄煤层、金鸡滩煤矿8m 超大采高综采、金鸡滩煤矿9 m 以上硬煤特厚煤层综放开采进行应用,效果显著,实现了陕北侏罗纪1.1m 硬煤薄煤层高效智能化无人开采,8m 超大采高工作面人-机-环智能耦合高效综采,9m 以硬煤上特厚煤层超大采高智能化综放开采。Abstract: Intelligent mining has become the core technical support for the high-quality development of coal industry. After years of development, intelligent mining in China has formed four intelligent mining modes: intelligent unmanned operation of thin and medium-thick coal seams, man-machine-loop intelligent coupling high-efficiency fully-mechanized mining in large mining height coal seam, intelligent control and manual intervention to assist coal caving in fully-mechanized top-coal caving mining face, and intelligent + mechanized mining mode of complex conditions. In order to solve the problem of intelligent decision-making for fully-mechanized equipment in the working face, the intelligent collaborative control system (ICCS) of the working face has been developed to realize the self-adaptive coal cutting and self-sensing anti-collision of shearer, hydraulic power support, scraper conveyor and other fully-mechanized mining equipment based on the intelligent perception of coal flow, linkage control of fully-mechanized mining equipment, end and advanced support at working face. The above-mentioned research results have been applied in the Jurassic 1.1 m hard coal thin seam of Northeern Shaanxi, the fully-mechanized mining of the Jinjitan Coal Mine with an ultra-large cutting height of 8 m and the fully-mechanized top-coal caving mining in the Jinjitan Coal Mine of 9 m or more hard coal and extra-thick seams, the effects were remarkable. It has realized high-efficiency and intelligent unmanned mining in the Jurassic 1.1 m hard coal thin seam of northern Shaanxi, man-machine-loop intelligent coupling high-efficiency fully-mechanized mining with 8 m super large mining height, and intelligent fully-mechanized caving mining with ultra-large mining height for hard coal and extra-thick seam over 9 m.

-

下载:

下载: