Exploration and summary of prevention and control of rock burst in steeply inclined and ultra-thick coal seam

-

摘要:

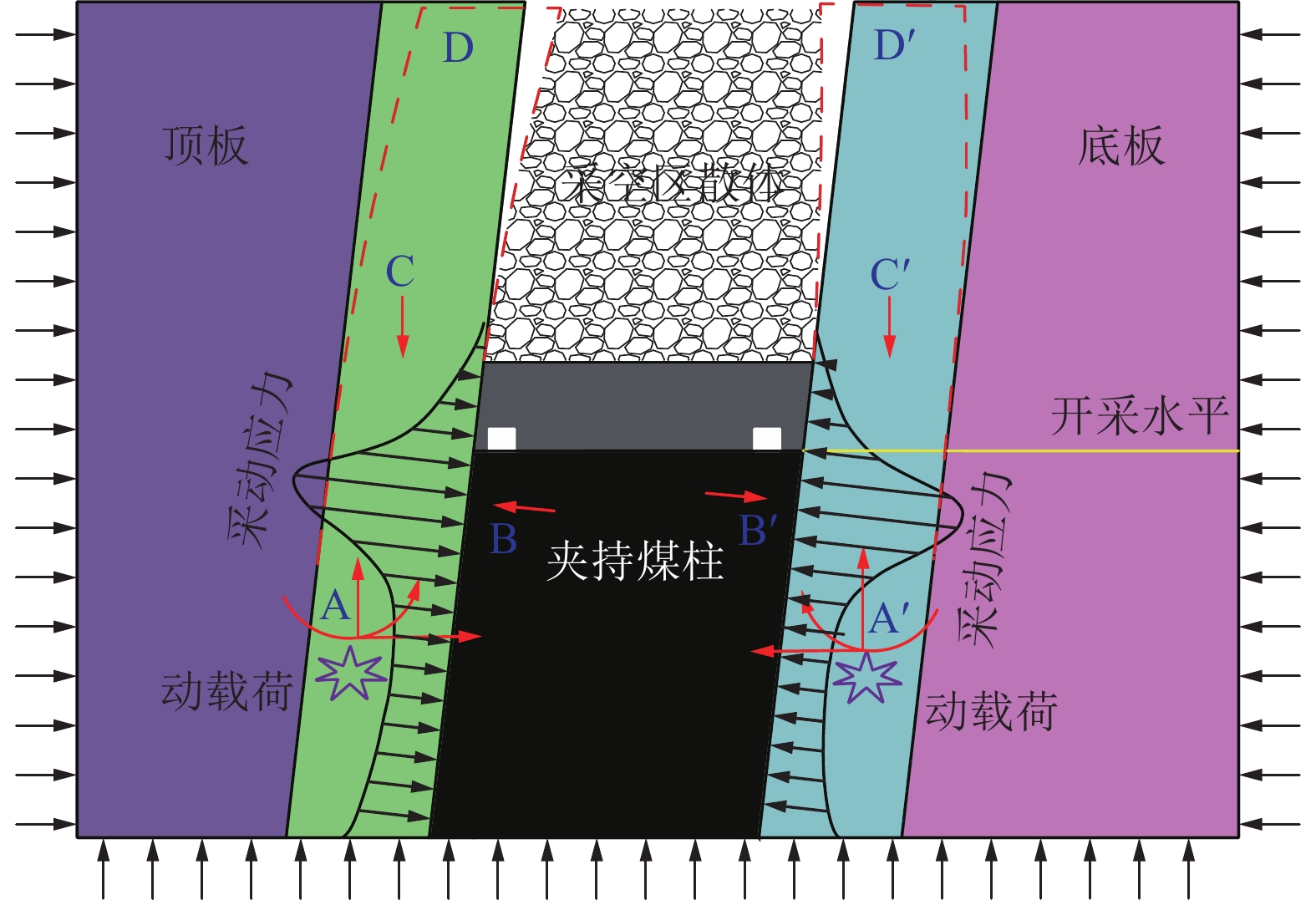

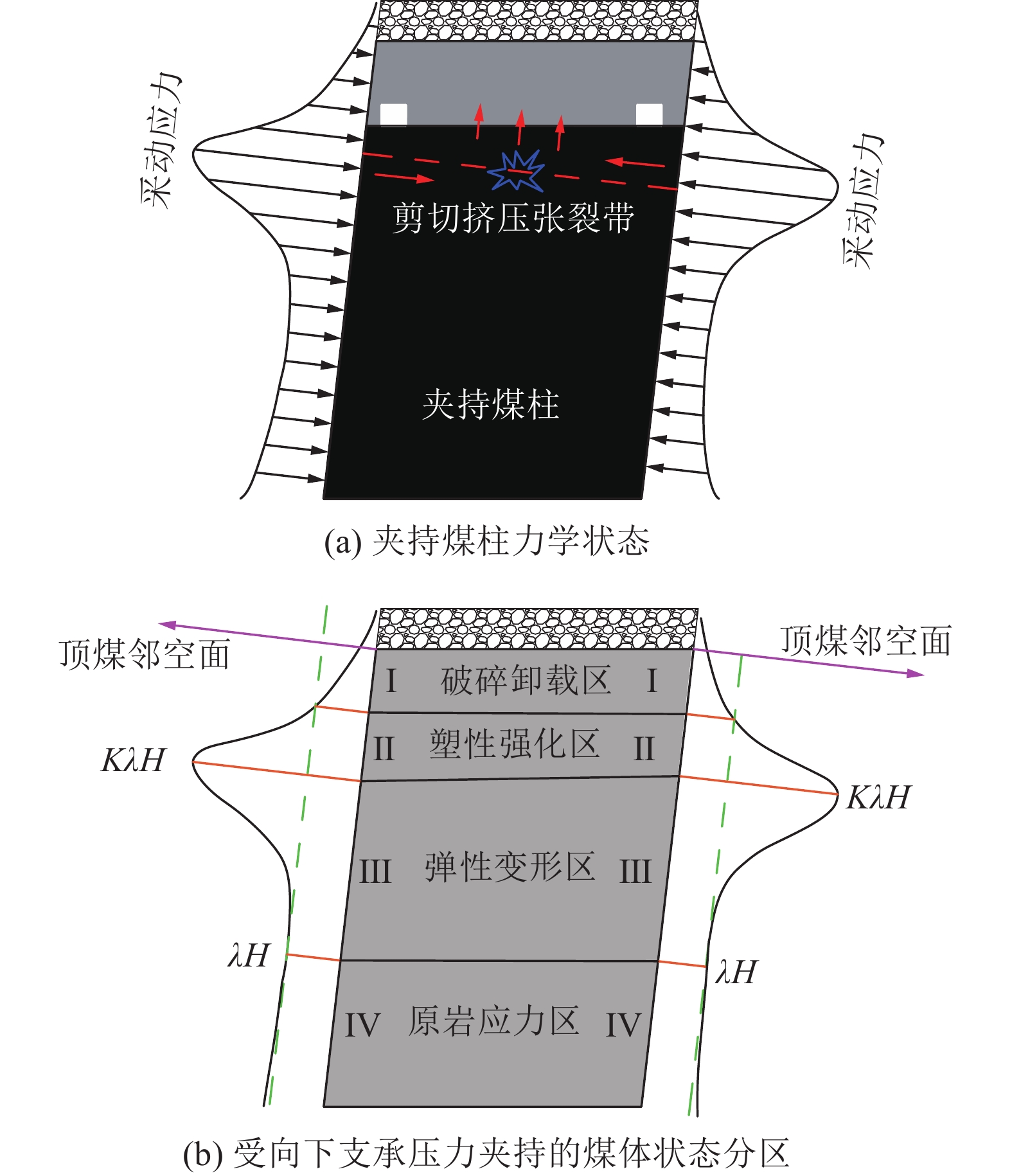

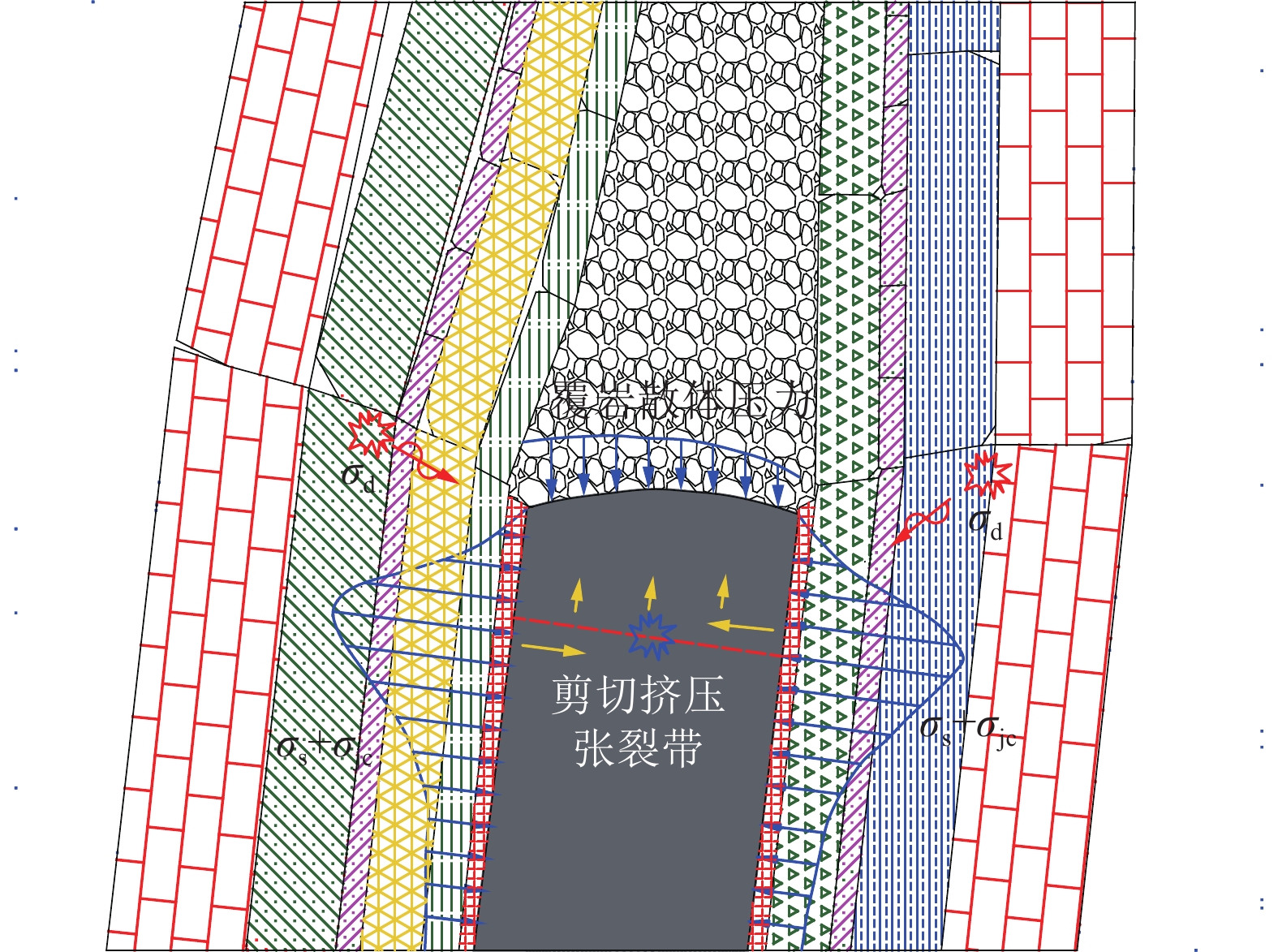

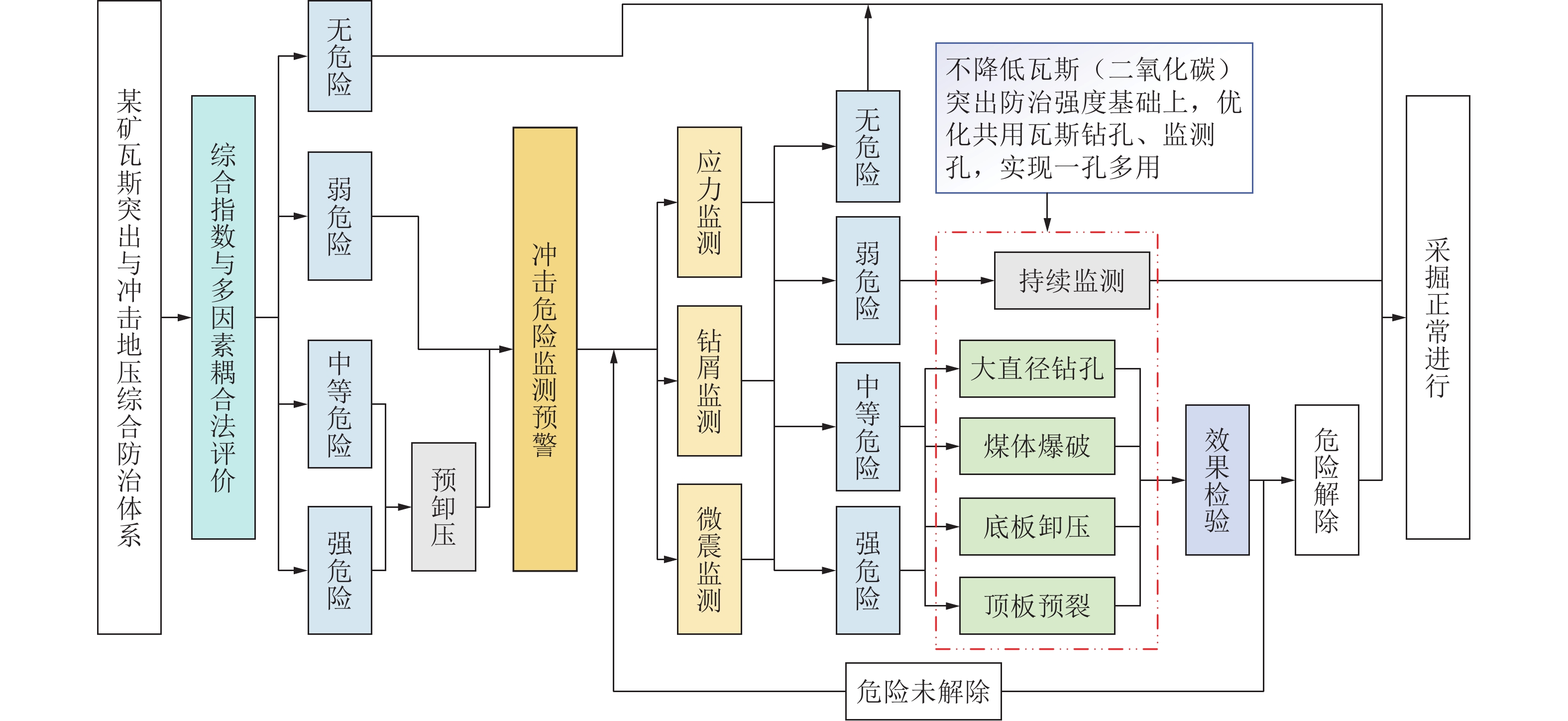

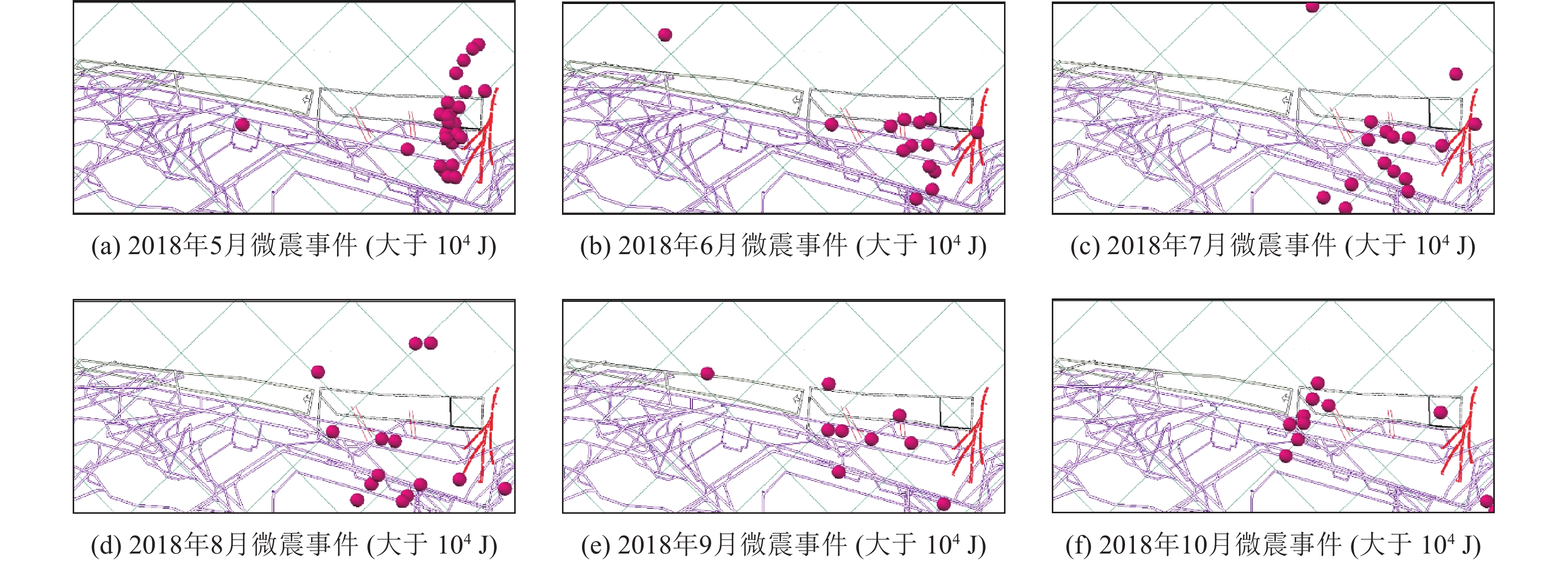

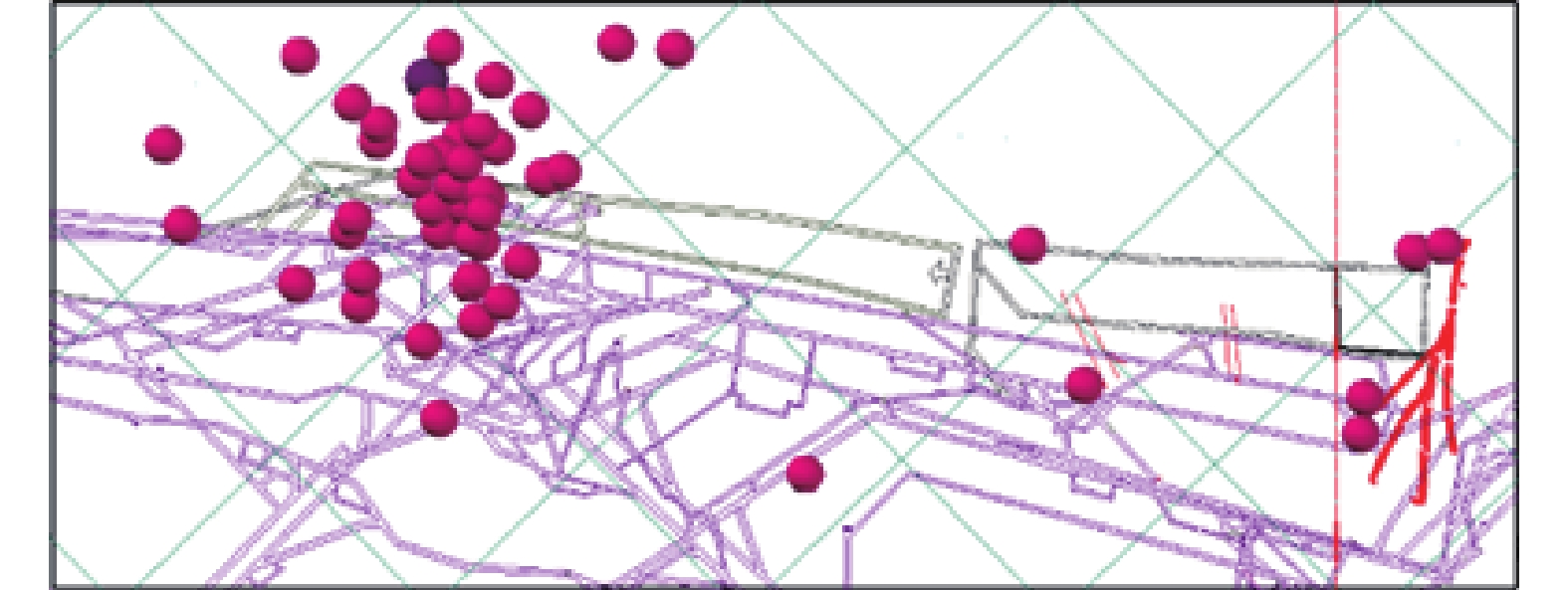

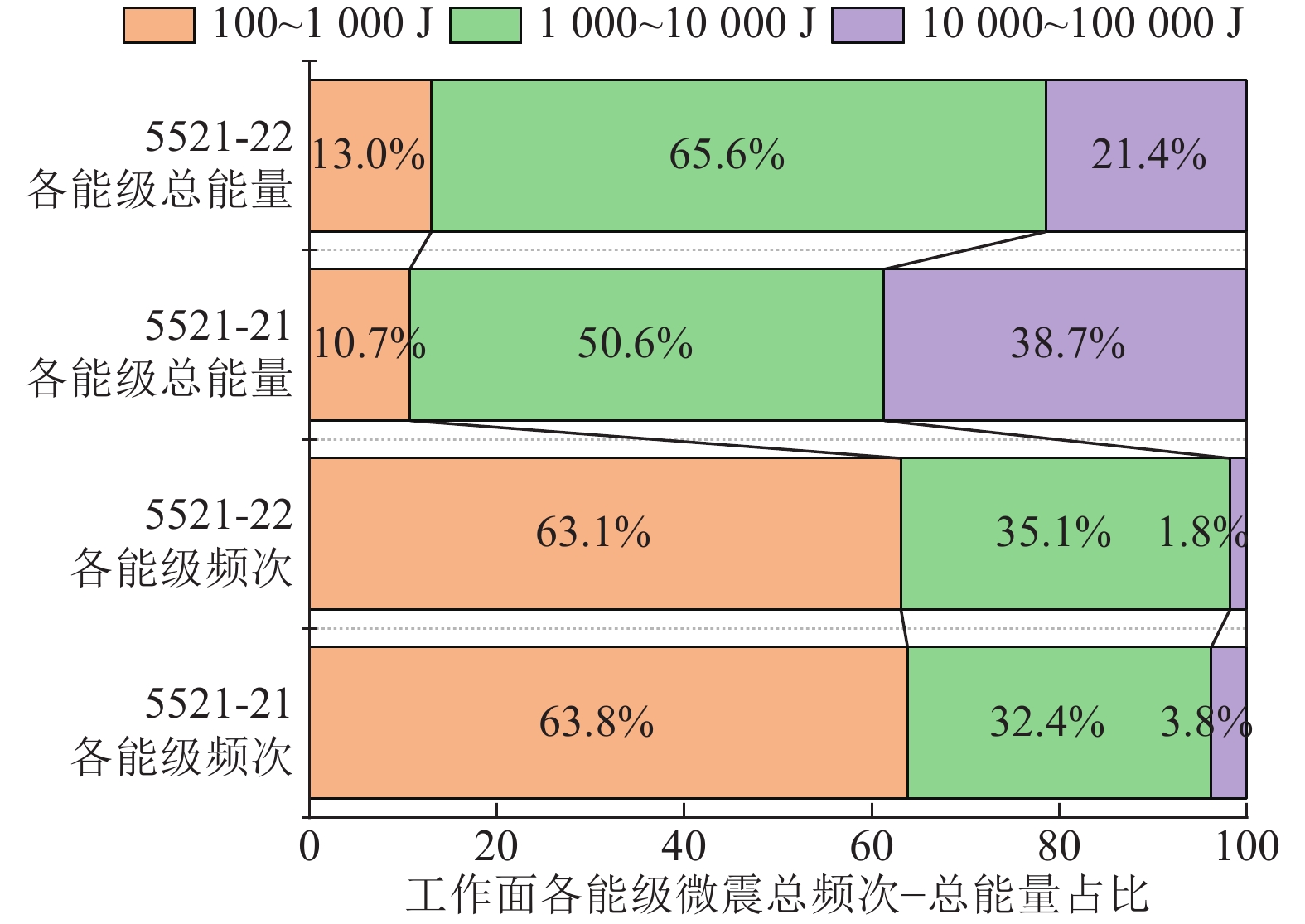

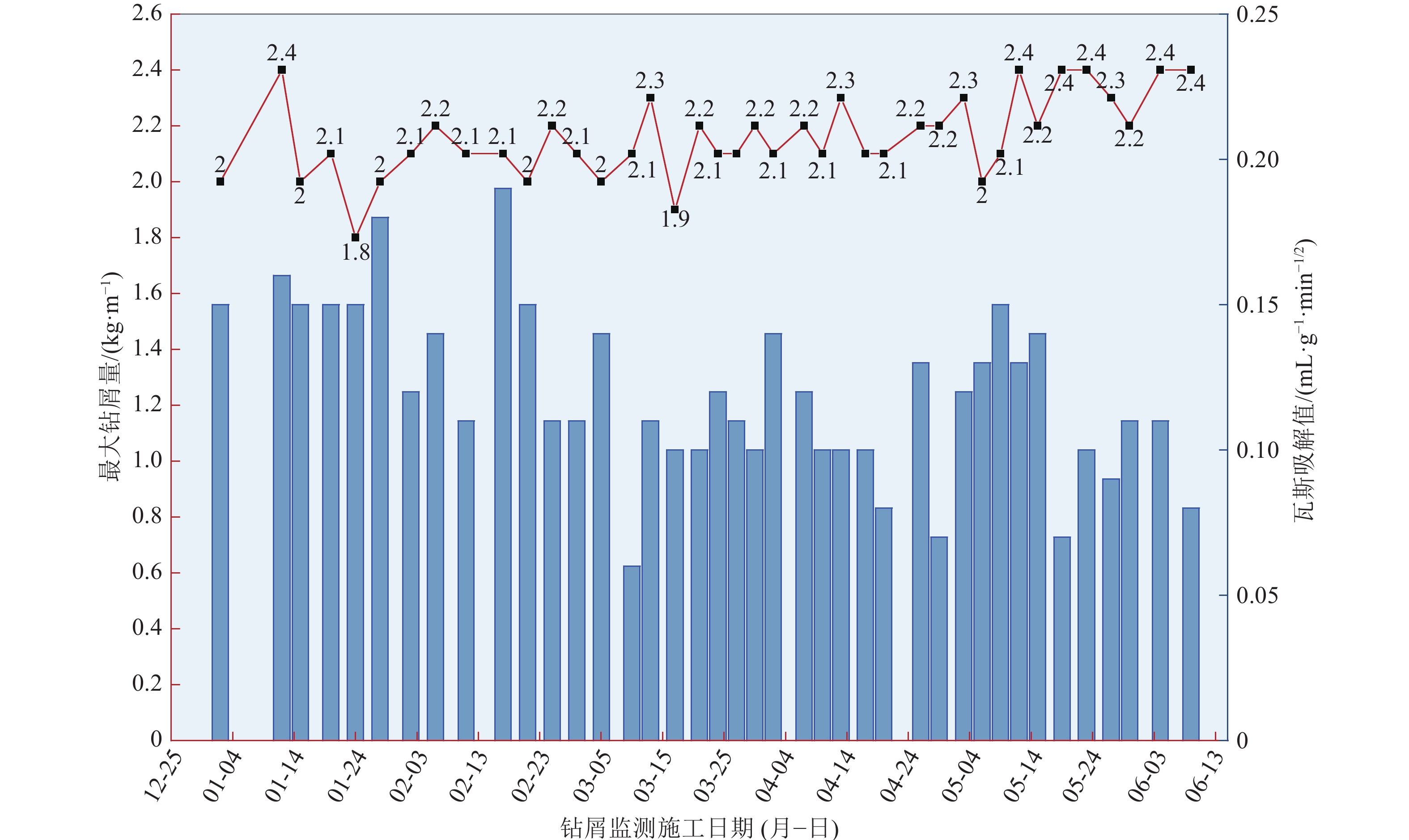

急倾斜特厚煤层开采顶板破断运动复杂,应力和能量演化规律特殊,在深部“三高一扰动”影响下,冲击地压防治不容乐观。基于某矿2016年冲击地压事故后急倾斜特厚煤层水平分段开采冲击地压防治经验,从急倾斜特厚煤层水平分段开采冲击地压发生机理、瓦斯突出与冲击地压综合防治和冲击地压管理详细介绍了该矿7年来急倾斜特厚煤层冲击地压防治经验。冲击地压发生机理方面,建立了顶板岩层倾斜悬臂梁模型,揭示了顶、底板覆岩结构破断失稳演化过程,划分了夹持煤体受力状态分区,提出了急倾斜特厚煤层冲击“夹持理论”。瓦斯突出与冲击地压综合防治方面,基于冲击地压灾害控制解危技术的强度弱化减冲理论,结合原有防突措施体系,提出了既能防冲且对防突有利的解危措施,形成了某矿瓦斯/CO2突出−冲击地压“双防”技术体系,建立了适用于某矿急倾斜特厚煤层水平分段开采的冲击地压防治体系,以钻屑量和瓦斯吸解值验证了瓦斯突出防治的强度保障,同时以加强实施卸压措施工作面的微震事件分布及各能级总频次和能量对比,论证说明了卸压方案防治效果的有效性。冲击地压管理方面,形成了预测评价、监测预警、治理预防、效果检验、安全防护和教育培训“六位一体”综合防治架构,基于《煤矿安全规程》和《防治煤矿冲击地压细则》等各项规定,制定了Q/YJMD—FC 0104—2022《窑街煤电集团有限公司煤矿冲击地压防治 第四部分:冲击地压防治技术规范》。

Abstract:The roof breaking movement of steeply inclined and ultra-thick coal seam mining is complex, and the evolution law of stress and energy is special. Under the influence of deep ‘three highs and one disturbance’, the prevention and control of rock burst is not optimistic. Based on the experience of rock burst prevention and control in horizontal section mining of steeply inclined and ultra-thick coal seam after the rock burst accident in a mine in 2016, the experience of rock burst prevention and control in steeply inclined and ultra-thick coal seam in the past seven years is introduced in detail from the mechanism of rock burst in horizontal section mining of steeply inclined and ultra-thick coal seam, the comprehensive prevention and control of gas outburst and rock burst and the management of rock burst. In terms of the mechanism of rock burst, the inclined cantilever beam model of roof strata is established, the evolution process of fracture instability of roof and floor overburden structure is revealed, and the ‘clamping theory’ of rock burst in steeply inclined and ultra-thick coal seam is put forward. In terms of comprehensive prevention and control of gas outburst and rock burst, based on the theory of strength weakening and rock burst reduction of rock burst disaster control and disaster relief technology, combined with the original outburst prevention measures system, this paper puts forward the measures that can prevent and benefit the outburst prevention, forms a mine gas/carbon dioxide outburst/rock burst ‘integrated control’ technology system, and establishes a rock burst prevention and control system suitable for the horizontal section mining of steeply inclined thick coal seam in a mine. The intensity of gas outburst prevention and control is verified by the amount of drilling cuttings and the value of gas absorption and desorption. At the same time, the distribution of microseismic events and the total frequency and energy of each energy level are compared in the working face with pressure relief measures. The effectiveness of the control effect of the pressure relief scheme is demonstrated. In terms of rock burst management, a “six-in-one” comprehensive prevention and control framework has been formed, including prediction and evaluation, monitoring and early warning, treatment and prevention, effect test, safety protection and education and training. Based on the “Coal Mine Safety Regulations” and “Detailed Rules for Prevention and Control of Coal Mine Rock Burst” and other provisions, the Q/YJMD-FC 0104-2022“Yaojie Coal and Electricity Group Co., Ltd. Coal Mine Rock Burst Prevention and Control Part IV: Technical Specification for Prevention and Control of Rock Burst” was formulated.

-

0. 引 言

煤矸石智能分拣已经成为煤矿智能化、绿色化的重要组成部分,现有的煤矸石智能分拣系统主要包括煤矸带式输送系统、识别系统、分拣系统等,主要分拣方法有抓取分拣、拨叉分拣和气动分拣等[1]。拨叉智能分拣系统利用视觉或射线识别煤与矸石位置,并控制拨叉在其进入分拣区域后将其拨出输送带,实现自动分拣。抓取分拣同样依赖于煤矸石识别结果,并通过图像方法对煤矸石进行定位跟踪,控制机械臂对煤矸石进行抓取分拣。气动分拣则是在煤矸石识别定位的基础上,根据煤矸石位姿变化对气枪进行动态控制,用高压气体将煤矸石分拣出来。分析现有煤矸石智能分拣系统架构和原理,其共性关键技术主要包含:煤矸石识别、煤矸石分拣特征提取、分拣器动态目标跟踪和多任务多分拣器协同控制等[2]。在煤矸石智能分拣系统共性关键技术中,煤矸石图像的分析处理贯穿始终,对于提高分拣精度和效率发挥着决定性的作用。

煤矸石识别方法[3-5]均以煤矸石图像为基础(如RGB图像,射线图像,多光谱图像等),从图像中提取煤矸石识别特征[6-8],通过AI算法实现自动识别,并构建煤矸石图像信息库;分拣器动态目标跟踪则需要通过视觉方式获取煤矸石图像,并对目标矸石进行匹配和跟踪,以此实时获取目标矸石位姿信息[9-10];多任务多分拣器协同控制则是在煤矸石图像信息库的基础上,结合分拣器状态,完成煤矸石任务分配、分拣器路径规划、轨迹跟踪[11-14]和多分拣器协同控制[15-18]。

由此可见,在煤矸石智能分拣系统中,图像是实现煤矸石智能分拣的基础,不仅作为系统的感知输入,更是在整个流程中,从图像的采集与识别特征提取,到后续的目标匹配、姿态估计、动态跟踪与多分拣器协同控制,起到了连接感知、认知与执行的关键枢纽作用。图像贯穿煤矸石识别、煤矸石分拣特征提取、分拣器动态目标跟踪和多任务多分拣器协同控制等全过程,决定了煤矸石智能分拣系统分拣效率、智能化程度,是实现系统高精度、高效率运行的核心支撑。因此,本文提出“拣矸就是拣图像”的智能拣矸学术思想。

1. “拣矸就是拣图像”学术思想系统架构

为了系统化阐述“拣矸就是拣图像”的核心思想,本文结合煤矸石智能分拣系统中的关键技术,构建了该学术思想的逻辑架构,如图1所示。该架构全面梳理了图像在信息采集与预处理、神经网络识别分析、任务目标匹配、精准跟踪与抓取控制、多机械臂协同决策等关键环节中的作用,形成了从感知输入到智能执行的完整闭环,突出展现了图像在煤矸石分拣过程中的基础性与枢纽性地位。

2. 基于图像的煤矸石识别

煤矸石的准确识别是实现机器人高效智能分拣的首要条件。基于图像的煤矸石识别可以将分拣目标数字化,为整个分拣过程提供数据支撑。通过图像对煤矸石进行识别主要有2个目的,一是通过图像分析获得目标类别信息;二是获得目标在煤矸石分拣机器人系统中的位姿信息。

煤矸石识别受光照、粉尘以及煤矸石污染程度等因素影响。在井上识别煤矸石时,可利用视觉系统,通过提取煤矸石灰度和纹理信息,计算灰度均值、灰度共生矩阵最大值、二阶矩、对比度、相关性、熵等参数[19-21],同时结合小波变换[22-23]、支持向量机[24]等方法进行阈值计算实现煤矸识别,且具有较高的识别准确率,但适应性较弱。基于卷积神经网络的煤矸石识别方法[25-26]能提取到更多煤矸石表面特征,通过深度学习[27-29]能够提高算法的实时性和鲁棒性。

在煤矿井下,由于煤矸石表面被煤泥严重包裹,通过视觉图像难以识别,可利用射线检测方法获取煤矸石图像[30-31],具有较高的识别率,但无法获取图像的深度信息。因此,融合射线图像和视觉图像获取煤矸石分拣位姿信息,能够有效提高煤矸石识别的准确率,提高分拣效率。原理如图2所示。

在获取煤矸石识别结果的基础上,构建煤矸石图像信息库,信息库主要包括煤矸石的质心位置坐标、分拣角度、分拣宽度、矸石厚度、矸石模板和质量等参数信息,如图3所示。

3. 基于图像的煤矸石分拣特征提取

在准确获取煤矸石目标类别信息和位置信息的基础上,如何控制分拣器以最佳姿态对煤矸石进行精准分拣是实现机器人高效分拣的关键所在。从力学角度分析,无论以何种方式对煤矸石进行分拣,分拣器与煤矸石质心的作用关系是实现精准分拣的前提。

气动分拣和机械手“拨叉”分拣在得到目标的质心位置坐标后即可执行分拣动作,但对于机械手“抓取”分拣形式,除需以质心为依据外,还需考虑最佳分拣角度、分拣宽度、矸石厚度等姿态信息。因此,煤矸石分拣特征主要包括质心位置坐标、分拣角度、分拣宽度、矸石厚度等。

分拣宽度、分拣角度可通过对目标煤矸石图像进行图像分割和边缘提取等处理,获取其二维图像包络矩形后计算得出,如图4所示。但分拣矩形只获得目标煤矸石的平面图像信息,只能计算出形心坐标,无法得到质心坐标。因此,可通过X射线识别煤矸石并提取轮廓特征,生成煤矸石包络矩形;融合煤矸石X射线图像与双目视觉点云图像,对目标煤矸石点云数据进行目标分割,采用OBB包围盒算法生成煤矸石抓取特征,基于此特征构建煤矸石最优抓取立方体,如图5所示。分拣立方体包含了质心位置坐标、分拣角度、分拣宽度、矸石厚度等参数信息[32-33],煤矸石分拣特征提取原理如图6所示。

4. 图像驱动的分拣器动态目标跟踪

煤矸石分拣器对煤矸石进行高效分拣取决于煤矸石的精确定位和同步跟踪。现有的定位方法主要是通过时间和带速来计算分拣位置,得到目标运动轨迹。但未考虑带式输送机在运行过程中存在带速波动或跑偏因素。在获取目标质心位置后,分拣器不能直接进行分拣动作,还需要对分拣器进行控制,确保分拣器对目标煤矸石精准跟踪。因此,基于图像驱动的动态目标煤矸石实时定位和分拣器路径规划与轨迹跟踪是亟待破解的关键难题。

4.1 基于图像的动态目标煤矸石实时定位

动态目标煤矸石从识别区域进入分拣区域后,常常会出现位姿变化和遮挡等现象。因此,分拣器在执行分拣动作之前,需通过目标模板图像匹配检测图像,确定待分拣目标煤矸石。在目标煤矸石被遮挡时,仅采用匹配算法无法满足对目标位置信息的精确获取。因此,需进一步采用图像跟踪算法(如FDSST跟踪算法[34-35]、基于深度学习的跟踪算法[36-37]、基于孪生神经网络跟踪算法[38-39])对动态煤矸石进行跟踪,确保目标煤矸石位姿信息的实时准确获取。基于图像的动态目标煤矸石实时定位原理如图7所示。

4.2 图像驱动的分拣器路径规划与轨迹跟踪

基于图像的动态目标煤矸石实时定位方法为分拣器同步跟踪提供了准确的位置信息。煤矸运输具有速度快、矸石质量大等特点,机械手直接抓取存在冲击载荷,极易造成抓取失败或机械手损坏。因此,融合分拣器末端位姿信息和目标煤矸石位姿信息,建立基于全局规划和局部优化的“位置−速度−加速度”多约束条件分拣器动态目标路径规划模型[13,40]在此基础上,融合最短跟踪时间和最优分拣位姿,建立分拣器轨迹跟踪模型,以此来提高分拣精度和效率。分拣器路径规划和轨迹跟踪原理如图8所示。

5. 基于煤矸石图像信息的多任务多分拣器智能协同控制

在多任务、多分拣器煤矸石协同拣矸系统中,基于煤矸石图像信息(位姿、尺寸和质量)的多分拣器多任务分配、多分拣器协同控制和多分拣器数量最优配置等是亟待解决的关键难题。

5.1 多分拣器多任务分配

通过分拣器动态煤矸石跟踪方法可得到分拣器分拣煤矸石路径和分拣时间。多分拣器多任务分配在煤矸石图像信息库的基础上,构建分拣器综合收益函数,获得分拣器任务收益矩阵。结合分拣器工作空间可行域和煤矸石图像分布对分拣器任务空间进行优化,获得分拣器任务可行域。分拣器按照可行域内收益最大的原则进行任务分配。多分拣器多任务分配原理如图9所示。

5.2 多任务多分拣器协同控制

多分拣器煤矸石分拣系统中,分拣器之间既相互约束又相互协同。多分拣器系统在煤矸石图像信息库的基础上,通过对分拣器状态进行监测,按照多分拣器多任务分配方法进行任务分配。分拣器根据图像驱动的动态煤矸石跟踪模型进行路径规划,对目标煤矸石进行跟踪分拣。多分拣器协同控制策略库根据执行任务分布图谱进行分拣器和任务可执行度分析,当分拣器路径发生冲突时,通过全局策略收益评价函数对分拣器执行任务全局收益进行评价,选择收益最大任务执行。同时通过分拣避让协同控制模型对其他分拣器进行协同动作控制。当任务分布图谱密度较大时,采用多分拣器协同路径控制模型对多分拣器路径进行控制。利用强化学习过程计算多分拣器系统效益,建立奖惩机制并对煤矸石图像信息库进行更新,根据煤矸石图像信息对分拣器动作进行动态控制,并更新控制策略,同时反馈一定的奖惩给多分拣器控制系统进一步优化感知决策过程,借助煤矸石图像信息库进行决策训练。多任务多分拣器智能协同控制系统框架如图10所示。

5.3 分拣器数量最优配置

分拣器数量配置与含矸率、过煤量、带式输送机带速和拣矸要求等因素密切相关。在煤矸石图像信息库的基础上,结合分拣器数量影响因素,构建多分拣器系统任务动态库。通过多分拣器协同控制方法构建分拣器数量配置数学模型,将分拣器数量影响因素参数化,并作为分拣器数量配置数学模型输入,以拣矸效率作为评价指标,求解分拣器最优数量。分拣器数量配置原理如图11所示。

6. 实验验证

基于“拣矸就是拣图像”的学术思想,研发了双机械臂桁架式煤矸石分拣机器人系统,系统由煤矸石识别子系统、机械臂分拣子系统、检测与控制子系统、带式输送机等组成。双机械臂煤矸石分拣机器人系统如图12所示。

系统通过图像识别子系统获取大量煤矸图像,构建了煤矸图像数据集,采用改进的VGG-16网络识别算法[41]实现对煤和矸石的分类识别,获得煤矸石分拣特征参数,识别准确率为97.58%,结果如图13—图14所示。

机械臂通过匹配跟踪算法获取目标煤矸石的实时精准位姿。分拣器根据煤矸石质心位姿信息,采用多约束条件分拣器动态目标路径规划方法[42],对分拣器路径进行实时规划;采用基于长短期神经网络的分拣器轨迹跟踪方法,控制分拣器对规划的路径进行跟踪,结果如图15所示。图中分拣器末端在接收到分拣任务后,其位置超前于目标位置,因此,分拣器在实时路径规划时,首先反向逼近目标,然后再进行同向跟踪,当分拣器与动态目标煤矸石快速同步后执行分拣动作。

通过制备不同含矸率的试验样本,结合多任务多分拣器系统控制原理,采用基于免疫动态工作空间多分拣器协同控制方法[15]进行实验。试验结果如图16所示。分拣器未达到最大分拣能力时,随着含矸率的增加,分拣器的分拣能力增强,但是到达一定程度后,分拣能力保持稳定,分拣能力为1.96 t/min,充分发挥多分拣器的分拣效能,实现煤矸石的高效分拣。

7. 结 论

1)煤矸石识别就是对图像的识别。基于图像的识别方法不仅能够获得煤矸石表面特征,也可以获得其内部特征,将视觉图像和射线图像融合,提高煤矸石识别的准确率。

2)煤矸石分拣特征提取就是对图像特征的提取。对煤矸石平面特征和深度特征进行提取和融合,构建煤矸石分拣立方体,得到煤矸石质心坐标和其他特征参数,为分拣器的精准控制提供数据支撑。

3)动态煤矸石跟踪是对动态图像的跟踪。通过基于图像的煤矸石匹配跟踪方法对煤矸石质心进行精准定位,以此对分拣器进行路径规划,并驱动分拣器准确跟踪目标煤矸石,提高分拣的精准性和可靠性。

4)多分拣器智能协同就是对煤矸石图像序列的协同分拣。以煤矸石图像信息库为基础,通过构建分拣器综合收益函数,实现多分拣器多任务最优分配;融合强化学习方法,实现多分拣器智能协同控制。在此基础上获得分拣器数量最优配置,提高多分拣器系统的分拣效率。

-

表 1 矿井小孔径水压致裂法地应力实测

Table 1 In-situ stress measured by small aperture hydraulic fracturing method in mine

测站编号 H/m $ {\sigma _{\mathrm{v}}} $/MPa $ {\sigma _{\mathrm{H}}} $/MPa $ {\sigma _{\mathrm{h}}} $/MPa 最大主

应力方向七采区 1 440 11.00 16.23 10.22 N56.9° E 2 440 11.00 18.71 10.96 N53.5° E 3 450 11.25 14.52 7.39 N65.7° E 五采区 4 450 11.25 15.13 9.48 N10.4° W 5 500 12.50 19.97 12.15 N66.9° W 6 500 12.50 18.50 10.03 N48.4° W 7 500 12.50 13.44 6.88 N56.5° W 注:H、$ {\sigma _{\mathrm{v}}} $、$ {\sigma _{\mathrm{H}}} $、$ {\sigma _{\mathrm{h}}} $分别为测站埋深、垂直应力、最大水平主应力、最小水平主应力。 -

[1] 屠洪盛,屠世浩,白庆升,等. 急倾斜煤层工作面区段煤柱失稳机理及合理尺寸[J]. 中国矿业大学学报,2013,42(1):6−11. TU Hongsheng,TU Shihao,BAI Qingsheng,et al. Instability of a coal pillar section located at a steep mining face:pillar size selection[J]. Journal of China University of Mining & Technology,2013,42(1):6−11.

[2] 崔 峰,张随林,来兴平,等. 急倾斜特厚煤层组开采煤岩体联动诱冲机制与防冲调控[J]. 岩石力学与工程学报,2023,42(S1):3226−3241. CUI Feng,ZHANG Suilin,LAI Xingping,et al. Coal and rock mass linkage induced impact mechanism and prevention and control rock burst in steeply-inclined and extremely-thick coal seam group[J]. Chinese Journal of Rock Mechanics and Engineering,2023,42(S1):3226−3241.

[3] 谢和平,张 茹,张泽天,等. 深地科学与深地工程技术探索与思考[J]. 煤炭学报,2023,48(11):3959−3978. XIE Heping,ZHANG Ru,ZHANG Zetian,et al. Reflections and explorations on deep earth science and deep earth engineering technology [J]. Journal of China Coal Society,2023,48(11):3959−3978.

[4] 齐庆新,马世志,孙希奎,等. 煤矿冲击地压源头防治理论与技术架构[J]. 煤炭学报,2023,48(5):1861−1874. QI Qingxin,MA Shizhi,SUN Xikui,et al. Theory and technical framework of coal mine rock burst origin prevention[J]. Journal of China Coal Society,2023,48(5):1861−1874.

[5] 潘一山,宋义敏,刘 军. 我国煤矿冲击地压防治的格局、变局和新局[J]. 岩石力学与工程学报,2023,42(9):2081−2095. PAN Yishan,SONG Yimin,LIU Jun. Pattern,change and new situation of coal mine rockburst prevention and control in China[J]. Chinese Journal of Rock Mechanics and Engineering,2023,42(9):2081−2095.

[6] 窦林名,田鑫元,曹安业,等. 我国煤矿冲击地压防治现状与难题[J]. 煤炭学报,2022,47(1):152−171. DOU Linming,TIAN Xinyuan,CAO Anye,et al. Present situation and problems of coal mine rock burst prevention and control in China[J]. Journal of China Coal Society,2022,47(1):152−171.

[7] 贺 虎,郑有雷,张 雄,等. 基于动静应力分析的复杂工作面冲击危险评价[J]. 煤炭科学技术,2019,47(7):265−270. HE Hu,ZHENG Youlei,ZHANG Xiong,et al. Rock burst risk evaluation based on dynamic-static stress analysis in complex working face[J]. Coal Science and Technology,2019,47(7):265−270.

[8] 防治煤矿冲击地压细则[S]. 北京:国家煤矿安全监察局,2018. [9] 王家臣. 我国综放开采40年及展望[J]. 煤炭学报,2023,48(1):83−99. WANG Jiachen. 40 years development and prospect of long wall top coal caving in china[J]. Journal of China Coal Society,2023,48(1):83−99.

[10] 张 强,袁崇亮,孟嘉彬,等. 窑街矿区冲击地压防治经验探索与总结[J]. 科技创新与应用,2023,13(3):157−160. ZHANG Qiang,YUAN Chongliang,MENG Jiabin,et al. Exploration and summary of experience in prevention and control of rock burst in Yaojie mining area[J]. Technology Innovation and Application,2023,13(3):157−160.

[11] 来兴平,雷照源,李 柱. 急倾斜特厚煤层综放面顶板运移特征综合分析[J]. 西安科技大学学报,2016,36(5):609−615. LAI Xingping,LEI Zhaoyuan,LI Zhu. Comprehensive analysis of roof migration characteristics of top-caving roof in extremely steep and thick coal seams[J]. Journal of Xi’an University of Science and Technology,2016,36(5):609−615.

[12] 吴锋锋,岳 鑫,刘长友,等. 急倾斜特厚煤层开采覆岩结构演化特征及支架工作阻力计算[J]. 采矿与安全工程学报,2022,39(3):499−506. WU Fengfeng ,YUE Xin ,LIU Changyou,et al. Movement law of overburden in steep inclined ultra thick seam and calculation of support working resistance [J]. Journal of Mining & Safety Engineering,2022,39(3):499−506.

[13] ZHANG G,LI Q,XU Z,et al. Roof fractures of near-vertical and extremely thick coal seams in horizontally grouped top-coal drawing method based on the theory of a thin plate[J]. Sustainability,2022,14(16):10285.

[14] 来兴平,贾 冲,崔 峰,等. 急倾斜特厚煤层开采深度影响的覆岩能量演化规律研究[J]. 岩石力学与工程学报,2023,42(2):261−274. LAI Xingping,JIA Chong,CUI Feng,et al. Study on the evolution law of overburden energy of steeply inclined extra-thick coal seam influenced by mining depth[J]. Chinese Journal of Rock Mechanics and Engineering,2023,42(2):261−274.

[15] 崔 峰,张随林,来兴平,等. 急倾斜特厚煤层矿震诱冲机制及时−空特征研究[J/OL]. 煤炭学报:1−16[2023-11-10] https://kns.cnki.net/kcms2/article/abstract?v=jd-zW4Ocutwym-piEe02OGGB6TKemU4yBEqJ-pOvUnIESauLkD-ddTlOwDCc_0790xoNGpGnr8ORPffjkE0MGUP7auMxxtArc3hieSyETRS5t5-9BeOlHU4t7siuelRN1jkOC5nldns=&uniplatform=NZKPT&language=CHS. CUI Feng,ZHANG Suilin,LAI Xingping,et al. Study on the mechanism of rock burst induced by mine earthquake and the time-space characteristics of in steep and extremely thick coal seam [J/OL]. Journal of China Coal Society:1−16[2023-11-10] https://kns.cnki.net/kcms2/article/abstract?v=jd-zW4Ocutwym-piEe02OGGB6TKemU4yBEqJ-pOvUnIESauLkD-ddTlOwDCc_0790xoNGpGnr8ORPffjkE0MGUP7auMxxtArc3hieSyETRS5t5-9BeOlHU4t7siuelRN1jkOC5nldns=&uniplatform=NZKPT&language=CHS.

[16] 屠洪盛,刘送永,黄昌文,等. 急倾斜煤层走向长壁工作面底板破坏机理及稳定控制[J]. 采矿与安全工程学报,2022,39(2):248−254. TU Hongsheng,LIU Songyong,HUANG Changwen,et al. Failure mechanism and stable control of floor in long wall mining face a long strike with steep coal seam[J]. Journal of Mining & Safety Engineering,2022,39(2):248−254.

[17] 王崧玮,曹安业,王 华,等. 急倾斜特厚煤层“错动−夹持”型冲击地压机理[J]. 采矿与安全工程学报,2022,39(4):711−719. WANG Songwei,CAO Anye,WANG Hua,et al. Mechanism of “dislocation-clamping”rock burst in steeply inclined and extra thick coal seam[J]. Journal of Mining & Safety Engineering,2022,39(4):711−719.

[18] 王德发,张颖异,解盘石,等. 急倾斜中厚煤层伪俯斜采场覆岩运移规律研究[J]. 煤炭工程,2023,55(1):76−80. WANG Defa,ZHANG Yingyi,XIE Panshi,et al. Strata movement law in pitching oblique stope of steeply inclined medium thick coal seam[J]. Coal Engineering,2023,55(1):76−80.

[19] ZHAO B,CAO J,SUN H,et al. Experimental investigations of stress-gas pressure evolution rules of coal and gas outburst:A case study in Dingji coal mine,China[J]. Energy Science & Engineering,2020,8(1):61−73.

[20] ZHAO Y,NIU X. Experimental study on work of adsorption gas expansion after coal and gas outburst excitation[J]. Frontiers in Earth Science,2022,10:886309. doi: 10.3389/feart.2022.886309

[21] SHI X,SONG D. Study of the solid-gas-stress coupling model and its application[J]. Scientific Reports,2023,13:51351.

[22] 郭德勇,揣筱升,张建国,等. 构造应力场对煤与瓦斯突出的控制作用[J]. 煤炭学报,2023,48(8):3076−3090. GUO Deyong,CHUAI Xiaosheng,ZHANG Jianguo,et al. Controlling effect of tectonic stress field on coal and gas outburst[J]. Journal of China Coal Society,2023,48(8):3076−3090.

[23] 胡千庭,周世宁,周心权. 煤与瓦斯突出过程的力学作用机理[J]. 煤炭学报,2008,33(12):1368−1372. HU Qianting,ZHOU Shining,ZHOU Xinquan,et al. Mechanical mechanism of coal and gas out burst process[J]. Journal of China Coal Society,2008,33(12):1368−1372.

[24] 张超林,蒲静轩,宋世豪,等. 煤与瓦斯突出两相流运移规律研究进展[J]. 煤炭科学技术,2023,51(8):129−139. ZHANG Chaolin,PU Jingxuan,SONG Shihao,et al. Research progress on the two-phase flow migration law of coal and gas outburst[J]. Coal Science and Technology,2023,51(8):129−139.

[25] 宋大钊,郭明功,杨 港,等. 支撑体软硬煤分层非同步变形诱发煤与瓦斯突出机理[J]. 煤炭科技,2023,44(3):1−8. SONG Dazhao,GUO Minggong,et al. Mechanism of coal and gas out burst induced by a synchronous deformation of soft and hard coal layer in the support body[J]. Coal Science & Technology Magazine,2023,44(3):1−8.

[26] 胡千庭,赵旭生. 中国煤与瓦斯突出事故现状及其预防的对策建议[J]. 矿业安全与环保,2012,39(5):1−6. HU Qianting,ZHAO Xusheng. Present situation of coal and gas outburst accidents in china's coal mines and countmeasures and suggestions for their prevention[J]. Mining Safety & Environmental Protection,2012,39(5):1−6.

[27] 潘一山. 煤与瓦斯突出、冲击地压复合动力灾害一体化研究[J]. 煤炭学报,2016,41(1):105−112. PAN Yishan. Integrated study on compound dynamic disaster of coal-gas outburst and rockburst[J]. Journal of China Coal Society,2016,41(1):105−112.

[28] 刘淑敏,李学龙. 深部开采的突出和冲击耦合致灾机理探讨[J]. 煤炭技术,2016,35(9):134−136. LIU Shumin,LI Xuelong. Discussion on coupling disaster mechanism of coal and gas outburst and rock burst in deep coal mining[J]. Coal Technology,2016,35(9):134−136.

[29] 朱丽媛,潘一山,李忠华,等. 深部矿井冲击地压、瓦斯突出复合灾害发生机理[J]. 煤炭学报,2018,43(11):3042−3050. ZHU Liyuan,PAN Yishan,LI Zhonghua,et al. Mechanisms of rockburst and outburst compound disaster in deep mine[J]. Journal of China Coal Society,2018,43(11):3042−3050.

[30] 袁瑞甫. 深部矿井冲击-突出复合动力灾害的特点及防治技术[J]. 煤炭科学技术,2013,41(8):6−10. YUAN Ruifu. Features of dynamic disasters combined rockburst and gas outburst in deep coal mine and its preventive measures[J]. Coal Science and Technology,2013,41(8):6−10.

[31] 陈国红. 沿沟煤矿煤与瓦斯突出诱发冲击地压事故分析[J]. 煤矿安全,2013,44(7):156−158. CHEN Guohong. Analysis of coal and gas outburst induced rock burst accidents in Yangou Coal Mine[J]. Safety in Coal Mines,2013,44(7):156−158.

[32] 袁崇亮,王永忠,施现院,等. 近直立特厚煤层分段综放夹持煤柱冲击机理[J]. 采矿与安全工程学报,2023,40(1):60−68. YUAN Chongliang,WANG Yongzhong,SHI Xianyuan,et al. Impact mechanism of clamped coal pillar in sublevel fully mechanized top coal caving in the near vertical extra thick coal seam[J]. Journal of Mining & Safety Engineering,2023,40(1):60−68.

[33] 何 江,窦林名,蔡 武,等. 薄煤层动静组合诱发冲击地压的机制[J]. 煤炭学报,2014,39(11):2177−2182. HE Jiang,DOU Linming,CAI Wu,et al. Mechanism of dynamic and static combined load inducing rock burst in thin coal seam[J]. Journal of China Coal Society,2014,39(11):2177−2182.

[34] 窦林名,何 江,曹安业,等. 煤矿冲击地压动静载叠加原理及其防治[J]. 煤炭学报,2015,40(7):1469−1476. DOU Linming,HE Jiang,CAO Anye,et al. Rock burst prevention methods based on theory of dynamic and static combined induced in coal mine[J]. Journal of China Coal Society,2015,40(7):1469−1476.

下载:

下载: