移动扫码阅读

移动扫码阅读

目前煤炭仍是我国的主体能源,在碳达峰、碳中和目标下,对煤炭绿色开采提出了更高的要求。我国厚煤层可采储量大,其安全、高效、绿色开采对我国煤炭能源的兜底保障作用具有重要意义。随着煤炭科学技术和煤炭开采装备的不断进步,针对厚及特厚煤层的大采高、快速推进及综放等高强度开采技术近年来飞速发展,加之深部矿井、西部特殊地质和生态条件等使得煤矿水害发生机理日趋复杂,防控难度显著增大,水害防控与水资源协同保护成为今后煤炭资源开发面临的重大科学和技术难题。而煤矿开采引起的导水裂缝带高度是水害防控和保水采煤的关键参数,对于煤矿水害防控、地表建构筑物防护、水资源保护都具有极其重要的意义。

国内各矿区应用不同的方法进行了大量针对不同覆岩和开采条件的导水裂缝带高度实测,并分析了导水裂缝带高度的发育特征,总结出了单层采厚在1~3 m,厚煤层分层开采的“两带”高度预计公式,写入到《建筑物、水体、铁路及主要井巷煤柱留设与压煤开采规范》中(以下简称《规范》)[1]。许延春等[2-3]利用华北矿区多个矿井中硬和软弱覆岩综放开采导水裂缝带高度数据,回归了综放开采经验公式。但由于厚煤层综放开采或者一次采全高导水裂缝带实测成果相对较少,且不同地质条件下高强度开采导水裂缝带发育高度存在较大的差异性,预计公式在实际应用中还不具有普适性。郭文兵等[3]从厚煤层(大采高)、推进速度快、工作面尺寸大等角度给出了高强度开采的定义;文献[4-6]针对黄陇区域深埋特厚煤层综放开采覆岩导水裂缝带的发育高度开展了一系列的现场实测和理论研究,基于实测数据得出了白垩纪特厚煤层综放开采导水裂缝带高度与采高的关系;文献[7-9]采用钻孔冲洗液、分布式光纤和并行电法等手段实测了软弱覆岩地层大采高工作面覆岩破坏高度,得出了上海庙、新疆矿区软弱覆岩厚煤层综放开采工作面的垮采比和裂采比;李江华等[10]采用钻孔冲洗液消耗量和钻孔电视观测相结合的方法,测得了坚硬和软弱地层高强度开采条件下覆岩破坏裂隙发育特征,得出坚硬顶板高强度开采综合垮采比为9.39~9.62,裂采比大于17.80,约为软弱覆岩的2倍。近年来,随着陕北矿区浅埋特厚煤层的大规模开采,文献[11]研究了榆神府矿区不同隔水岩组厚度与采高比条件下的采动顶板垮落和导水裂缝带发育高度。张玉军[1]从水体下采煤视角,总结了采动覆岩破坏规律和控制技术的发展现状,重点划分了浅埋薄基岩高强度开采导水裂缝带异常发育特征模式。曹祖宝等[12]研究了4 种典型覆岩结构对导水裂缝带发育高度的影响特征;王振荣等[13]针对布尔台煤矿多煤层重复采动条件,实测了导水裂缝带高度。

虽然以上研究针对厚及特厚煤层各矿区进行了导水裂缝带高度实测,但是获得的数据还相对比较零散,大多是针对局部煤矿或矿区的测试与研究成果,缺乏全国范围的高强度开采导水裂缝带分布特征与规律的深入总结研究。为解决这一突出问题,以《建筑物及水体、铁路及主要井巷煤柱留设与压煤开采指南》及笔者单位近年的实测数据以及查阅文献获取的数据为基础,分析了我国厚及特厚煤层高强度开采导水裂缝带发育高度区域分布规律和影响因素,并以此数据为基础回归了导水裂缝带高度预计公式。

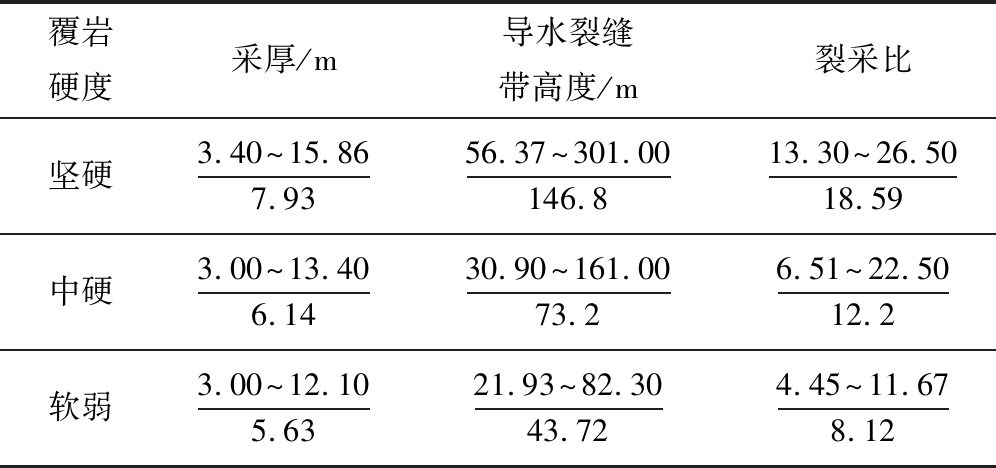

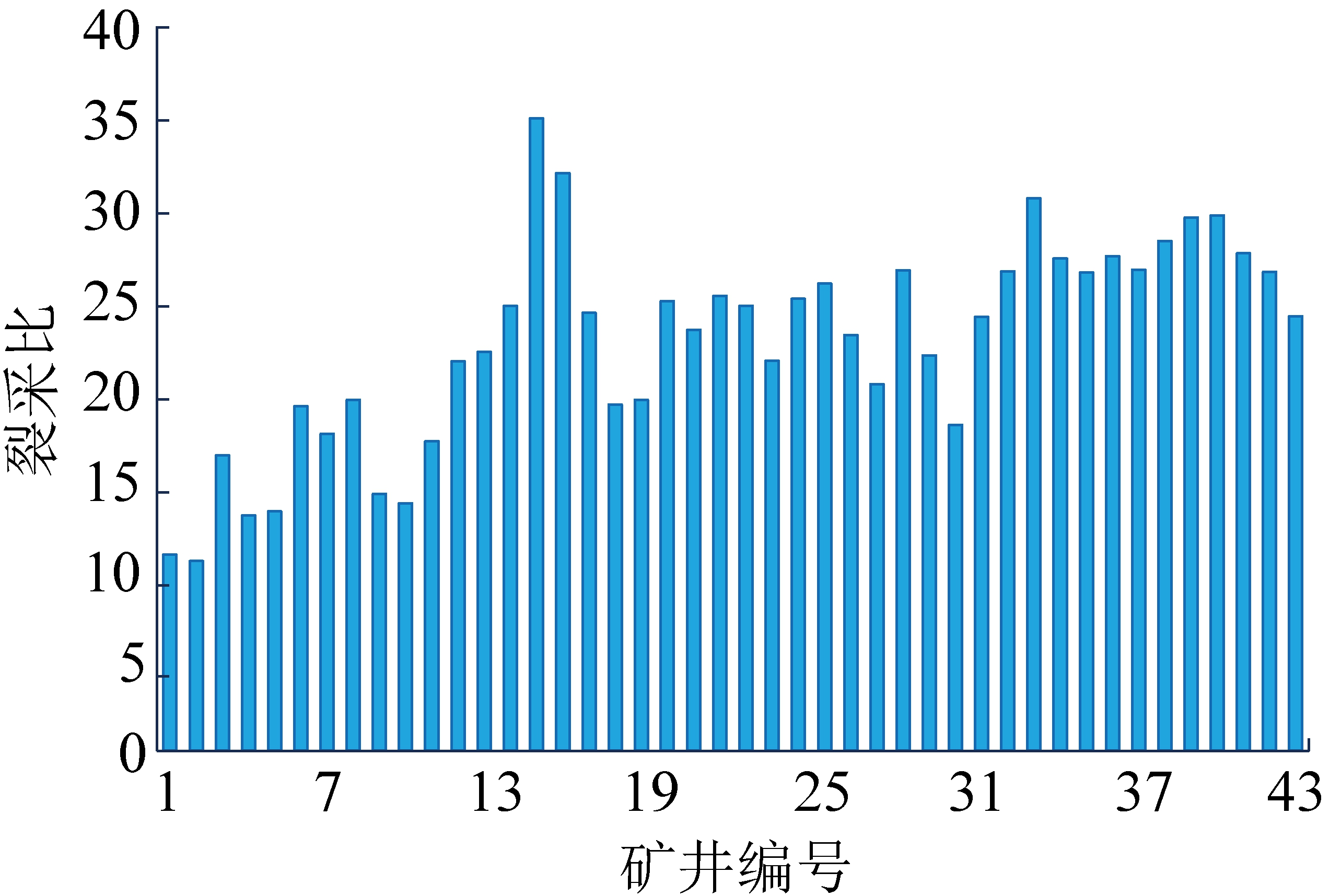

系统收集整理了179组国内近年来厚及特厚煤层综放和一次采全高条件下导水裂缝带高度的实测数据,坚硬、中硬和软弱覆岩类型数据分别为51组、100组和28组。数据主要来源于《建筑物、水体、铁路及主要井巷煤柱留设与压煤开采指南》以及查阅文献获取的数据等。通过对实测数据的统计、归类,最终以我国14个大型煤炭基地为区域,分别列出了各大基地煤矿区不同覆岩类型条件下的导水裂缝带高度和裂采比(导水裂缝带高度与采厚的比值)的范围以及平均值(图1和表1)。

图1 我国厚及特厚煤层高强度开采导水裂缝带发育高度分布

Fig.1 Height distribution of water diversion fracture zone in high strength mining of thick and extra thick coal seams in China

表1 我国煤炭基地高强度开采导水裂缝带高度实测值(部分基地和矿井)

Table 1 Measured value of high-intensity coal base in China (part base and mines)

基地矿井覆岩硬度采厚/m导水裂缝/带高度m裂采比基地矿井覆岩硬度采厚/m导水裂缝/带高度m裂采比蒙东基地黄陇基地两淮基地河南基地宁东基地铁北矿灵东矿峻德矿兴安矿兴安矿新陆矿益新矿峻德矿兴安矿益新矿富力矿崔木矿崔木矿崔木矿亭南矿亭南矿亭南矿亭南矿蒋家河下沟矿下沟矿大佛寺大佛寺胡家河高家堡顾北潘一矿张集矿张集矿谢桥矿潘三矿张集矿龙固矿新集矿新集矿超化矿超化矿枣泉矿石嘴山软弱软弱中硬中硬中硬中硬中硬中硬中硬中硬中硬中硬中硬中硬坚硬坚硬坚硬坚硬坚硬坚硬坚硬坚硬坚硬坚硬坚硬中硬中硬中硬中硬中硬中硬中硬软弱中硬中硬坚硬坚硬软弱中硬3.2029.009.1011.6062.005.6012.00190.3515.867.60139.8018.398.50153.8518.1011.50232.7220.2010.00174.0017.4011.00186.0016.908.60162.8018.905.5076.0013.803.7536.709.8012.00239.4219.956.50192.2129.578.40170.7520.338.30164.1619.787.5096.5012.879.90165.8016.756.00136.2022.707.4082.2611.129.90125.8112.718.90149.4816.8011.00296.7826.9812.55189.1015.0713.50225.4016.706.00120.0020.003.5024.096.883.4032.839.663.8030.007.896.0041.006.835.0073.2814.663.4040.1611.813.8049.0512.9112.1082.306.805.7560.7010.567.7683.9010.818.50148.2017.449.00159.4917.728.0062.007.755.9073.5012.46神东基地鲁西基地晋东基地冀中基地红柳林中硬6.5070.5010.85大柳塔中硬7.20117.5016.32活鸡兔中硬3.7048.0913.00锦界中硬3.3043.6413.22隆德中硬3.9676.8519.41王家塔中硬5.0071.0014.20纳二矿中硬5.30116.922.06麻黄梁中硬9.06223.0024.61补连塔中硬4.40153.9534.99榆阳中硬3.5084.8024.23韩家湾中硬4.43110.1124.86榆树湾中硬5.50138.3025.15杭来湾中硬4.50116.2025.82金鸡滩中硬5.50146.1826.58薛庙滩中硬6.30167.0026.51柠条塔中硬5.46149.2827.34张家峁中硬5.60165.9029.63布尔台中硬3.0079.4026.47鲍店矿中硬8.7597.6011.15南屯矿中硬5.8070.7012.19兴隆庄中硬8.2070.308.57济宁三中硬6.8080.2011.79东滩中硬8.7078.809.06白庄矿中硬4.9063.6012.98唐阳中硬4.4065.0014.77新巨龙中硬8.6094.7011.01付村中硬5.4061.5011.39许厂中硬5.1051.3010.06唐口中硬4.1050.9012.41华丰中硬6.5075.6011.63粱家软弱4.1038.809.46郭庄矿坚硬6.50103.0015.85王庄矿坚硬5.70114.8720.15高河矿坚硬6.00114.2019.03王坡矿坚硬5.80104.9018.09东峰矿坚硬5.89105.4017.89唐山矿中硬10.00161.0016.10东欢坨中硬3.7056.8015.35钱家营中硬3.0040.0013.33

从区域上划分,蒙东基地的鹤岗矿区覆岩类型以坚硬为主,裂采比为15.43~22.93,平均18.51;蒙东基地(辽宁矿区)中硬覆岩类型裂采比为9.46~11.23,平均10.23;蒙东基地(扎赉诺尔、敏东、大雁等矿区)软弱覆岩类型裂采比为5.6~11.67,平均9.25。神东基地覆岩类型以中硬为主,基岩厚度足够大的情况下裂采比为9.03~22.06,平均15.52;对于局部埋深浅基岩薄的区域,裂采比集中在19~28,最大达到35。新疆基地覆岩类型以中硬偏软弱为主,裂采比为11.38~13.59,平均为12.24。宁东基地坚硬覆岩类型裂采比为23.05,中硬覆岩类型为12.46,软弱覆岩类型为7.75。陕北基地覆岩类型以中硬为主,裂采比为10.47~19.41,平均14.98。黄陇基地坚硬覆岩类型裂采比为13.33~23.33,平均为18.58,中硬覆岩类型为9.95~13.67,平均为11.76。晋北基地覆岩类型以软弱为主,裂采比为5.91~7.82,平均6.87。晋东基地覆岩类型以坚硬为主,裂采比为15.85~20.15,平均17.94。冀中基地中硬覆岩类型裂采比为11.08~16.1,平均13.97,软弱覆岩类型裂采比为4.45~8.25,平均6.35。鲁西基地中硬覆岩类型裂采比为7.52~14.77,平均10.61,软弱覆岩类型裂采比为6.8~9.69,平均8.67。河南基地中硬覆岩类型裂采比平均17.58,软弱覆岩类型裂采比平均8.29。两淮基地坚硬覆岩类型裂采比为15.74~20.8,平均17.67,中硬覆岩类型裂采比为8.85~14.66,平均为11.45,软弱覆岩类型裂采比为6.83~10.1,平均8.08。

总体来看,目前现有的实测数据基本涵盖了我国的主要产煤基地,能够为全国各大矿区的安全生产提供一定的依据。

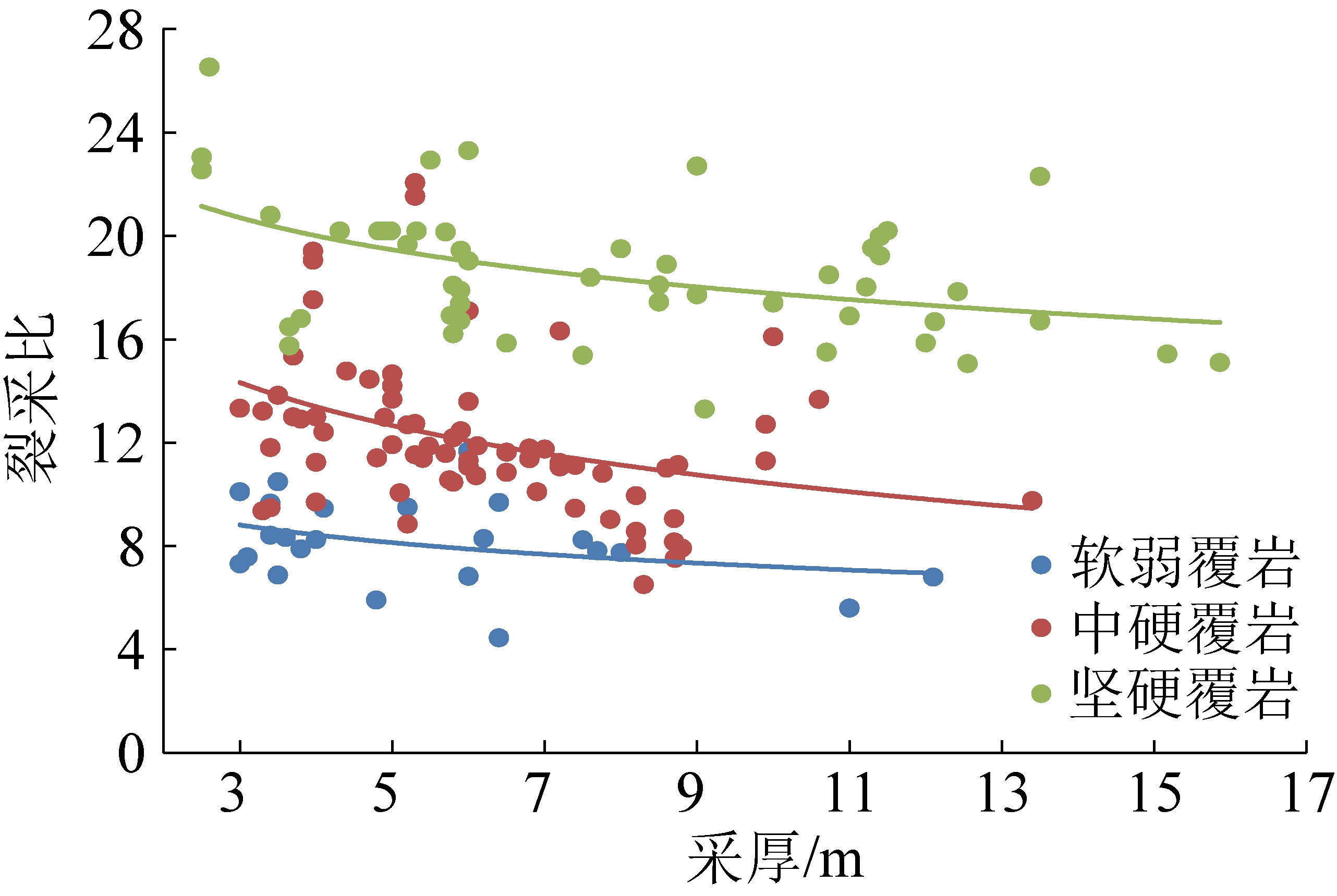

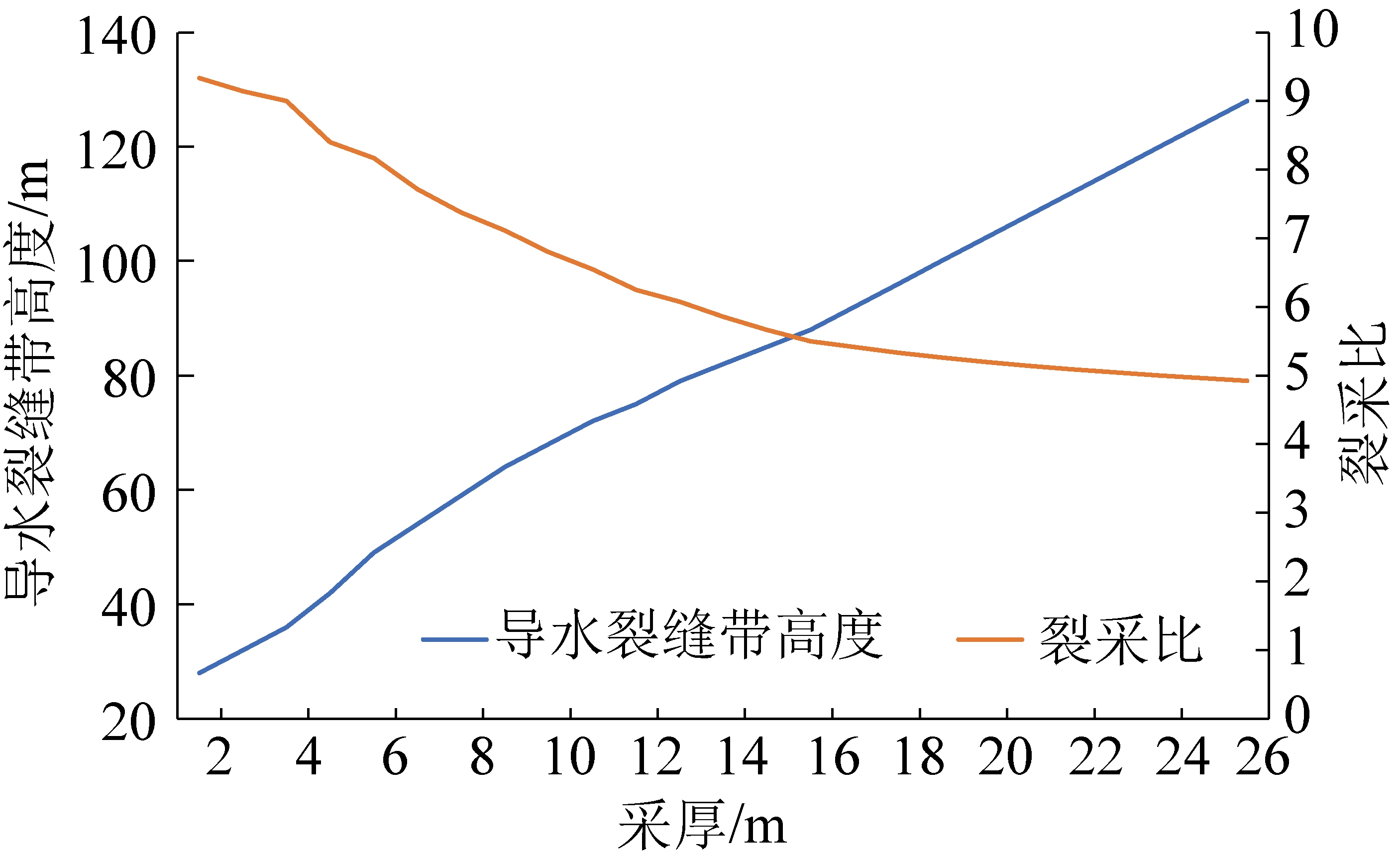

依据实测数据统计发现,不同覆岩条件下厚及特厚煤层高强度开采的导水裂缝带高度分布规律有较大差异,见表2和图2。通过对比分析可知,实测平均裂采比随着覆岩由坚硬、中硬到软弱依次降低,坚硬覆岩条件下的平均裂采比值是中硬覆岩的1.52倍,是软弱覆岩的2.29倍,而中硬覆岩平均裂采比值则是软弱覆岩的1.5倍。

表2 不同覆岩类型导水裂缝带高度与裂采比

Table 2 Different overburden types of water-flowing fracture zone height and fracture-mining ratio

覆岩硬度采厚/m导水裂缝带高度/m裂采比坚硬3.40~15.867.9356.37~301.00146.813.30~26.5018.59中硬3.00~13.406.1430.90~161.0073.26.51~22.5012.2软弱3.00~12.105.6321.93~82.3043.724.45~11.678.12

注:数据格式为(最小值~最大值)/平均值。

图2 不同覆岩导水裂缝带高度和裂采比

Fig.2 Water-flowing fracture zone height and fracture-mining ratio of different overlying racks

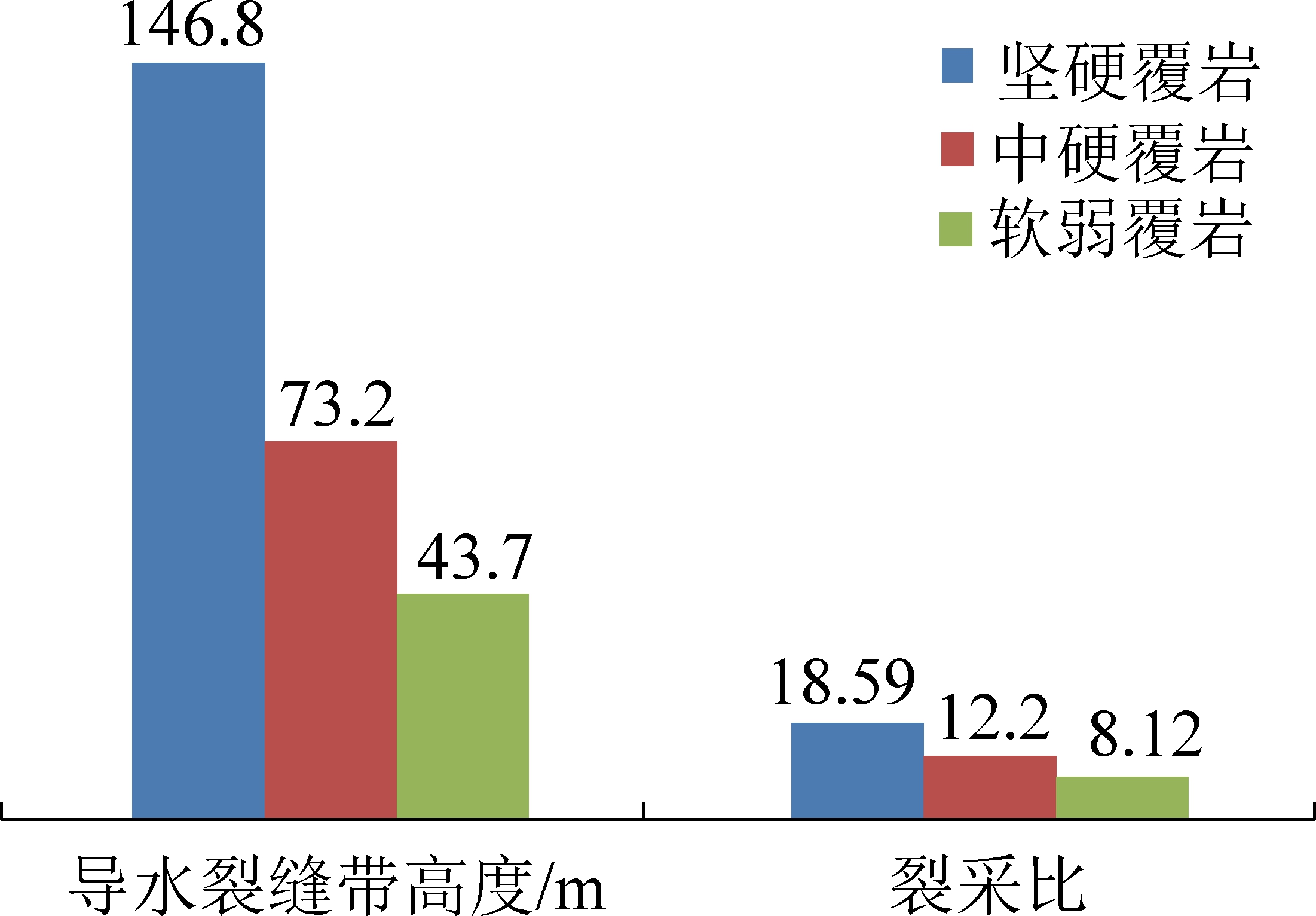

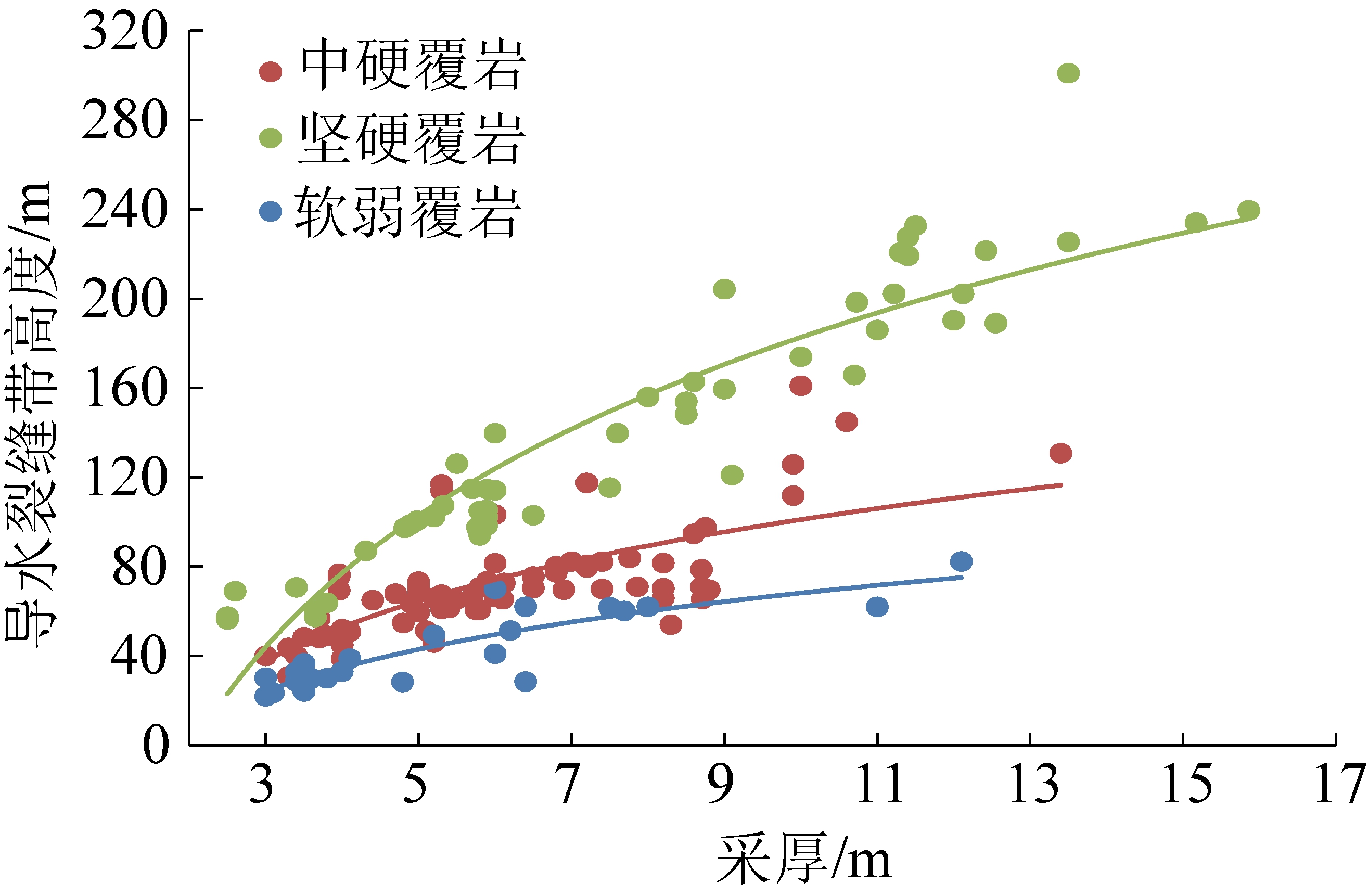

依据实测数据绘制了不同覆岩类型条件下导水裂缝带高度以及裂采比分别与采厚的关系图,如图3和图4所示。从图3中可以看出,坚硬、中硬和软弱覆岩条件下的导水裂缝带高度整体上均随着采厚的增加而呈现逐步增大的趋势,尤其是采厚达到6 m时,增加的速率明显加快,且坚硬覆岩条件下增加的速率明显要高于中硬和软弱覆岩。由图4可知,坚硬覆岩的裂采比明显高于中硬和软弱覆岩,但裂采比均随着采厚的增加而呈现逐渐降低的趋势,且减小速率随着采厚达到一定厚度后有趋于稳定的趋势。

图3 不同覆岩类型导水裂缝带高度与采厚关系

Fig.3 Relationship between coal seam thickness and water-conducting crack zone height

图4 不同覆岩类型裂采比与采厚关系

Fig.4 Relationship between fracture-mining ratio and mining thickness of different ovelying rock types

14个大型煤炭基地生产能力达到全国的95%以上,其中神东、陕北、黄陇、蒙东等矿区煤炭赋存主要以厚及特厚煤层为主。因此,重点分析以下3个典型矿区的覆岩破坏特征。

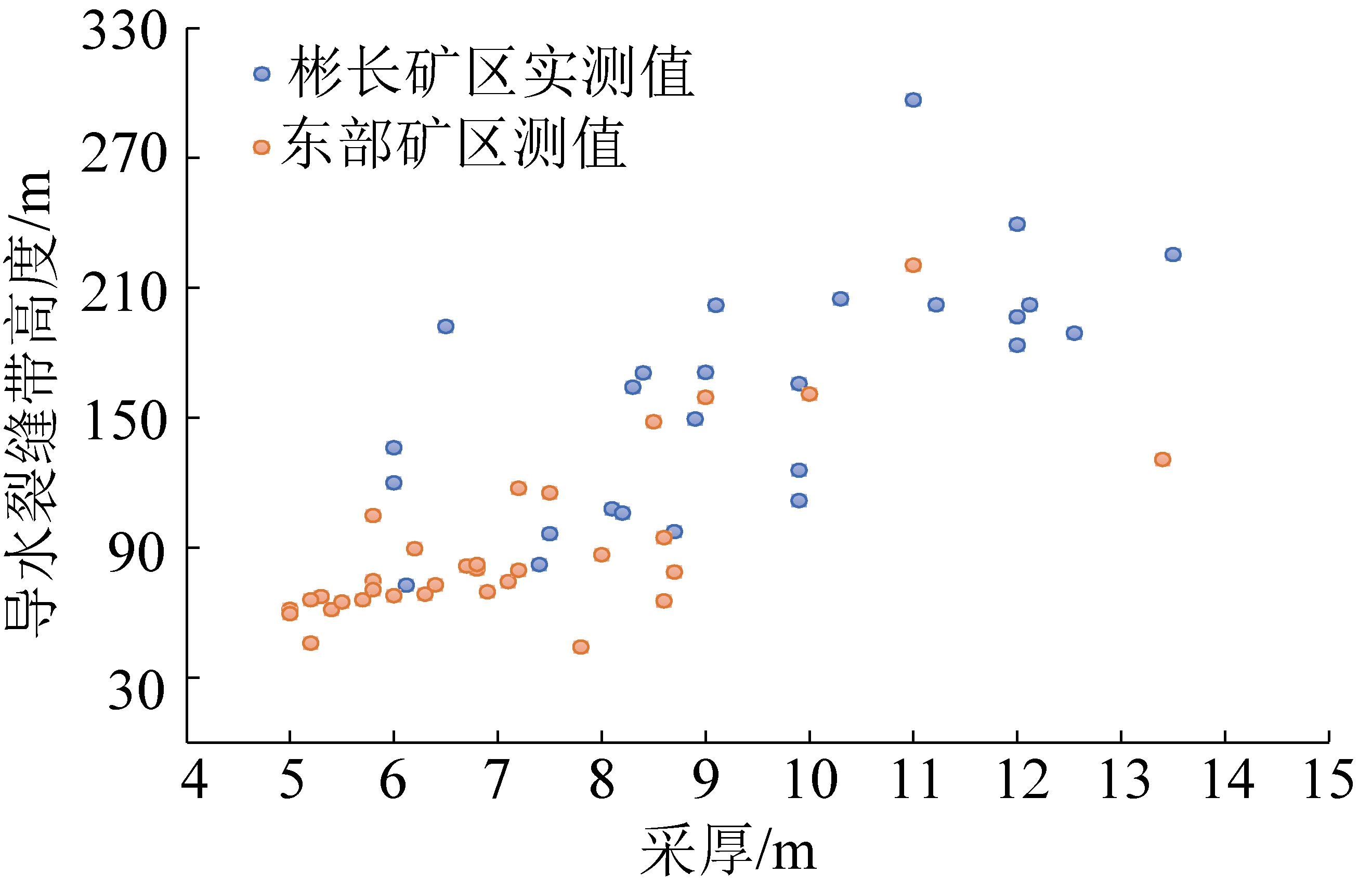

黄陇煤炭基地包括彬长(含永陇)、黄陵、旬耀、蒲白、澄合、韩城、华亭矿区。其中彬长矿区是我国新兴的西部煤炭生产基地,地处鄂尔多斯盆地南缘,主采煤层为侏罗系延安组含煤地层,厚度大,是我国大规模的综放式开采矿区,覆岩类型为中硬。从实测数据中整理了彬长矿区7个煤矿25组数据,同时选取全国东部矿区同类覆岩(采厚大于5 m)24个煤矿33组数据进行统计对比分析,得出该矿区导水裂缝带发育高度具有以下3个方面特征:

1)导水裂缝带发育高度、裂采比与采厚、工作面长度的关系,总体上具有一定的规律性,随着煤层采厚的增加,导水裂缝带发育高度随之增加,但增加趋势逐步减缓;随着采厚的增加,裂采比则呈降低趋势(图5、图6)。

图5 彬长及东部矿区导水裂缝带高度与采厚关系

Fig.5 Relationship between height of water-flowing fracture zone and mining thickness in Binchang and eastern mining area of China

图6 彬长矿区导水裂缝带高度、裂采比与工作面长度关系

Fig.6 Relationship between height of water-flowing fractured zone,fracture-mining ratio and working face length in Binchang Mining Area

2)中硬覆岩条件下,国内东部矿区在采厚5.0~13.4 m,平均7.1 m的条件下实测平均裂采比12.4,而彬长矿区在采厚6.0~13.5 m,平均9.4 m的条件下实测平均裂采比为17.3,同类覆岩条件下采厚相同,导水裂缝带高度和裂采比明显高于东部矿区,其原因在于彬长矿区的开采强度(工作面尺寸、推进速度)明显高于东部矿区。

3)从图6可以看到,工作面长度以170 m为分界点,成为影响彬长矿区导水裂缝带高度发育的主要影响因素。工作面长度大于170 m时导水裂缝带发育高度受工作面长度影响较大,其高度及裂采比随着工作面长度增加,呈明显增高增大趋势,且增加速率加快。

蒙东(东北)基地主要包括内蒙古东部的呼伦贝尔市、伊敏、通辽、赤峰平庄、兴安盟和锡林郭勒盟,同时也包括辽宁阜新、铁法矿区,以及黑龙江鸡西、鹤岗、双鸭山等矿区。覆岩分为内蒙古东部的软弱-极软弱类型和鹤岗矿区的中硬-坚硬类型。

2.2.1 蒙东基地极软弱覆岩矿区

扎赉诺尔矿区顶板岩石单向抗压强度多小于20 MPa,且固结性差,属于极软弱类覆岩。对于该类覆岩条件,由于采动裂缝被压实和闭合的时间很短,且软弱覆岩对导水裂缝具有很好的抑制作用,因此很难实测获得其最大高度,因此收集到的实测数据主要是基于现场开采实践并根据采动影响范围内含水层的水位变化而确定的,如该矿区的铁北煤矿在采厚3.2 m时推断导水裂缝带高度约29 m,裂采比约为9.1;灵东矿在采厚不超过11.60 m时,第三含水层距煤层超过62 m的情况下,导水裂缝带没有直接波及含水层,推断裂采比小于5.6;灵东煤矿采厚按照2.5~16.0 m、导水裂缝带高度与采厚的比值约为5~10进行预计,矿井涌水量无明显增加,实现了首采工作面含水层下的安全回采[14-15]。由此,提出采用趋势分析方法来预计极软弱覆岩条件下的导水裂缝带发育高度,图7为绘制的趋势图,由图7可知,该类覆岩条件下裂采比明显小于国内软弱覆岩条件下的裂采比,最小裂采比仅为5,采厚达到16 m时仅为全国软弱覆岩平均裂采比的68%。

图7 极软弱覆岩条件下的导水裂缝带发育高度及趋势

Fig.7 Development height and trend of water-flowing fracture zone under extremely weak overburden

2.2.2 蒙东基地鹤岗矿区坚硬覆岩

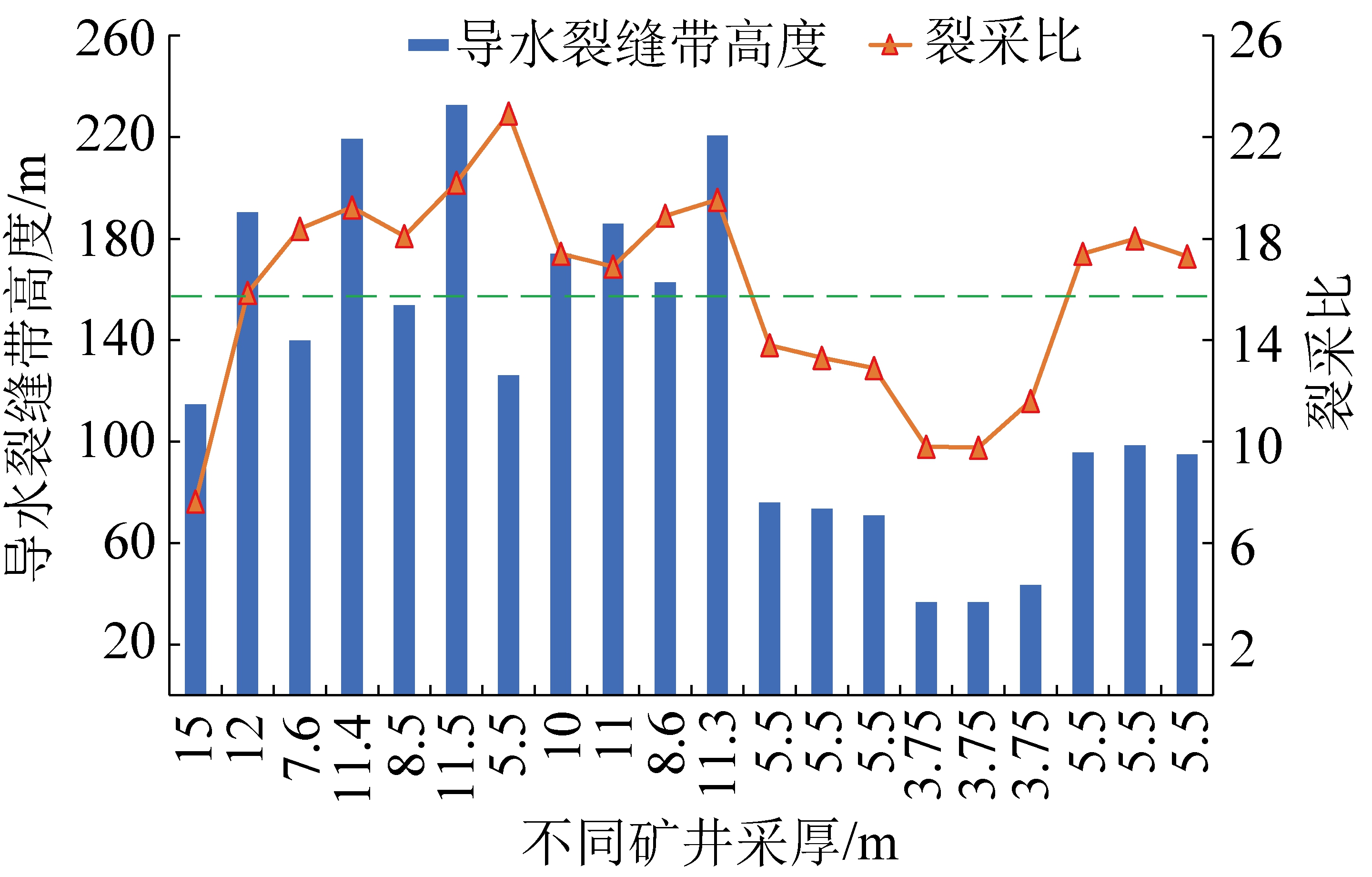

鹤岗矿区煤层覆岩平均抗压强度为58.3~89.8 MPa,属于中硬-坚硬覆岩类型,整个矿区开采具有断层发育、开采煤层多、累计开采厚度大、地层受反复扰动等特征。收集整理了该矿区8个煤矿不同条件下的导水裂缝带高度实测数据,见表1和图8。由实测数据分析可知,在采厚为3.5~12.0 m,裂采比绝大多数介于16~23,但是受断层影响相同采厚条件下导水裂缝带发育高度差异较大。无断层存在的条件下平均裂采比为15.26,断层存在条件下平均裂采比为17.69,断层构造条件下综放开采覆岩破坏高度增大了16%。

图8 鹤岗矿区导水裂缝带高度及裂采比分布

Fig.8 Height and ratio distribution of water-flowing fracture zone in Hegang Mining Area

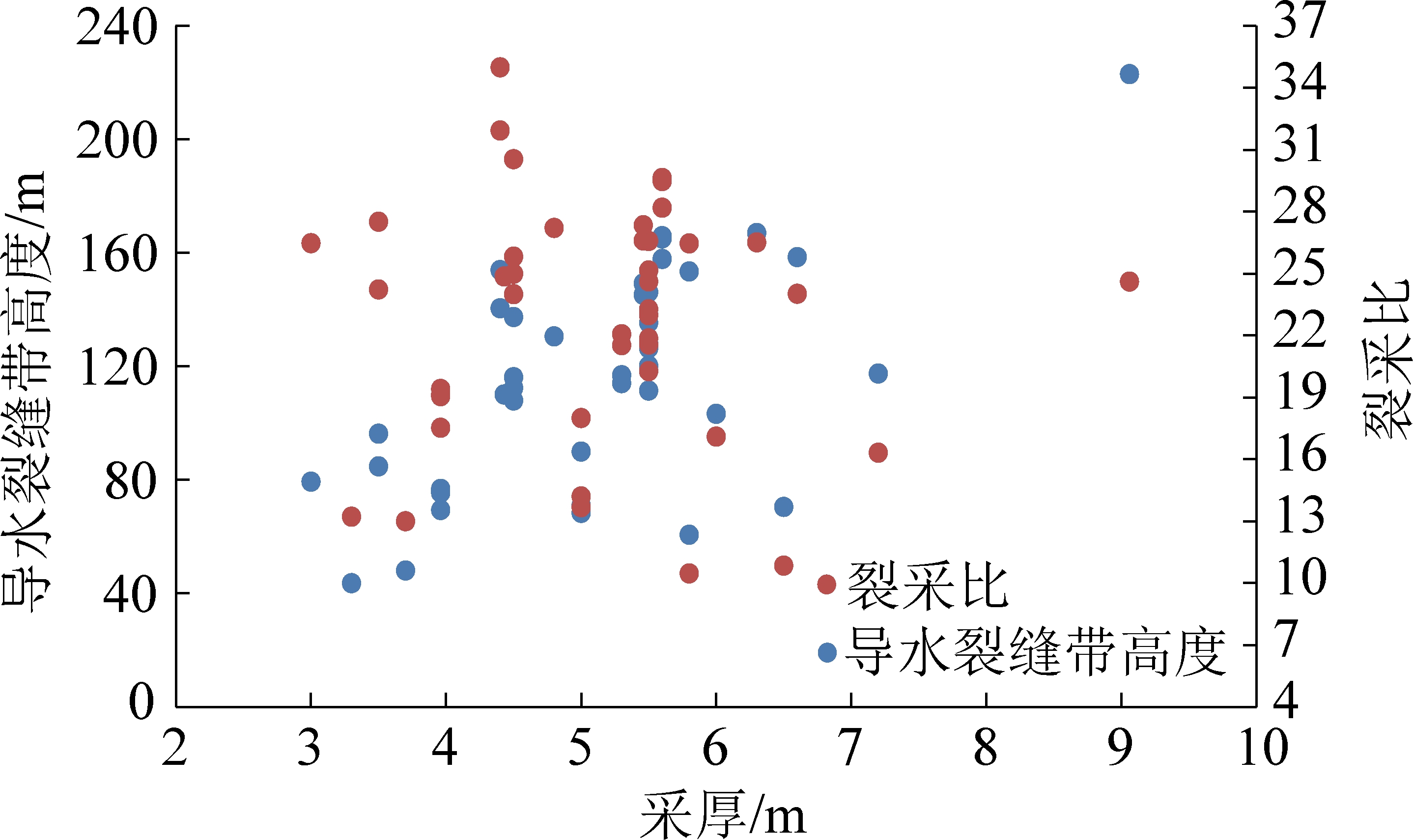

神东基地位于陕西以北榆林地区、内蒙古东部东胜地区,以神府煤田、东胜煤田为主。该矿区具有“埋深浅、基岩薄、土层厚”高强度开采的特点,因而大部分矿井仅存在 “两带”,无弯曲下沉带,甚至常发生切冒、抽冒、台阶下沉等非均衡性覆岩破坏形式。受以上条件因素的影响,实测获得的导水裂缝带高度差异性极大(图9、图10),在采厚3.00~9.06 m,中硬覆岩条件下导水裂缝带高度实测值整体离散性较大,不具有规律性。在采厚3~6 m时,裂采比集中在19~28,最大达到35,明显高于全国尤其是东部矿区中硬覆岩条件的裂采比。但是部分矿井由于厚土层的存在,尤其是厚层红土层对导水裂缝带发育具有明显抑制作用,实测裂采比7.16~7.78,较类似软弱覆岩条件下开采裂采比仍降低了15%~53%。因此,该矿区导水裂缝带高度特征有以下3个方面:

图9 神东矿区实测导水裂缝带高度、裂采比与采厚关系

Fig.9 Relationship between measured water-flowing fractured zone height,fracture-mining ratio and mining thickness in Shendong Mining Area

图10 神东矿区实测裂采比柱状

Fig.10 Column chart of measured fracture-mining ratio in Shendong Mining Area

1)基岩厚度足够大,“两带”发育完整、充分,其中的导水裂缝带和垮落带高度、分布形态和破坏程度均发育正常,但是由于采深较小,受基岩风化带和土层的影响导水裂缝带高度将随着采深的减小而降低[16-17]。

2)基岩厚度足够小且开采高度较大时,覆岩(土)层被垂直裂缝完全贯穿,导水裂缝带甚至直接发育至地表,此时实测获得的裂采比通常较大,接近甚至超过坚硬覆岩条件下实测获得的裂采比。

3)基岩厚度较小时,但存在较厚的隔水性较好的土层,导水裂缝带高度将受到黏性土层的抑制,“两带”高度会大幅度降低,接近软弱覆岩条件实测获得的裂采比。

从上述各个典型矿区及全国导水裂缝带实测数据发育趋势来看,总体具有一定的规律性,但也同时发现不仅在同一矿区即使同一矿井实测值有时差别较大,分析其原因主要有以下5个方面:

1)地层及覆岩结构的差异性影响。同一矿区甚至是同一矿井覆岩结构存在着差异,比如神东矿区实测导水裂缝带高度受地层结构、埋深等因素影响显著。

2)导水裂缝带高度实测方法确定标准存在差异性。目前,导水裂缝带高度实测的主要方法有地面钻孔冲洗液漏失量、井下仰上钻孔注水试验、钻孔电视、物探、微震以及现场水位观测等。各方法确定裂缝带顶点的标准不同,导致实测结果存在较大的差异。据初步统计,以上收集的实测数据中采用传统的钻孔冲洗液漏失量观测方法占到了65%以上,该方法钻孔从地面施工,自上而下从完整岩层逐步过渡到采动影响的破碎岩层寻找冲洗液漏失量的突变值,依据裂隙的导水性确定裂缝顶点,容易把握,取得的数据可靠且真实。

3)实测位置的差异性。对于地面钻孔观测方法而言,钻孔位置设计决定了导水裂缝带高度实测值是否为最大值。

4)实测时间的差异性。实测时间视地层与工作面推进情况而定,一般滞后于工作面对应位置回采后1~2个月可获得导水裂缝带最大高度。

5)综放开采放煤厚度的不均匀性影响。对于综放开采,放煤高度是否均匀决定了采厚的波动,从而会导致导水裂缝带高度的变化,甚至会出现台阶状分布规律。

根据收集的实测数据对导水裂缝带高度与采厚的关系分别按照线性和分式函数形式进行拟合,并求得公式的中误差。其中分式函数拟合过程如下:将原始实测数据按照式(1)做相对应的变换,规范经验公式形式为

(1)

式中:H为导水裂隙带高度;M为采厚;a和b为系数;±m为中误差,利用贝塞尔公式![]() 求得(n为测量次数;V为剩余误差),将经验公式变换为:

求得(n为测量次数;V为剩余误差),将经验公式变换为:

(2)

令![]() 则式(2)变为

则式(2)变为

(3)

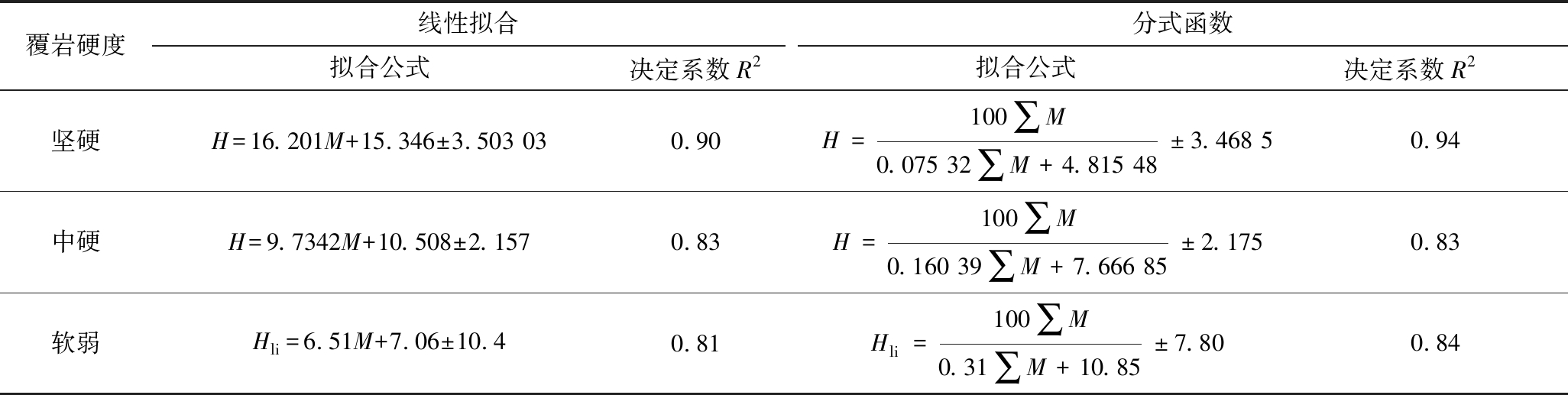

得到3种覆岩条件导水裂缝带高度预计公式,见表3。由表3可知,无论是线性拟合还是分式函数拟合,导水裂缝带高度均符合线性和分式函数增长规律,尤其是坚硬覆岩拟合决定系数R2达到0.90~0.94,其次为中硬和软弱覆岩,R2也分别达到了0.81~0.84。

表3 厚及特厚煤层高强度开采导水裂缝带预计公式

Table 3 Prediction formula of water-flowing fractured zone in high strength mining of thick and extra thick coal seam

覆岩硬度线性拟合拟合公式决定系数R2分式函数拟合公式决定系数R2坚硬H=16.201M+15.346±3.503 030.90H=100∑M0.075 32∑M+4.815 48±3.468 50.94中硬H=9.7342M+10.508±2.1570.83H=100∑M0.160 39∑M+7.666 85±2.1750.83软弱Hli=6.51M+7.06±10.40.81Hli=100∑M0.31∑M+10.85±7.800.84

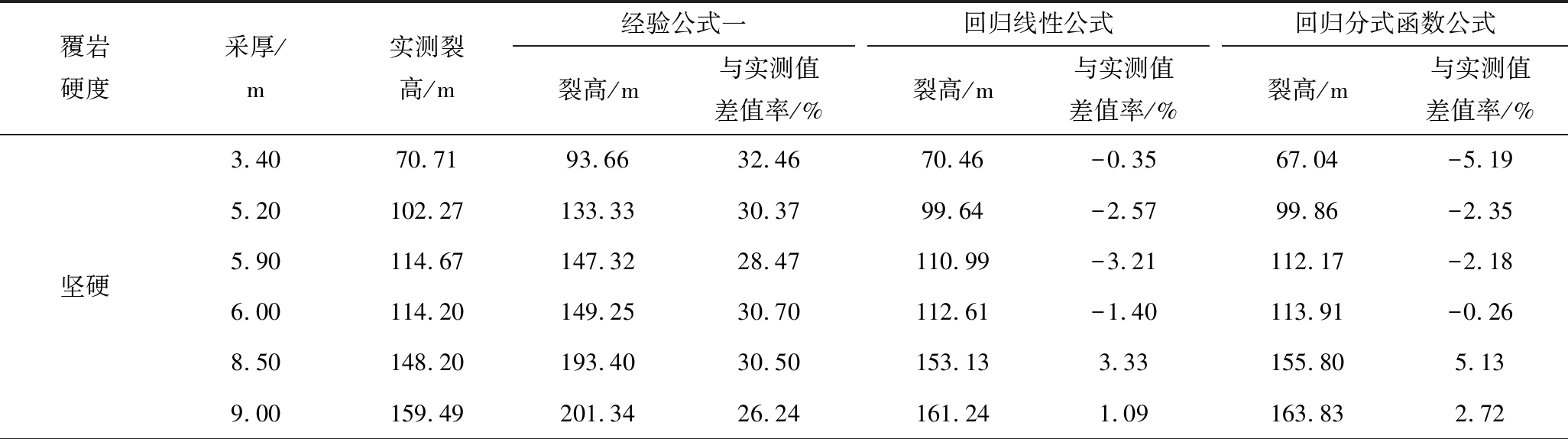

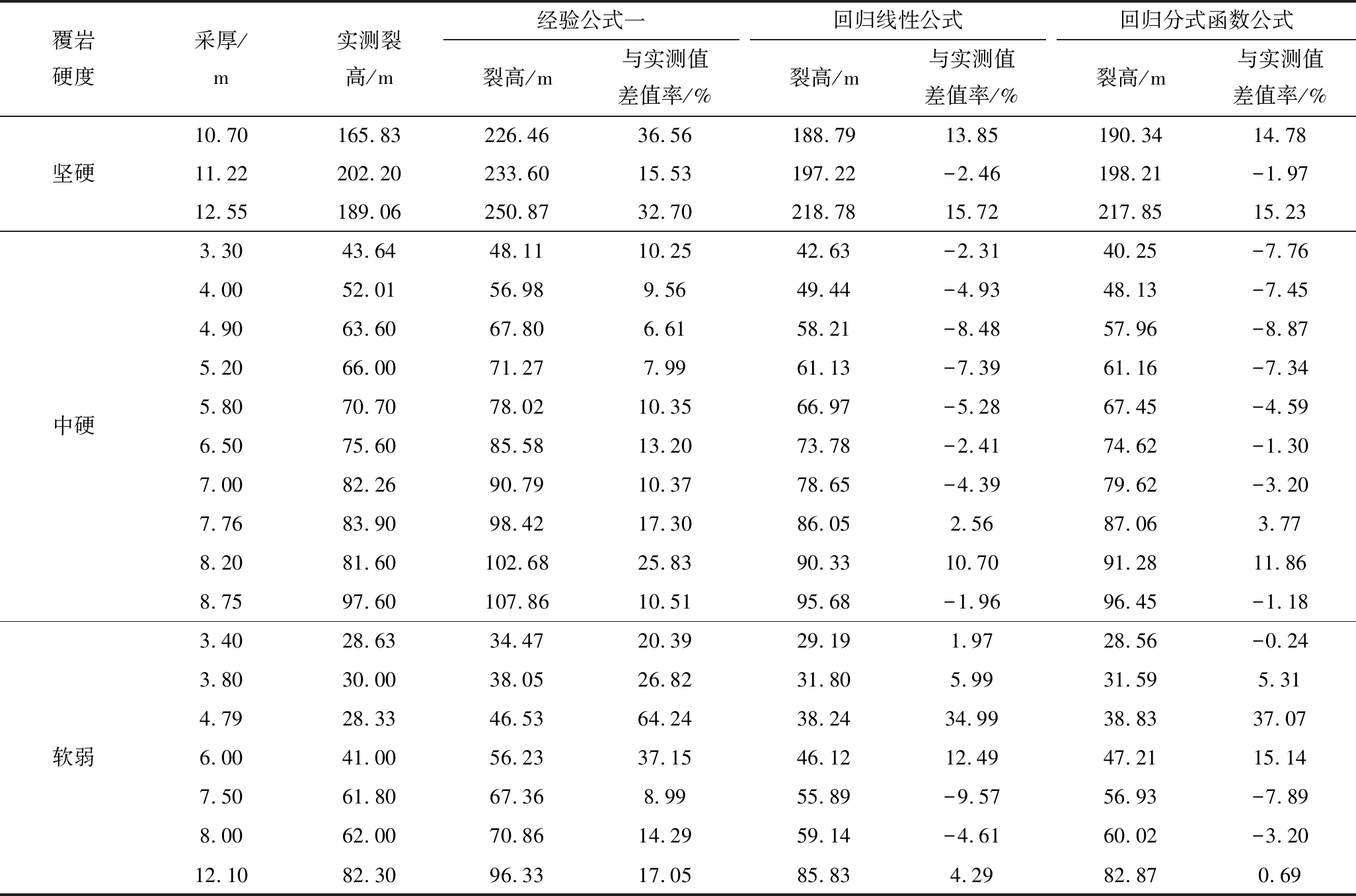

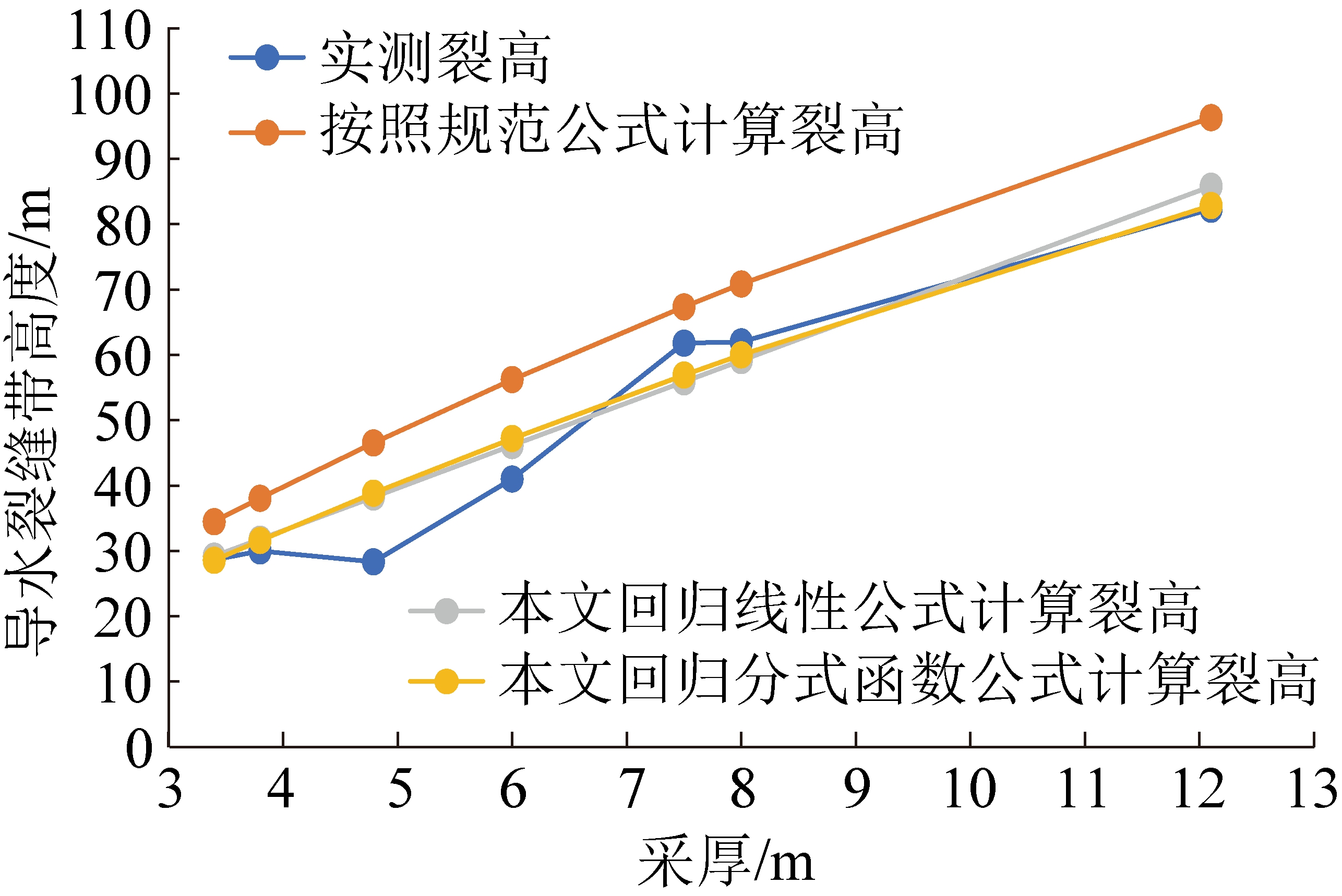

现将回归得到的线性和分式函数预计公式、以及《建筑物、水体、铁路及主要井巷煤柱留设与压煤开采指南》(简称《指南》)中的经验公式一[18]计算结果与不同采厚和覆岩条件下的实测值进行对比,见表4。

表4 不同覆岩导水裂缝带计算结果(部分)

Table 4 Calculation results of different overburden water-flowing fractured zone (part)

覆岩硬度采厚/m实测裂高/m经验公式一裂高/m与实测值差值率/%回归线性公式裂高/m与实测值差值率/%回归分式函数公式裂高/m与实测值差值率/%坚硬3.4070.7193.6632.4670.46-0.3567.04-5.195.20102.27133.3330.3799.64-2.5799.86-2.355.90114.67147.3228.47110.99-3.21112.17-2.186.00114.20149.2530.70112.61-1.40113.91-0.268.50148.20193.4030.50153.133.33155.805.139.00159.49201.3426.24161.241.09163.832.72

续表

覆岩硬度采厚/m实测裂高/m经验公式一裂高/m与实测值差值率/%回归线性公式裂高/m与实测值差值率/%回归分式函数公式裂高/m与实测值差值率/%坚硬10.70165.83226.4636.56188.7913.85190.3414.7811.22202.20233.6015.53197.22-2.46198.21-1.9712.55189.06250.8732.70218.7815.72217.8515.23中硬3.3043.6448.1110.2542.63-2.3140.25-7.764.0052.0156.989.5649.44-4.9348.13-7.454.9063.6067.806.6158.21-8.4857.96-8.875.2066.0071.277.9961.13-7.3961.16-7.345.8070.7078.0210.3566.97-5.2867.45-4.596.5075.6085.5813.2073.78-2.4174.62-1.307.0082.2690.7910.3778.65-4.3979.62-3.207.7683.9098.4217.3086.052.5687.063.778.2081.60102.6825.8390.3310.7091.2811.868.7597.60107.8610.5195.68-1.9696.45-1.18软弱3.4028.6334.4720.3929.191.9728.56-0.243.8030.0038.0526.8231.805.9931.595.314.7928.3346.5364.2438.2434.9938.8337.076.0041.0056.2337.1546.1212.4947.2115.147.5061.8067.368.9955.89-9.5756.93-7.898.0062.0070.8614.2959.14-4.6160.02-3.2012.1082.3096.3317.0585.834.2982.870.69

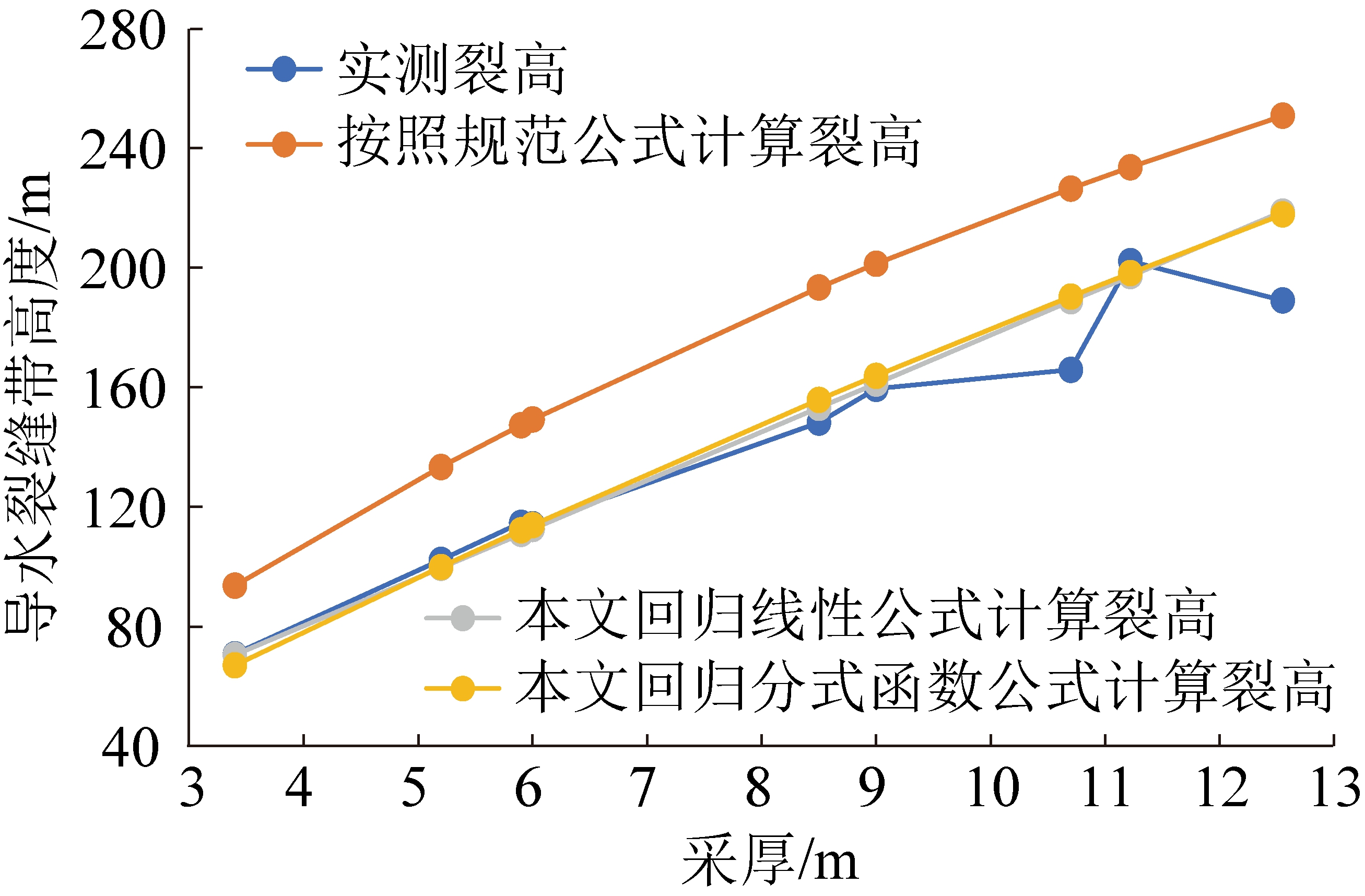

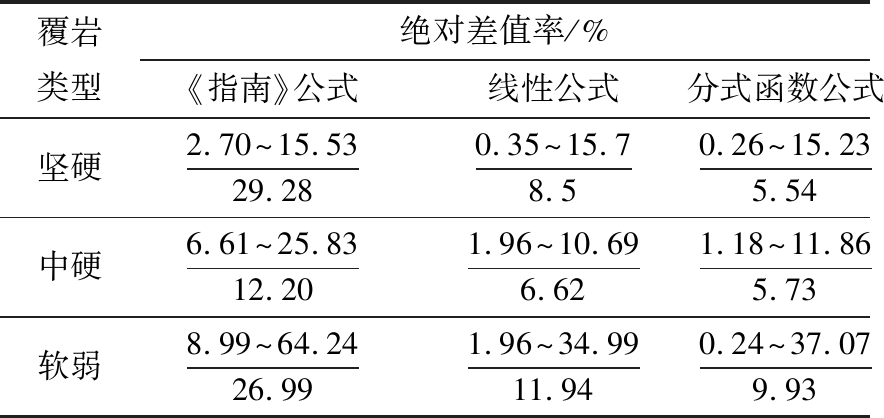

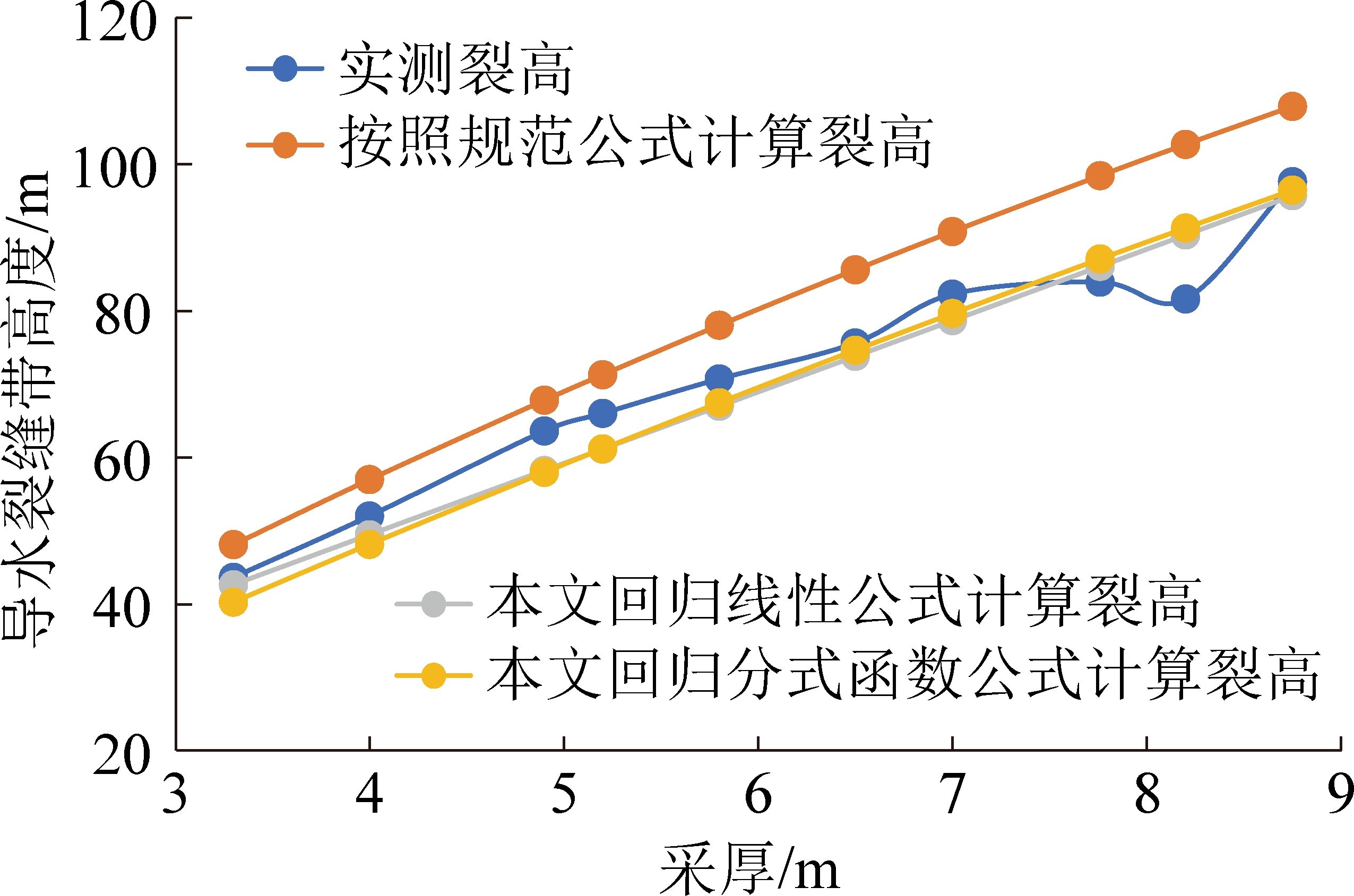

由表5和图11—图13可知,坚硬覆岩条件下用回归的线性公式计算得到的导水裂缝带高度与实测值差值率绝对值平均8.5%;按照分式函数关系回归的计算公式计算得到的导水裂缝带高度与实测值差值率绝对值平均差值率5.54%。中硬覆岩条件下分别为12.20%、6.62%和5.73%。软弱覆岩条件下分别为26.99%、11.94%和9.93%。综上分析,回归得出的厚及特厚煤层高强度开采导水裂缝带公式明显优于《规范》中的经验公式,具有良好的适用性,且分式函数公式优于线性函数公式。

图11 坚硬覆岩导水裂缝带高度预计公式计算结果与实测值对比

Fig.11 Comparison between predicted calculation results and measured values of height of water-flowing fractured zone in hard overburden

表5 计算导水裂缝带高度与实测值绝对差值率

Table 5 Absolute difference rate between calculated fracture zone height and measured value

覆岩类型绝对差值率/%《指南》公式线性公式分式函数公式坚硬2.70~15.5329.280.35~15.78.50.26~15.235.54中硬6.61~25.8312.201.96~10.696.621.18~11.865.73软弱8.99~64.2426.991.96~34.9911.940.24~37.079.93

注:数据格式为(最小值~最大值)/平均值。

图12 中硬覆岩导水裂缝带高度预计公式计算结果与实测值对比

Fig.12 Comparison between predicted calculation results and measured values of height of water-flowing fractured zone in medium hard overburden

图13 软弱覆岩导水裂缝带高度预计公式计算结果与实测值对比

Fig.13 Comparison between predicted formula and measured value of water-flowing fractured zone height of weak overburden

1)基于179组国内厚及特厚煤层综放或者大采高综采条件下导水裂缝带高度实测数据,从我国14大煤炭基地区域角度分析了不同覆岩类型条件下的导水裂缝带高度和裂采比的范围和分布特征,初步绘制了中国煤矿导水裂缝带高度分布图,对我国的主要产煤基地高强度开采条件下导水裂缝带发育高度区域分布规律有了新的认识。

2)覆岩类型和采厚是影响导水裂缝带高度的重要因素。实测平均裂采比随着岩性由软弱、中硬到坚硬依次递增,坚硬覆岩的平均裂高分别是中硬覆岩和软弱覆岩的1.52倍和2.29倍,中硬覆岩平均裂高是软弱覆岩的1.5倍;相同覆岩类型的导水裂缝带高度都随着采厚的增加而增加,裂采比则随着采厚的增加而降低,且减小速率随着采厚达到一定厚度有趋于稳定的趋势。

3)从矿区地层及覆岩结构的赋存特征、导水裂缝带高度实测方法确定标准、实测时间和位置等方面,分析了实测导水裂缝带高度存在较大差异性的原因。黄陇基地永陇-彬长矿区导水裂缝带高度和裂采比,明显高于同类覆岩和采厚条件下的东部矿区,其原因在于彬长矿区的开采强度(工作面尺寸、推进速度)明显高于东部矿区;蒙东基地扎赉诺尔矿区覆岩条件下裂采比明显小于国内软弱覆岩条件下的裂采比,最小裂采比仅为5;神东基地实测获得的导水裂缝带高度差异性极大,实测结果与工作面的埋深、基岩厚度以及上覆黏性土层的采动隔水性能密切相关。

4)基于统计的实测数据,按照线性和分式函数2种形式回归得到了厚及特厚煤层高强度开采导水裂缝带高度预计公式,预计结果明显优于《规范》中的经验公式,具有良好的适用性,且分式函数公式优于线性函数公式,可为全国不同覆岩类型条件下厚及特厚煤层高强度开采导水裂缝带高度预计提供依据。

[1] 张玉军,张志巍.煤层采动覆岩破坏规律与控制技术研究进展[J].煤炭科学技术,2020,48(11):85-97.

ZHANG Yujun,ZHANG Zhiwei.Research progress on failure law and control technology of overlying strata in coal seam mining[J].Coal Science and Technology,2020,48(11):85-97.

[2] 许延春,李俊成,刘世奇,等.综放开采覆岩“两带”高度的计算公式及适用性分析[J].煤矿开采,2011,16(2):4-7,11.

XU Yanchun,LI Juncheng,LIU Shiqi,et al.Calculation formula and applicability analysis of “two zones” height of overburden in fully mechanized caving mining [J].Coal Mining,2011,16(2):4-7,11.

[3] 郭文兵,王云广.基于绿色开采的高强度开采定义及其指标体系研究[J].采矿与安全工程学报,2017,34(4):616-623.

GUO Wenbing,WANG Yunguang.Research on the definition and index system of high strength mining based on green mining[J].Journal of Mining and Safety Engineering,2017,34 (4):616-623.

[4] 刘英锋,王世东,王晓蕾.深埋特厚煤层综放开采覆岩导水裂缝带发育特征[J].煤炭学报,2014,39(10):1970-1976.

LIU Yingfeng,WANG Shidong,WANG Xiaolei.Development characteristics of water-conducting fracture zone in deep-buried ultra-thick coal seam fully mechanized caving mining [J].Journal of China Coal Society,2014,39(10):1970-1976.

[5] 李超峰.黄陇煤田综放采煤顶板导水裂缝带高度发育特征[J].煤田地质与勘探,2019,47(2):133-140.

LI Chaofeng.Characteristics of high development of water-conducting fracture zone in roof of fully mechanized coal mining in Huanglong coalfield [J].Coalfield Geology and Exploration,2019,47(2):133-140.

[6] 王晓振,许家林,韩红凯,等.顶板导水裂隙高度随采厚的台阶式发育特征[J].煤炭学报,2019,44(12):3740-3749.

WANG Xiaozhen,XU Jialin,HAN Hongkai,et al.The development characteristics of roof water guide fissure height with the step type of mining thickness [J].Journal of China Coal Society,2019,44(12):3740-3749.

[7] 吕文斌,杜明泽,管彦太,等.弱胶结地层大采高工作面覆岩“两带”发育高度研究[J].煤炭工程,2021,53(8):92-97.

LYU Wenbin,DU Mingze,GUAN Yantai,et al.Study on the development height of overburden“two zones”in large mining height working face of weakly cemented strata[J].Coal Engineering,2021,53 (8):92-97.

[8] 方 杰,徐会军,曹志国,等.软弱覆岩下厚煤层综放开采导水断裂带高度计算[J].煤炭科学技术,2016,44 (8):67-73.

FANG Jie,XU Huijun,CAO Zhiguo,et al.Height calculation of water-conducting fault zone in fully-mechanized caving mining of thick coal seam under soft overburden[J].Coal Science and Technology,2016,44 (8):67-73.

[9] 孙庆先,牟 义,杨新亮.红柳煤矿大采高综采覆岩“两带”高度的综合探测[J].煤炭学报,2013,38(S2):283-286.

SUN Qingxian,MOU Yi,YANG Xinliang.Comprehensive detection of“two zones”height of overlying strata in large mining height of Hongliu Coal Mine [J].Journal of China Coal Society,2013,38(S2):283-286.

[10] 李江华,王东昊,黎 灵,等.不同覆岩类型高强度采动裂隙发育特征对比研究[J].煤炭科学技术,2021,49(10):9-15.

LI Jianghua,WANG Donghao,LI Ling,et al.Comparative study on the development characteristics of high-intensity mining fractures in different overburden types[J].Coal Science and Technology,2021,49 (10):9-15.

[11] 王双明,黄庆享,范立民.生态脆弱矿区含(隔)水层特征及保水开采分区研究[J].煤炭学报,2010,35(1):7-14.

WANG Shuangming,HUANG Qingxiang,FAN Limin.Studyon the characteristics and water-retaining mining zones in ecologically fragile mining area [J].Journal of China Coal Society,2010,35(1):7-14.

[12] 曹祖宝,王庆涛.基于覆岩结构效应的导水裂隙带发育特征[J].煤田地质与勘探,2020,48(3):145-151.

CAO Zubao,WANG Qingtao.Development characteristics of water flowing fractured zone based on overburden structure effect [J].Coal Geology and Exploration,2020,48(3):145-151.

[13] 王振荣,赵立钦,康 健,等.多煤层重复采动导水裂隙带高度观测技术研究[J].煤炭工程,2018,50(12):82-85.

WANG Zhenrong,ZHAO Liqin,KANG Jian,et al.Study on height observation technology of water flowing fractured zone in repeated mining of multiple coal seams[J].Coal Engineering,2018,50 (12):82-85.

[14] 张玉军.控水采煤技术原理、关键技术及在砂岩含水层下综放开采实践[J].煤炭学报,2020,45(10):3380-3388.

ZHANG Yujun.Principle and key technologies of controlled water mining and practice of fully-mechanized mining under soft sandstone aquifer[J].Journal of China Coal Society,2020,45(10):3380-3388.

[15] 宋业杰,秦旭卫.敏东一矿覆岩含水层富水性评价及充水溃砂影响分析[J].煤炭技术,2015,34(11):112-114.

SONG Yejie,QIN Xuwei.Water abundance evaluation of overburden aquifer and effect analysis of water filling and sand bursting in Mindong No.1 Coal Mine[J].Coal Engineering,2015,34(11):112-114.

[16] 张玉军,宋业杰,樊振丽,等.鄂尔多斯盆地侏罗系煤田保水开采技术与应用[J].煤炭科学技术,2021,49(4):159-168.

ZHANG Yujun,SONG Yejie,FAN Zhenli,et al.Technology and application of water-preserving mining in Jurassic coalfield in Ordos Basin[J].Coal Science and Technology,2021,49(4):159-168.

[17] 张玉军,李凤明.浅埋煤层高强度开采覆岩(土)破坏演化及溃沙控制技术[J].煤炭学报,2016,41(S1):44-52.

ZHANG Yujun,LI Fengming.Deformation of overlying rock (soil)in high-strength mining of shallow coal mining and control of sand breakage [J].Journal of China Coal Society,2016,41(S1):44-52.

[18] 《建筑物、水体、铁路及主要井巷煤柱留设与压煤开采指南》[M].北京:煤炭工业出版社,2017.