移动扫码阅读

黄 强1,傅雪海1,张庆辉2,李玉寿1

(1.中国矿业大学 煤层气资源与成藏过程教育部重点实验室,江苏 徐州 221116;2.山西省煤炭地质勘查研究院,山西 太原 030031)

摘 要:为了研究中、高煤阶煤储层在覆压条件下孔隙度、渗透率及应力敏感性的差异变化特征,从山西沁水盆地采集4块中煤阶样品和4块高煤阶样品,开展了覆压孔渗试验对比研究,探讨了中煤阶煤和高煤阶煤的应力敏感性的差异,研究了应力敏感性随煤阶改变的变化规律。研究结果表明:煤的孔隙度随镜质组最大反射率Ro,max的增大呈现先增大后减小的趋势,而渗透率则与镜质组最大反射率之间无明显关系;中、高煤阶煤覆压下的孔隙度和渗透率均随有效应力增加呈现指数式减小;高煤阶煤平均孔隙压缩系数、应力敏感性系数分别是中煤阶煤的1.61倍和1.26倍,高煤阶煤的孔隙度和渗透率损害率分别是中煤阶煤的1.42倍和1.1倍,中、高煤阶煤的无因次渗透率曲率随有效应力的增加而降低,当有效应力为12 MPa时,高煤阶煤的平均渗透率曲率是中煤阶煤的1.33倍。随Ro,max的增大,煤的应力敏感性呈现增强的趋势,即高煤阶煤的应力敏感性高于中煤阶煤。因此,在不同煤阶煤储层排采过程中,针对不同煤阶煤储层所采用的生产压差应当有所差异。与中煤阶煤储层相比,高煤阶煤储层随有效应力增加孔隙度、渗透率损害率高,渗透率曲率降低幅度大,因此针对高煤阶煤储层排采过程中所采用的生产压差应低于中煤阶煤储层,才能获得较高的煤层气产出量。

关键词:煤层气;覆压孔渗;差异性;应力敏感性;中、高煤阶储层

中图分类号:P618.11

文献标志码:A

文章编号:0253-2336(2019)06-0164-07

HUANG Qiang1,FU Xuehai1,ZHANG Qinghui2,LI Yushou1

(1.Key Laboratory of Coalbed Methane Resources & Reservoir Formation Process,Ministry of Education,China University of Mining and Technology,Xuzhou 221116,China;2.Shanxi Institute of Coal Geology Exploration,Taiyuan 030031,China;)

Abstract:In order to study the variation characteristics of porosity,permeability and stress sensitivity of medium and high rank coal reservoirs in net confining stress,four medium and high rank coal samples were collected from Qinshui Basin in Shanxi Province.Comparative study of the porosity and permeability of coal in net confining stress experiments.This study discussed the difference of stress sensitivity between medium-rank coal and high-rank coal.And it studied the change rule of stress sensitivity with the change of coal rank.The results show that the porosity of coal increases first and then decreases with the increase of Ro,max.There is no obvious relationship between permeability and Ro,max.The porosity and permeability of medium and high coal rank coal in net confining stress decrease exponentially with the increase of effective stress.The average pore compressibility coefficient and stress sensitivity coefficient of high-rank coal are 1.61 times and 1.26 times of medium-rank coal respectively.The damage rate of porosity and permeability of high-rank coal is 1.42 times and 1.1 times of that of medium-rank coal,respectively.The permeability curvature of medium and high coal grade coal decreases with the increase of effective stress.When the effective stress is 12 MPa,the average permeability curvature of high rank coal is 1.33 times of that medium coal rank coal.With the increase of Ro,max,the stress sensitivity of coal tends to increase,that is,the stress sensitivity of high-rank coal is higher than that of medium-rank coal.Therefore,in the process of drainage and mining of different coal-rank coal reservoirs,the production pressure differential adopted for different coal-rank coal reservoirs should be different.Compared with medium-rank coal reservoirs,high-rank coal reservoirs show that as porosity increases with effective stress and permeability damage rate is high,permeability curvature decreases by a large margin.Therefore,in order to obtain a higher CBM output,the production pressure differential used in the drainage and mining process of high-rank coal reservoirs should be lower than that of medium-rank coal reservoirs.

Key words:coalbed methane;porosity and permeability in net confining stress;differential;stress sensitivity;medium and high rank coals reservoirs

黄 强,傅雪海,张庆辉,等.沁水盆地中高煤阶煤储层覆压孔渗试验研究[J].煤炭科学技术,2019,47(6):164-170.doi:10.13199/j.cnki.cst.2019.06.025

HUANG Qiang,FU Xuehai,ZHANG Qinghui,et al.Experimental study on overburden pore permeability of medium and high rank coal reservoirs in Qinshui Basin[J].Coal Science and Technology,2019,47(6):164-170.doi:10.13199/j.cnki.cst.2019.06.025

收稿日期:2018-12-27

责任编辑:王晓珍

基金项目:国家自然科学基金资助项目(41772158);中国矿业大学双一流建设自主创新专项计划资助项目(2018ZZCX05)

作者简介:黄 强(1995—),男,河南兰考人,硕士研究生。E-mail:154560847@qq.com

煤储层的孔隙度和渗透率是影响煤层气资源开发成败的主要因素之一[1]。由于不同煤阶煤的物性条件存在较大的差异,其在应力条件下的孔隙度和渗透率也存在着较大的差异。因此,对不同煤阶煤储层的孔隙度和渗透率进行试验研究和对比分析,可以为不同煤阶煤层气井排采方案的制定提供理论指导,在针对不同煤阶煤层气资源探采过程起到了极其重要的作用。

国内外学者针对不同煤阶煤储层的孔隙度和渗透率与有效应力的关系研究取得大量试验成果。普遍认为随有效应力的增大,煤储层产生压缩变形,煤体结构发生变化,煤的基质孔隙以及裂隙空间不断被压缩减少,表现为煤储层的渗透率和孔隙度逐渐降低[2-3];通过定义孔隙压缩系数和应力敏感系数及其相互关系来表示煤储层孔隙度、渗透率与有效应力之间的关系[4-7];并通过分析不同应力条件下煤中裂隙、煤岩显微组分和含水情况对煤储层渗透性的影响,建立应力与煤储层孔隙度和渗透率变化关系的数学模型[8-12]。但是对于不同煤阶煤储层孔隙度和渗透率对应力的敏感程度的差异性对比很少涉及,特别是随有效应力变化不同煤阶煤的孔隙度和渗透率表现出的阶段性变化对比亦少见报道。笔者通过对沁水盆地中、高煤阶储层煤样进行覆压孔渗试验,对比研究了中、高煤阶煤孔隙度、渗透率及应力敏感性随有效应力的变化曲线,揭示了中、高煤阶煤孔隙度、渗透率随有效应力变化的差异性,并对中、高煤阶煤层气井排采过程中所采用的生产压差的选取进行探讨,对中、高煤阶储层煤层气开发具有理论和实际意义。

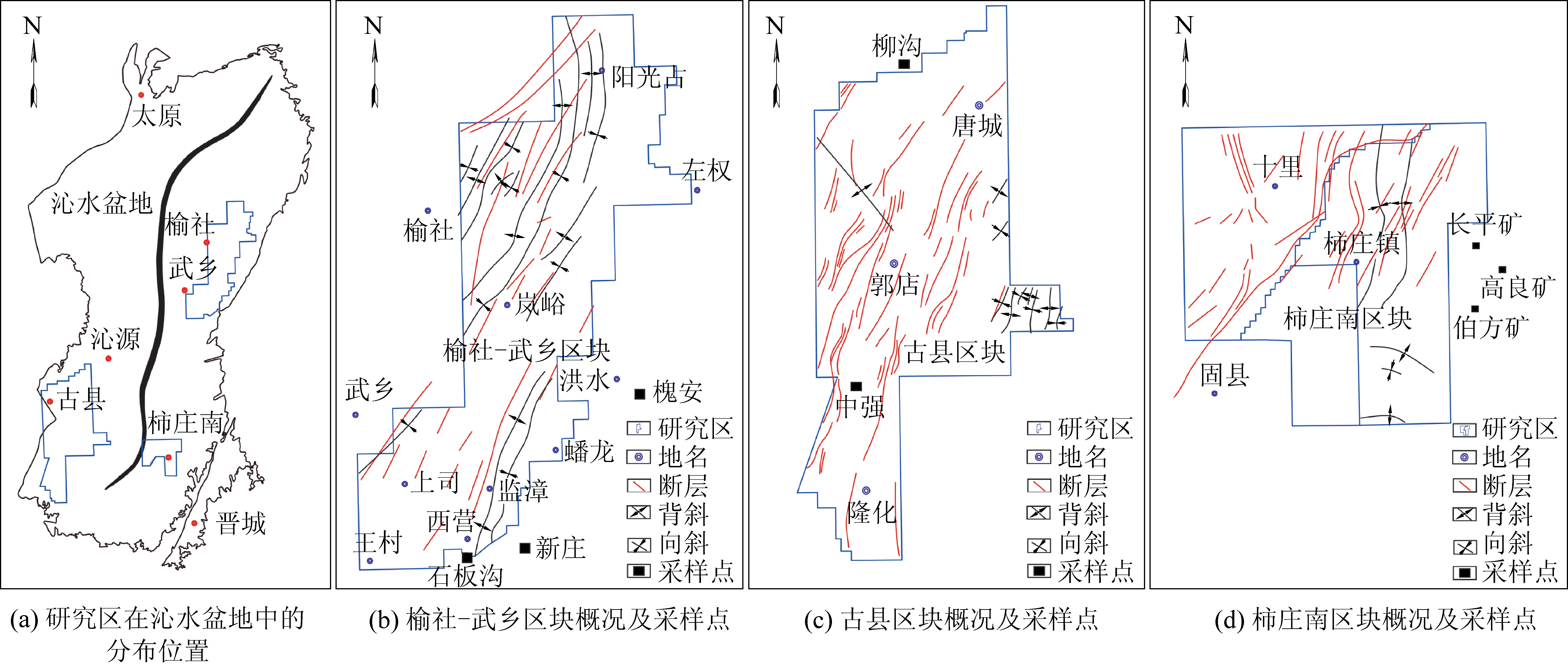

3块试验样品取自柿庄南区块外围高良煤矿、伯方煤矿、长平煤矿的3号煤层;2块取自古县区块外围柳沟煤矿9号煤层、中强煤矿10号煤层;3块取自榆社-武乡区块外围新庄煤矿、石板沟煤矿、槐安煤矿的15号煤层(图1)。

图1 研究区概况及取样位置[13-14]

Fig.1 General situations of study region and sampling location[13-14]

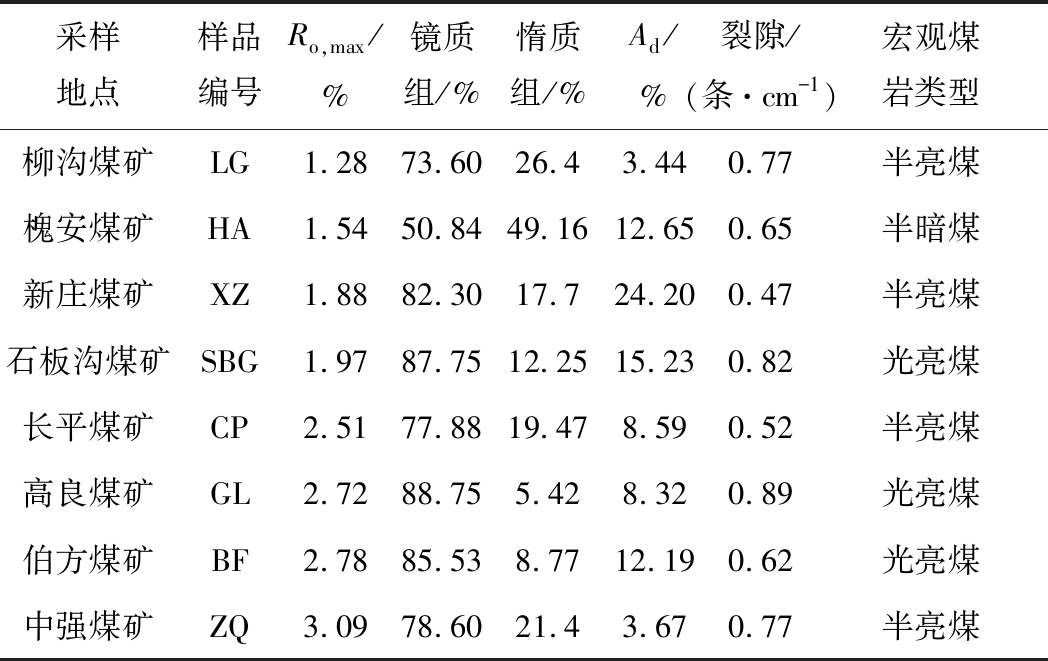

在采集的样品上沿平行层理方向钻取25 mm×50 mm的圆柱状样,在试验前不进行特殊的烘干处理,尽量保持样品原有的孔隙结构,试验煤样镜质组反射率Ro,max=1.28%~3.09%,即有4个Ro,max<2.0%的中煤阶煤样和4个Ro,max>2.0%的高煤阶煤样(表1)。

4个中煤阶煤(Ro,max=1.28%~1.97%)宏观煤岩类型以半亮煤为主,具条带状与均一状结构,显微煤岩组分中镜质组含量为50.84%~87.75%,平均值为73.62%,裂隙发育程度中等;4个高煤阶煤(Ro,max为2.51%~3.09%)宏观煤岩类型为半亮煤或光亮煤,具条带状与均一状结构,显微煤岩组分中镜质组含量为77.88%~88.75%,平均值为82.69%,裂隙发育程度中等。

表1 覆压下孔渗试验样品信息

Table 1 Experimental samples information of porosity and permeability in net confining stress

依照石油天然气行业标准SY/T6385—1999《覆压下岩石孔隙度和渗透率测定方法》,模拟覆压条件下煤样的孔隙度和渗透率物理条件。使用氦气作为测试介质,维持孔压3 MPa不变,以避免滑脱效应影响煤样的渗透率。利用平流泵逐渐增大各样品的围压值(5~15 MPa),每个围压值应当保持较长的时间(平衡时间一般在30 min以上),测定煤样在该压力点下的孔隙度和渗透率。

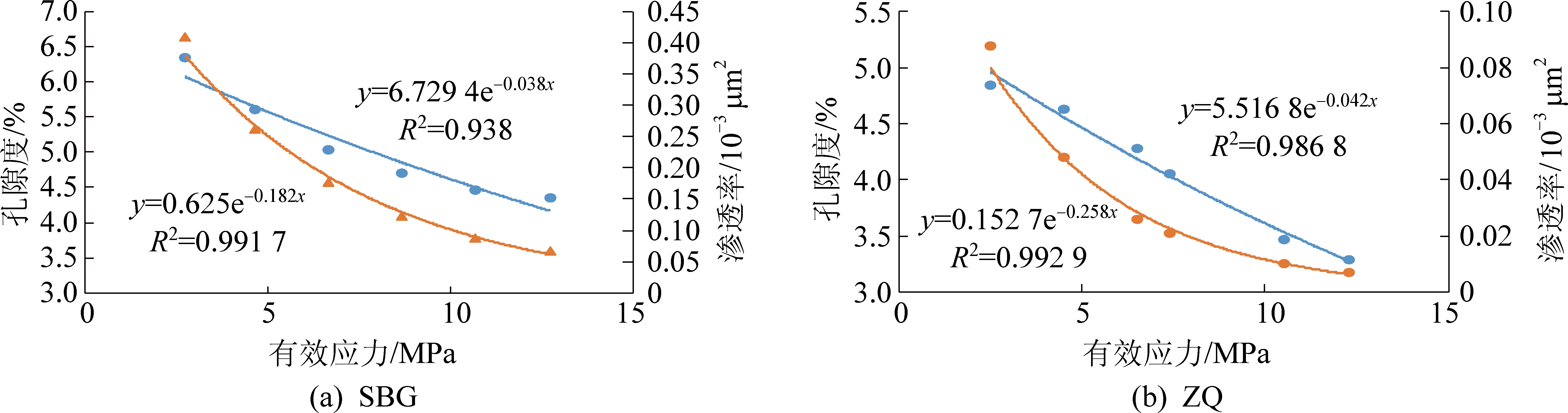

2.1.1 孔隙度与有效应力之间的关系

中、高煤阶煤样的孔隙度随有效应力的增加呈负指数式降低(图2),二者之间的回归分析表明:中煤阶煤样在初始有效应力为0时测得的孔隙度[15]φ0为5.30%~6.73%(图3),平均孔隙度为6.02%;高煤阶煤初始孔隙度为1.95%~5.57%,平均为4.43%。中、高煤阶煤平均孔隙度比值为1∶0.736。孔隙压缩系数指同一样品有效应力每增加1 MPa,孔隙体积的变化量[16]。覆压条件下中煤阶煤样品的孔隙压缩系数Cp为0.018~0.041 MPa-1(图3),平均为0.033 MPa-1;高煤阶煤孔隙压缩系数为0.038~0.092 MPa-1(图3),平均为0.053 MPa-1。中、高煤阶煤平均孔隙度压缩系数比值为1∶1.61。

图2 中、高煤阶煤样孔隙度、渗透率与有效应力之间的关系

Fig.2 Relationship between porosity、permeability and effective confining pressure of medium and high rank coals

2.1.2 渗透率与有效应力之间的关系

初始有效应力为0时测得的渗透率大小![]() 与煤阶的关系不明显(图3)。中煤阶煤样应力敏感性系数a[18]为0.111~0.234 MPa-1(图3),平均为0.175 MPa-1,其中LG应力敏感性系数最大,为0.234 MPa-1;高煤阶煤样应力敏感性系数为0.175~0.258 MPa-1,平均为0.223 MPa-1,其中ZQ应力敏感性系数最大,为0.258 MPa-1。中、高煤阶煤样应力敏感性回归系数平均比值为1∶1.26。

与煤阶的关系不明显(图3)。中煤阶煤样应力敏感性系数a[18]为0.111~0.234 MPa-1(图3),平均为0.175 MPa-1,其中LG应力敏感性系数最大,为0.234 MPa-1;高煤阶煤样应力敏感性系数为0.175~0.258 MPa-1,平均为0.223 MPa-1,其中ZQ应力敏感性系数最大,为0.258 MPa-1。中、高煤阶煤样应力敏感性回归系数平均比值为1∶1.26。

图3 覆压孔渗、应力敏感性系数、孔隙度压缩系数与煤阶的关系

Fig.3 Relationship between coal rank and porosity and permeability in net confining stress, permeability stress sensitivity coefficient as well as porosity compressibility coefficient respectively

为了对比中、高煤阶煤渗透率对应力的敏感程度的差异,通过计算有效应力作用下煤的孔隙度、渗透率衰减百分数和无因次渗透率曲率综合进行对比研究[19-21]。

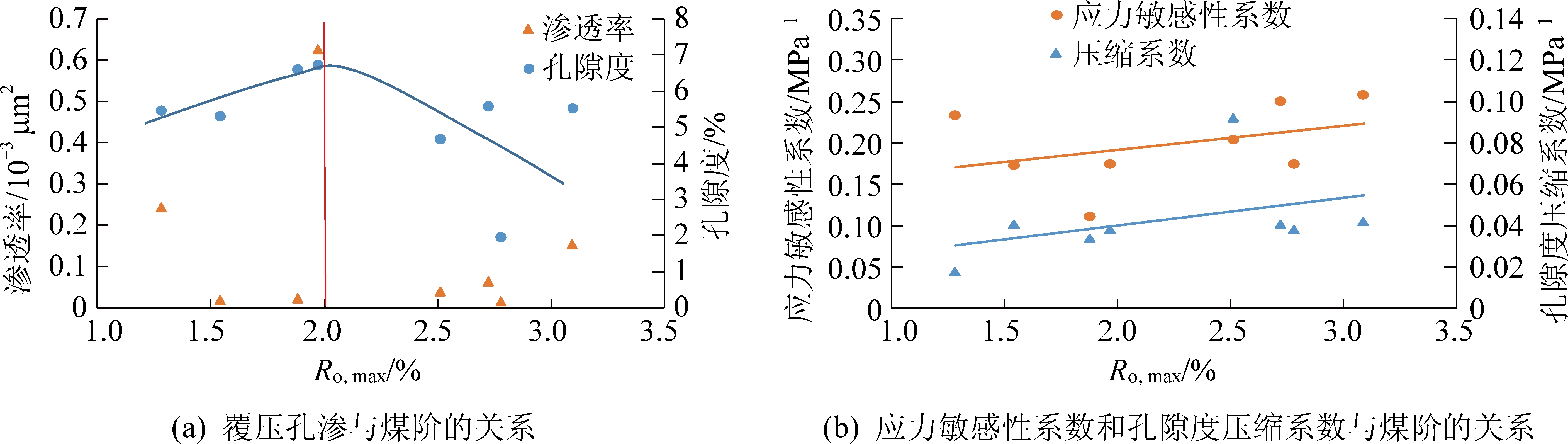

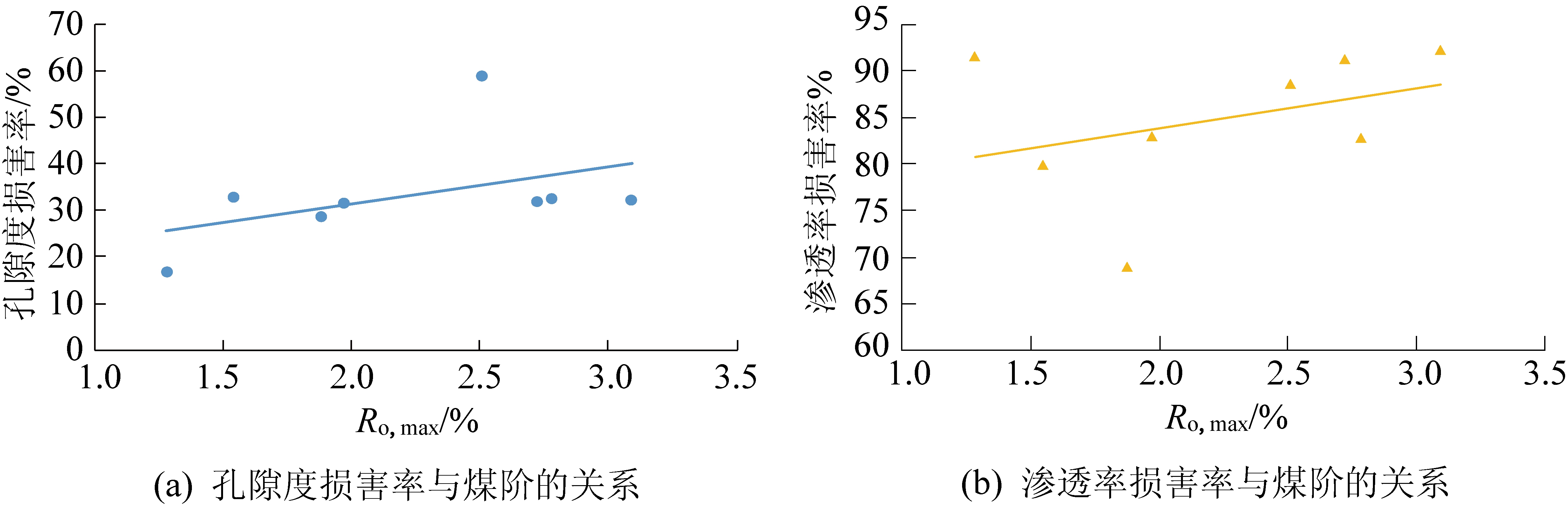

2.2.1 孔隙度和渗透率应力损害率

孔隙度和渗透率应力损害率分别表示煤储层受到有效应力条件下孔隙度和渗透率衰减的百分比,储层孔隙度或渗透率应力损害率越高,说明该储层孔隙度或渗透率受有效应力损害程度越严重,对应的应力敏感性越高。当有效应力达到12 MPa时,中煤阶煤的孔隙度应力损害率Dφ[19]为16.69%~32.91%(图4),平均为27.41%,其中HA损害率最大,为32.91%;高煤阶煤样损害率为31.87%~58.95%,平均为38.9%,其中CP损害率最大,为58.95%。中、高煤阶煤平均孔隙度损害率比值为1∶1.42。

中煤阶煤的渗透率应力损害率Dk[20]为68.95%~91.55%,平均为80.82%,其中LG的损害率最大,为91.55%;高煤阶无烟煤渗透率损害率为83.00%~92.16%(图4),平均为88.81%,其中GL损害率最大,为92.16%。中、高煤阶煤平均渗透率损害率比值为1∶1.1。参考石油天然气行业标准SY/T 5358—2010《覆压下岩石孔隙度和渗透率测定方法》,研究区内中煤样XZ的渗透率损害率50<Dk2≤70,损害程度中等偏强,研究区内其他煤样的损害率均大于70,损害程度强。

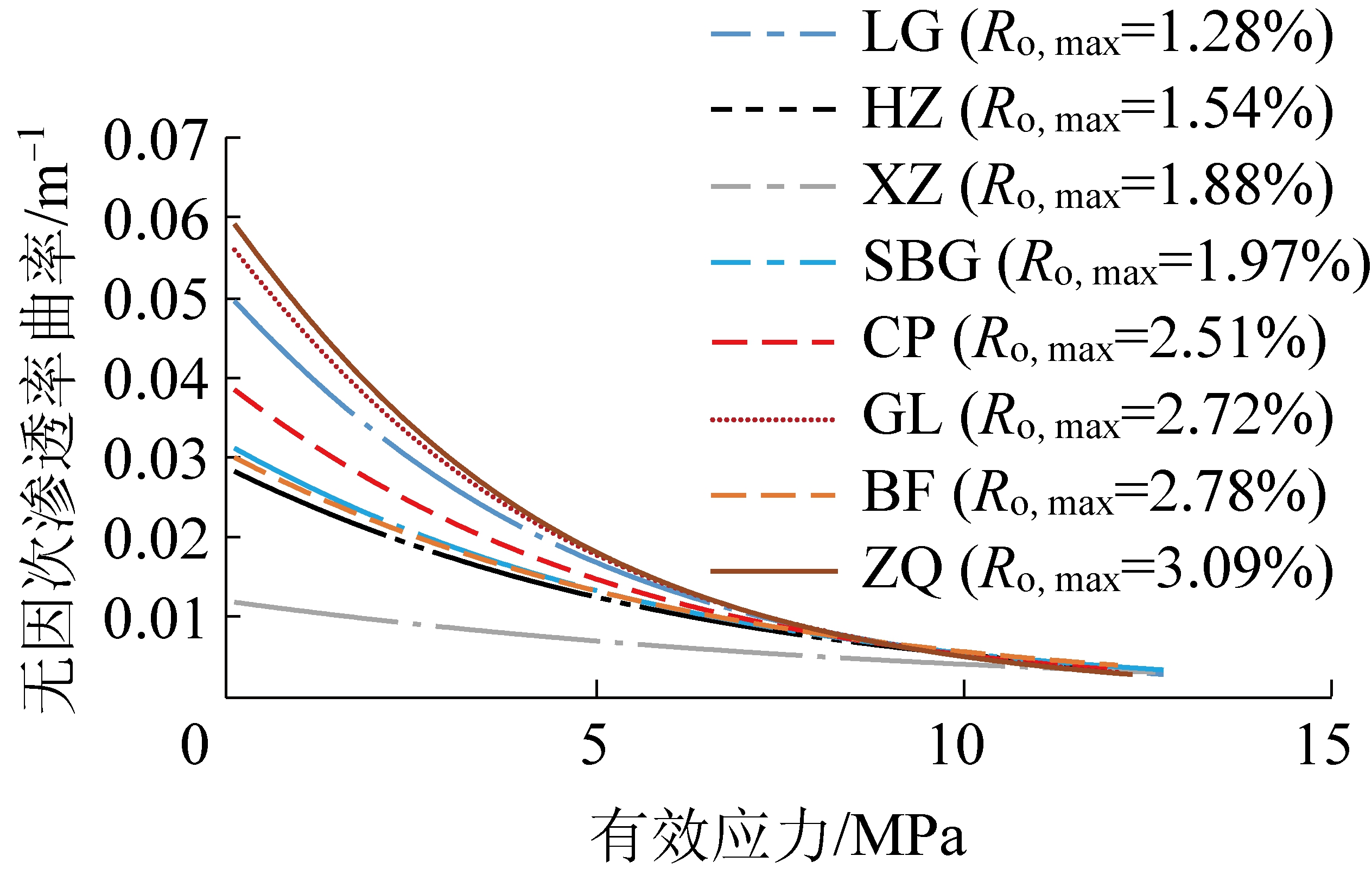

2.2.2 无因次渗透率曲率

为了进一步分析煤样的应力敏感性,对比分析有效应力对中、高煤阶煤渗透率的变化率的影响程度,同时为了抵消因样品差异对渗透率造成的影响,便于研究渗透率对有效应力的敏感性,引入无因次渗透率曲率的概念[21]。曲率越大,表明渗透率越易受有效应力的影响,储层敏感性越强;曲率降低,表明渗透率受有效应力的影响程度降低,储层敏感性逐渐变弱;当曲率值趋向某一固定值时,表明渗透率受有效应力的作用基本忽略不计。

图4 有效应力为12 MPa条件下中、高煤阶煤孔隙度与渗透率、应力损害率与煤阶的关系

Fig.4 Relationship between porosity、permeability stress damage rate of medium、high rank coals and coal rank under effective stress of 12 MPa

中、高煤阶煤的无因次渗透率曲率曲线随有效应力的增加整体呈现下降态势,表明有效应力增加导致储层应力敏感性减弱。虽不同煤阶煤样曲率存在较大差异,但均呈现:当有效应力<4 MPa时,应力的增加导致曲率曲线显著下降,表明在这一过程中煤储层中大部分孔裂隙被压缩闭合,渗透率下降显著,应力敏感性强;当有效应力为4~8 MPa时,随应力的增加,曲率曲线减小的趋势有所缓和,逐渐减缓,表明在这一过程中虽然煤储层中的孔裂隙被压缩闭合,但不如前期剧烈,渗透率下降幅度减慢,应力敏感性逐渐减弱;当有效应力>8 MPa时,随应力的增加曲率曲线变化微弱,趋于稳定,表明在这一过程中煤中孔裂隙基本已被压缩闭合,渗透率下降不明显,此时煤层应力敏感性微弱(图5)。

图5 中、高煤阶煤渗透率曲率与有效应力的关系

Fig.5 Relationship between permeability curvature and effective stress of medium and high rank coals

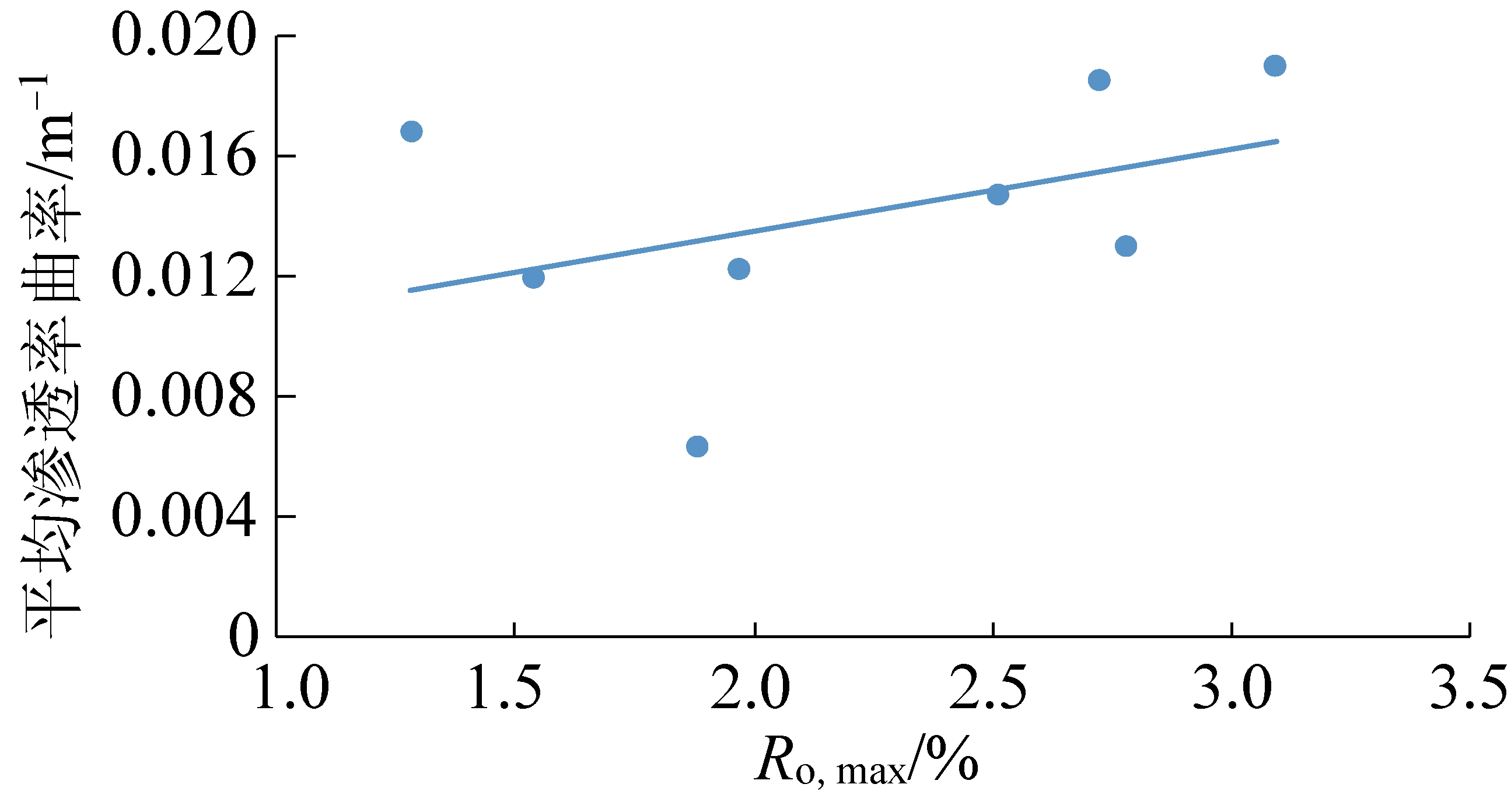

平均渗透率曲率随Ro,max增大呈现上升的趋势,当有效应力为12 MPa时,中煤阶煤的平均渗透曲率为0.006~0.017 m-1(图6),平均为0.012 m-1;而高煤阶煤平均渗透率曲率为0.012~0.019 m-1,平均为0.016 m-1。中、高煤阶煤平均渗透率曲率比值为1∶1.33。

图6 中、高煤阶煤渗透率曲率平均值与煤阶的关系

Fig.6 Relationship between the average permeability curvature of medium、high rank coals-coal ranks

中煤阶煤的孔隙度损害率和渗透率损害率均小于高煤阶煤,说明高煤阶煤孔隙度、渗透率受应力作用影响大,孔隙更容易被压缩,渗透率受应力作用影响更强。同一煤阶不同煤样渗透率应力敏感性也存在着较大差异,这可能与不同煤样中裂隙的差异相关,当有效应力为12 MPa时,通过对比各煤样渗透率曲率的平均值发现:高煤阶煤平均渗透率曲率大于中煤阶煤,即相对于中煤阶煤,高煤阶煤应力敏感性更大。

在实际的排水采气过程中,煤储层压力逐步降低,导致煤储层受到的有效应力增大,进而对煤储层的渗透率产生影响。因此,可通过有效应力对煤储层渗透率的影响表示煤层气井排采过程中生产压差对渗透率的影响。不同煤阶煤储层应力敏感性差异性显著,而应力敏感性又制约着煤层气的产能,所以针对不同煤阶煤储层所采用的生产压差应当有所差异,不可盲目增大或降低井底流压,以图快速提高产能。如果井底流压过低,生产压差就会过大,煤储层的应力敏感性会受到严重损害,将对煤层气井产能造成不可逆损害;反之,井底流压越大,生产压差越低,产气量越低。因此,针对不同煤阶煤储层,应根据储层实际情况制定合理的生产压差和优化排采方案,在确保气井产能的同时又避免造成储层应力敏感性的损伤。

1)中、高煤阶煤孔隙压缩系数和应力敏感性存在差异。沁水盆地中、高煤阶煤平均孔隙压缩系数比值为1∶1.61,应力敏感性系数比值为1∶1.26。

2)中、高煤阶煤孔隙度、渗透率损害率存在差异。当有效应力为12 MPa时,沁水盆地中、高煤阶煤平均孔隙度损害率比值为1∶1.42,平均渗透率损害率比值为1∶1.1;中、高煤阶煤无因次渗透率曲率随有效应力增加呈降低的态势,当有效应力为12 MPa时,沁水盆地中、高煤阶煤的平均渗透率曲率比值为1∶1.33。

3)随Ro,max增大,煤的应力敏感性增强,即高煤阶煤的应力敏感性高于中煤阶煤。在进行不同煤阶煤储层排采过程中针对不同煤阶煤储层所采用的生产压差应当有所差异。与中煤阶煤相比,高煤阶煤随有效应力增加孔隙度、渗透率损害率高,渗透率曲率降低幅度大,采用的生产压差应低于中煤阶煤。

参考文献(References):

[1] 傅雪海,秦 勇,姜 波,等.煤割理压缩试验及渗透率数值模拟[J].煤炭学报,2001,26(6):573-577.

FU Xuehai,QIN Yong,JIANG Bo,et al.Compress experiment of coal cleat and mathematical simulation of coal reservoir permeability[J].Journal of China Coal Society,2001,26(6):573-577.

[2] 汪 岗,秦 勇,申 建,等.基于变孔隙压缩系数的深部低阶煤层渗透率试验[J].石油学报,2014,35(3):462-468.

WANG Gang,QIN Yong,SHEN Jian,et al.Experimental studies of deep low-rank coal reservoirs′permeability based on variable pore compressibility[J].Acta Petrolei Sinica,2014,35(3):462-468.

[3] 孟 雅,李治平.覆压下煤的孔渗性试验及其应力敏感性研究[J].煤炭学报,2015,40(1):154-159.

MENG Ya,LI Zhiping.Experimental study on the porosity and permeability of coal in net confining stress and its stress sensitivity[J].Journal of China Coal Society,2015,40(1):154-159.

[4] Min K B,Rutqvist J,Tsang C F,et al.Stress-dependent permeability of fractured rock masses:a numerical study[J].International Journal of Rock Mechanics & Mining Sciences,2004,41(7):1191-1210.

[5] ZHANG J,Standifird W B,Roegiers J C,et al.Stress-dependent fluid flow and permeability in fractured media:from lab experiments to engineering applications[J].Rock Mechanics & Rock Engineering,2007,40(1):3-21.

[6] TENG T,GAO F,YANG J,et al.How moisture loss affects coal porosity and permeability during gas recovery in wet reservoirs?[J].International Journal of Mining Science and Technology,2017,27(6):899-906.

[7] Enever J R,Henning A.The relationship between permeability and effective stress for Australian coal and its implications with respect to coalbed methane exploration and reservoir modeling[C]//Proceedings of the 1997 International Coalbed Methane Symposium.1997:13-22.

[8] 贾慧敏,孙世轩,毛崇昊,等.基于煤岩应力敏感性的煤层气井单相流产水规律研究[J].煤炭科学技术,2017,45(12):189-193.

JIA Huimin,SUN Shixuan,MAO Chonghao,et al.Study on water production law of single-phase flow in CBM wells based on stress sensitivity of coal and rock [J].Coal Science and Technology,2017,45 (12):189-193.

[9] 陈 浩,秦 勇,李贵中,等.基于脉冲衰减法的煤岩渗透率应力敏感性研究[J].煤炭科学技术,2018,46(6):167-172.

CHEN Hao,QIN Yong,LI Guizhong,et al.Study on stress sensitivity of coal rock permeability based on pulse-decay method[J].Coal Science and Technology,2018,46(6):167-172.

[10] 王运海.延川南深部煤层气井排采制度研究[J].煤炭科学技术,2018,46(6):132-137.

WANG Yunhai.Study on drainage and production system of deep coalbed methane well in South Yanchuan Block[J].Coal Science and Technology,2018,46(6):132-137.

[11] 侯旭伟,周效志,陶智辉,等.重复荷载下不同饱水压力中阶煤应力敏感性研究[J].煤炭科学技术,2018,46(8):120-124.

HOU Xuwei,ZHOU Xiaozhi,TAO Zhihui,et al.Stress sensitivity of medium-rank coal under different saturated pressures under repeated loading [J].Coal Science and Technology,2018,46 (8):120-124.

[12] JASINGE D,RANJITH P G,CHOI S K.Effects of effective stress changes on permeability of latrobe valley brown coal[J].Fuel,2011,90(3):1292-1300.

[13] 杨晓东,张 苗,魏 巍,等.沁水盆地古县区块煤系“三气”储层孔隙特征对比[J].天然气地球科学,2017,28(3):356-365.

YANG Xiaodong,ZHANG Miao,WEI Wei,et al.Comparison of pore characteristics of the “Three Gas” reservoir in the coal seams of Guxian County,Qinshui Basin[J].Natural Gas Geoscience,2017,28(3):356-365.

[14] 程 鸣,傅雪海,张 苗,等.沁水盆地古县区块煤系“三气”储层覆压孔渗试验对比研究[J].天然气地球科学,2018,29(8):1163-1171.

CHENG Ming,FU Xuehai,ZAHNG Miao,et al.Comparative study on porosity and permeability in net confining stress of three natural gases in coal series reservoirs in Guxian County,Qinshui Basin[J].Natural Gas Geoscience,2018,29(8):1163-1171.

[15] 陈振宏,王一兵,郭 凯,等.高煤阶煤层气藏储层应力敏感性研究[J].地质学报,2008,82(10):1390-1395.

CHEN Zhenhong,WANG Yibing,GUO Kai,et al.Stress sensitivity of high-rank coalbed methane reservoir[J].Acta Geologica Sinica,2008,82(10):1390-1395.

[16] 苏付义.围限压力下煤岩孔隙度的变化特征及应用[J].煤田地质与勘探,1994,22(3):27-31.

SU Fuyi.Characteristics of coal rock porosity change under confining pressure and its application[J].Coal Geology Exploration,1994,22(3):27-31.

[17] 杨满平,王 刚,许胜洋,等.考虑应力敏感性的煤层气稳定流动气井产能方程[J].天然气地球科学,2011,22(2):347-351.

YANG Manping,WANG Gang,XU Shengyang,et al.Steady flow productivity equation for stress sensitivity coal bed methane gas well[J].Natural Gas Geoscience,2011,22(2):347-351.

[18] 孟召平,侯泉林.高煤阶煤储层渗透性与应力耦合模型及控制机理[J].地球物理学报,2013,56(2):667-675.

MENG Zhaoping,HOU Quanlin.Coupling model of stress-dependent permeability in high-rank coal reservoir and its control mechanism[J].Chinese Journal of Geophysics-Chinese Edition,2013,56(2):667-675.

[19] 陈术源,秦 勇,申 建,等.高阶煤渗透率温度应力敏感性试验研究[J].煤炭学报,2014,39(9):1845-1851.

CHEN Shuyuan,QIN Yong,SHEN Jian,et al.Experimental study on temperature sensitivity of high rank coal permeability[J].Journal of China Coal Society,2014,39(9):1845-1851.

[20] 朱庆忠,汤达祯,左银卿,等.樊庄区块开发过程中煤储层渗透率动态变化特征[J].煤炭科学技术,2017,45(7):85-92.

ZHU Qingzhong,TANG Dazhen,ZUO Yinqing,et al.Permeability dynamic variation features of coal reservoir in exploitation process of Fanzhuang Block[J].Coal Science and Technology,2017,45(7):85-92.

[21] 陈 刚,秦 勇.不同煤阶煤储层应力敏感性差异及其对煤层气产出的影响[J].煤炭学报,2014,39(3):504-509.

CHEN Gang,QIN Yong.Different stress sensitivity of different coal rank reservoir permeability and its effect on the coalbed methane output[J].Journal of China Coal Society,2014,39(3):504-509.