Fractal characteristics of pore structures on different coal structures and its research significance

-

摘要:

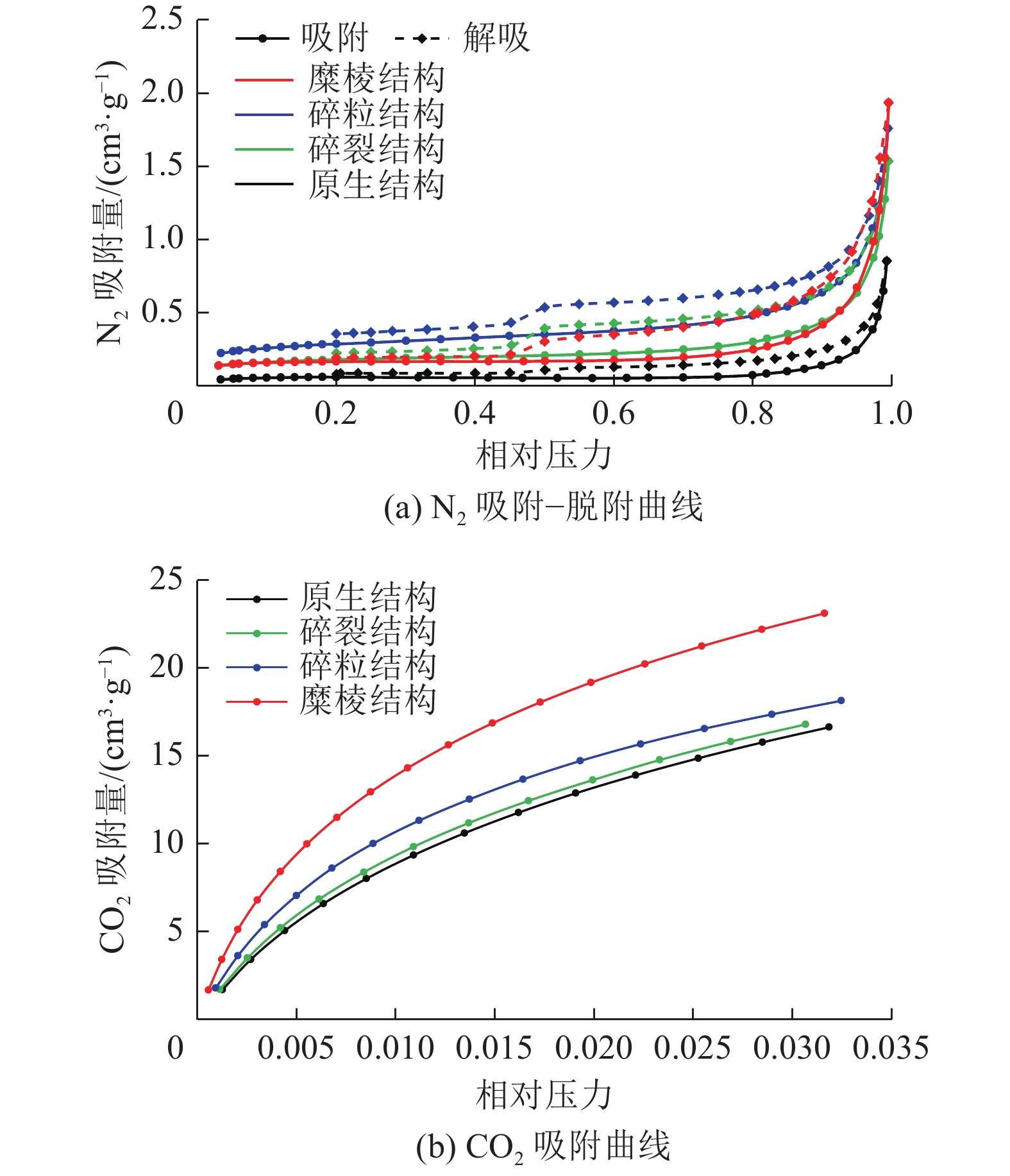

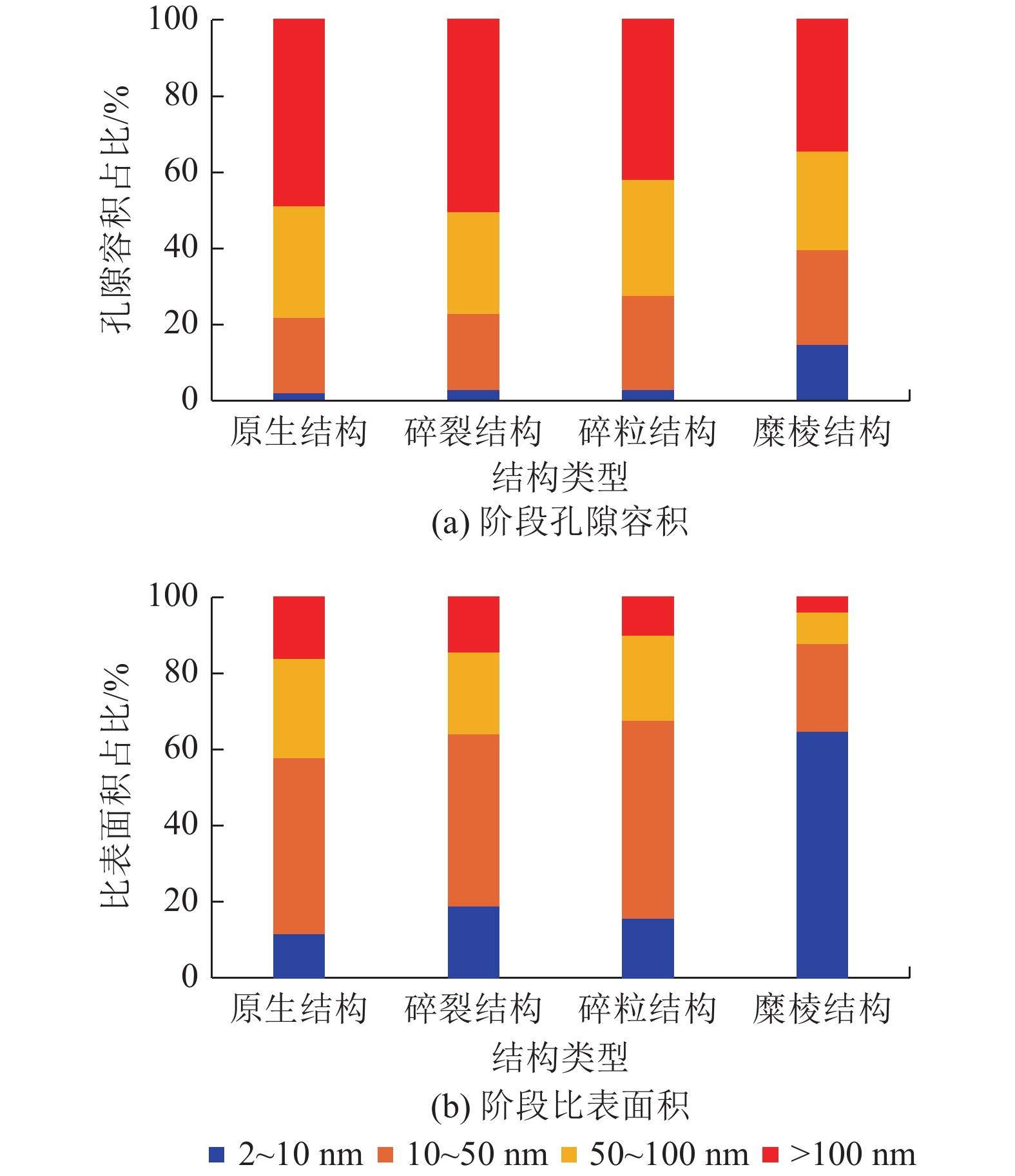

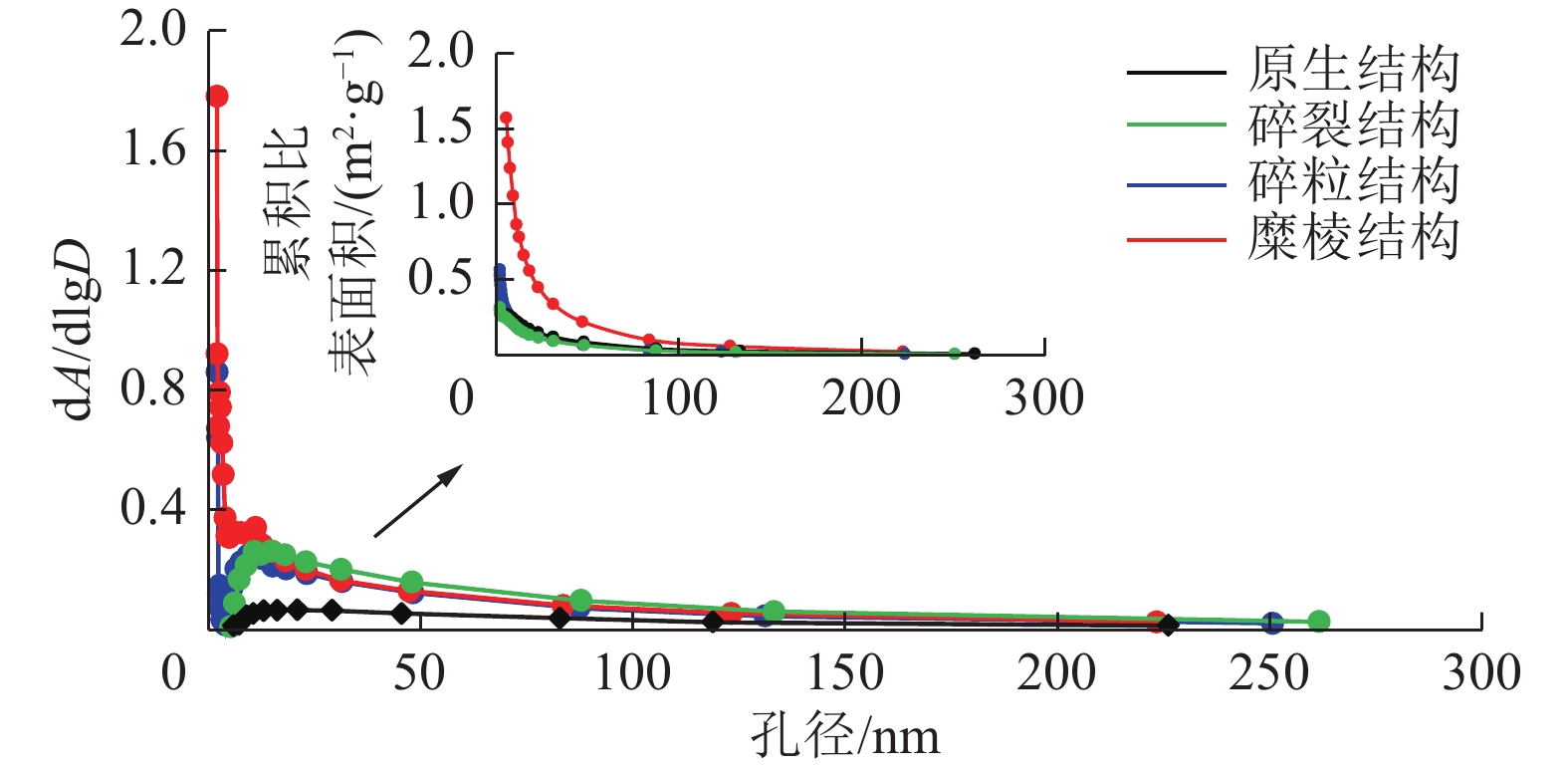

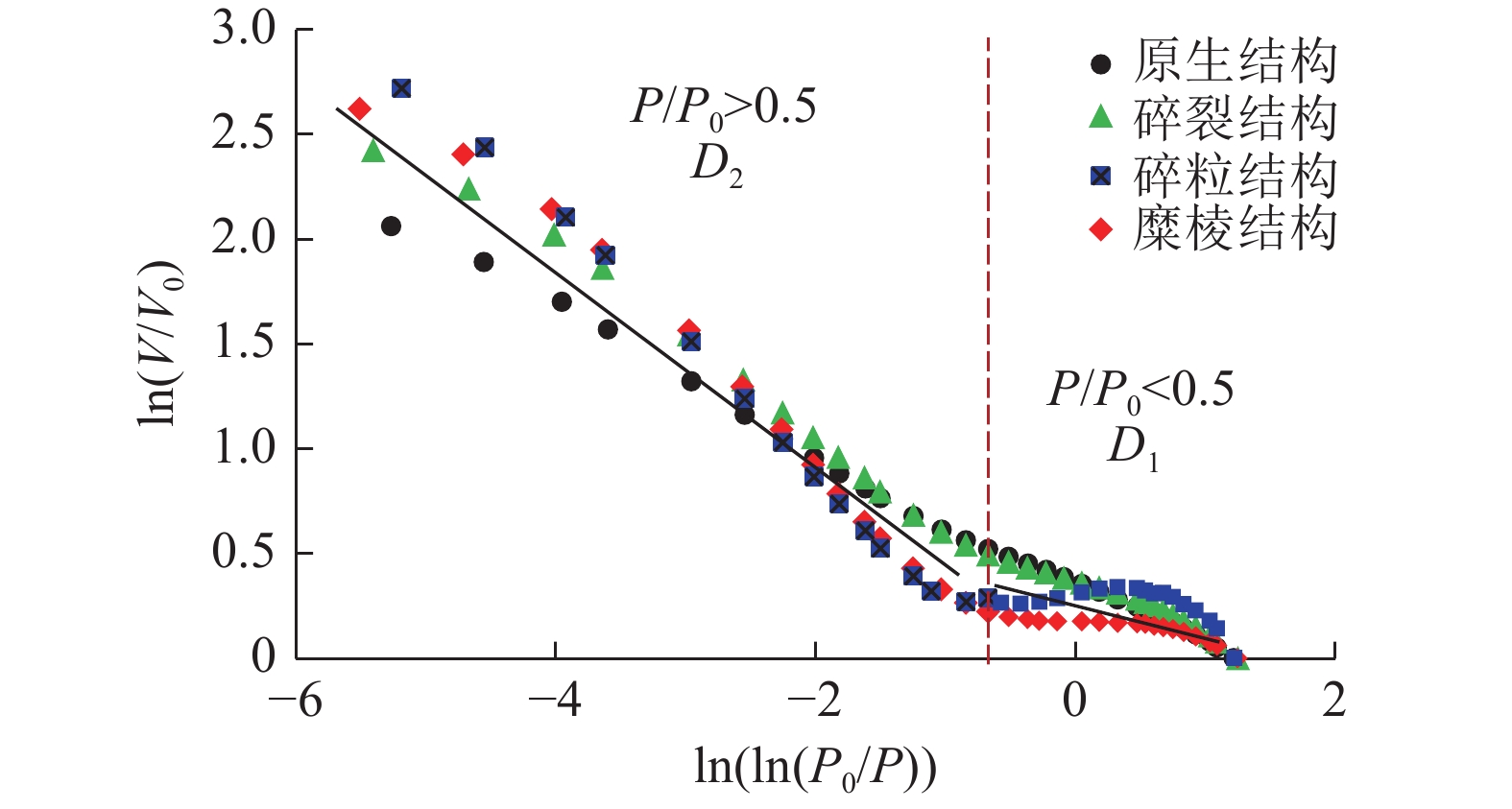

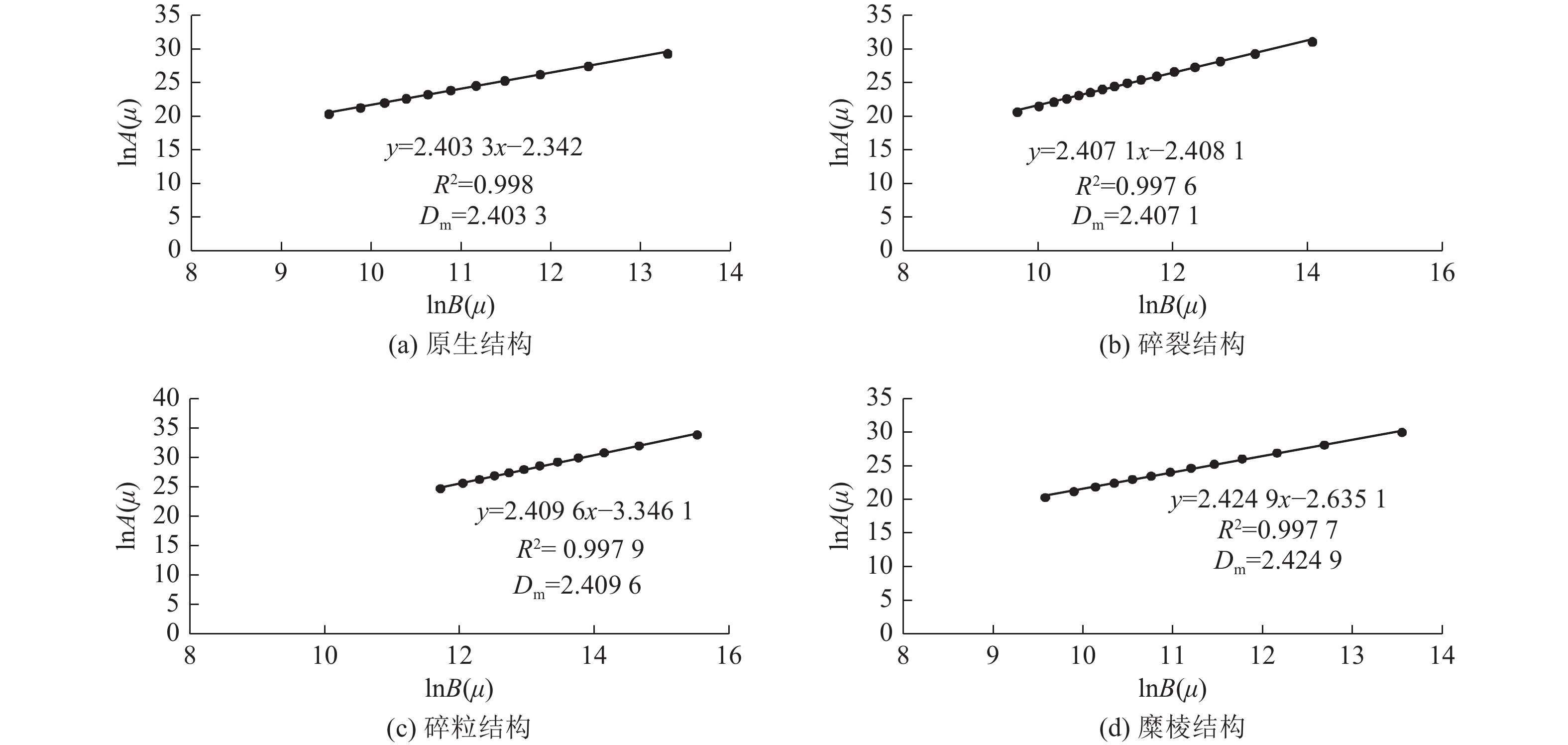

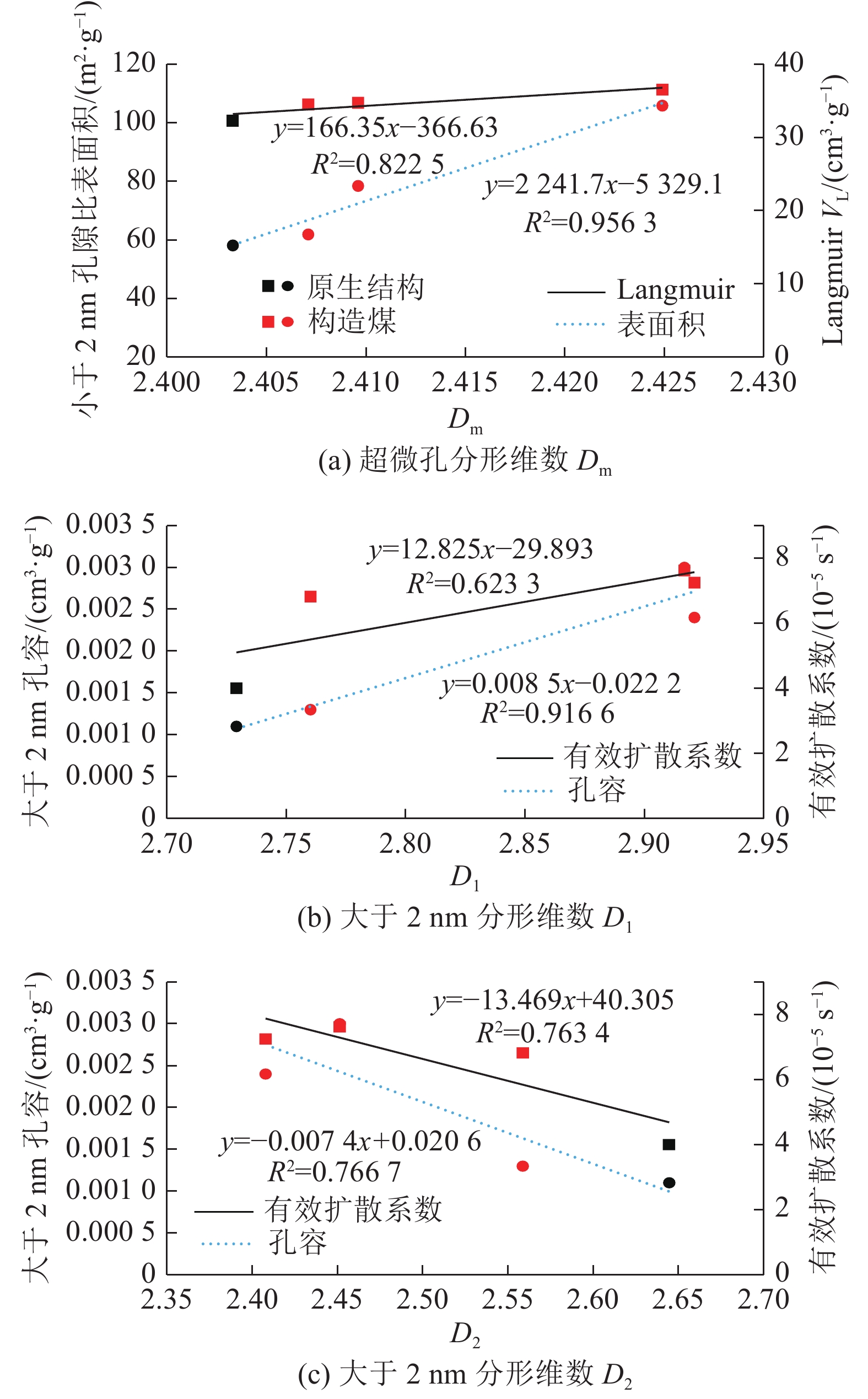

煤层气的赋存和产出与煤储层孔隙系统的发育程度有关,原生结构煤层受到破坏变形后其孔隙结构特征将发生明显的变化,从而影响煤层气的吸附/解吸和扩散过程。通过对沁水盆地赵庄井田3号煤层不同煤体结构样品进行低温液氮、低压二氧化碳吸附分析和等温吸附试验,分析了不同破坏强度煤的孔隙结构和吸附性变化规律;应用试验数据和数值分形模型,揭示了不同煤体结构煤的孔隙结构分形特征及其对煤中甲烷吸附、扩散的影响。结果表明:随着煤体结构破坏强度的增大,煤的比表面积和孔隙容积均增大,50~300 nm的孔隙所占比例逐渐降低,2~50 nm的微孔和中孔以及小于2 nm的超微孔增加,超微孔为煤中主要吸附孔,孔径主要分布在0.45~0.65 nm和0.80~1.0 nm。N2、CO2和CH4的吸附量随煤体结构破坏程度的增大而增加,吸附性由大到小顺序为原生结构>糜棱结构>碎粒结构>碎裂结构。微孔、中孔和大孔孔隙结构分形维数表明,构造变形后的煤孔隙结构将被简单化,破坏程度较强的煤具有较粗糙的孔隙表面(对应较高的D1)和较为均质的孔径分布(对应较低的D2);而超微孔分形维数Dm随着煤体结构破坏强度的增加逐渐增大,且与LangmuirVL和对应的比表面积呈正相关性,说明煤表面粗糙度增大导致比表面积增大,为煤中气体吸附提供了较多的具有高吸附势的吸附点位,吸附性增强。有效扩散系数、孔容与分形维数D1 呈正相关性,与D2成负相关性,表明原生结构煤孔隙结构被破坏后连通性变好,孔隙容积增大,气体进出效率提升,扩散效率增大。

Abstract:The occurrence and production of coalbed methane is related to the development degree of pore system in coal reservoirs. The pore structure characteristics of original structural coal seam will change significantly after damage and deformation, thus affecting the adsorption/desorption and diffusion process of coalbed methane. Through the low-temperature liquid N2 and low-pressure CO2 adsorption analysis and isothermal adsorption experiments on coal with different structures from the No. 3 coal seam in Zhaozhuang coalfield in Qinshui Basin, the variation laws of pore structure and adsorption of coals with various destructive strengths were analyzed. Applying experimental data and numerical fractal modeling, the pore fractal characteristics of coal with different structures and their effects on methane adsorption and diffusion in coal were revealed. The results shown that with the increase of the destructive intensity of coal structures, the specific surface area and pore volume of coal increased, the proportion of 50-300 nm pores gradually decreased, the micropores and mesopores of 2-50 nm and ultra-micropores of less than 2 nm increased. As the main adsorption pores in coal, the ultra-micropores size was mainly distributed in 0.45-0.65 nm and 0.80-1.0 nm. The adsorption amount of N2, CO2 and CH4 increased with the increasing destructive degree of coal structure. The order of adsorption capacity from large to small was: intact coal>mylonitic coal > granulated coal > cataclastic coal. The fractal dimensions of the micro-, meso- and macro-porous structures indicated that the pore structure of tectonically deformed coals will be simplified. Coal with a higher damage intensity had a rougher pore surface (corresponding to a higherD1) and a more homogeneous pore size distribution (corresponding to a lowerD2). The fractal dimension of ultra-microporous (Dm) gradually increased with the increasing structural destruction intensity of coal, and was positively correlated with Langmuir constant (VL) and the corresponding specific surface area, indicating that the increase of coal surface roughness led to the increase of specific surface area, which provided more adsorption points with high adsorption potential for gas adsorption and enhanced the adsorption capacity of coal. The effective diffusion coefficient and pore volume were positively correlated with the fractal dimensionsD1 and negatively correlated withD2, which indicated better pore connectivity, increased pore volume, improved gas inlet and outlet efficiency, and enhanced gas diffusion efficiency of destroyed intact coal.

-

Keywords:

- coal structures /

- pore structures /

- fractal model /

- fractal dimension /

- coalbed methane

-

-

表 1 样品工业分析及显微组分

Table 1 Proximate analysis of samples and macerals of coal structures

样品 Ro/% 工业分析/% 镜质组体积分数/% 惰质组体积分数/% Mad Ad Vdaf 原生结构 2.23 0.98 14.22 11.71 65.80 33.77 碎裂结构 2.50 1.07 13.14 10.57 65.93 34.07 碎粒结构 2.48 0.90 12.14 9.17 72.07 27.93 糜棱结构 2.43 0.96 12.47 11.87 63.84 35.91 表 2 液氮、二氧化碳及等温吸附实验测试结果

Table 2 Results of low temperature nitrogen, pressure carbon dioxide and isothermal adsorption experiment

样品 平均孔径/

nmBET比表面积 /

(m2·g−1)BJH孔容/

(cm3·g−1)CO2测试

孔径/nmDFT比表面积/

(m2·g−1)DFT孔容/

(cm3·g−1)Langmuir吸附量/

(cm3·g−1)Langmuir压力/

MPa原生结构 24.671 0.2141 0.0011 0.524~1.083 58.086 0.0196 32.26 1.64 碎裂结构 14.972 0.3251 0.0013 0.524~1.083 61.838 0.0208 34.48 1.62 碎粒结构 21.049 0.5683 0.0024 0.507~1.101 78.433 0.0267 34.72 1.56 糜棱结构 10.791 1.5716 0.0030 0.489~1.083 105.808 0.0340 36.50 1.65 表 3 不同煤体结构超微孔分布区间及对应的累积比表面积值

Table 3 Distribution of ultra-micropore and cumulative SSAs in different intervals

样品 孔径R1 孔径R2 孔径R3 区间/nm 比表面积/(m2·g−1) 区间/nm 比表面积/(m2·g−1) 区间/nm 比表面积/(m2·g−1) 原生结构 0.54~0.65 34.36 0.66~0.80 9.60 0.80~0.91 14.12 碎裂结构 0.54~0.63 33.88 0.63~0.80 13.99 0.80~0.93 13.96 碎粒结构 0.52~0.63 43.77 0.63~0.86 20.38 0.87~0.99 14.28 糜棱结构 0.49~0.65 72.12 0.66~0.82 15.11 0.82~0.93 18.57 表 4 基于液氮和二氧化碳吸附数据计算的分形维数

Table 4 Fractal dimension (D1, D2 and Dm) based adsorption analysis calculation

样品 P/P0<0.5 P/P0>0.5 D1 D2 Dm 原生结构 y = −0.2709x + 0.364 y = −0.3554x + 0.2532 2.7291 2.6336 2.4033 碎裂结构 y = −0.2399x + 0.3691 y = −0.4413x + 0.173 2.7601 2.5587 2.4071 碎粒结构 y = −0.079x + 0.2946 y = −0.5923x − 0.2843 2.921 2.4077 2.4096 糜棱结构 y = −0.0832x + 0.1773 y = −0.5487x − 0.1847 2.9168 2.4513 2.4249 -

[1] YAN J,MENG Z,ZHANG K,et al. Pore distribution characteristics of various rank coals matrix and their influences on gas adsorption[J]. Journal of Petroleum Science and Engineering,2020,189:107041.

[2] 杨 明,柳 磊,刘佳佳,等. 中阶煤孔隙结构的氮吸附-压汞-核磁共振联合表征研究[J]. 煤炭科学技术,2021,49(5):67−74. doi: 10.3969/j.issn.1673-1328.2020.02.035 YANG Ming,LIU Lei,LIU Jiajia,et al. Study on joint characterization of pore structure of middle-rank coal by nitrogen adsorption-mercury intrusion-NMR[J]. Coal Science and Technology,2021,49(5):67−74. doi: 10.3969/j.issn.1673-1328.2020.02.035

[3] BRUNAUER S,EMMETT P H,TELLER E. Adsorption of gases in multimolecular layers[J]. Journal of the American Chemical Society,1938,60(2):309−319.

[4] LI X,KANG Y,HAGHIGHI M. Investigation of Pore Size Distributions of Coals with Different Structures by Nuclear Magnetic Resonance (NMR) and Mercury Intrusion Porosimetry (MIP)[J]. Measurement,2018,116:122−128. doi: 10.1016/j.measurement.2017.10.059

[5] NIE B,LIU X,YANG L,et al. Pore structure characterization of different rank coals using gas adsorption and scanning electron microscopy[J]. Fuel,2015,158:908−917. doi: 10.1016/j.fuel.2015.06.050

[6] WEI M. ZHANG L. XIONG Y. et al. Nanopore structure characterization for organic-rich shale using the non-local-density functional theory by a combination of N2 and CO2 adsorption[J]. Microporous and Mesoporous Materials,2016,227:88−94. doi: 10.1016/j.micromeso.2016.02.050

[7] 王佑安,杨思敬. 煤和瓦斯突出危险煤层的某些特征[J]. 煤炭学报,1980,1(6):47−53. doi: 10.13225/j.cnki.jccs.1980.01.006 WANG Youan,YANG Sijing. Some characteristics of coal seams with hazard of outburst[J]. Journal of China Coal Society,1980,1(6):47−53. doi: 10.13225/j.cnki.jccs.1980.01.006

[8] JU Y. W, LI X. S. New research progress on the ultrastructure of tectonically deformed coals[J]. Progress in Natural Science,2009,19:1455−1466. doi: 10.1016/j.pnsc.2009.03.013

[9] YU S,BO J,MING L,et al. A review on pore-fractures in tectonically deformed coals[J]. Fuel,2020,278:118248. doi: 10.1016/j.fuel.2020.118248

[10] 王 涛,黄文涛. 江西省新华煤矿软分层煤层的孔隙结构特征[J]. 中国煤田地质,1994,6(4):57−59. WANG Tao,HUANG Wentao. Pore structure characteristics of soft stratified coal seam in Xinhua coal mine, Jiangxi Province[J]. Coal Geology of China,1994,6(4):57−59.

[11] 孟召平,刘珊珊,王保玉,等. 不同煤体结构煤的吸附性能及其孔隙结构特征[J]. 煤炭学报,2015,40(8):1865−1870. doi: 10.13225/j.cnki.jccs.2015.0620 MENG Zhaoping,LIU Shanshan,WANG Baoyu,et al. Adsorption capacity and its pore structure of coals with different coal body structure[J]. Journal of China Coal Society,2015,40(8):1865−1870. doi: 10.13225/j.cnki.jccs.2015.0620

[12] 金 毅,权伟哲,秦建辉,等. 孔隙-孔喉分形多孔介质复杂类型组构模式表征[J]. 煤炭学报,2020,45(5):1845−1854. JIN Yi,QUAN Weizhe,QIN Jianhui,et al. Quantitative characterization of complex assembly in fractal pore-throat porous media[J]. Journal of China Coal Society,2020,45(5):1845−1854.

[13] 傅雪海,秦 勇,张万红,等. 基于煤层气运移的煤孔隙分形分类及自然分类研究[J]. 科学通报,2005,50(S1):51−55. FU Xuehai,QIN Yong,ZHANG Wanhong,et al. Fractal classification and natural classification of coal pores based on coalbed gas migration[J]. Science China Press,2005,50(S1):51−55.

[14] 宋 昱,姜 波,李凤丽,等. 低-中煤级构造煤纳米孔分形模型适用性及分形特征[J]. 地球科学,2018,43(5):1611−1622. SONG Yu,JIANG Bo,LI Fengli,et al. Applicability of fractal models and nanopores’ fractal characteristics for low-middle rank tectonic deformed coals[J]. Earth Science,2018,43(5):1611−1622.

[15] 杨师宇,姚艳斌,魏 韧,等. 乌鲁木齐河东矿区煤储层渗流孔孔隙分形特征研究[J]. 煤炭科学技术,2020,48(8):175−183. doi: 10.13199/j.cnki.cst.2020.08.022 YANG Shiyu,YAO Yanbin,WEI Ren,et al. Study on fractal characteristics of seepage pores of coal reservoirs in Hedong Mining Area of Urumqi[J]. Coal Science and Technology,2020,48(8):175−183. doi: 10.13199/j.cnki.cst.2020.08.022

[16] 降文萍,宋孝忠,钟玲文. 基于低温液氮实验的不同煤体结构煤的孔隙特征及其对瓦斯突出影响[J]. 煤炭学报,2011,36(4):609−614. doi: 10.13225/j.cnki.jccs.2011.04.021 JIANG Wenping,SONG Xiaozhong,ZHONG Lingwen. Research on the pore properties of different coal body structure coals and the effects on gas outburst based on thelow-temperature nitrogen adsorption method[J]. Journal of China Coal Society,2011,36(4):609−614. doi: 10.13225/j.cnki.jccs.2011.04.021

[17] 金 毅,赵梦余,刘顺喜,等. 基于压汞法的煤基质压缩对孔隙分形特征的影响[J]. 中国煤炭,2018,44(8):103−109. doi: 10.19880/j.cnki.ccm.2018.08.020 JIN Yi,ZHAO Mengyu,LIU Shunxi,et al. Study on the effect of coal matrix compression on fractal characteristics of pore structures by mercury intrusion method[J]. China Coal,2018,44(8):103−109. doi: 10.19880/j.cnki.ccm.2018.08.020

[18] EVERETT D H. Manual of symbols and terminology for physicochemical quantities and units, appendix II: definitions, terminology and symbols in colloid and surface chemistry[J]. Pure and Applied Chemistry,1972,31(4):577−638.

[19] HODOT B B. Outburst of coal and coalbed gas (Chinese Translation)[M]. Beijing: China Industry Press, 1966: 10−50.

[20] HOU S,WANG X,WANG X,et al. Pore structure characterization of low volatile bituminous coals with different particle size and tectonic deformation using low pressure gas adsorption[J]. International Journal of Coal Geology,2017,183:1−13. doi: 10.1016/j.coal.2017.09.013

[21] VISHNYAKOV A,RAVIKOVITCH PI,NEIMARK A. Molecular level models for CO2 sorption in nanopores[J]. Langmuir,1999,15(25):8736−8742.

[22] WANG F,LI S. Determination of the surface fractal dimension for porous media by capillary condensation[J]. Industrial & Engineering Chemistry Research,1997,36(5):1598−1602.

[23] PFEIFER P,AVNIR D. Chemistry nonintegral dimensions between two and three[J]. Journal of Chemical Physics,1983,79(7):3369−3558.

[24] SING K S. IUPAC Recommendations 1984: reporting physisorption data for gas/solid systems with special reference to the determination of surface area and porosity[J]. Pure and Applied Chemistry,1985:603−619.

[25] JIN Y,ZHAO M,ZHENG J,et al. Characterizing the complexity assembly of pore structure in a coal matrix: principle, methodology, and modeling application[J]. Journal of Geophysical Research: Solid Earth,2020,125(12):e2020JB020110.

[26] 孟召平,张 昆,沈 振. 构造煤与原生结构煤中甲烷扩散性能差异性分析[J]. 煤田地质与勘探,2022,50(3):102−109. doi: 10.12363/issn.1001-1986.21.12.0799 MENG Zhaoping,ZHANG Kun,SHEN Zhen. Difference analysis of methane diffusion properties between tectonic coal and primary coal[J]. Coal Geology & Exploration,2022,50(3):102−109. doi: 10.12363/issn.1001-1986.21.12.0799

-

期刊类型引用(5)

1. 刘素平,蔡的妹,黄文辉. 沁水盆地深煤层煤层气资源潜力评价. 煤炭与化工. 2025(02): 103-107 .  百度学术

百度学术

2. 张亚飞,李思达,乐平,段静,宁伟,王志彬. 上部含水层对煤层气开发效果影响的数值模拟研究. 非常规油气. 2023(02): 63-72 .  百度学术

百度学术

3. 林海飞,季鹏飞,孔祥国,李树刚,白杨,龙航,李柏,和递. 我国低渗煤层井下注气驱替增流抽采瓦斯技术进展及前景展望. 煤炭学报. 2023(02): 730-749 .  百度学术

百度学术

4. 余杰,秦瑞宝,黄涛,李利. 基于核磁共振技术的煤层含气量评价方法. 煤炭科学技术. 2023(11): 158-165 .  本站查看

本站查看

5. 贺云超,翁炜,冯美贵,徐军军,郭强,吴烁,蒋睿. 煤层气水平井高效钻进关键技术研究——以山西沁水盆地某煤层气区块为例. 钻探工程. 2023(S1): 345-350 .  百度学术

百度学术

其他类型引用(2)

下载:

下载: