Adaptive intelligent coupling control of hydraulic support and working face system for 6−10 m super high mining in thick coal seams

-

摘要:

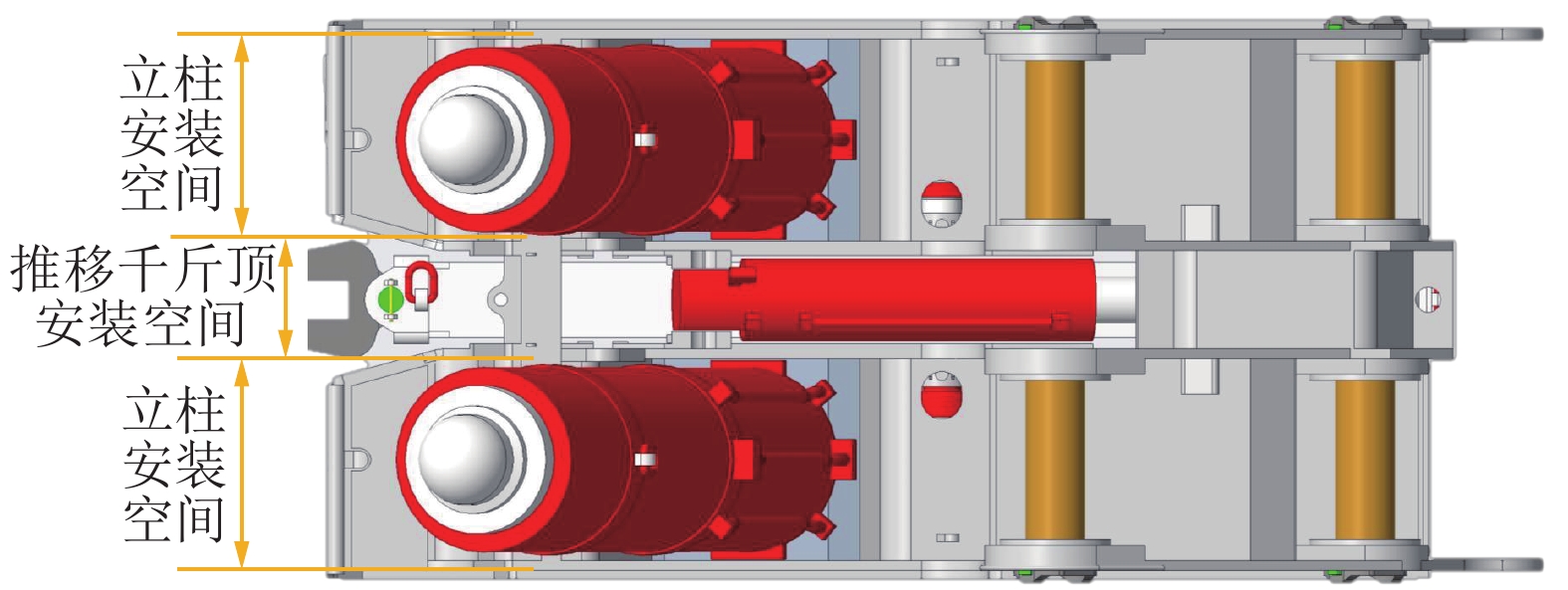

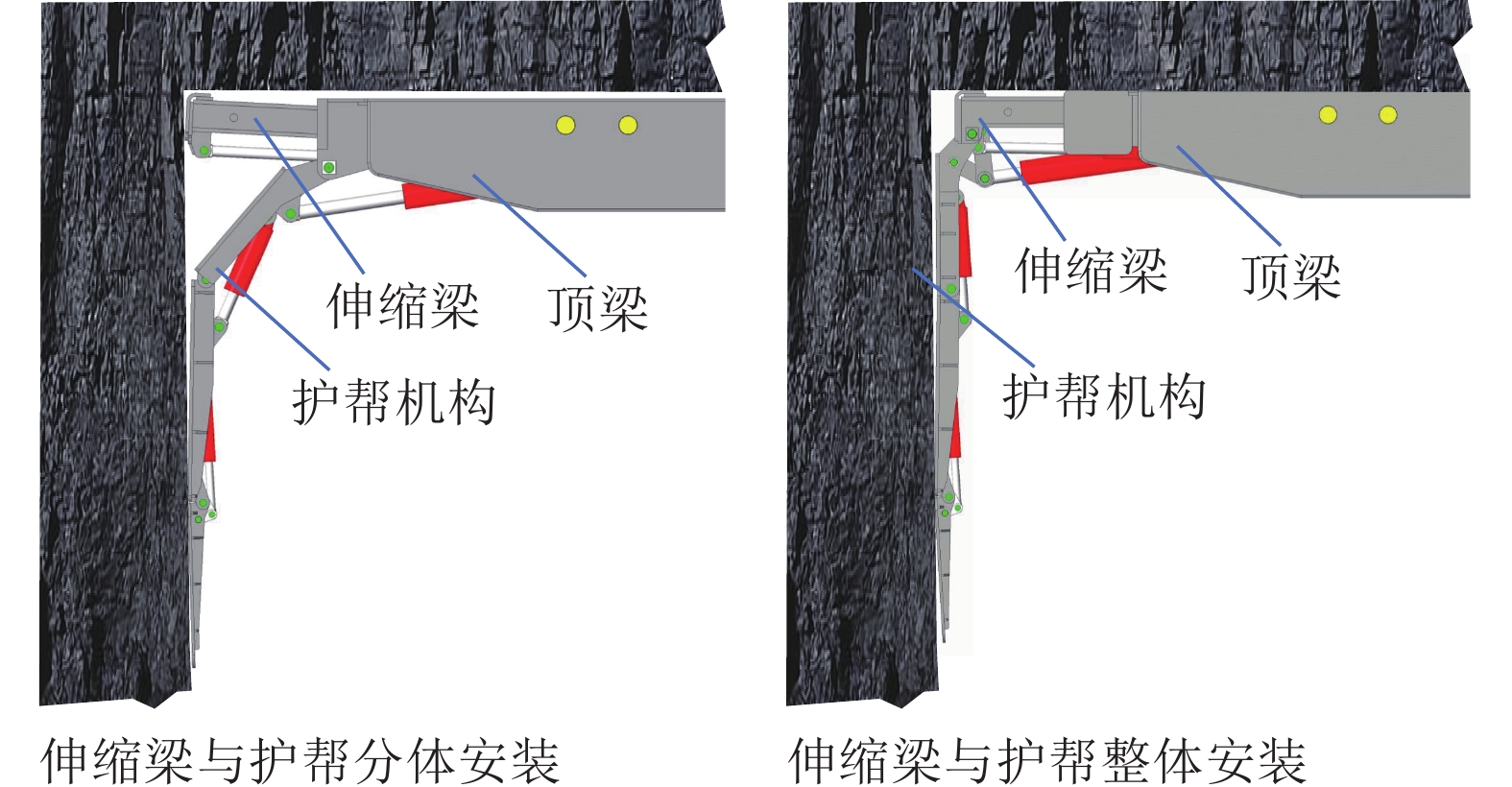

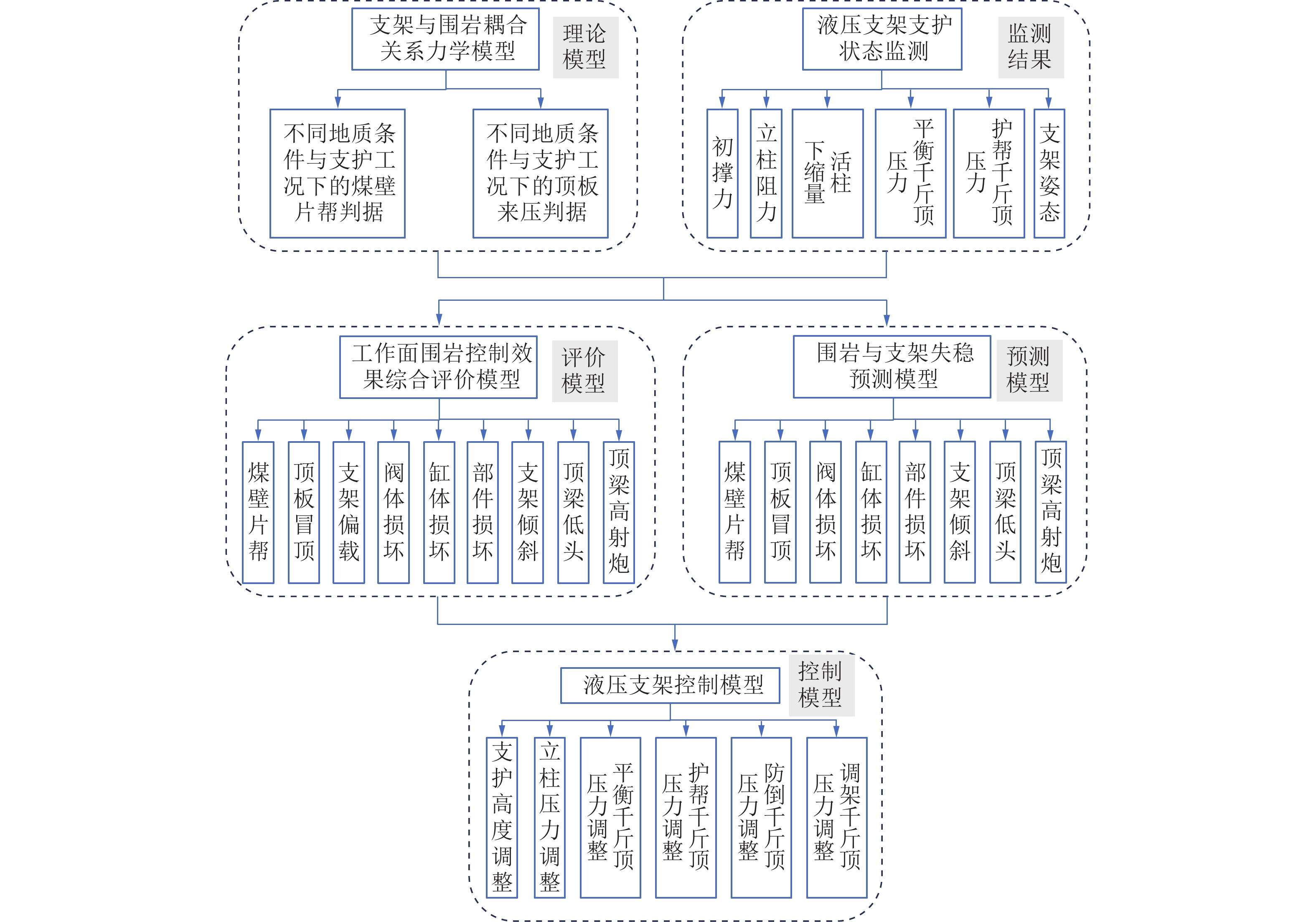

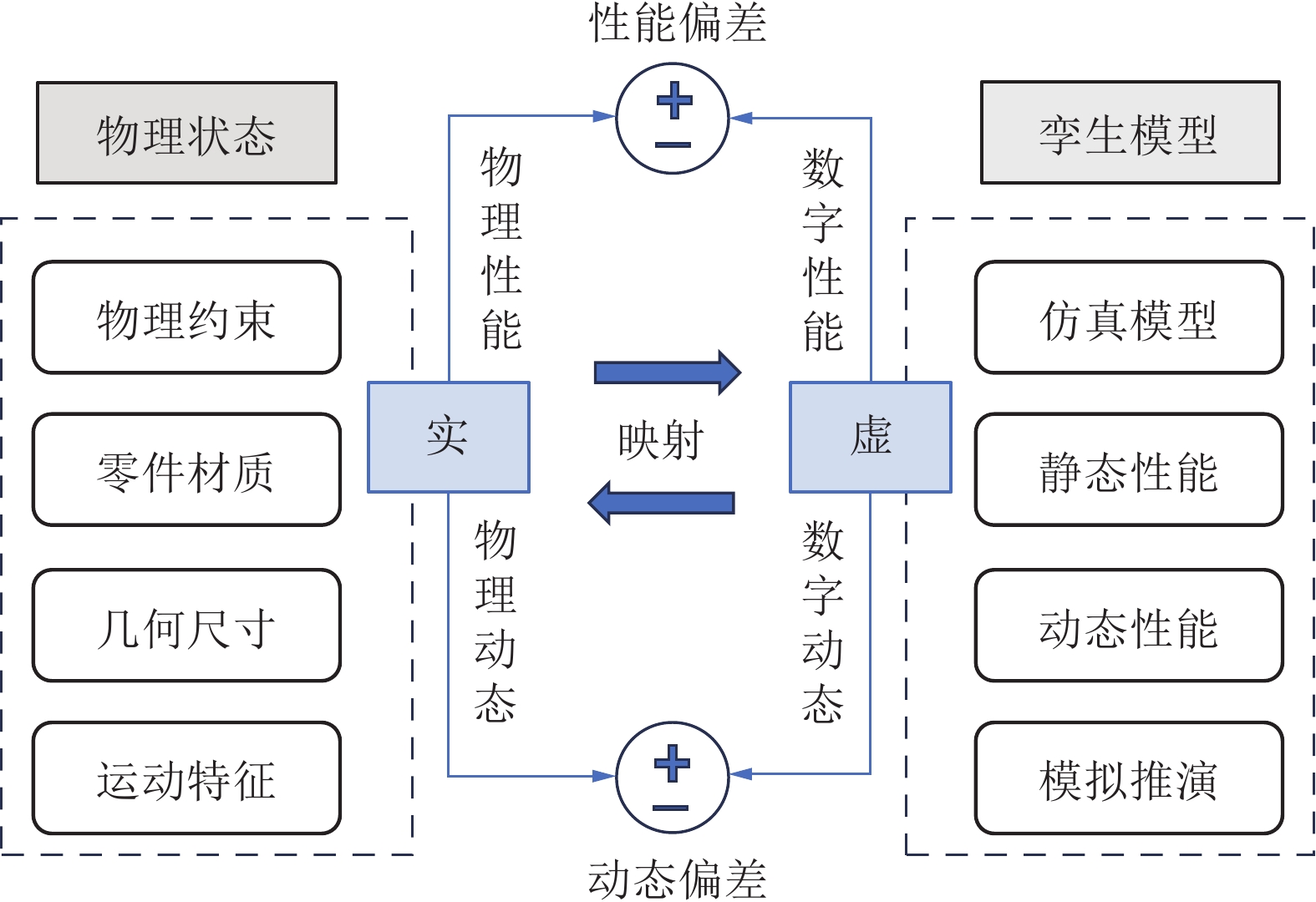

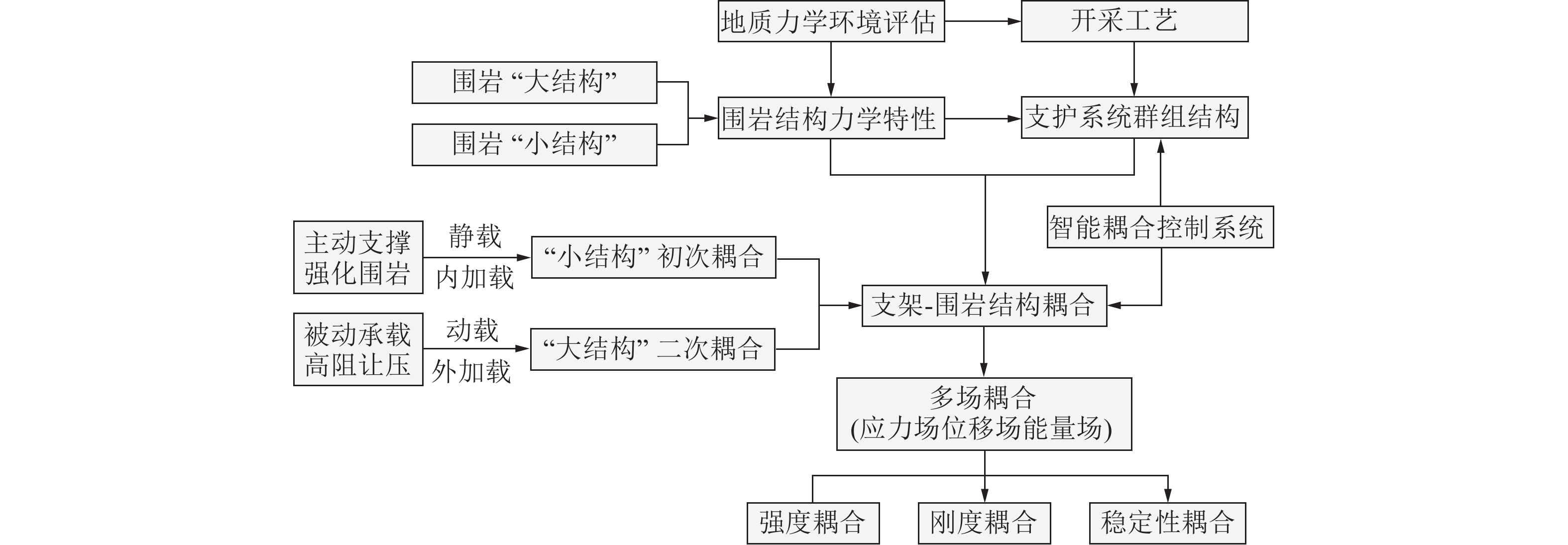

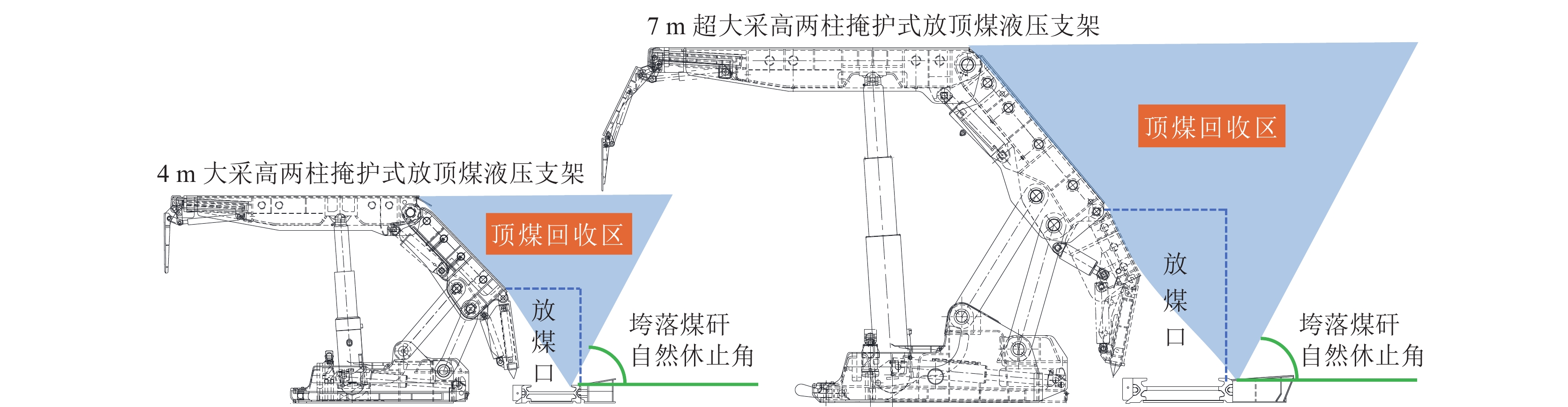

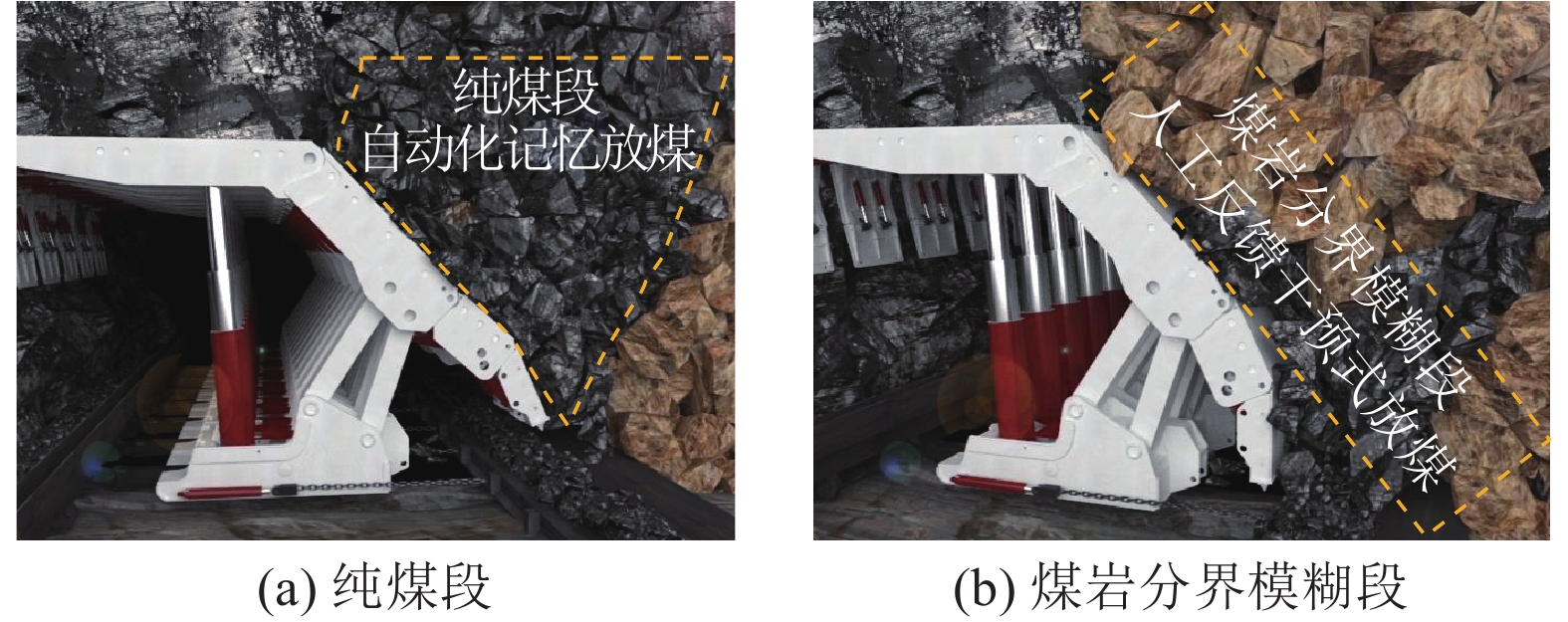

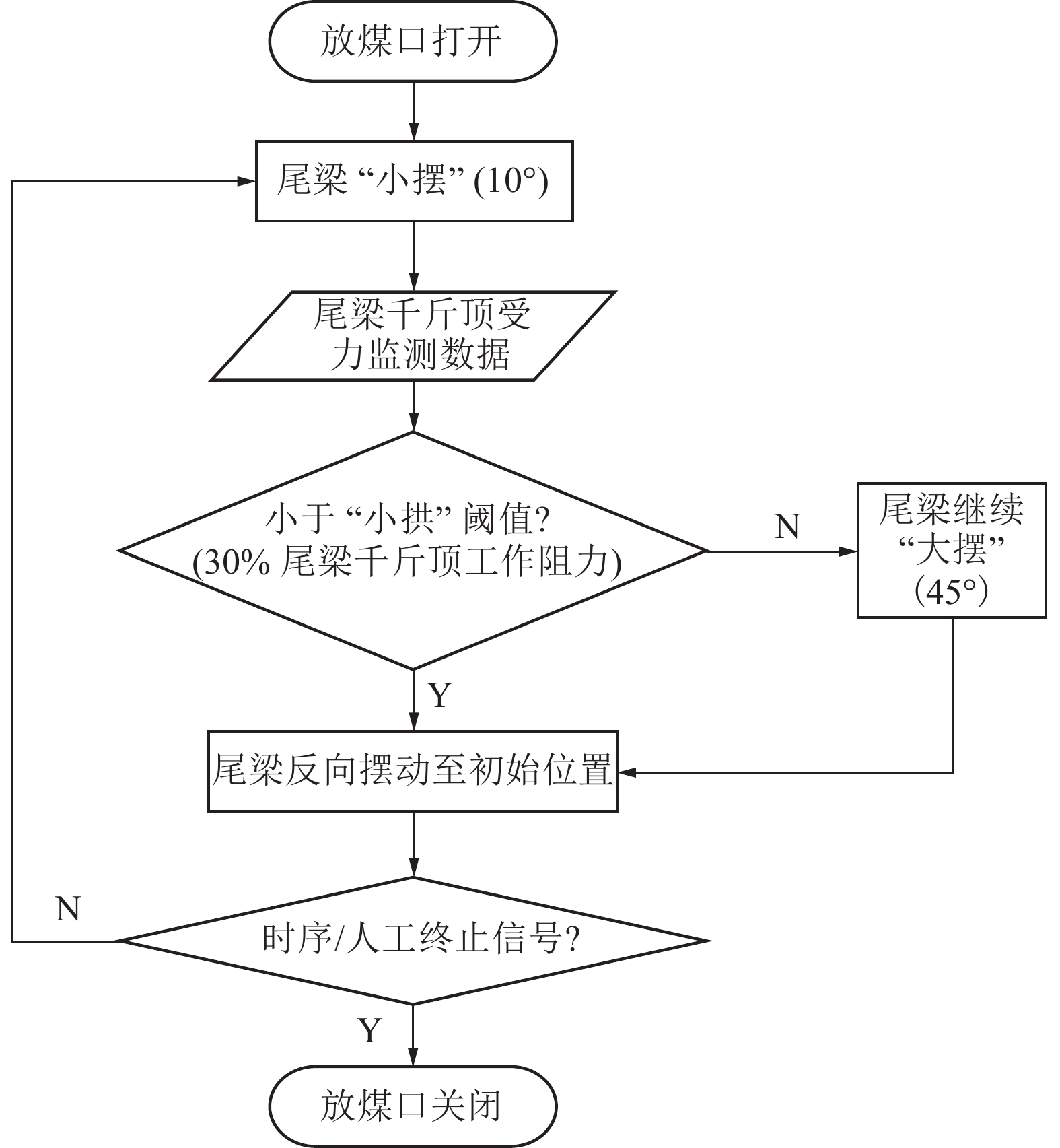

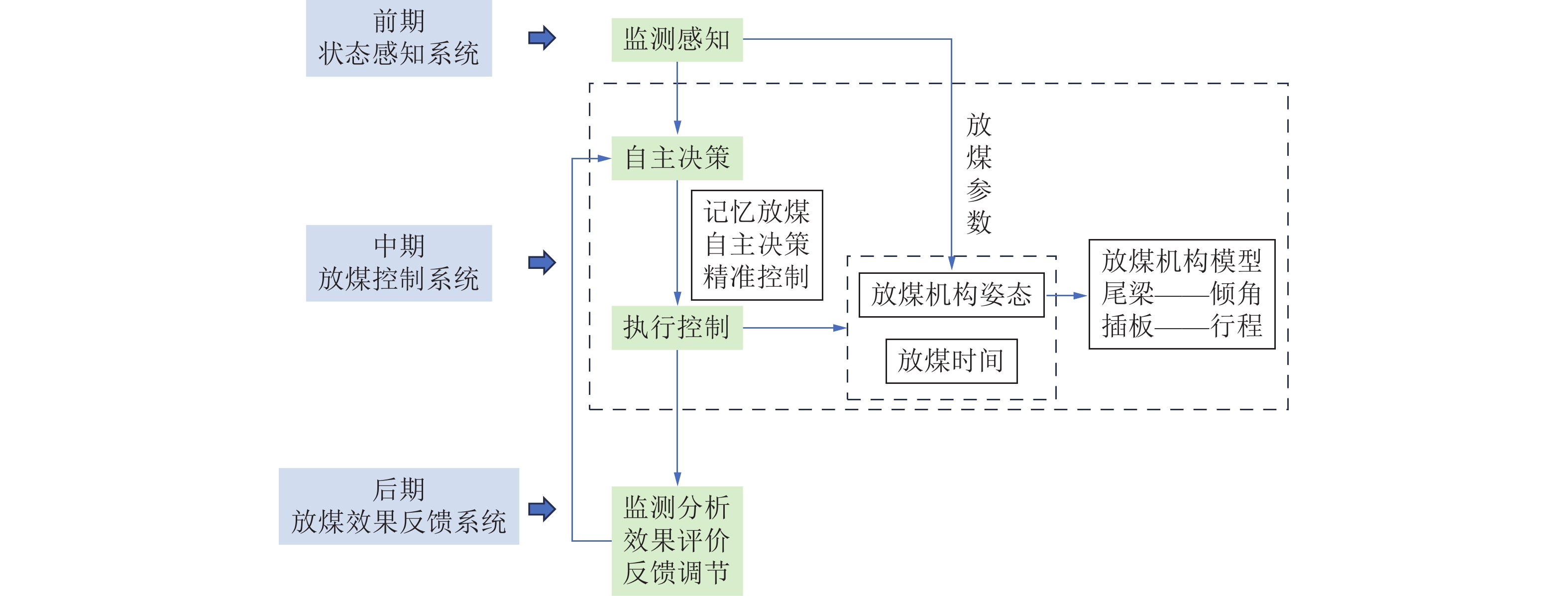

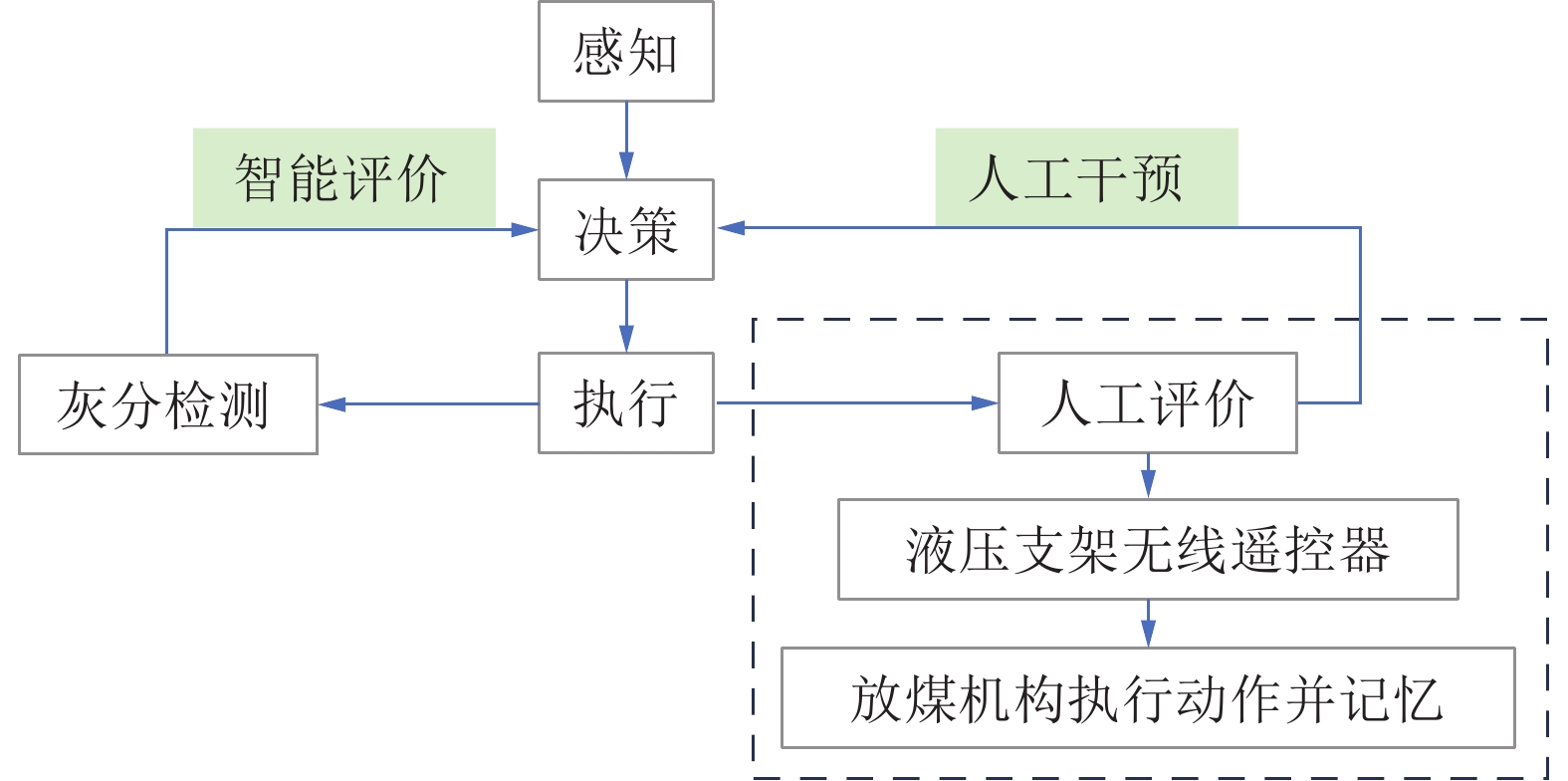

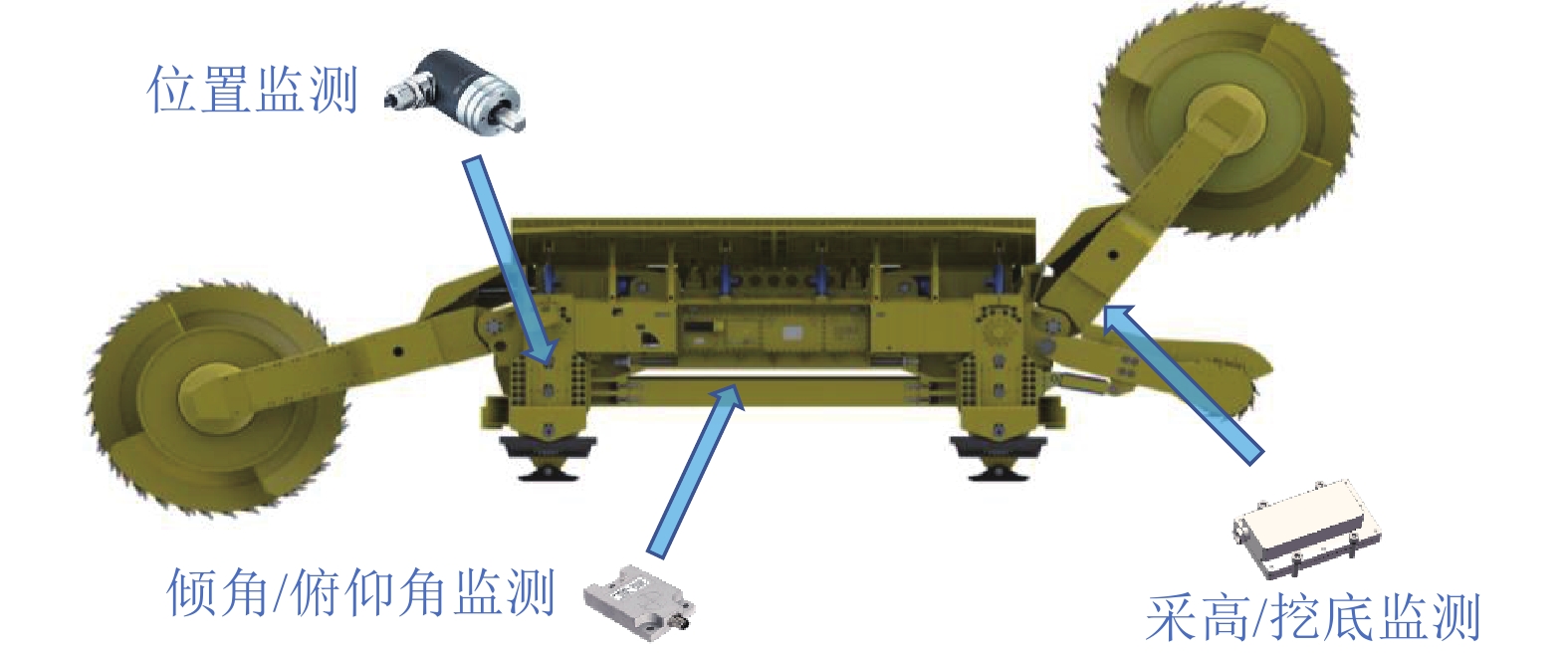

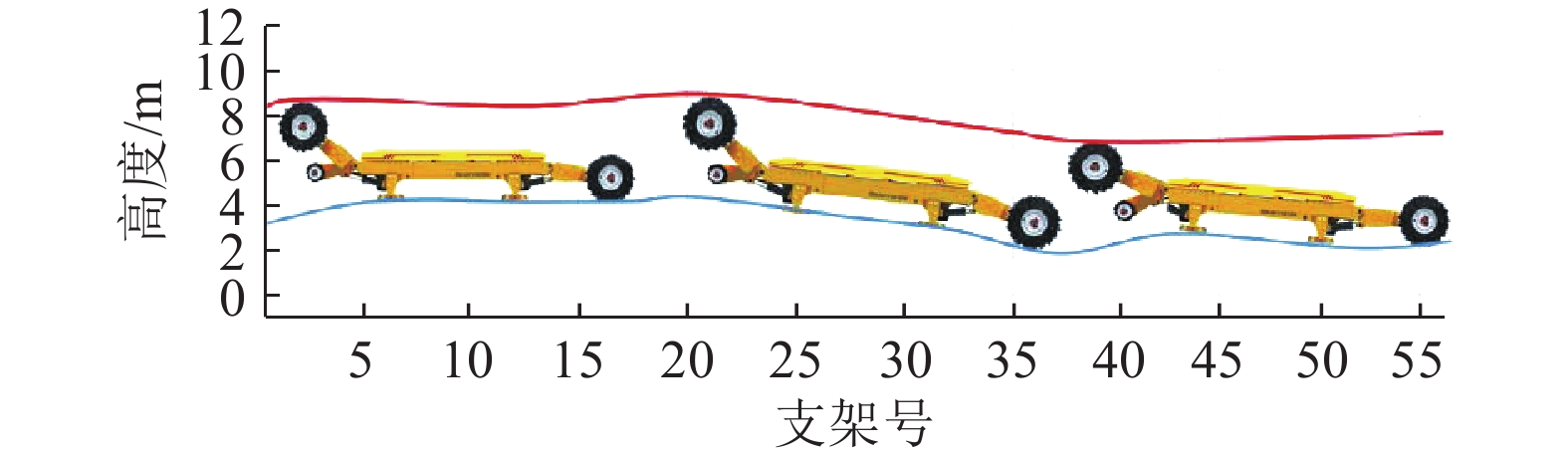

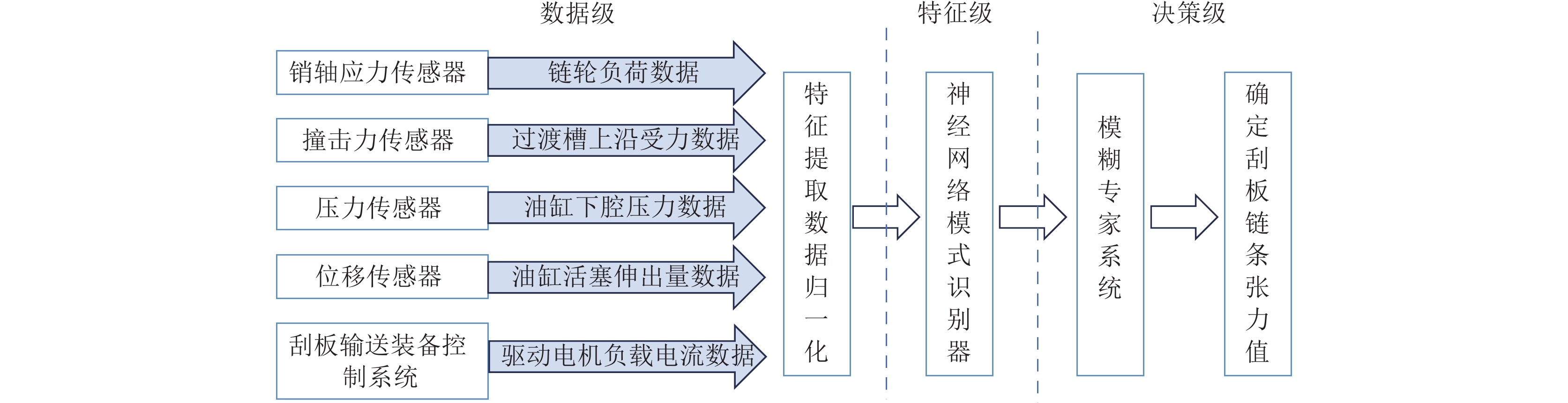

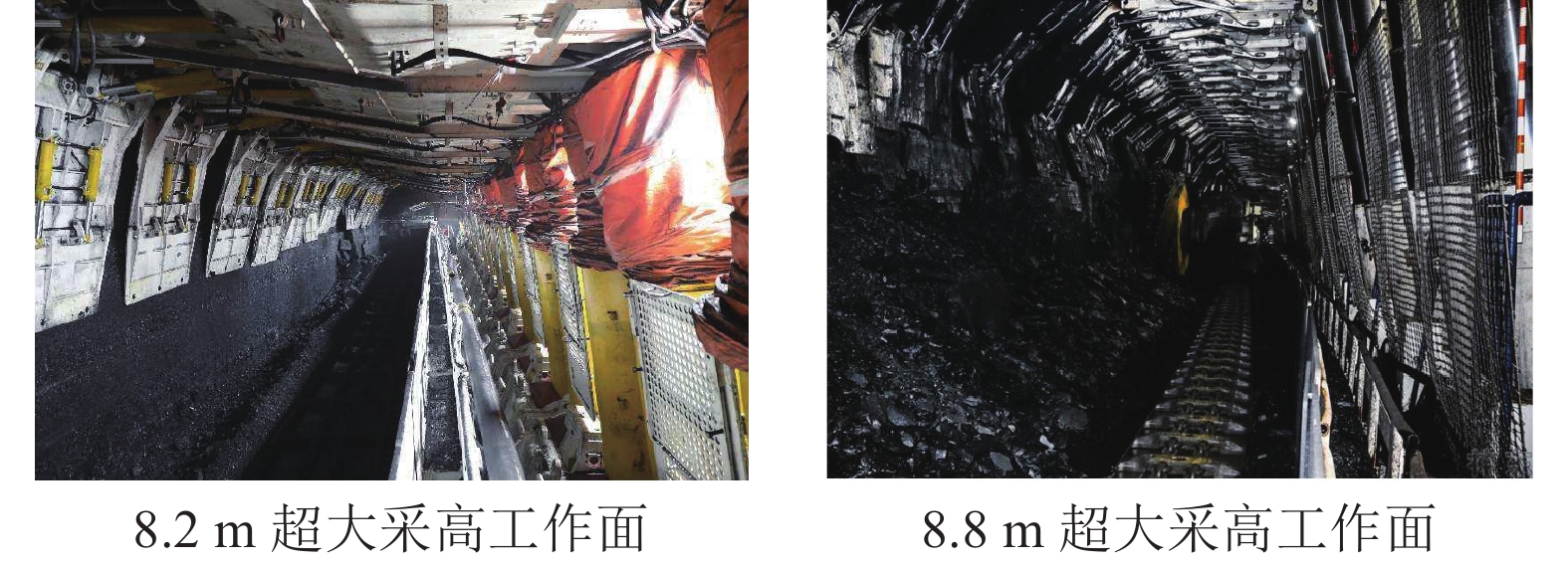

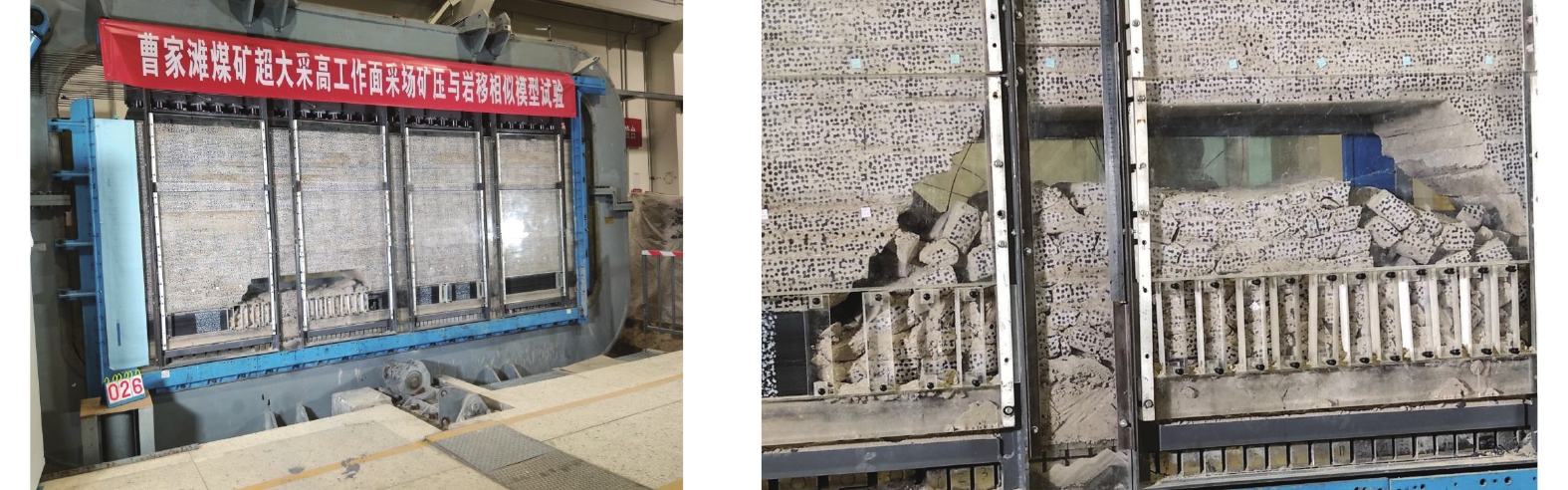

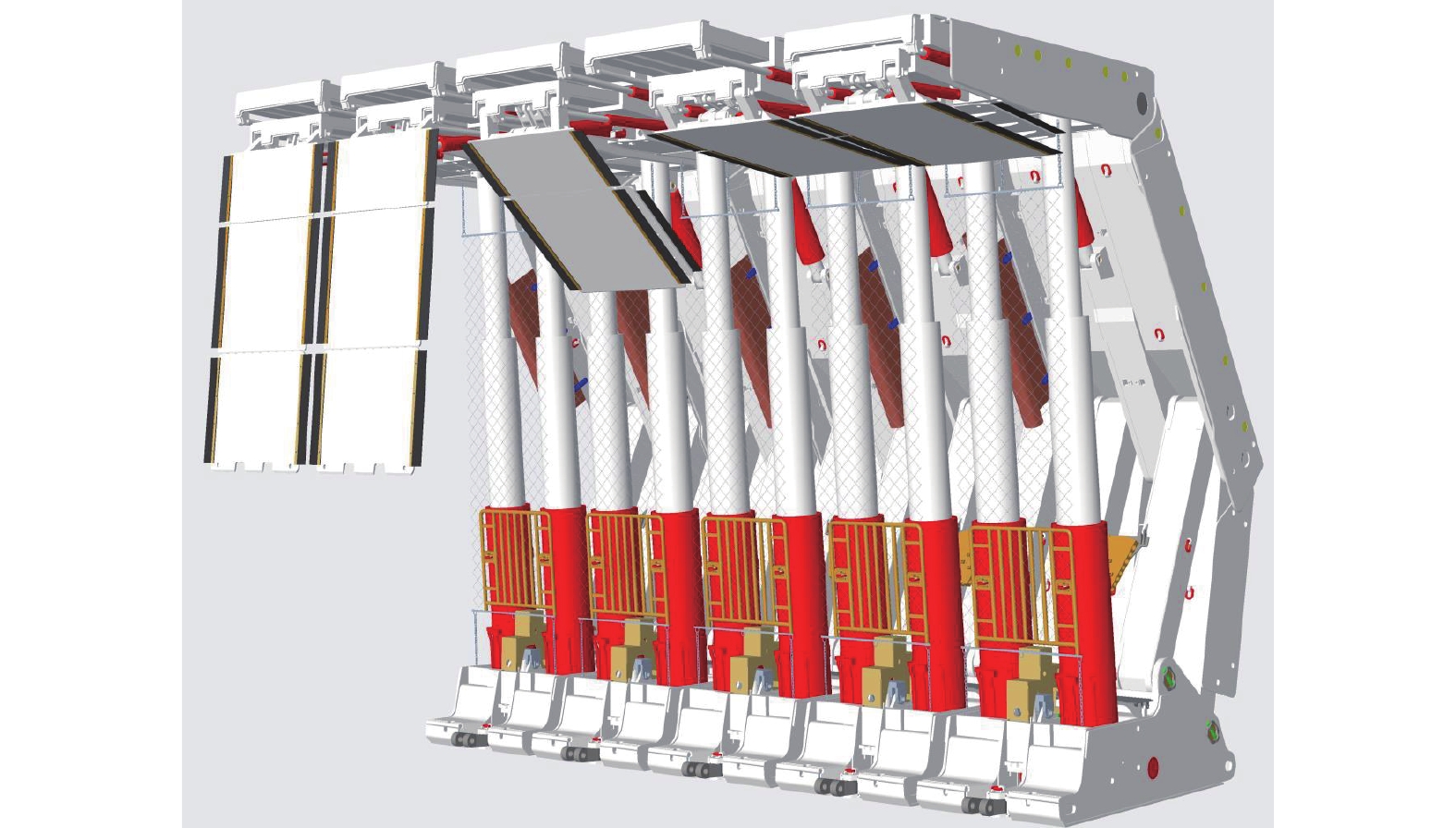

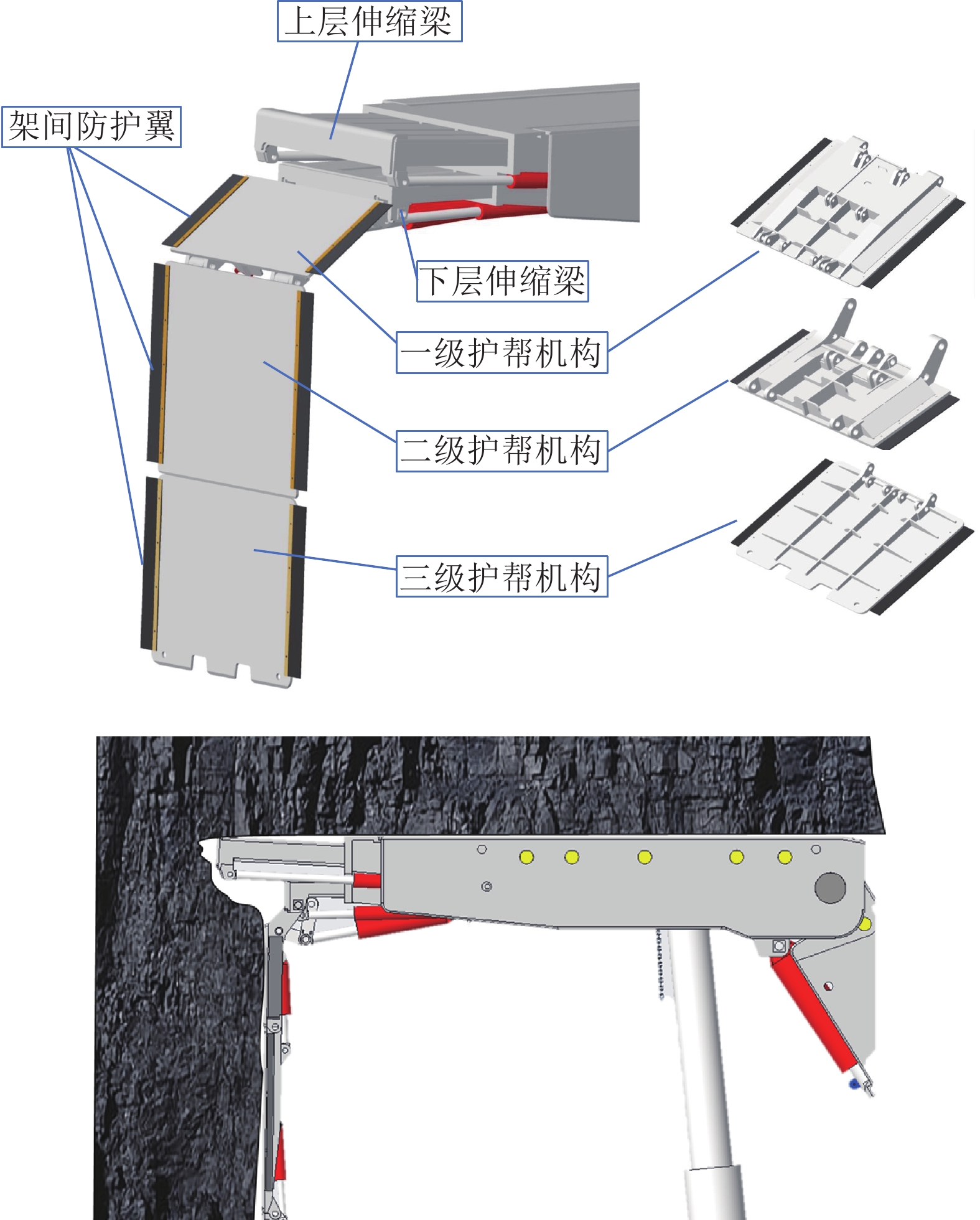

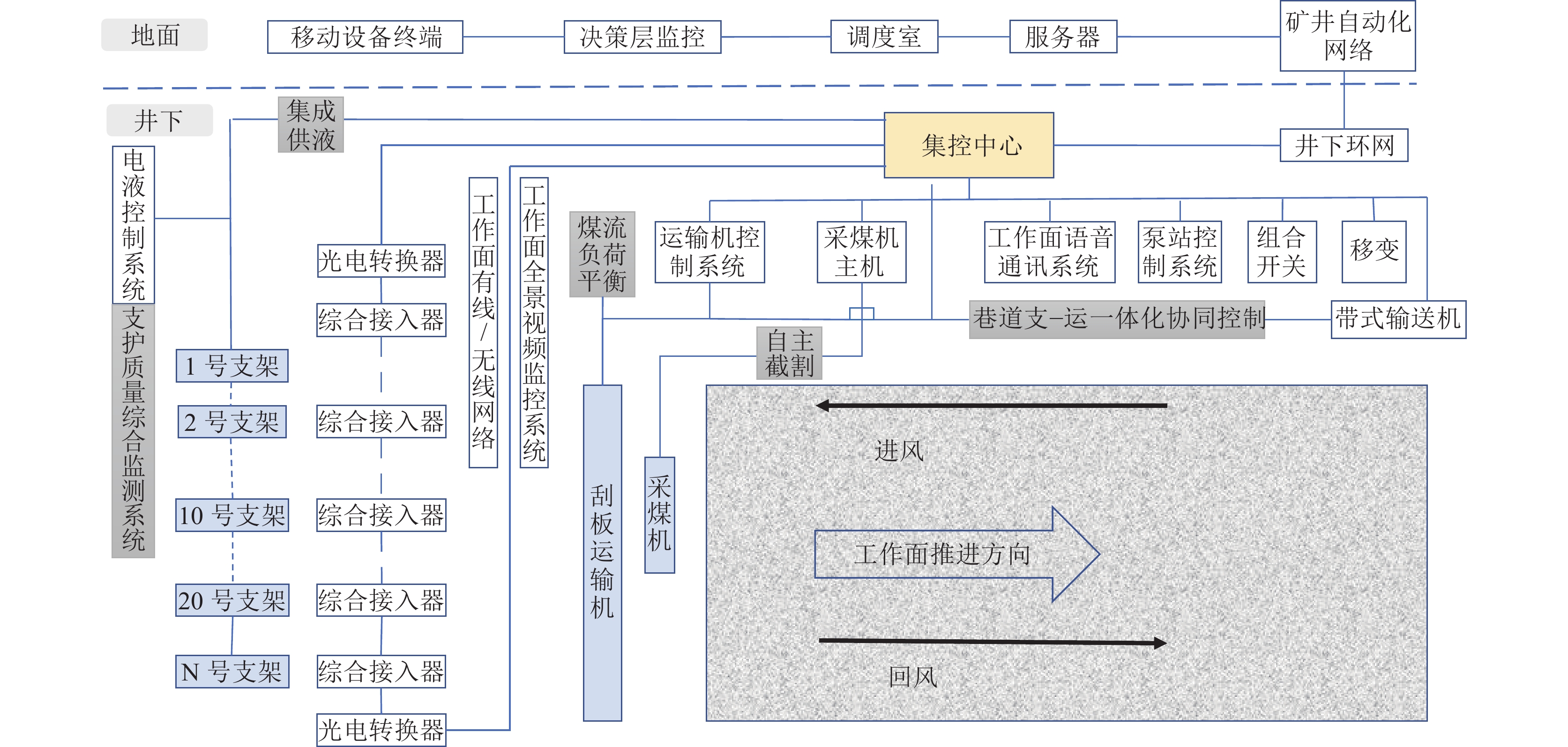

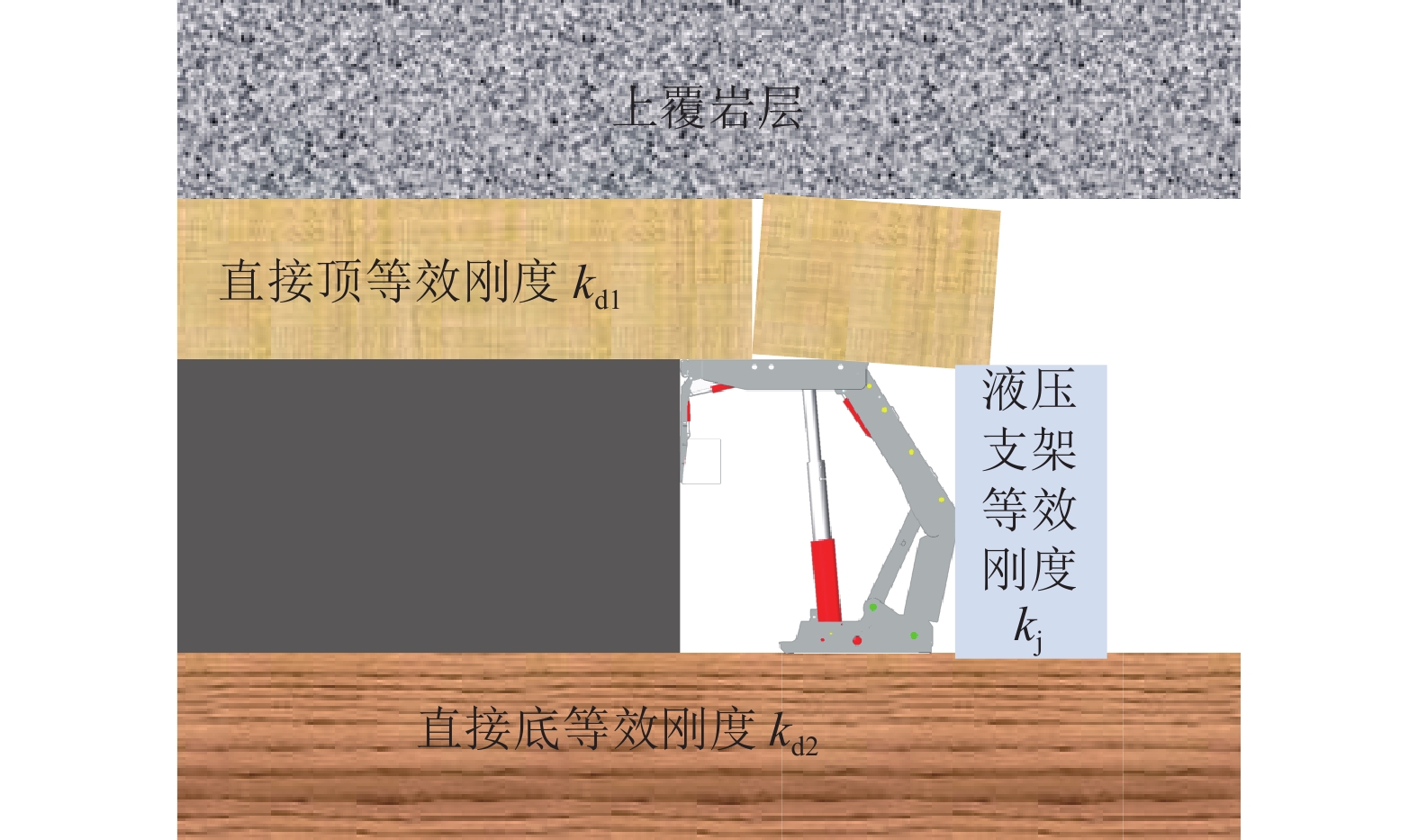

厚煤层储量及产量占我国原煤总储量及产量的一半,通过梳理厚煤层开采历史沿革,总结了我国厚煤层开采40年来的技术及装备研发实践,系统分析了以高端大采高液压支架及围岩智能耦合理论为代表的6~10 m大采高综采高效智能化综采技术及装备研究进展,提出了大采高支护理论及围岩智能耦合控制的突破是厚煤层一次开采高度突破的首要因素,完善的感知体系建立是液压支架自适应支护的前提,数字技术的应用为大采高工作面高效推进及装备智能协同控制提供了新的技术途径;阐明了大采高综放液压支架与围岩耦合关系,剖析了采高增加对硬煤层冒放性的有利影响,提出了基于煤矸识别、放煤机构控制的“纯煤段记忆放煤+煤岩分界模糊段人工反馈式干预放煤”的智能放煤控制策略;分析了大采高开采“采–运”协同智能耦合控制关键技术,构建了基于采煤机牵引速度与刮板输送机链速间联动调节的工作面装备间多机异构耦合自适应协同控制模型;研发了厚煤层开采中10 m超大采高液压支架,分析了厚煤层开采不断突破开采高度极限的新认识,从开采装备、控制系统等方面提出厚煤层一次开采高度的突破的研发方向。

Abstract:The reserves and production of thick coal seams account for half of the total reserves and production of raw coal in China. By combing the history of thick coal seam mining, we summarize the technology and equipment development practice of thick coal seam mining in China over the past 40 years, explained the development history from the introduction of large mining height technology and equipment to the successful development of the first domestic large mining height hydraulic support to the world’s first 8m-class large mining height comprehensive mining face production. Summarizing the research progress of high-efficiency and intelligent comprehensive mining technology and equipment for large mining height, represented by high-end large mining height hydraulic support and intelligent coupling theory of surrounding rock. Clarifying that the breakthrough of large mining height support theory and intelligent coupling control of the surrounding rock is the primary factor for the breakthrough of the primary mining height of thick coal seam. The establishment of a perfect perception system is a prerequisite for the adaptive support of the hydraulic support. The application of digital technology provides a new technical way for efficient advancement of large mining face and intelligent cooperative control of equipment. Clarified the coupling relationship between large mining height integrated release hydraulic support and surrounding rocks, illustrates the favorable influence of increasing mining height on hard coal seam venting, then an intelligent coal discharge control strategy based on coal gangue identification and coal discharge mechanism control, which includes “pure coal segment memory coal discharge + coal rock boundary fuzzy segment manual feedback intervention coal discharge” is proposed. The key technology of intelligent coupling control for large-scale mining and transportation cooperation is pointed out. It is pointed out that the multi machine heterogeneous coupling adaptive collaborative control between working face equipment is a key factor for the success of intelligent mining. The linkage adjustment between the traction speed of the shearer and the chain speed of the scraper conveyor is a necessary means to adapt to large-scale mining and transportation. Then research and development directions for breakthroughs in the height of primary mining of thick coal seams from the aspects of mining equipment, control systems are proposed.

-

-

表 1 ZYA29000/45/100D液压支架临界稳定角

Table 1 Critical stable angle of ZYA29000/45/100D hydraulic support

支架状态 支架临界稳定角/(°) 最低高度4.5 m 最高高度10 m 前倾失稳 38.9 16.5 后倾失稳 40.5 25.8 横向失稳 23.6 11.8 -

[1] 王国法,杜毅博,徐亚军,等. 中国煤炭开采技术及装备 50 年发展与创新实践:纪念《煤炭科学技术》创刊 50 周年[J]. 煤炭科学技术,2023,51(1):1−18. WANG Guofa,DU Yibo,XU Yajun,et al. Development and innovation practice of China coal mining technology and equipment for 50 years:Commemorate the 50th anniversary of the publication of Coal Science and Technology[J]. Coal Science and Technology,2023,51(1):1−18.

[2] 宋选民,朱德福,王仲伦,等. 我国煤矿综放开采40年:理论与技术装备研究进展[J]. 煤炭科学技术,2021,49(3):1−29. SONG Xuanmin,ZHU Defu,WANG Zhonglun,et al. Advances on longwall fully-mechanized top-coal caving mining technology in China during past 40 years:theory,equipment and approach[J]. Coal Science and Technology,2021,49(3):1−29.

[3] WANG Guofa,REN Huaiwei,ZHAO Guorui,et al. Research and practice of intelligent coal mine technology systems in China[J]. International Journal of Coal Science & Technology,2022,9:24.

[4] 许永祥,王国法,张传昌,等. 特厚坚硬煤层超大采高综放开采合理采高研究与实践[J]. 采矿与安全工程学报,2020,37(4):715−722. XU Yongxiang,WANG Guofa,ZHANG Chuanchang,et al. Investigation and practice of the reasonable cutting height at longwall top coal caving face with super-large mining height in hard and extra-thick coal seams[J]. Journal of Mining & Safety Engineering,2020,37(4):715−722.

[5] 韩会军,曾明胜,闫 跃,等. 硬煤超大采高智能化综放开采关键技术装备研究[J]. 煤炭工程,2020,52( 4) :1−5. HAN Huijun,ZENG Mingsheng,YAN Yue,et al. Key Technologies and Equipment for Intelligent Fully Mechanized Caving Mining of Hard Coal with Super Large Mining Height[J]. Coal Engineering,2020,52( 4) :1−5.

[6] 任怀伟,巩师鑫,刘新华,等. 煤矿千米深井智能开采关键技术研究与应用[J]. 煤炭科学技术,2021,49(4):149-158. REN Huaiwei,GONG Shixin,LIU Xinhua,et al. Research and application on key techniques of intelligent mining for kilo-meter deep coal mine[J]. Coal Science and Technology,2021,49(4):149−158.8

[7] 王国法,庞义辉. 特厚煤层大采高综采综放适应性评价和技术原理[J]. 煤炭学报,2018,43(1):33−42. WANG Guofa,PANG Yihui. Full-mechanized coal mining and caving mining method evaluation and key technology for thick coal seam[J]. Journal of China Coal Society,2018,43(1):33−42

[8] LYU Huayong,CHENG Zhanbo,LIU Fei. Study on the mechanism of a new fully mechanical mining method for extremely thick coal seam[J]. International Journal of Rock Mechanics & Mining Sciences,2021,142:1−12

[9] 王国法,庞义辉. 液压支架与围岩耦合关系及应用[J]. 煤炭学报,2015,40(1):30−34. WANG Guofa,PANG Yihui. Relationship between hydraulic support and surrounding rock coupling and its application[J]. Journal of China Coal Society,2015,40(1):30−34.

[10] 杨胜利,王兆会,吕华永. 大采高采场周期来压顶板结构稳定性及动载效应分析[J],采矿与安全工程学报,2019,36(2):315-321. YANG Shengli,WANG Zhaohui,LYU Huayong. Analysis of structure stability of main roof and dynamic loading effect during periodic weighting in a large mining height stope [J]. Journal of Mining & Safety Engineering,2019,36(2):315-321.

[11] 王国法,庞义辉,李明忠,等. 超大采高工作面液压支架与围岩耦合作用关系[J]. 煤炭学报,2017,42(2):518−526. WANG Guofa,PANG Yihui,LI Mingzhong,et al. Hydraulic support and coal wall coupling relationship in ultra large height mining face[J]. Journal of China Coal Society,2017,42(2):518−526.

[12] 韩会军. 超大采高液压支架稳定性分析[J]. 煤矿机械,2017,38(4):61−63. HAN Huijun. Stability Analysis of Powered Support with Large Mining Height[J]. Coal Mine Machinery,2017,38(4):61−63.

[13] 许永祥. 特厚坚硬煤层超大采高综放开采支架–围岩结构耦合关系研究[D]. 北京:煤炭科学研究总院,2020. XU Yongxiang. Study on structure coupling between hydraulic roof support and surrounding rock in extra-thick and hard coal seam with super-large mining height and longwall top coal caving method[D]. Beijing:China Coal Research Institute,2020.

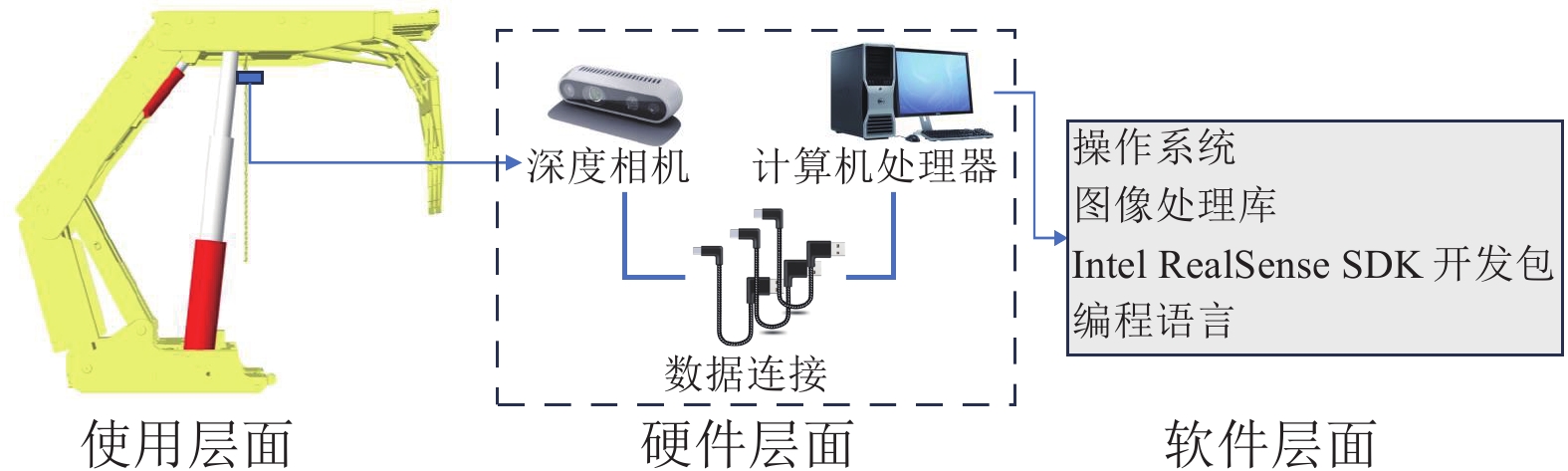

[14] 任怀伟,李帅帅,赵国瑞,等. 基于深度视觉原理的工作面液压支架支撑高度与顶梁姿态角测量方法研究[J]. 采矿与安全工程学报,2022,39(1):11. REN Huaiwei,LI Shuaishuai,ZHAO Guorui. et al. Measurement method of support height and roof beam posture angles for working face hydraulic support based on depth vision[J]. Journal of Mining & Safety Engineering,2022,39(1):11.

[15] 满溢桥. 液压支架护帮板与采煤机滚筒截割干涉监测技术研究[D]. 徐州:中国矿业大学,2019. MAN Yiqiao. Research on the monitoring technology of cutting interference between hydraulic support face guard and shearer drum[D]. Xuzhou:China University of Mining and Technology,2019.

[16] 许永祥,王国法,李明忠,等. 特厚坚硬煤层超大采高综放开采支架–围岩结构耦合关系[J]. 煤炭学报,2019,44(6):1666−1678. XU Yongxiang,WANG Guofa,LI Mingzhong,et al. Structure coupling between hydraulic roof support and surrounding rock in extra-thick and hard coal seam with super large cutting height and longwall top coal caving operation[J]. Journal of China Coal Society,2019,44(6):1666−1678.

[17] Hongfei DUAN,Lijuan ZHAO,Haiyan YANG,et al. Development of 3D top coal caving angle model for fully mechanized extra-thick coal seam mining[J]. International Journal of Mining Science and Technology,2022,32:1145−1152. doi: 10.1016/j.ijmst.2022.08.010

[18] 马 英. 基于尾梁振动信号采集的煤矸识别智能放煤方法研究[J]. 煤矿开采,2016,21(4):40−42. MA Ying. Intelligent coal caving with gangue identification based on tail beam vibration signal collection[J]. Coal Mining Technology,2016,21(4):40−42.

[19] 马 英. 综放工作面自动化放顶煤系统研究[J]. 煤炭科学技术,2013,41(11):22−24. MA Ying. Study on automatic top coal caving system in fully-mechanized coal caving face[J]. Coal Science and Technology,2013,41(11):22−24.

[20] 牛剑峰. 综采放顶煤工作面自动放煤控制系统研究[J]. 工矿自动化,2018,44(6):27−30. NIU Jianfeng. Research on automatic drawing control system on fully-mechanized coal face with sublevel caving[J]. Industry and Mine Automation,2018,44(6):27−30.

[21] 张 良,牛剑峰,代 刚,等. 综放工作面煤矸自动识别系统设计及应用[J]. 工矿自动化,2014,40(9):121−124. ZHANG Liang,NIU Jianfeng,DAI Gang,et al. Design of automatic identification system of coal and gangue for fully-mechanized coal caving working face and its application[J]. Industry and Mine Automation,2014,40(9):121−124.

[22] 许永祥,李申龙,王国法,等. 特厚坚硬煤层超大采高综放首采工作面智能化技术[J]. 煤炭科学技术,2020,48(7):186-194. XU Yongxiang,LI Shenlong,WANG Guofa, et al. Intelligent technology of first-mining face of longwall top-coal caving with super large cutting height in extra-thick and hard coal seam[J]. Coal Science and Technology,2020,48(7):186-194.

[23] 郜高峰,杜恩友,梁文立,等. 在线灰分检测仪在裴沟煤矿的应用[J]. 煤炭技术,2009,28(11):139−140. GAO Gaofeng,DU Enyou,LIANG Wenli,et al. Applicution of online ash instrumentation inspection instrument in peigou coal mine[J]. Coal Technology,2009,28(11):139−140.

[24] 王国法,庞义辉. 8.2 m 超大采高综采成套装备研制及应用[J]. 煤炭工程,2017,49(11):1−5. WANG. Guofa,PANG Yihui. Development and application of complete equipment for fully mechanized mining with 8. 2 m super-large mining height[J]. Coal Engineering,2017,49(11):1−5.

[25] 崔 耀,王旭峰,潘占仁. 上湾煤矿8.8m超大采高智能化综采控制系统研究与应用[J]. 智能矿山,2023,4(4):45−51. [26] 冀宏波,李玉福. 8.8 m超大采高综采工作面支架选型应用及顶板管理研究[J]. 中国煤炭,2020,46(7):92-96. JI Hongbo,LI Yufu. Research on supprot selection and roof management technology in 8.8 m multra-high fully mechanized mining face[J]. China Coal, 2020,46(7) :92-96.

-

期刊类型引用(5)

1. 郑寓超, 刘国磊, 崔嵛, 王泽东, 曲效成. 低透煤层巷道中心体突出预测与多参量关联性. 地下空间与工程学报. 2025(03)  百度学术

百度学术

2. 周玉军, 李振华, 李嘉诚. 低透气性坚硬煤层联合卸压增透关键技术研究. 煤炭科学技术. 2025(S1)  本站查看

本站查看

3. 赵洪宝 ,高璐 ,程辉 ,荆士杰 ,王乐 ,陈超男 . 基于开采高度对工作面覆岩裂隙演化影响的钻孔瓦斯抽采研究. 矿业科学学报. 2024(03): 435-445 .  百度学术

百度学术

4. 张通,胡艳婷,李印鹏. 基于PSO-BP神经网络的煤与瓦斯突出预测方法. 煤炭技术. 2023(11): 128-131 .  百度学术

百度学术

5. 李新宇. 五里堠煤业15号煤层瓦斯分布规律与突出危险性分析. 煤. 2022(03): 101-102 .  百度学术

百度学术

其他类型引用(0)

下载:

下载: