Quantitative characterization of pore structure in coal measure shales based on deep learning

-

摘要:

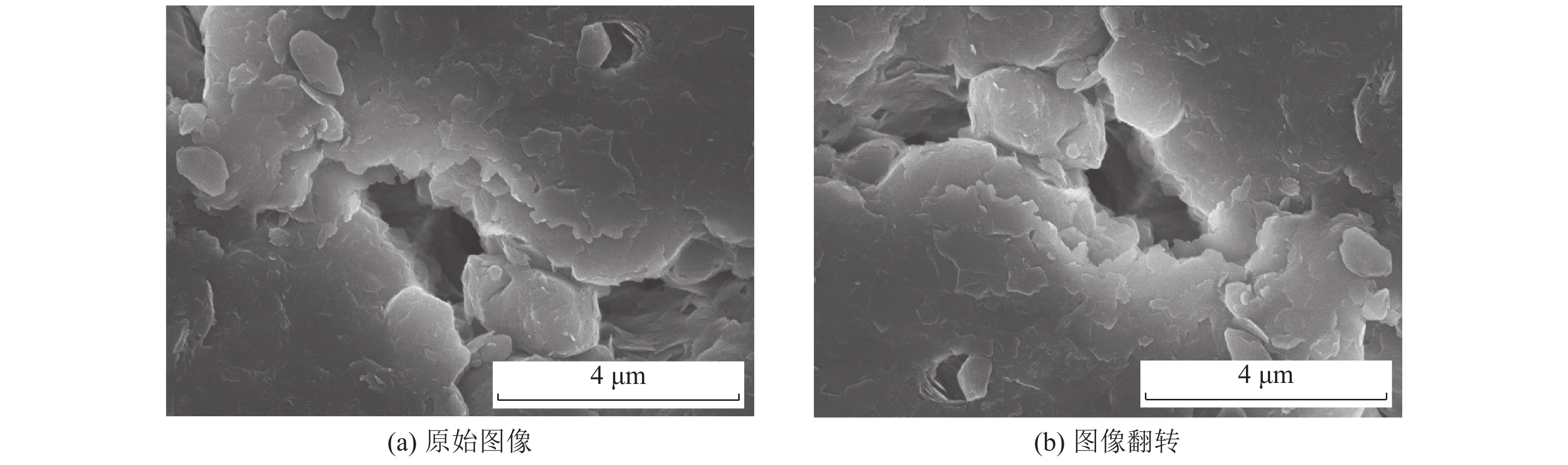

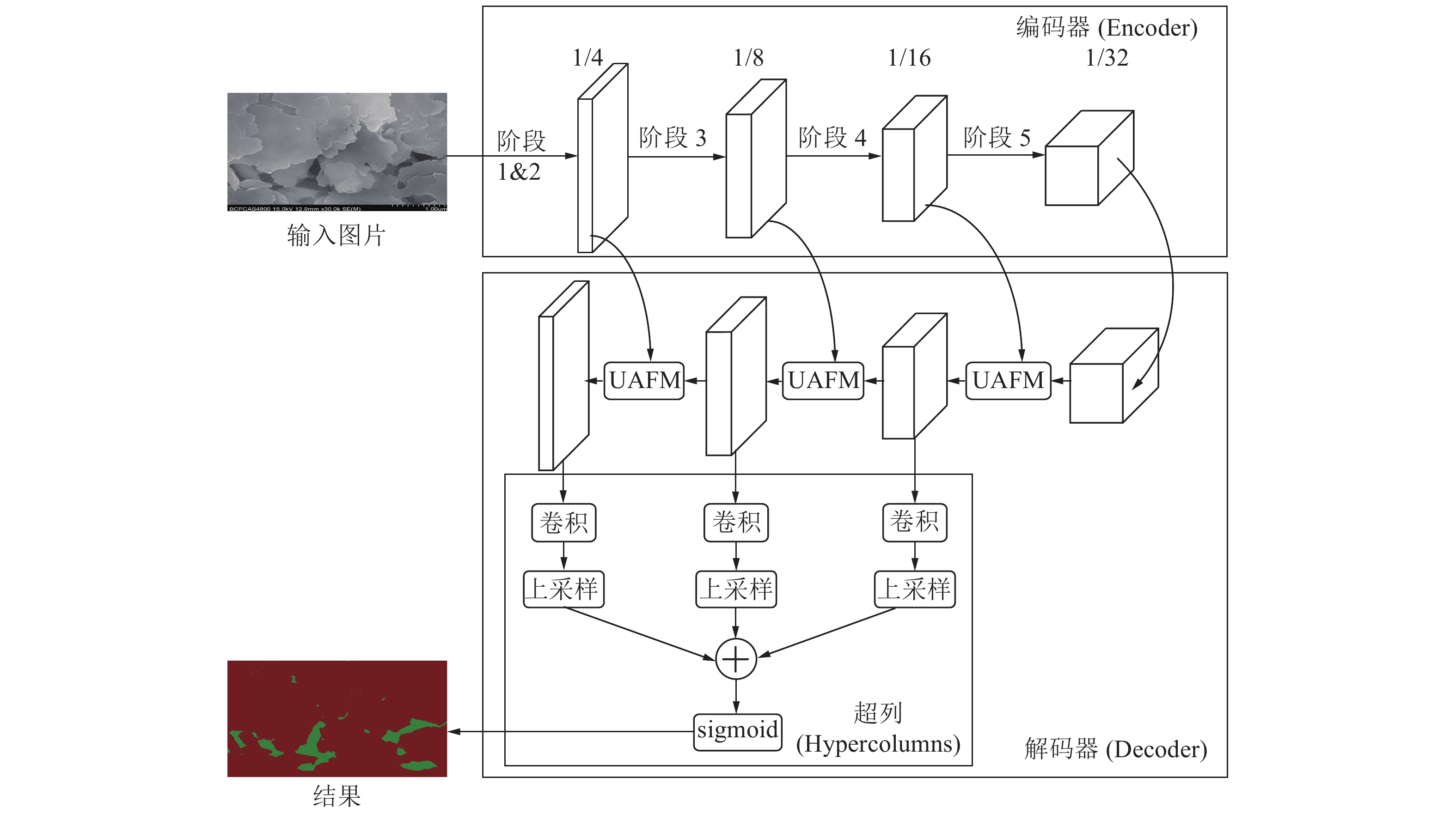

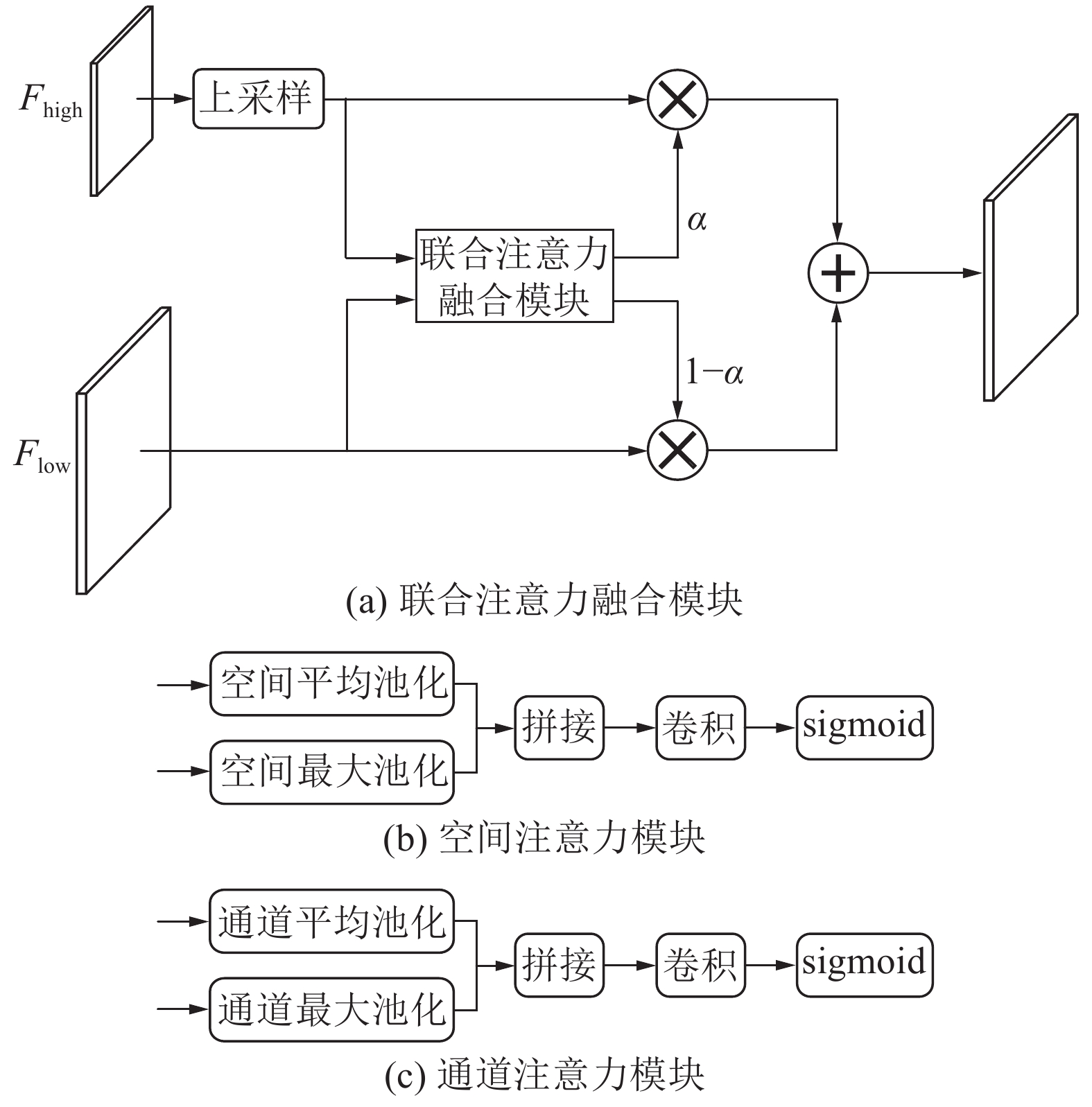

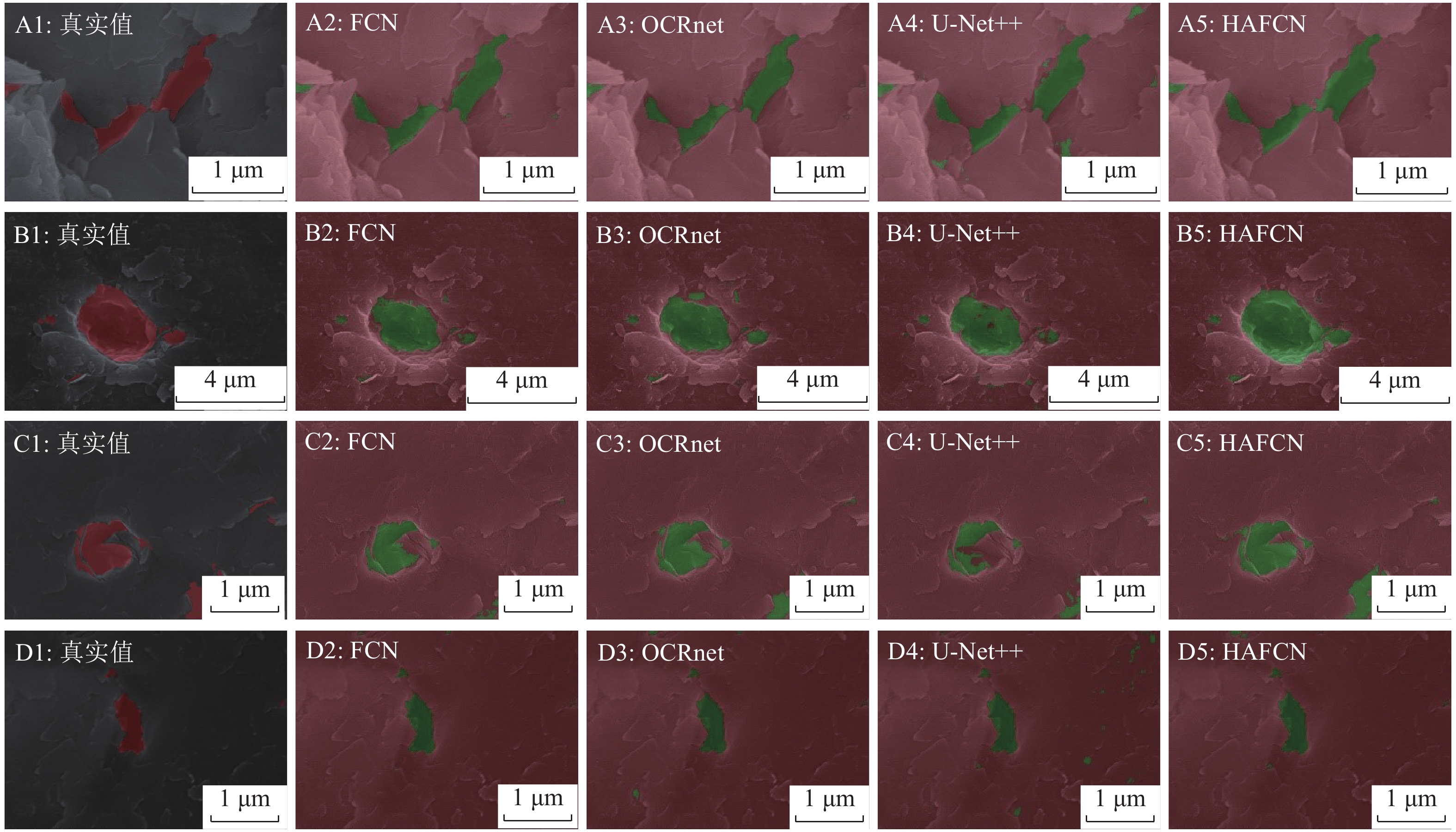

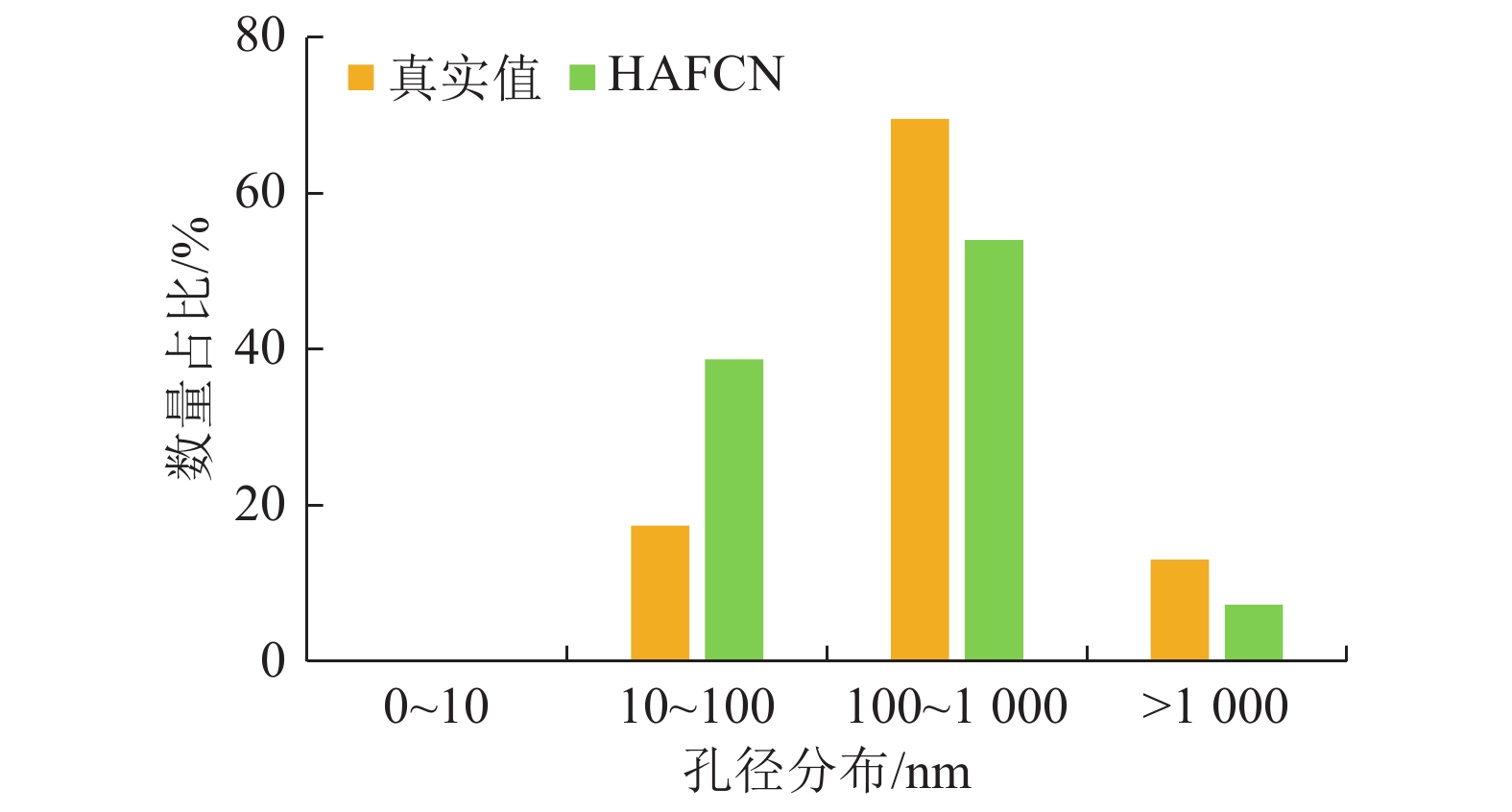

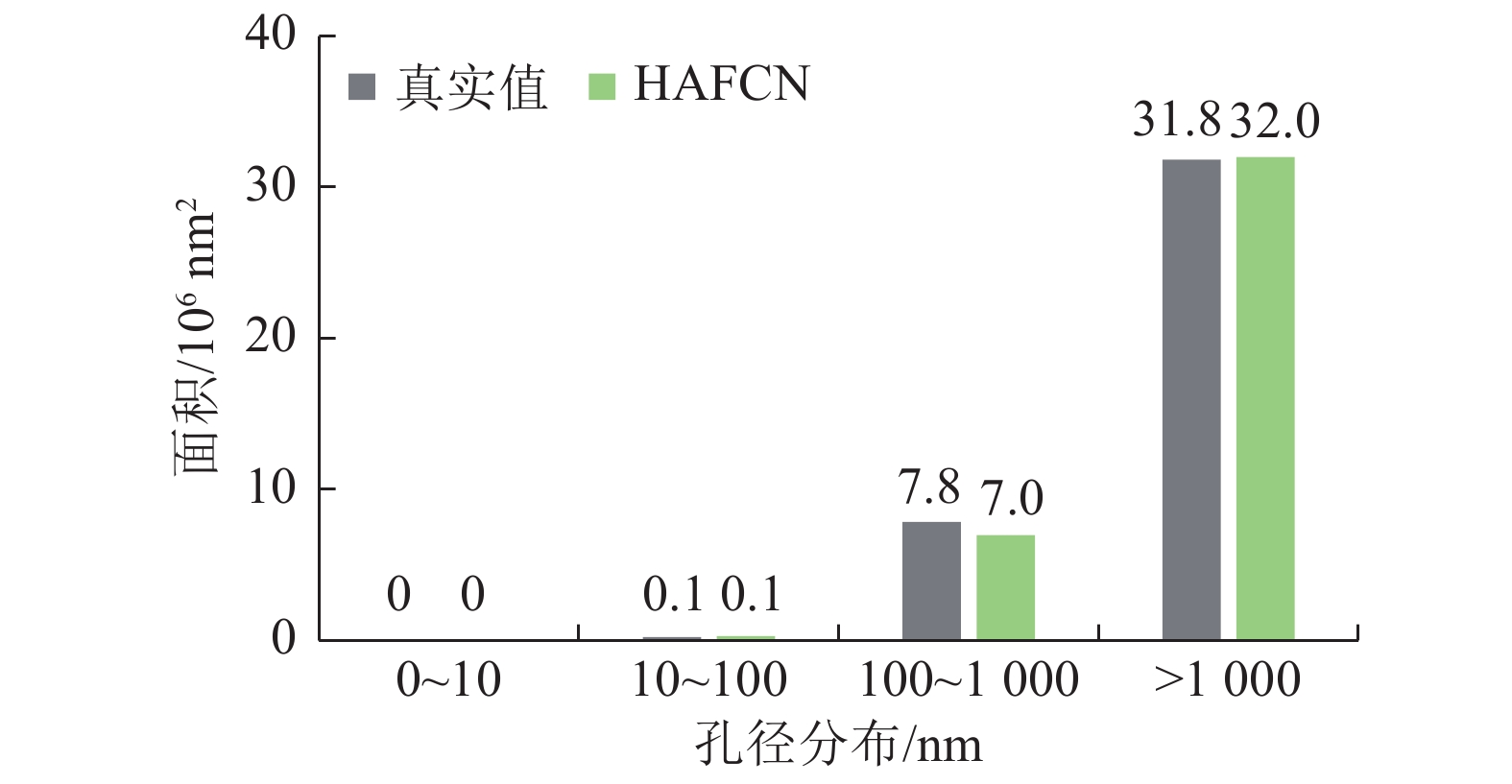

储层孔隙结构是页岩气勘探开发的重要影响因素。为准确表征煤系页岩储层中纳米孔隙结构,以青海木里地区煤系页岩为研究对象,利用扫描电镜采集页岩孔隙结构图像,建立页岩孔隙图像数据集,并基于深度学习技术设计出针对页岩孔隙图像分割的HAFCN模型。将孔隙识别效果与3种经典语义分割模型(FCN模型,U-Net++模型,OCRNet模型)做对比,结果表明:HAFCN模型分割效果明显占优,其平均交并比(mIoU)达到

0.8576 ,像素准确率达到0.9702 ,实现了快速分析页岩孔隙扫描电镜图像的目的,并获得了孔隙结构各项参数。将识别后的孔隙参数与原始孔隙参数值(Ground-truth)对比,发现两者孔隙结构参数相近,证实了模型的可靠性;所测煤系页岩样品的孔径以小孔及中孔为主;小孔、中孔及大孔孔径段的平均形状因子分别为1.65、2.38、4.10,其平均长宽比分别为2.97、2.76、3.01,说明随着页岩孔隙的增大,孔隙形态越偏离理想球形,形状越不规则。Abstract:Reservoir pore structure is an important factor affecting shale gas exploration and development. In order to accurately characterize the nanopore structure in coal-measure shale reservoirs, this paper takes coal-measure shale in the Muli area of Qinghai province as the research object, and uses shale pore structure images collected from scanning electron microscopy (SEM) to establish a shale pore image data set. A semantic image segmentation model named HAFCN (Hypercolumns Attention Fully Convolutional Networks) was proposed for shale pore segmentation based on deep learning technology. Compared with other three classical semantic segmentation models (FCN, U-Net++, OCRNet models) for pore images recognition, the HAFCN` model had better pore recognition results than other models, with an average intersection-over-union ratio (mIoU) of

0.8576 and a pixel accuracy of 0.97, so that the purpose of rapid analysis of shale pore SEM images was achieved, and various parameters of pore structure was obtained. Compared with the identified pore parameters with the original pore parameter values (Ground-truth), it is found that the pore structure parameters of the two are similar, which confirms the reliability of the model. The average shape factors of small, medium and large pore diameter sections are 1.65, 2.38, and 4.10, respectively, and their average aspect ratios are 2.97, 2.76, and 3.01, respectively, indicating that with the diameter increase of shale pores, the pore shape is more irregular.-

Keywords:

- deep learning /

- image analysis /

- shale reservoirs /

- pore structure /

- quantitative characterization

-

-

表 1 不同模型页岩孔隙识别训练效果

Table 1 Training results of different models in shale pores identification

模型 mIOU PA FCN 0.774 6 0.956 8 OCRNet 0.734 5 0.932 9 U-Net++ 0.739 3 0.949 9 HAFCN 0.857 6 0.970 2 表 2 孔隙结构特征参数

Table 2 Parameters of pore structures

孔径段/nm 平均孔径/nm 面积占比/% S均值 λ均值 10~100 55.0 0.03 1.65 2.97 100~ 1 000 303.2 1.81 2.38 2.76 >1 000 1 690.3 8.32 4.10 3.01 -

[1] JARVIE Daniel M,Hill Ronald J,RUBLE Tim E,et al. Unconventional shale-gas systems:the Mississippian Barnett Shale of north-central Texas as one model for thermogenic shale-gas assessment[J]. AAPG Bulletin,2007,91(4):475−499. doi: 10.1306/12190606068

[2] SZOLUCHA Anna. A social take on unconventional resources:Materiality,alienation and the making of shale gas in Poland and the United Kingdom[J]. Energy Research & Social Science,2019,57:101254.

[3] TAN Huimin,GABRIELLE Wong-Parodi,XU Jianhua. Not under my backyard? Psychological distance,local acceptance,and shale gas development in China[J]. Energy Research & Social Science,2020,61:101336.

[4] 王安民,曹代勇,魏迎春,等. 青海聚乎更矿区煤系页岩脆/韧性变形对孔隙结构的影响[J]. 煤炭科学技术,2022,50(3):193−200. WANG Anmin,CAO Daiyong,WEI Yingchun,et al. Effects of brittle/ductile deformation of coal measure shale on pore structure in Juhugeng Mining Area,Qinghai[J]. Coal Science and Technology,2022,50(3):193−200.

[5] JU Yiwen,SUN Ying,TAN Jingqiang,et al. The composition,pore structure characterization and deformation mechanism of coal-bearing shales from tectonically altered coalfields in eastern China[J]. Fuel,2018,234:626−642. doi: 10.1016/j.fuel.2018.06.116

[6] LIANG Mingliang,WANG Zongxiu,GAO Li,et al. Evolution of pore structure in gas shale related to structural deformation[J]. Fuel,2017,197:310−319. doi: 10.1016/j.fuel.2017.02.035

[7] ZHU Hongjian,JU Yiwen,QI Yu. Impact of tectonism on pore type and pore structure evolution in organicrich shale:Implications for gas storage and migration pathways in naturally deformed rocks[J]. Fuel,2018,228:272−289. doi: 10.1016/j.fuel.2018.04.137

[8] GB/T 21650.1—2008. 压汞法和气体吸附法测定固体材料孔径分布和孔隙度[S]. 北京:中国标准出版社,2008. GB/T 21650.1–2008. Pore size distribution and porosity of solid materials by mercury porosimetry and gas adsorption[S].

[9] CURTIS M E,SONDERGELD C H,AMBROSE R J,et al. Microstructural investigation of gas shales in two and three dimensions using nanometer-scale resolution imaging[J]. AAPG Bulletin,2012,96:665−677. doi: 10.1306/08151110188

[10] DEWERS Thomas A,HEATH Jason,EWY Russ,et al. Three-dimensional pore networks and transport properties of a shale gas formation determined from focused ionbeam serial imaging[J]. International Journal of Oil,Gas and Coal Technology,2012,5:229−248. doi: 10.1504/IJOGCT.2012.046322

[11] ZAMBRANO M ,TONDI E,MANCINI L , et al. 3D Pore-network quantitative analysis in deformed carbonate grainstones[J]. Marine and Petroleum Geology,2017,82:251−264.

[12] SUN Yingfeng,ZHAO Yixin,YUAN Liang. Quantifying nano-pore heterogeneity and anisotropy in gas shale by synchrotron radiation nano-CT[J]. Microporous and Mesoporous Materials,2018,258:8−16. doi: 10.1016/j.micromeso.2017.08.049

[13] GUO Xuejing,SHEN Yinghao,HE Shunli. Quantitative pore characterization and the relationship between pore distributions and organic matter in shale based on nano-CT image analysis:a case study for a lacustrine shale reservoirs in the Triassic Chang 7 member,Ordos basin,China[J]. Journal of Natural Gas Science and Engineering,2015,27:1630−1640. doi: 10.1016/j.jngse.2015.10.033

[14] ZHOU Shangwen,YAN Gang,XUE Hhuaqing,et al. 2D and 3D nanopore characterization of gas shale in Longmaxi formation based on FIB-SEM[J]. Marine and Petroleum Geology,2016,73:174−180. doi: 10.1016/j.marpetgeo.2016.02.033

[15] WANG Qiangchang,GUO Guodong. Benchmarking deep learning techniques for face recognition[J]. Journal of Visual Communication and Image Representation,2019,65:102663. doi: 10.1016/j.jvcir.2019.102663

[16] TRAPP M ,BOGOCLU C ,NESTOROVIC T , et al. Intelligent optimization and machine learning algorithms for structural anomaly detection using seismic signals[J]. Mechanical Systems and Signal Processing,2019,133:106250.

[17] 蔡宇恒,滕奇志,涂秉宇. 基于深度学习的岩石铸体薄片图像孔隙自动提取[J]. 科学技术与工程,2020,20(28):11685−11692. CAI Yuheng,TENG Qizhi,TU Bingyu. Automatic extraction of pores in thin slice images of rock castings based on deep learning[J]. Science Technology and Engineering,2020,20(28):11685−11692.

[18] 陈宗铭,唐 玄,梁国栋,等. 基于深度学习的页岩扫描电镜图像有机质孔隙识别与比较[J]. 地学前缘,2023,30(3):208−220. doi: 10.13745/j.esf.sf.2022.5.45 CHEN Zongming,TANG Xuan,LIANG Guodong,et al. Identification and comparison of organic matter-hosted pores in shale by SEM image analysis—a deep learning-based approach[J]. Earth Science Frontier,2023,30(3):208−220. doi: 10.13745/j.esf.sf.2022.5.45

[19] LONG J,SHELHAMER E,DARRELL T. Fully convolutional networks for semantic segmentation[A]. IEEE Conference on Computer Vision and Pattern Recognition[C]// New York:IEEE,2016:3431–3440.

[20] RONNEBERGER Olaf,PISCHER Philipp,BROX Thomas. U-net:Convolutional networks for biomedical image segmentation[A]. International Conference on Medical image computing and computer-assisted intervention[C]//Cham,Switzerland:Springer,2015:234−241.

[21] ZHOU Zongwei,SIDDIQUEE M M R,TAJBAKHSH N , et al. Unet++:Redesigning skip connections to exploit multiscale features in image segmentation[J]. IEEE Transactions on Medical Imaging,2019,39(6):1856−1867.

[22] MARIUS C,MOHAMED O,SEBASTIAN R, et al. The cityscapes dataset for semantic urban scene understanding[A]. IEEE conference on computer vision and pattern recognition[C]// New York:IEEE,2016:3213–3223.

[23] HARIHARAN B,ARBELAEZ P,GIRSHICK R, et al. Hypercolumns for object segmentation and fine-grained localization[A]. IEEE Conference on Computer Vision and Pattern Recognition (CVPR) [C]. //New York:IEEE,2015,1411:5752v2.

[24] JONATHAN L,EVAN S,TREVOR D. Fully convolutional networks for semantic segmentation[A]. IEEE conference on computer vision and pattern recognition[C]// New York:IEEE,2015:3431–3440.

[25] LIN Tsung-Yi ,GOYAL Priya ,GIRSHICK Ross , et al. Focal loss for dense object detection[A]. IEEE Transactions on Pattern Analysis & Machine Intelligence[C]//New York:IEEE,2017:2999−3007.

[26] BERMAN M,TRIKI A R,BLASCHKO M B. The Lovasz-Softmax loss:A tractable surrogate for the optimization of the Intersection-Over-Union measure in neural networks[A]. IEEE Conference on Computer Vision and Pattern Recognition [C]// New York:IEEE,2018:4413−4421.

[27] WANG Anmin,WEI Yingchun,YUAN Yuan,et al. Coalbed methane reservoirs’ pore-structure characterization of different macrolithotypes in the southern Junggar Basin of Northwest China[J]. Marine & Petroleum Geology,2017,86:675−688.

[28] 方永浩,王 锐,庞二波,等. 水泥–粉煤灰泡沫混凝土抗压强度与气孔结构的关系[J]. 硅酸盐学报,2010,38(4):621−626. FANG Yonghao,WANG Rui,PANG Erbo,et al. Relationship between compressive strength and air-void structure of foamed cement-fly ash concrete[J]. Journal of the Chinese Ceramic Society,2010,38(4):621−626.

下载:

下载: