Design and application of intelligent blasthole detection and path planning system

-

摘要:

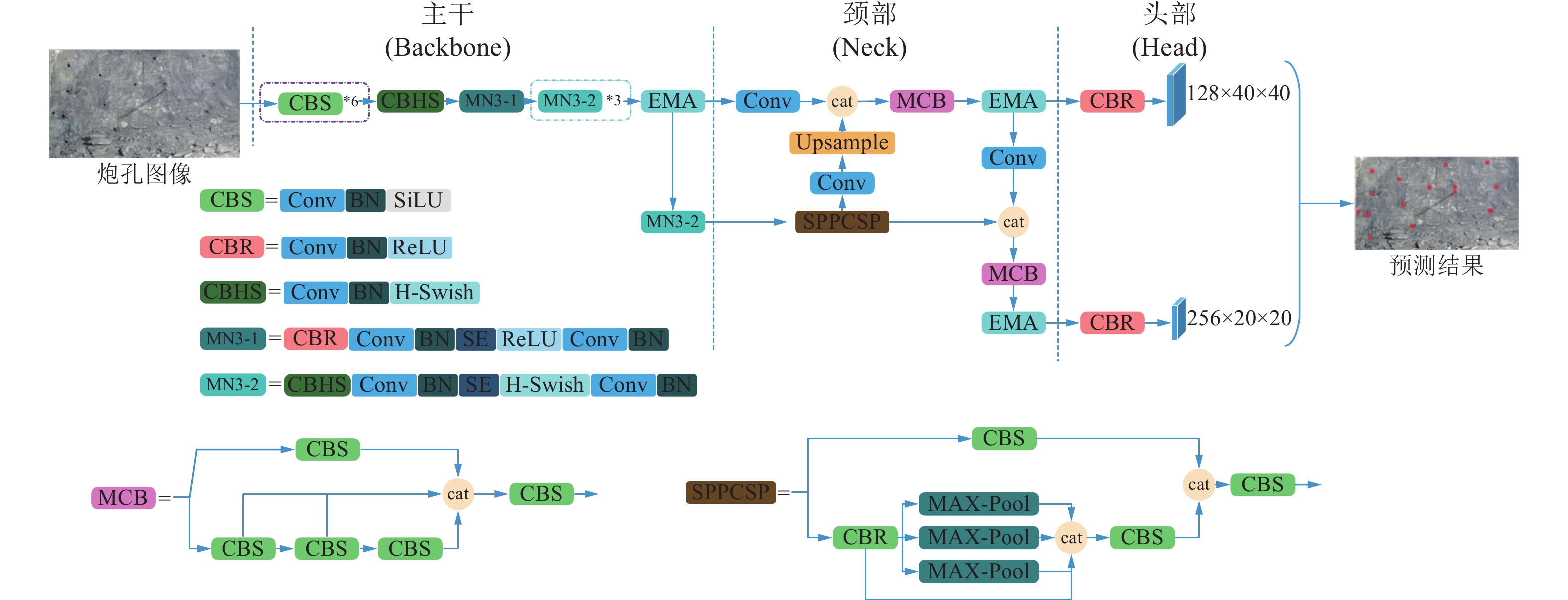

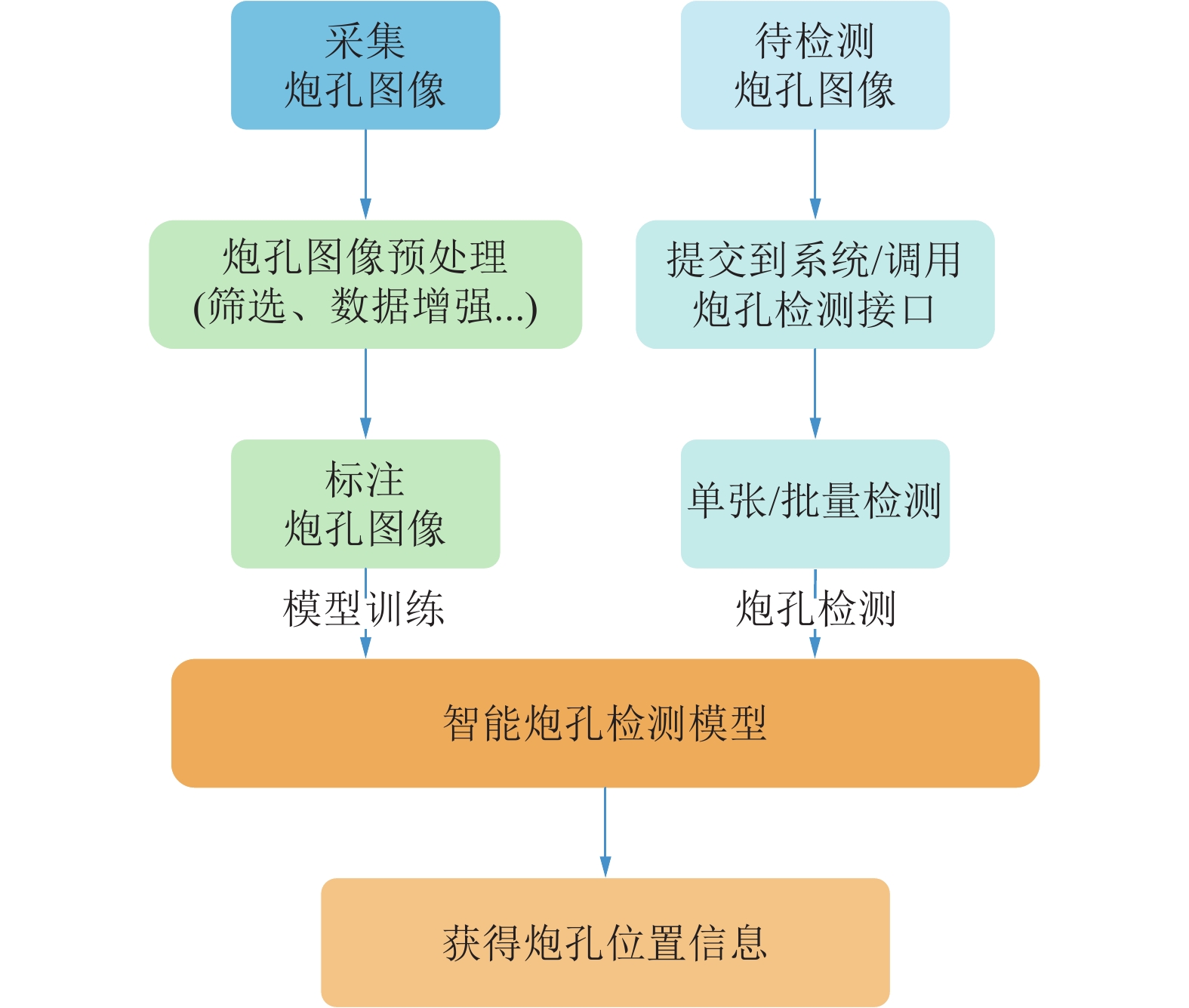

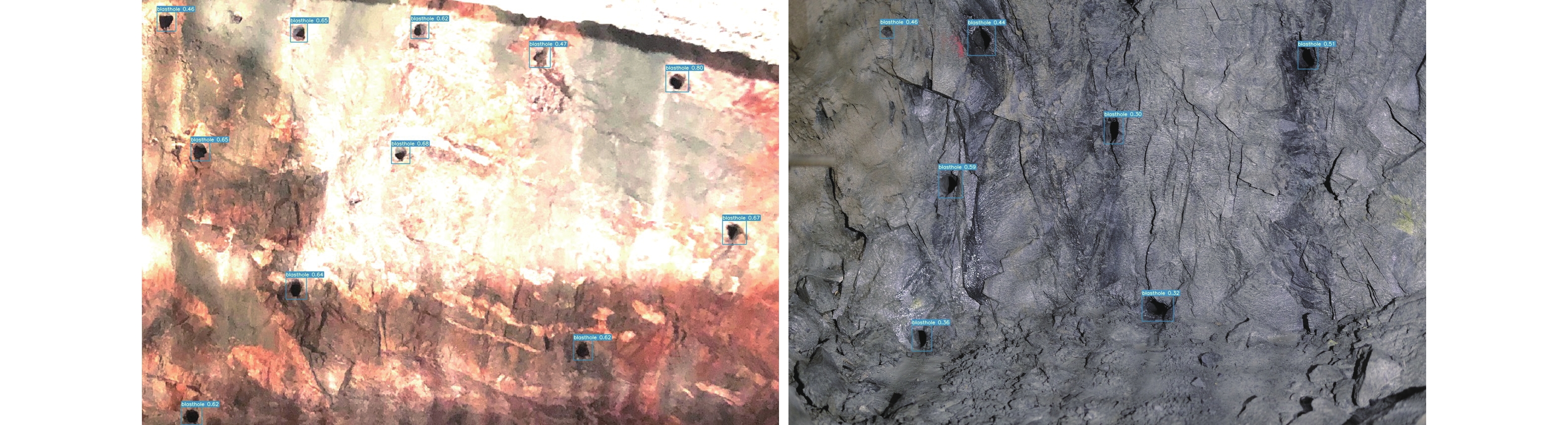

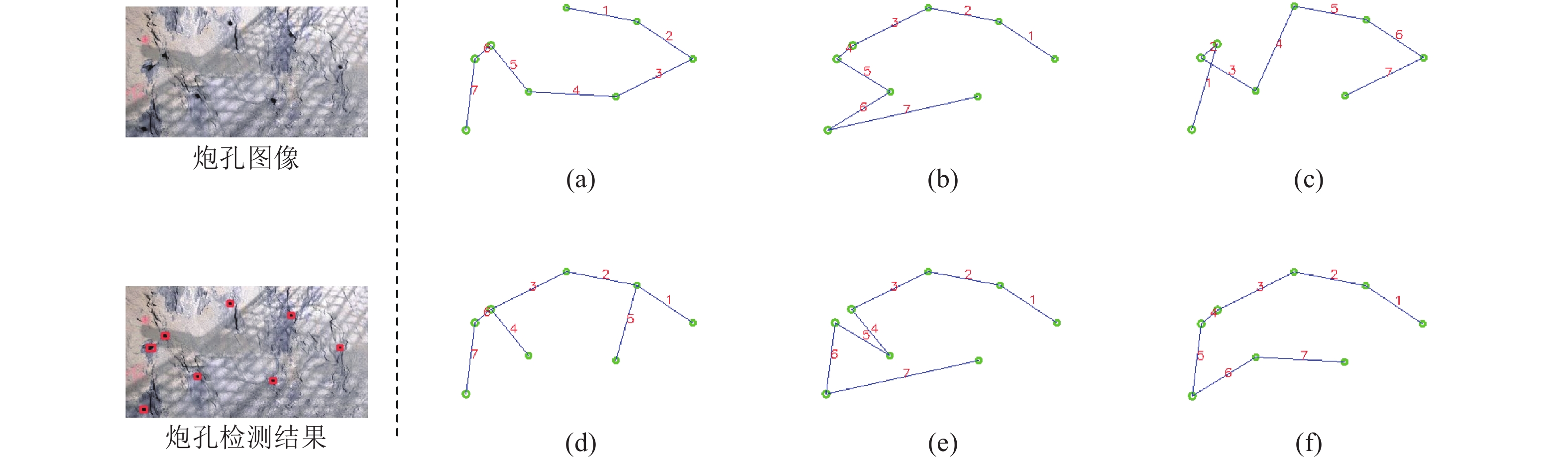

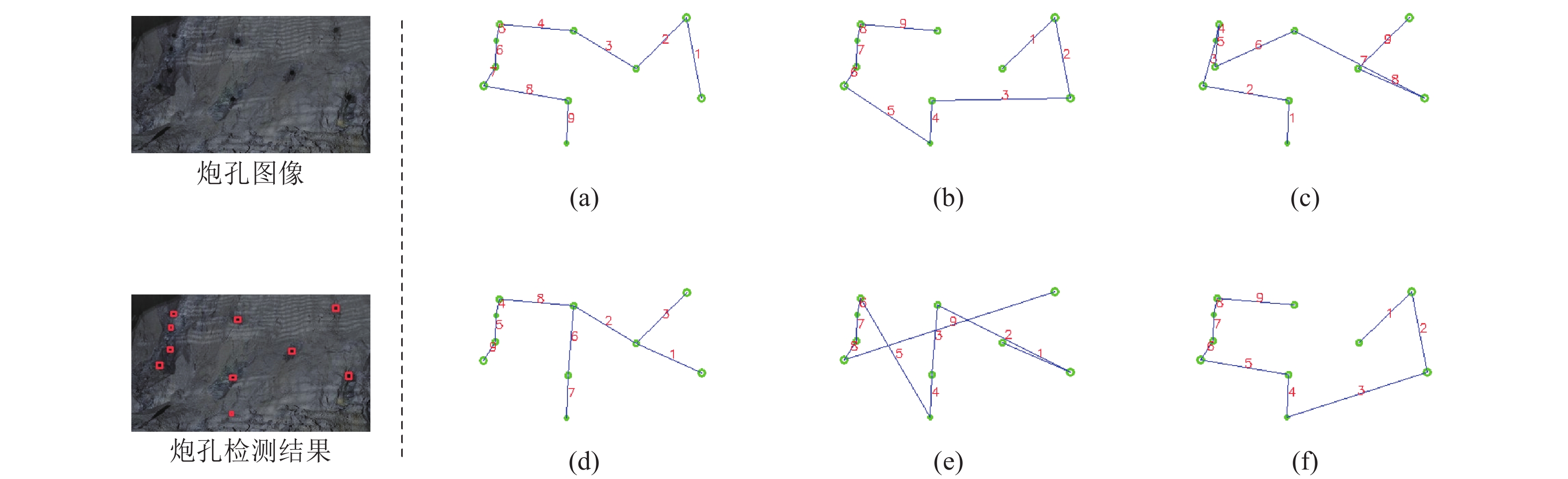

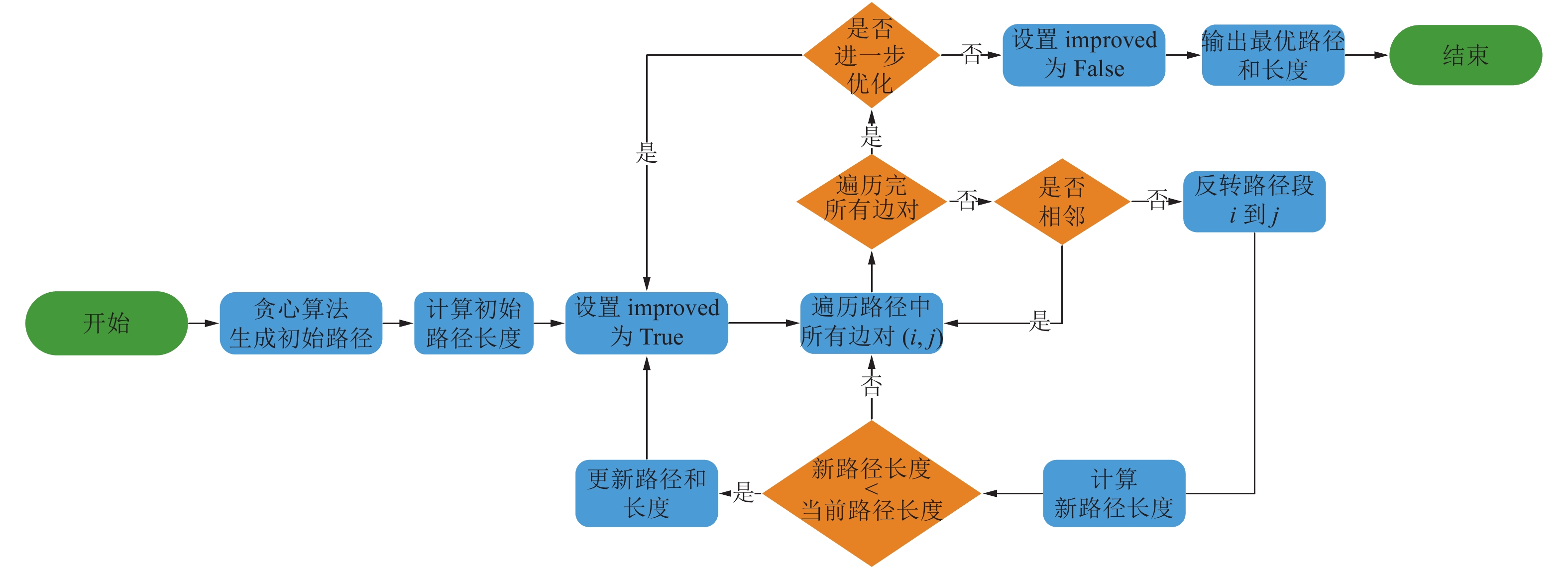

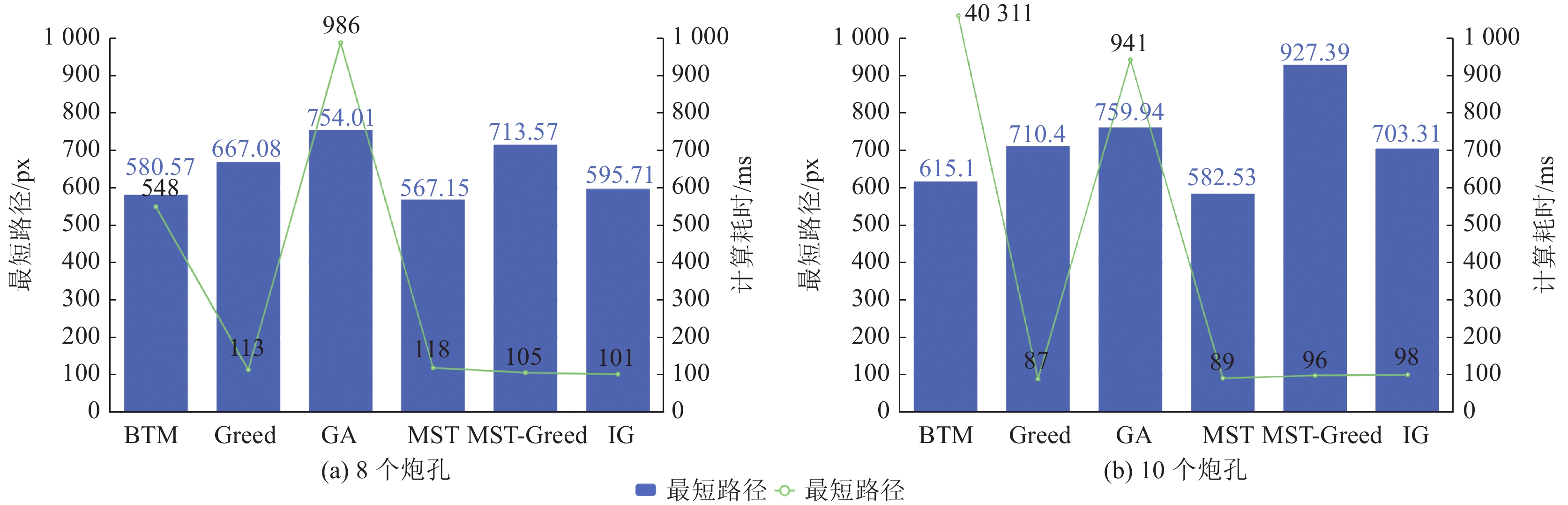

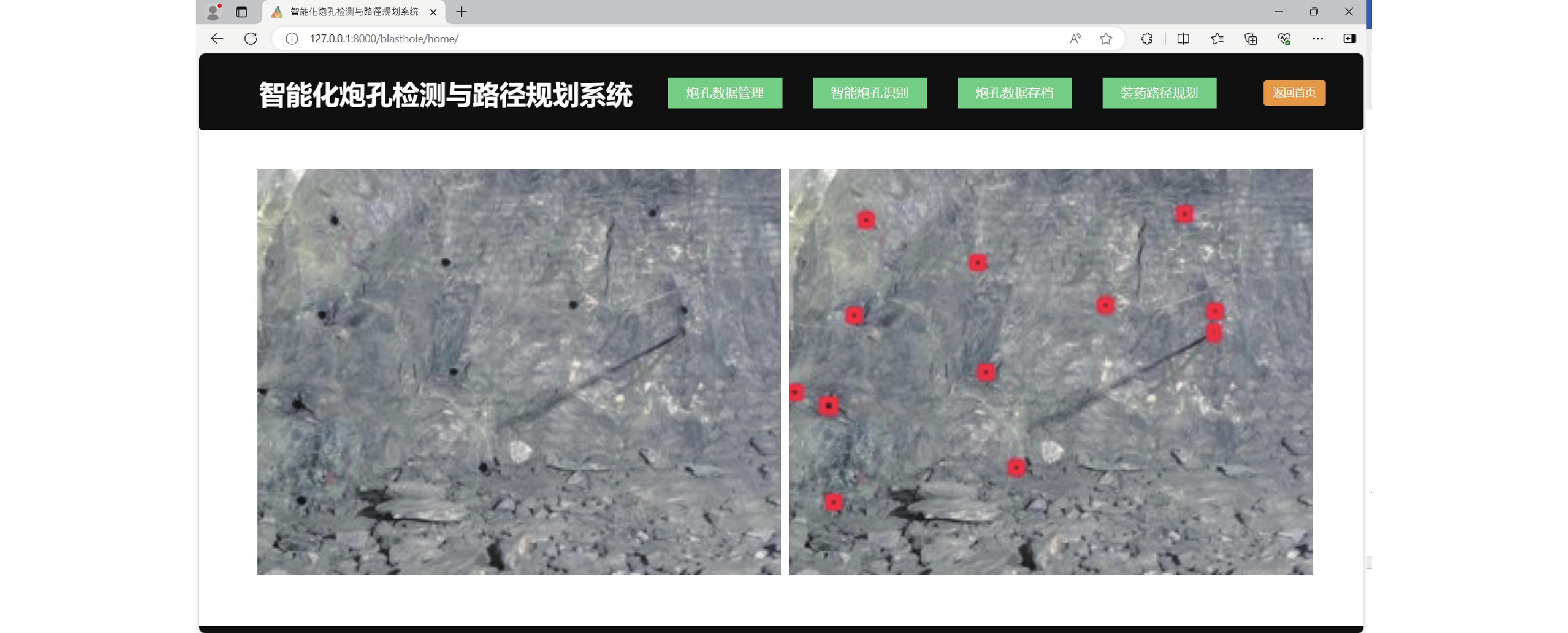

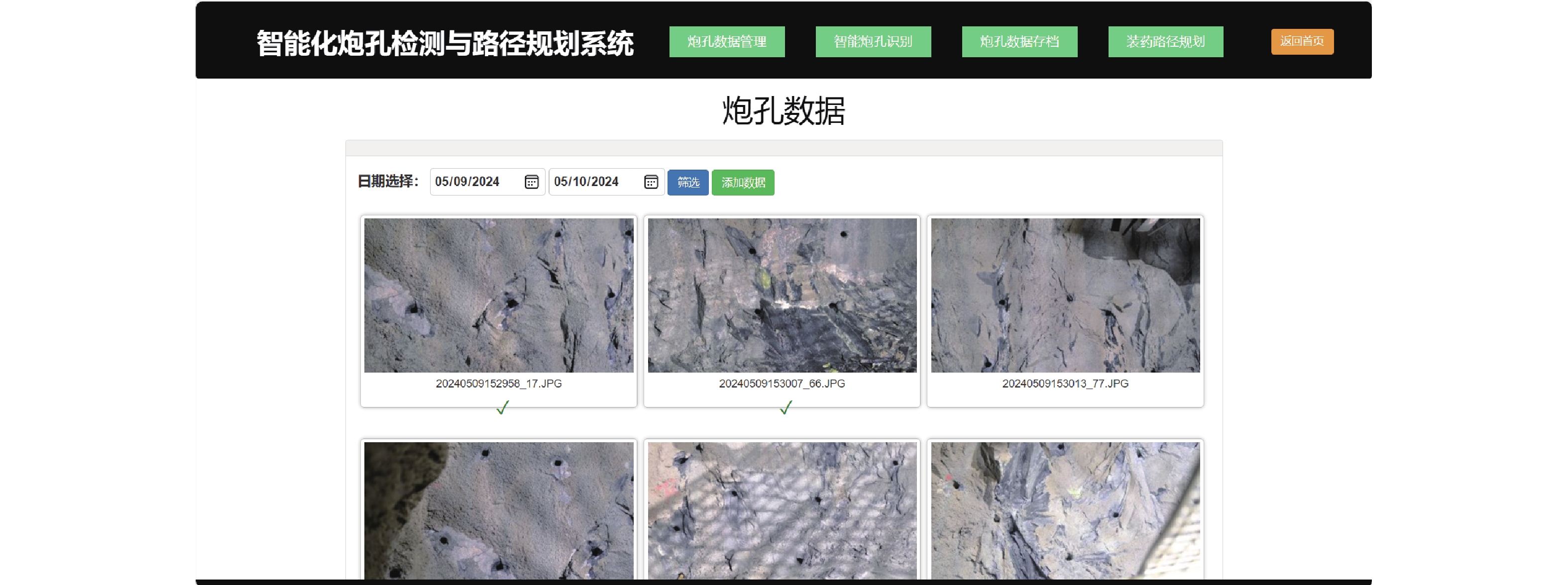

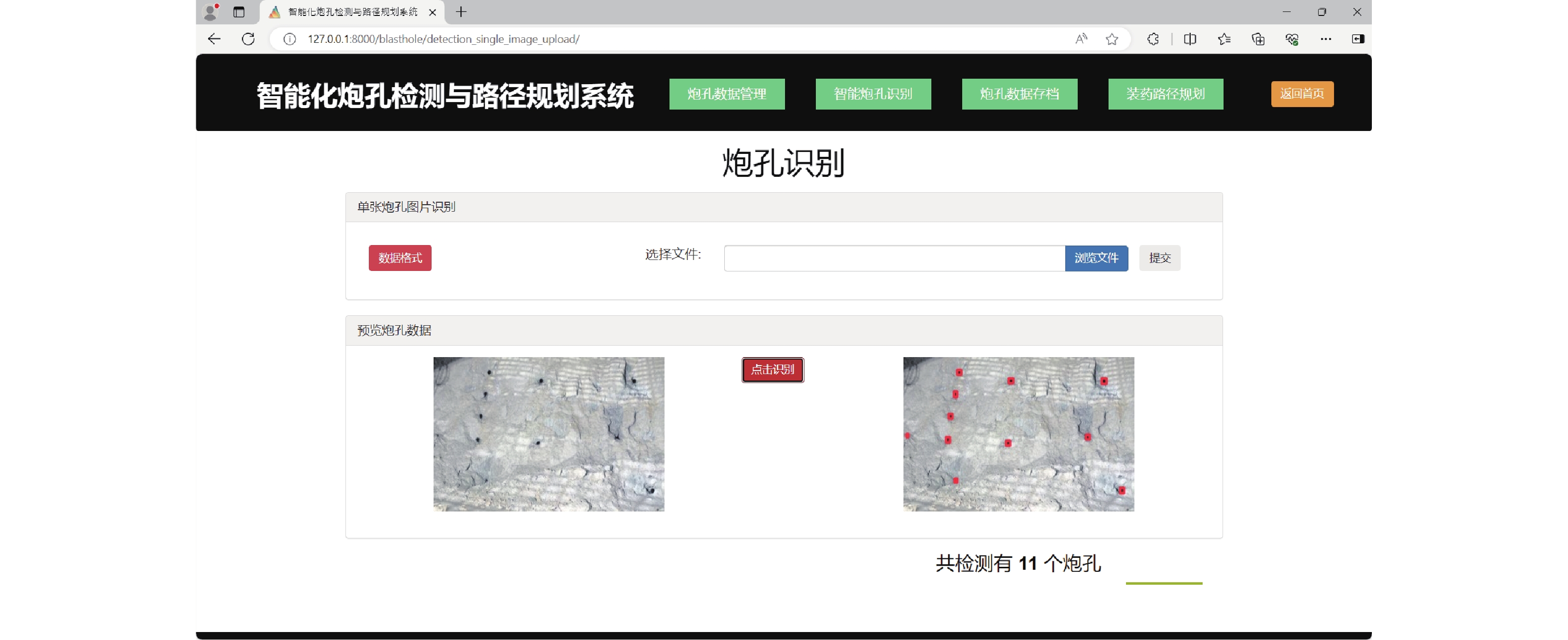

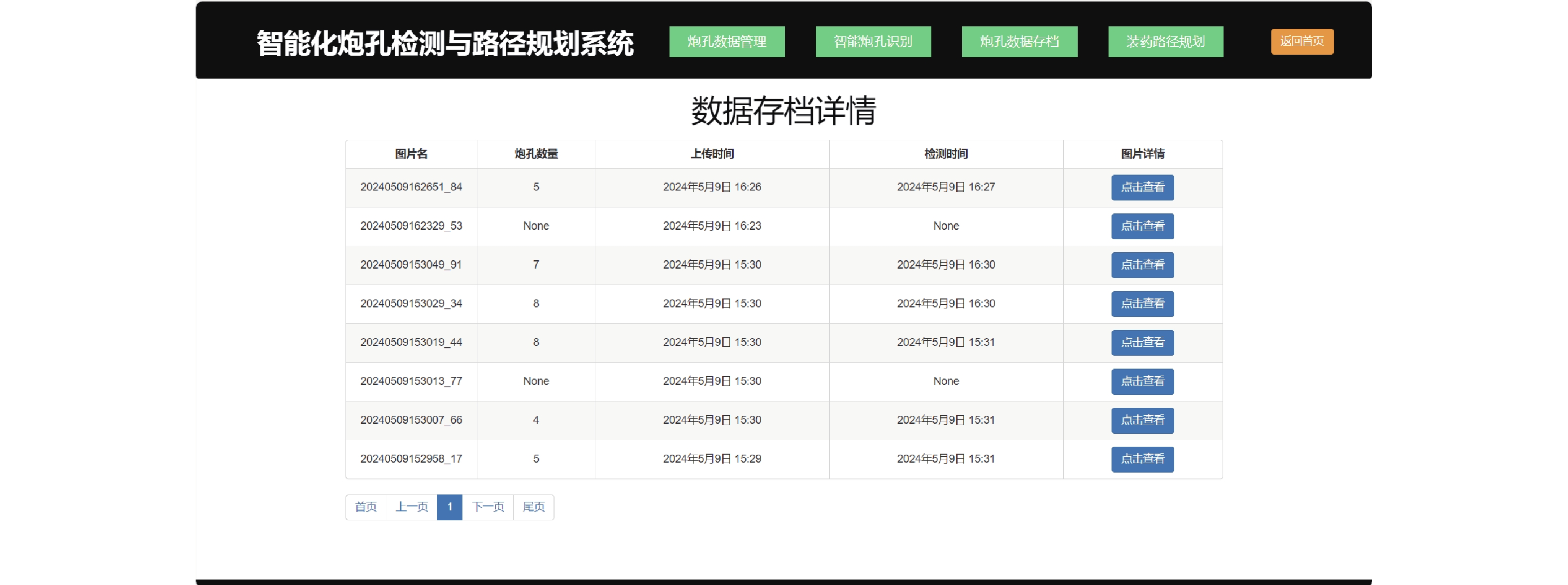

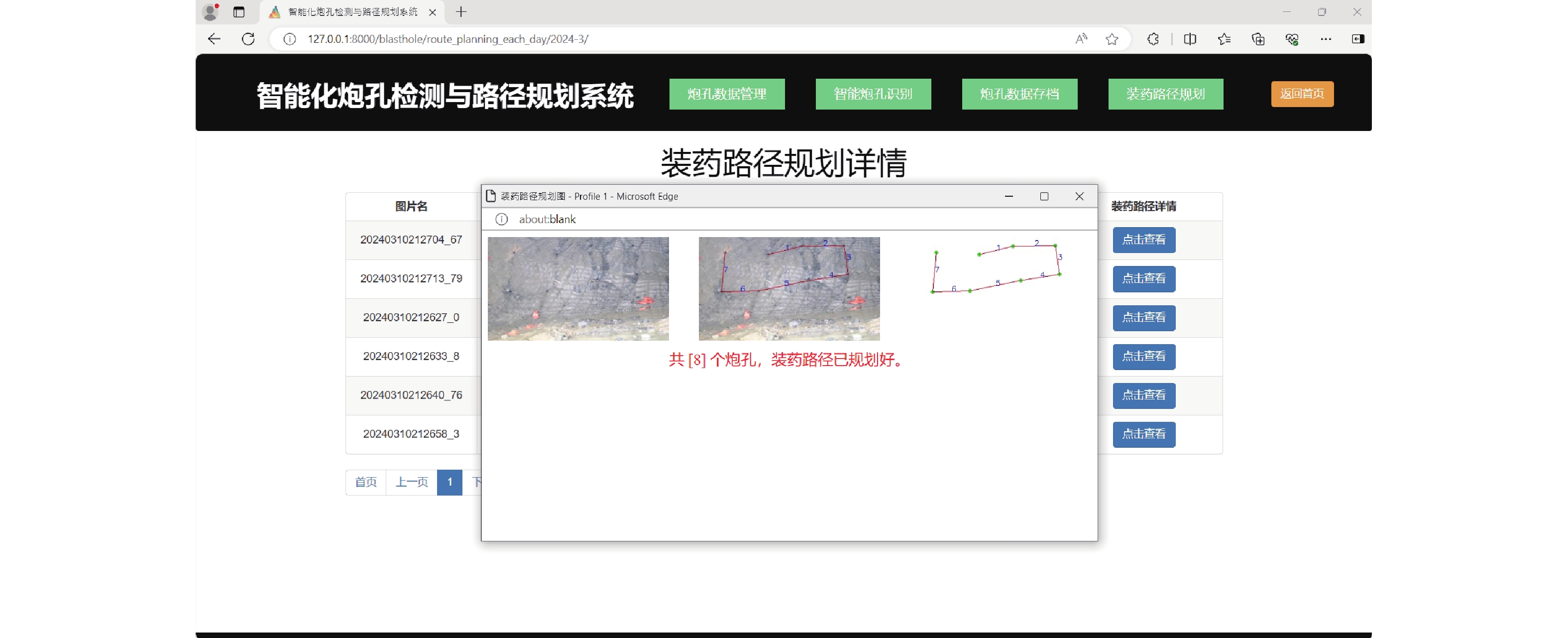

钻爆法巷道掘进的装药作业是巷道掘进的一个重要工序环节,传统的装药过程机械化程度较低,依赖人工操作,导致耗时费力且安全性较差。为了解决巷道掘进过程中钻爆法装药存在的问题,基于深度学习与智能算法技术,创新性地提出了智能化改进方案——智能炮孔检测与路径规划系统。该系统可以提高装药精度和施工效率,为钻爆法的智能化装药提供技术支持。系统架构为数据访问层、业务逻辑层和表示层,包括图像采集、数据处理、炮孔检测、路径规划和可视化界面等模块。首先,通过高精度图像传感器获取掘进工作面上的炮孔图像数据;其次,采用基于深度学习的炮孔智能检测模型进行数据处理和分析,实现对炮孔数据的准确检测和识别;最后,将改进贪心算法与2−opt局部搜索算法相结合,设计装药路径规划算法,实现了对装药顺序的高效规划和优化。系统集成了可视化功能,提供了直观的炮孔数据管理、智能炮孔识别、炮孔数据存档和装药路径规划等操作,方便施工人员进行实时监控和动态调整。研究结果表明,该系统在炮孔检测方面的准确率可达96.24%,路径规划算法的平均计算耗时为100 ms左右,该系统可提高钻爆法施工过程中装药的效率、安全性和智能化水平,服务于钻爆法巷道掘进智能化装药过程中的炮孔检测与路径规划。

Abstract:The charging operation of roadway excavation by drilling and blasting is an important process link of tunnel excavation. The traditional charging process has a low degree of mechanization and relies on manual operation, which is time-consuming, labor-intensive and unsafe. In order to solve the problems of charging by drilling and blasting in tunnel excavation, an intelligent improvement scheme, intelligent blasthole detection and path planning system, is innovatively proposed based on deep learning and intelligent algorithm technology. The system can improve the charging accuracy and construction efficiency, and provide technical support for intelligent charging of drilling and blasting. The system architecture consists of data access layer, business logic layer and presentation layer, including modules such as image acquisition, data processing, blasthole detection, path planning and visualization interface. Firstly, the blasthole image data on the excavation working face is obtained by high-precision image sensors; secondly, the intelligent data processing and analysis of the blasthole intelligent detection model based on deep learning is adopted to realize accurate detection and identification of blasthole data; finally, the improved greedy algorithm is combined with the 2−opt local search algorithm to design a charging path planning algorithm, which realizes efficient planning and optimization of charging sequence. The system integrates visualization functions and provides intuitive blasthole data management, intelligent blasthole identification, blasthole data archiving, and charging path planning, which facilitates construction personnel to perform real-time monitoring and dynamic adjustment. The research results show that the accuracy of the system in blasthole detection can reach 96.24%, and the average calculation time of the path planning algorithm is about 100 milliseconds. The system can improve the efficiency, safety and intelligence level of charging during the drilling and blasting construction process, and serve the blasthole detection and path planning in the intelligent charging process of the drilling and blasting tunnel excavation.

-

-

表 1 模型实验对比

Table 1 Model experiment comparison

模型名称 平均精确率/% 召回率/% F1/% 本文模型 96.24 93.17 94.69 YOLOv7 93.98 92.31 93.14 -

[1] 王国法,庞义辉,任怀伟,等. 智慧矿山系统工程及关键技术研究与实践[J]. 煤炭学报,2024,49(1):181−202. WANG Guofa,PANG Yihui,REN Huaiwei,et al. System engineering and key technologies research and practice of smart mine[J]. Journal of China Coal Society,2024,49(1):181−202.

[2] 王雁冰,孔维文,王国豪,等. 深孔掏槽超深爆破破岩机制及最佳超深值研究[J]. 采矿与安全工程学报,2023,40(6):1210−1218. WANG Yanbing,KONG Weiwen,WANG Guohao,et al. Mechanism of rock breaking by deep hole ultra-deep cut blasting and the optimum ultra-deep value determination[J]. Journal of Mining & Safety Engineering,2023,40(6):1210−1218.

[3] 杨仁树,张召冉,安晨,等. 煤矿岩巷掘进爆破掏槽孔超深问题探讨[J]. 煤炭科学技术,2020,48(1):10−23. YANG Renshu,ZHANG Zhaoran,AN Chen,et al. Discussion on ultra-deep depth problem of slot hole in blasting excavation of rock roadway in coal mine[J]. Coal Science and Technology,2020,48(1):10−23.

[4] 王国法,赵国瑞,任怀伟. 智慧煤矿与智能化开采关键核心技术分析[J]. 煤炭学报,2019,44(1):34−41. WANG Guofa,ZHAO Guorui,REN Huaiwei. Analysis on key technologies of intelligent coal mine and intelligent mining[J]. Journal of China Coal Society,2019,44(1):34−41.

[5] 王国法. 煤矿智能化最新技术进展与问题探讨[J]. 煤炭科学技术,2022,50(1):1−27. doi: 10.3969/j.issn.0253-2336.2022.1.mtkxjs202201001 WANG Guofa. New technological progress of coal mine intelligence and its problems[J]. Coal Science and Technology,2022,50(1):1−27. doi: 10.3969/j.issn.0253-2336.2022.1.mtkxjs202201001

[6] 陆银龙,冯旭阳,吴开智,等. 煤矿井下巷道注浆智能数字化在线监测系统研发与应用[J]. 采矿与安全工程学报,2022,39(2):347−358. LU Yinlong,FENG Xuyang,WU Kaizhi,et al. Development and application of online intelligent digital monitoring system for grouting in underground roadway of coal mine[J]. Journal of Mining & Safety Engineering,2022,39(2):347−358.

[7] 张吉雄,屠世浩,曹亦俊,等. 深部煤矿井下智能化分选及就地充填技术研究进展[J]. 采矿与安全工程学报,2020,37(1):1−10,22. ZHANG Jixiong,TU Shihao,CAO Yijun,et al. Research progress of technologies for intelligent separation and in situ backfill in deep coal mines in China[J]. Journal of Mining & Safety Engineering,2020,37(1):1−10,22.

[8] 贾连辉,陈帅,贾正文,等. 钻爆法隧道智能建造体系及关键技术研究[J]. 隧道建设(中英文),2023,43(3):392−407. JIA Lianhui,CHEN Shuai,JIA Zhengwen,et al. Research on intelligent construction systems and key technologies for drilling-and-blasting tunnels[J]. Tunnel Construction,2023,43(3):392−407.

[9] 王青松. 关于我国山岭隧道钻爆法施工技术发展的一些思考[J]. 隧道建设(中英文),2023,43(S1):37−45. WANG Qingsong. Some thoughts on the development of construction technology of drilling and blasting method for mountain tunnels in China[J]. Tunnel Construction,2023,43(S1):37−45.

[10] 阎凤强. 隧道爆破施工技术的发展研究[J]. 建筑技术,2022,53(11):1494−1497. doi: 10.3969/j.issn.1000-4726.2022.11.018 YAN Fengqiang. Research on the development of tunnel blasting construction technology[J]. Architecture Technology,2022,53(11):1494−1497. doi: 10.3969/j.issn.1000-4726.2022.11.018

[11] 秦念稳. 钻爆法隧道炸药智能化装填系统研究与应用[J]. 铁道建筑技术,2024(6):175−178,201. doi: 10.3969/j.issn.1009-4539.2024.06.043 QIN Nianwen. Research and application of intelligent explosives filling system for drilling-and-blasting tunnels[J]. Railway Construction Technology,2024(6):175−178,201. doi: 10.3969/j.issn.1009-4539.2024.06.043

[12] 方俊波,刘洪震,翟进营. 山岭隧道爆破施工技术的发展与展望[J]. 隧道建设(中英文),2021,41(11):1980−1991. FANG Junbo,LIU Hongzhen,ZHAI Jinying. Development and prospect of blasting technology for mountain-crossing tunnels[J]. Tunnel Construction,2021,41(11):1980−1991.

[13] 张海涛. 隧道施工现场混装炸药设备研制与应用[J]. 铁道建筑技术,2024(5):9−12,30. doi: 10.3969/j.issn.1009-4539.2024.05.003 ZHANG Haitao. Development and application of mixed explosive equipment for tunnel construction site[J]. Railway Construction Technology,2024(5):9−12,30. doi: 10.3969/j.issn.1009-4539.2024.05.003

[14] 刘飞香,姬海东,肖正航. 川藏铁路隧道钻爆法施工成套装备技术体系研究[J]. 隧道建设(中英文),2021(8):1281−1289. LIU Feixiang,JI Haidong,XIAO Zhenghang. Complete set of equipment technology system for drill-and-blast tunnel construction in Sichuan-Tibet railway[J]. Tunnel Construction,2021(8):1281−1289.

[15] 张万志. 岩质隧道炮孔图像识别算法及光面爆破参数优化研究[D]. 济南:山东大学,2019. ZHANG Wanzhi. Study on image recognition algorithm of borehole in rock tunnel and optimization of smooth blasting parameters[D]. Jinan:Shandong University,2019.

[16] 岳中文,金庆雨,潘杉,等. 基于深度学习的轻量化炮孔智能检测方法[J]. 煤炭学报,2024,49(5):2247−2256. YUE Zhongwen,JIN Qingyu,PAN Shan,et al. Intelligent detection method of lightweight blasthole based on deep learning[J]. Journal of China Coal Society,2024,49(5):2247−2256.

[17] 李利平,邹浩,刘洪亮,等. 钻爆法隧道智能建造研究现状与发展趋势[J]. 中国公路学报,2024,37(7):1−21. LI Liping,ZOU Hao,LIU Hongliang,et al. Research status and development trends in intelligent construction of drill-and-blast tunnels[J]. China Journal of Highway and Transport,2024,37(7): 1−21.

[18] HINTON G E,SALAKHUTDINOV R R. Reducing the dimensionality of data with neural networks[J]. Science,2006,313(5786):504−507. doi: 10.1126/science.1127647

[19] GIRSHICK R,DONAHUE J,DARRELL T,et al. Rich feature hierarchies for accurate object detection and semantic segmentation[C]//2014 IEEE Conference on Computer Vision and Pattern Recognition. Columbus,OH,USA. IEEE,2014:580−587.

[20] GIRSHICK R. Fast R-CNN[C]//2015 IEEE International Conference on Computer Vision (ICCV). Santiago,Chile. IEEE, 2015:1440−1448.

[21] REN S Q,HE K M,GIRSHICK R,et al. Faster R-CNN:towards real-time object detection with region proposal networks[J]. IEEE Transactions on Pattern Analysis and Machine Intelligence,2017,39(6):1137−1149. doi: 10.1109/TPAMI.2016.2577031

[22] REDMON J,DIVVALA S,GIRSHICK R,et al. You only look once:unified,real-time object detection[C]//2016 IEEE Conference on Computer Vision and Pattern Recognition (CVPR). Las Vegas,NV,USA. IEEE,2016:779−788.

[23] REDMON J,FARHADI A. YOLO9000:better,faster,stronger[C]//2017 IEEE Conference on Computer Vision and Pattern Recognition (CVPR). Honolulu,HI,USA. IEEE,2017:6517−6525.

[24] REDMON J,FARHADI A. YOLOv3:an incremental improvement[EB/OL]. 2018:1804.02767. https://arxiv.org/abs/1804.02767v1

[25] BOCHKOVSKIY A,WANG C Y,LIAO H Y M. YOLOv4:optimal speed and accuracy of object detection[EB/OL]. 2020:2004.10934. https://arxiv.org/abs/2004.10934v1

[26] LI Chuyi,LI Lulu,JIANG Hongliang,et al. YOLOv6:A Single-Stage Object Detection Framework for Industrial Applications[EB/OL]. (2022−09−07)[2024−05−29]. https://arxiv.org/abs/2209.02976.

[27] WANG C Y,BOCHKOVSKIY A,LIAO H Y M. YOLOv7:Trainable bag-of-freebies sets new state-of-the-art for real-time object detectors[EB/OL]. 2022:2207.02696. https://arxiv.org/abs/2207.02696v1

[28] WANG C Y,YEH I H,LIAO H Y M. YOLOv9:learning what you want to learn using programmable gradient information[EB/OL]. 2024:2402.13616. https://arxiv.org/abs/2402.13616v2

[29] LIU W,ANGUELOV D,ERHAN D,et al. SSD:single shot MultiBox detector[M]//Lecture notes in computer science. Cham:Springer International Publishing,2016:21-37.

下载:

下载: