Experimental study on characterization of mine wire rope detection signal properties based on magnetic field model

-

摘要:

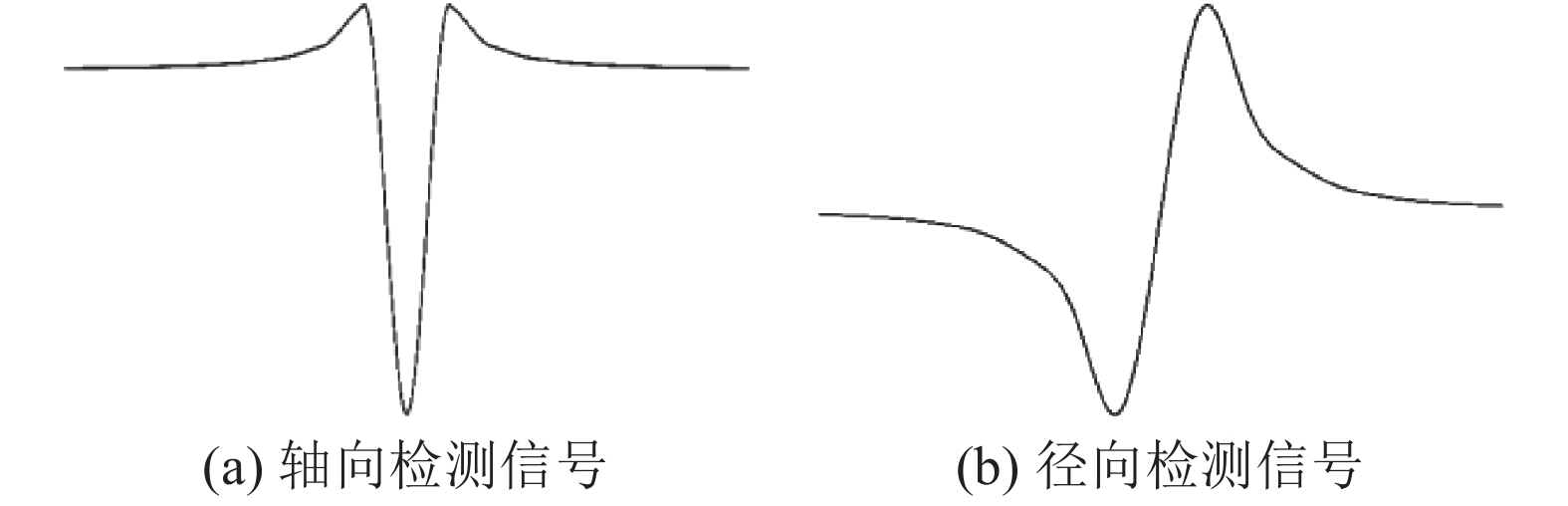

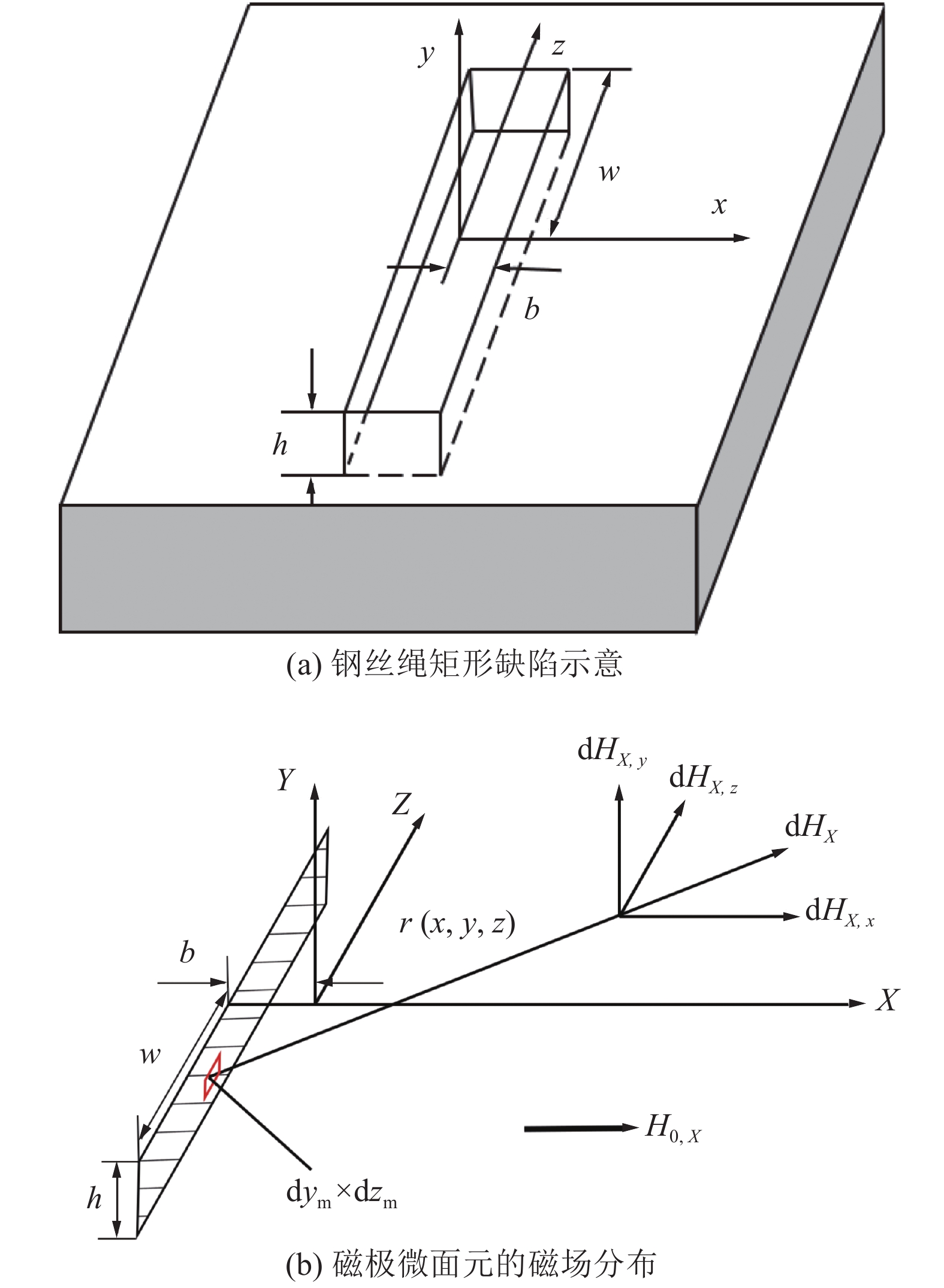

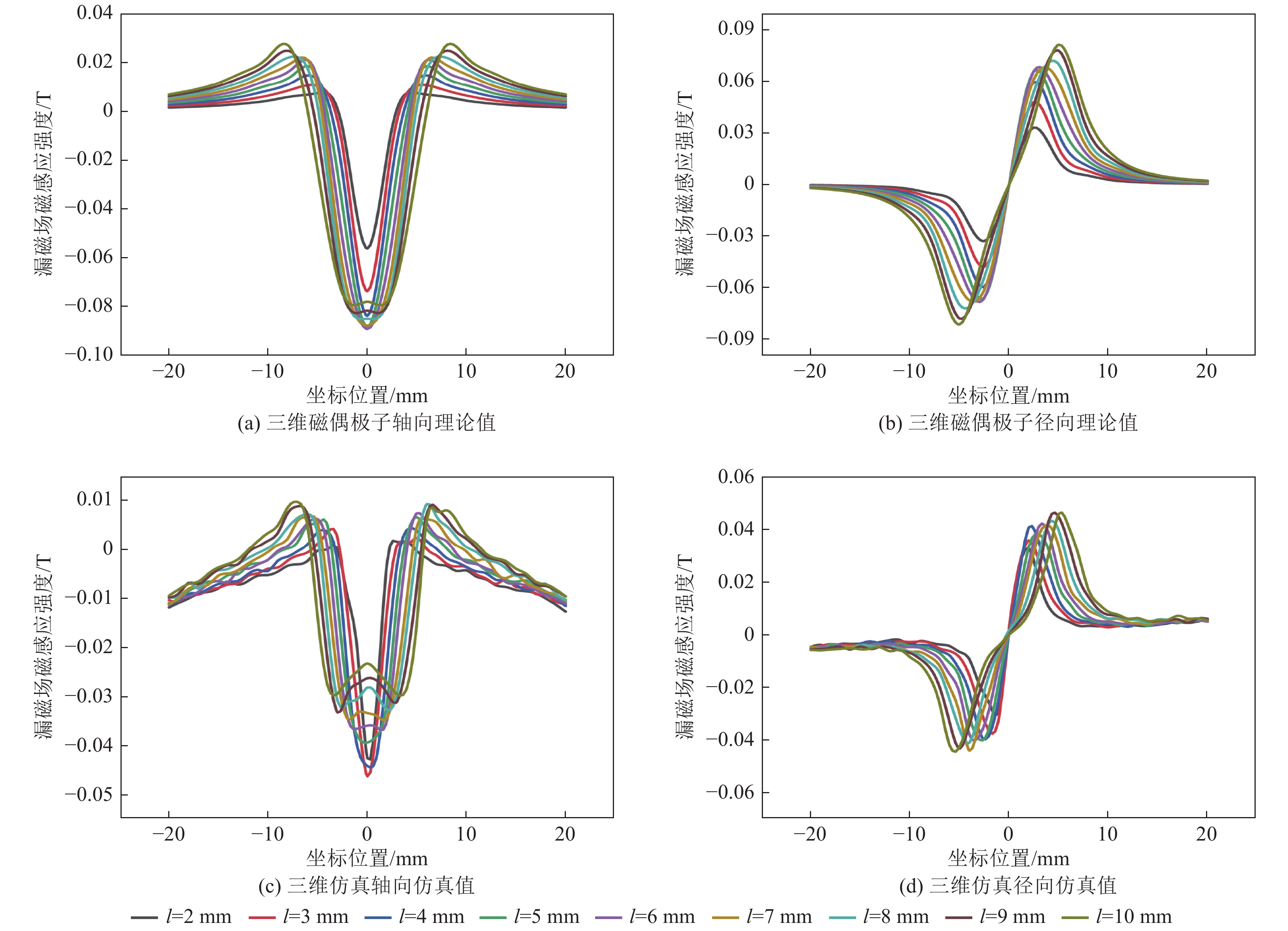

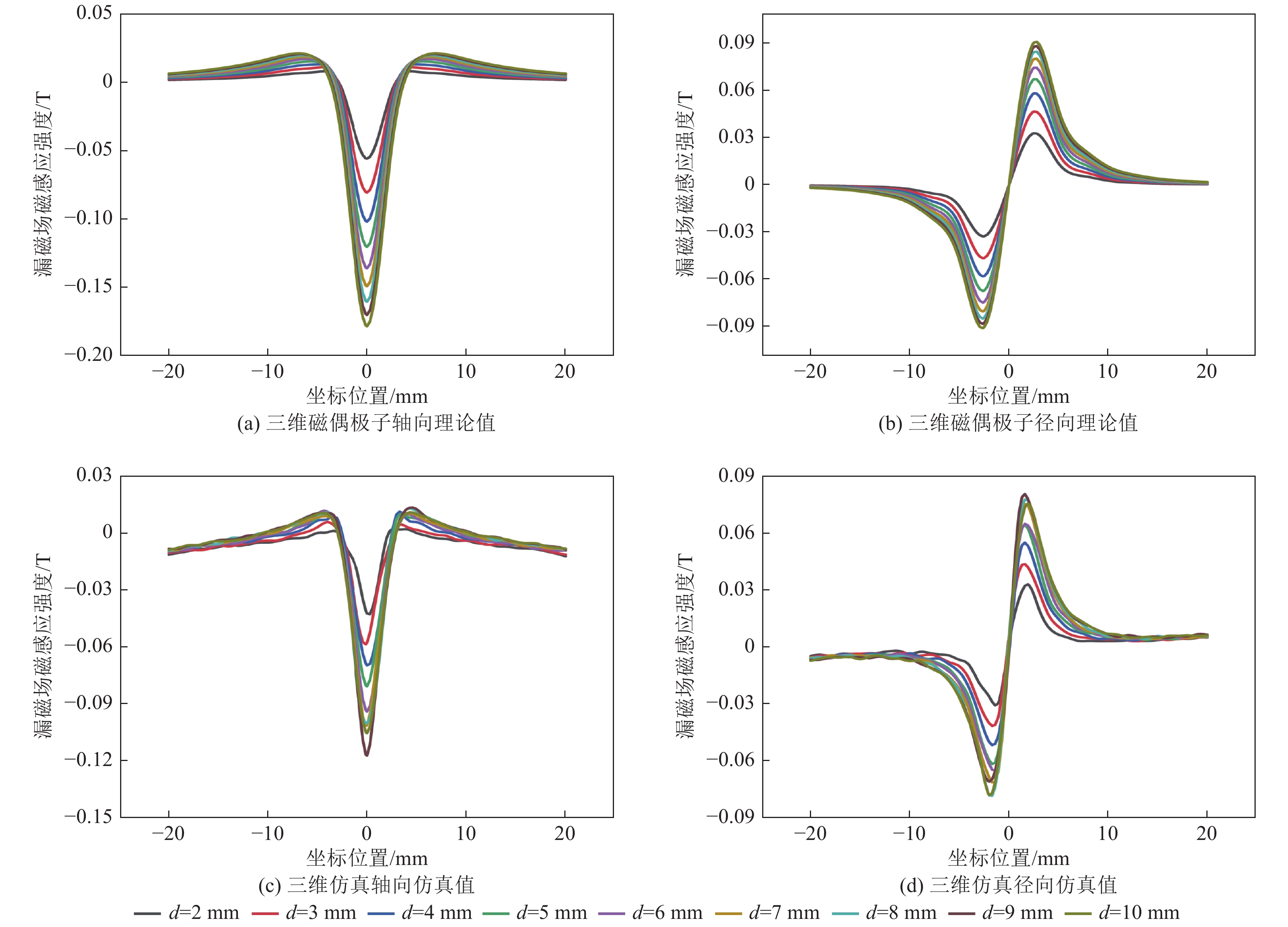

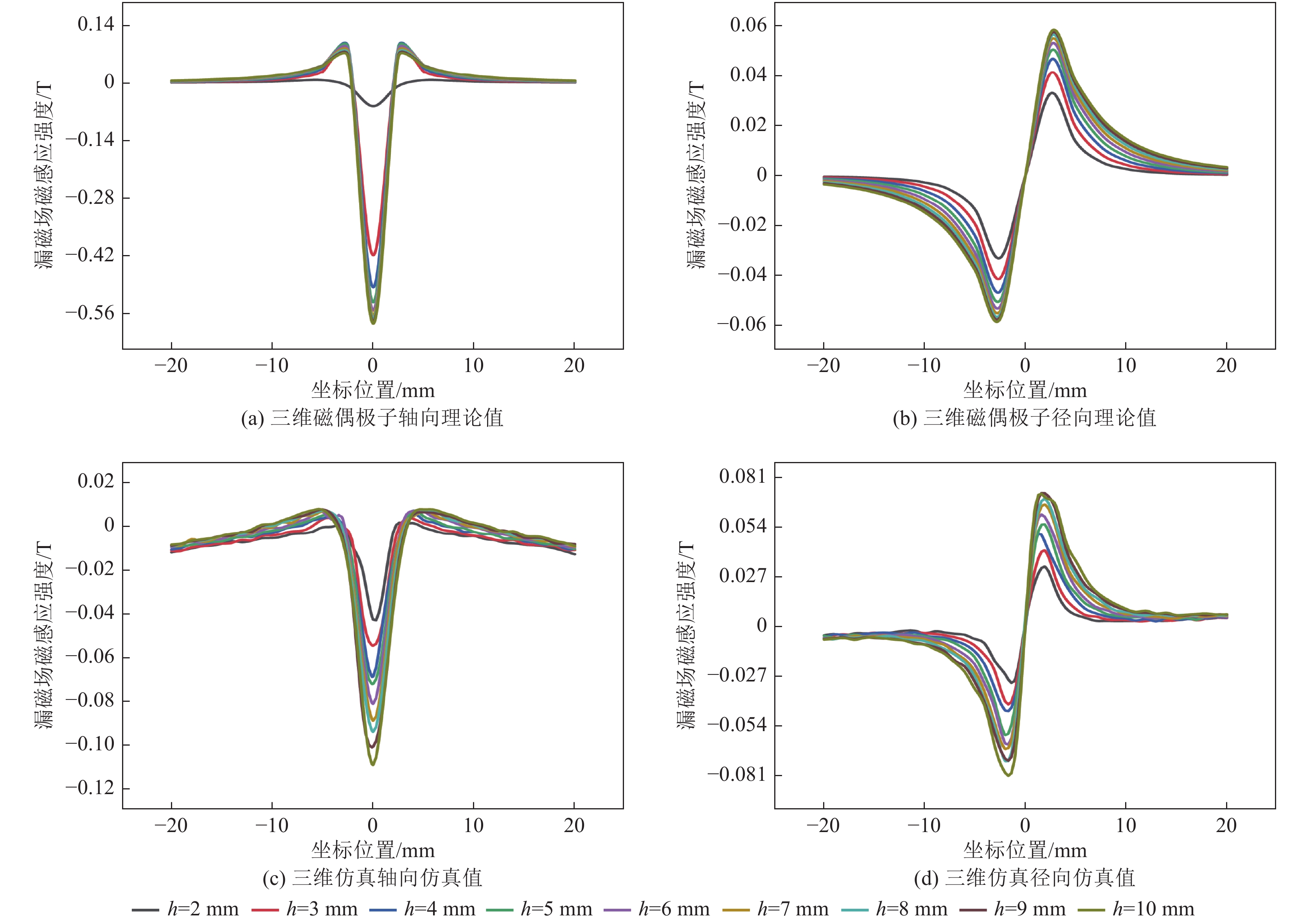

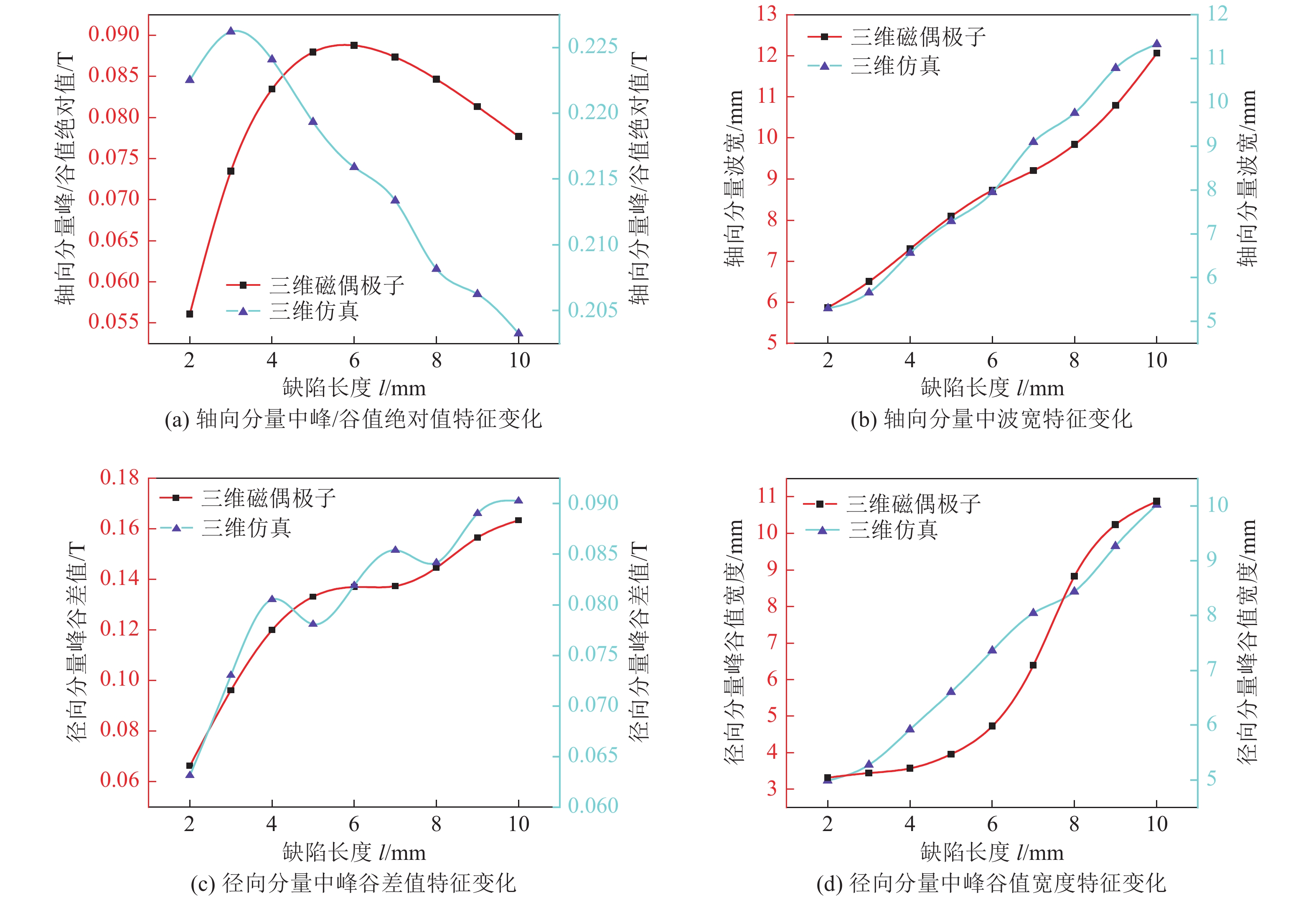

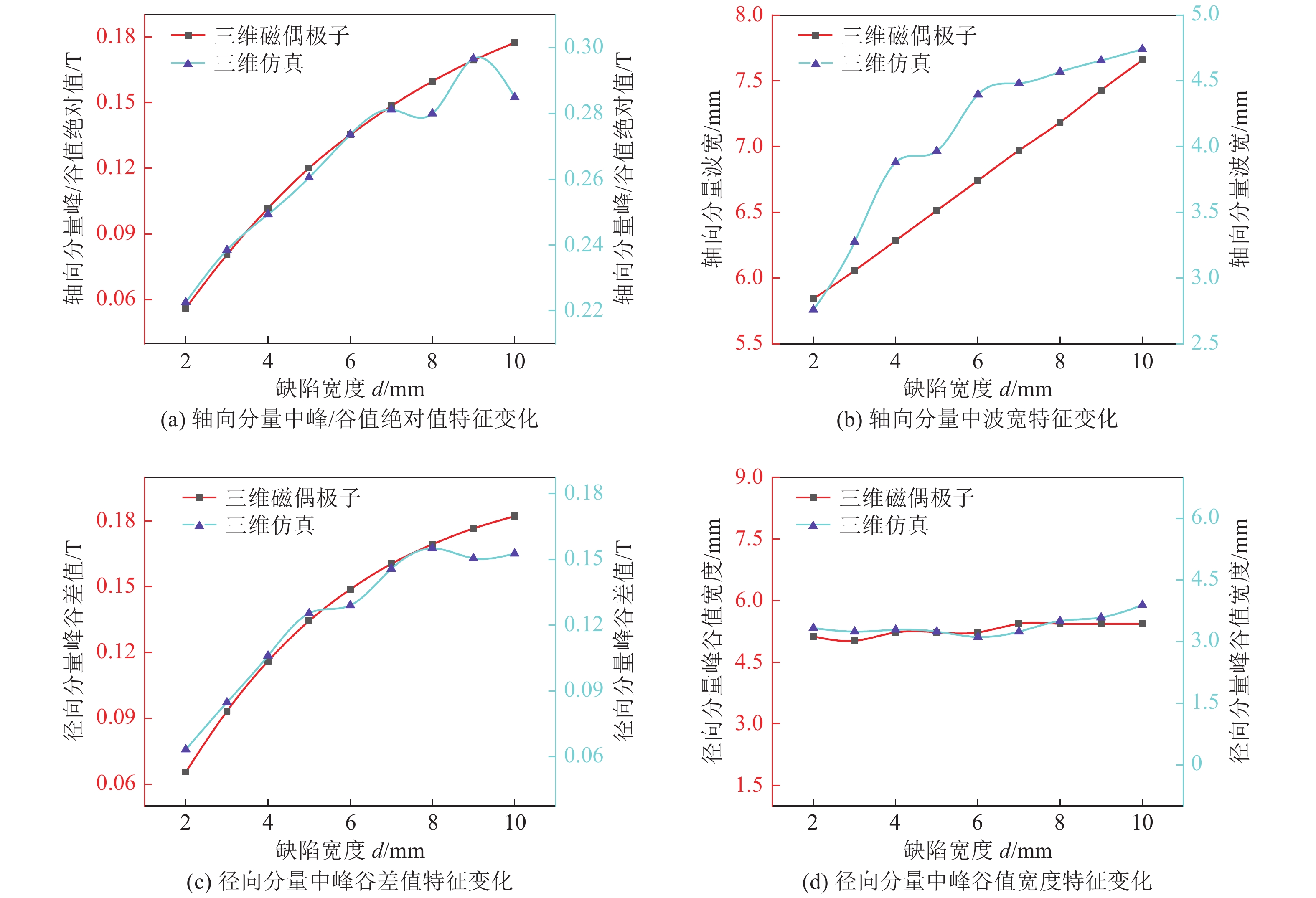

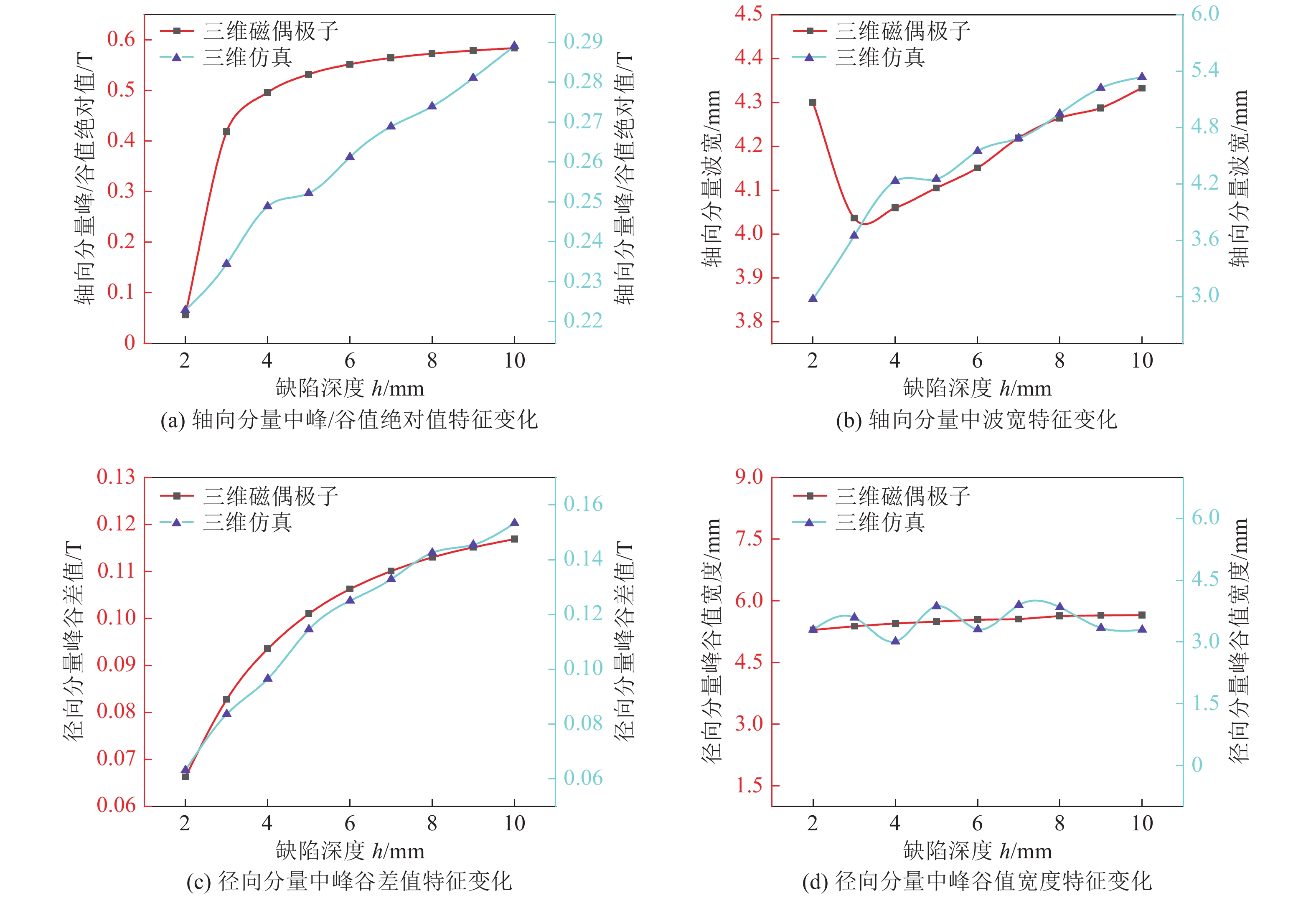

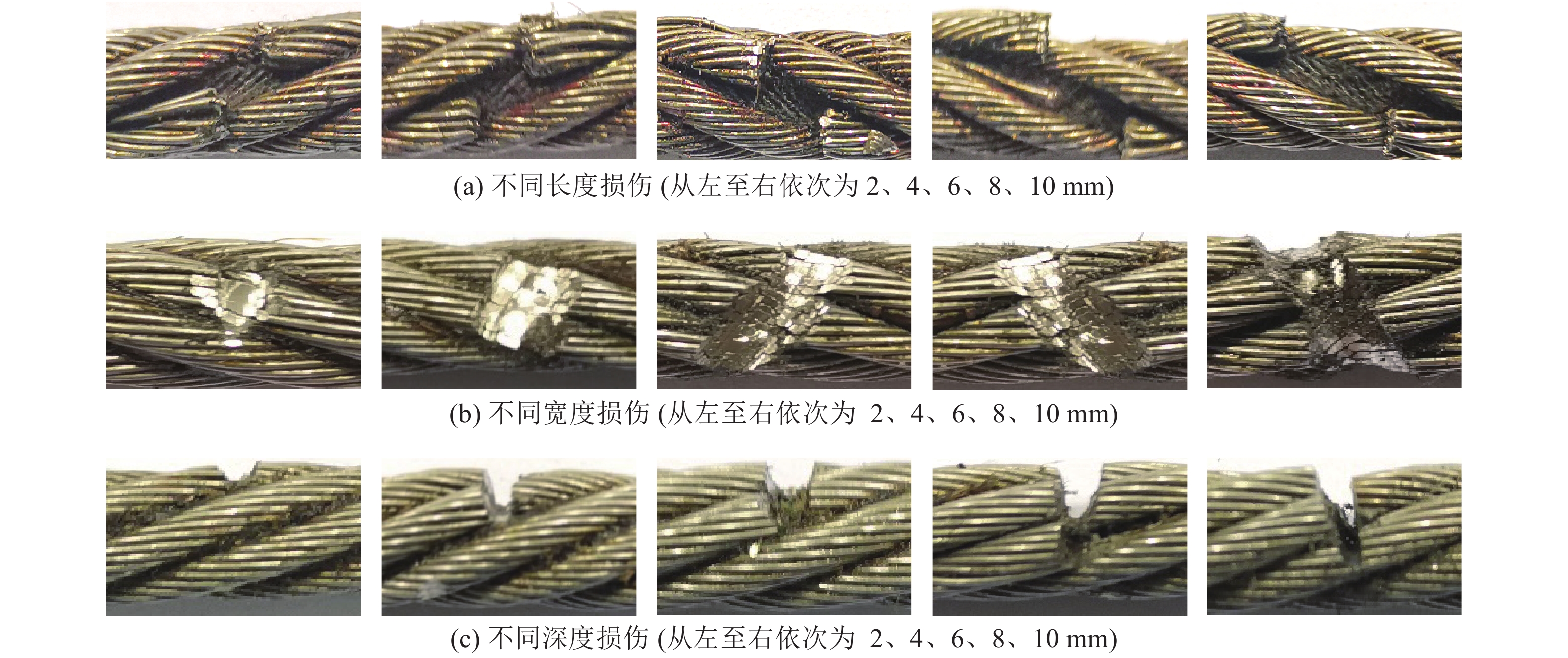

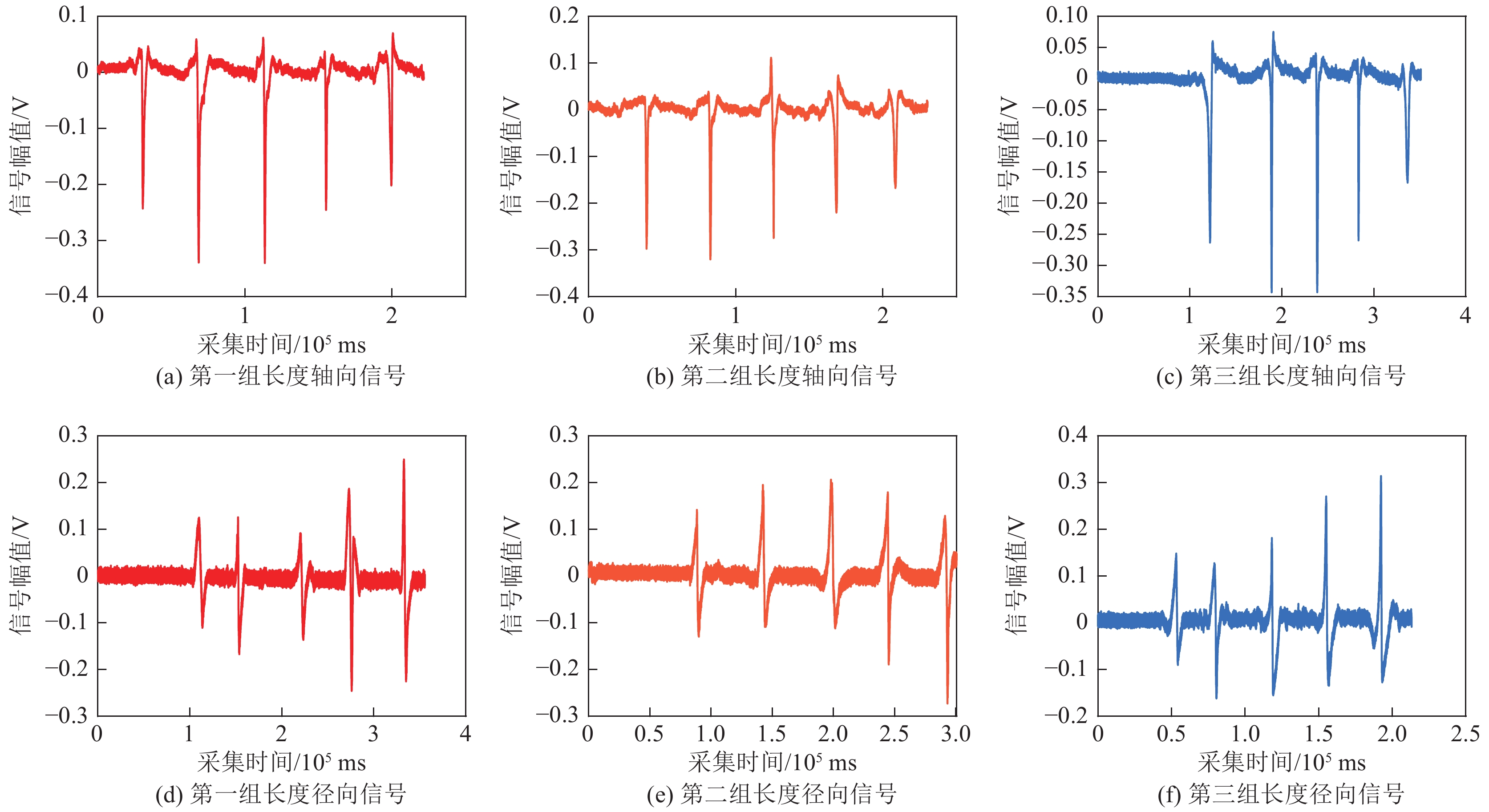

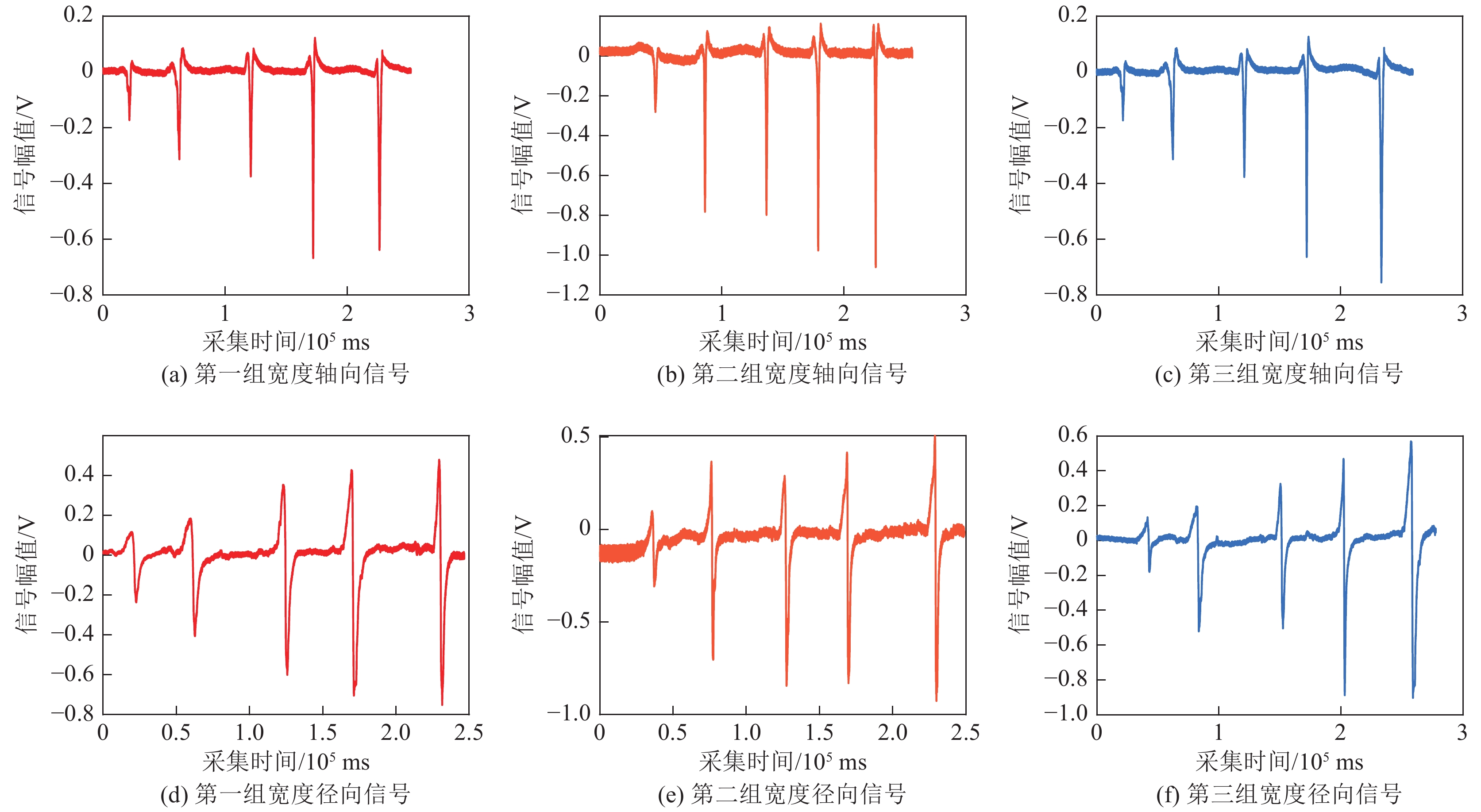

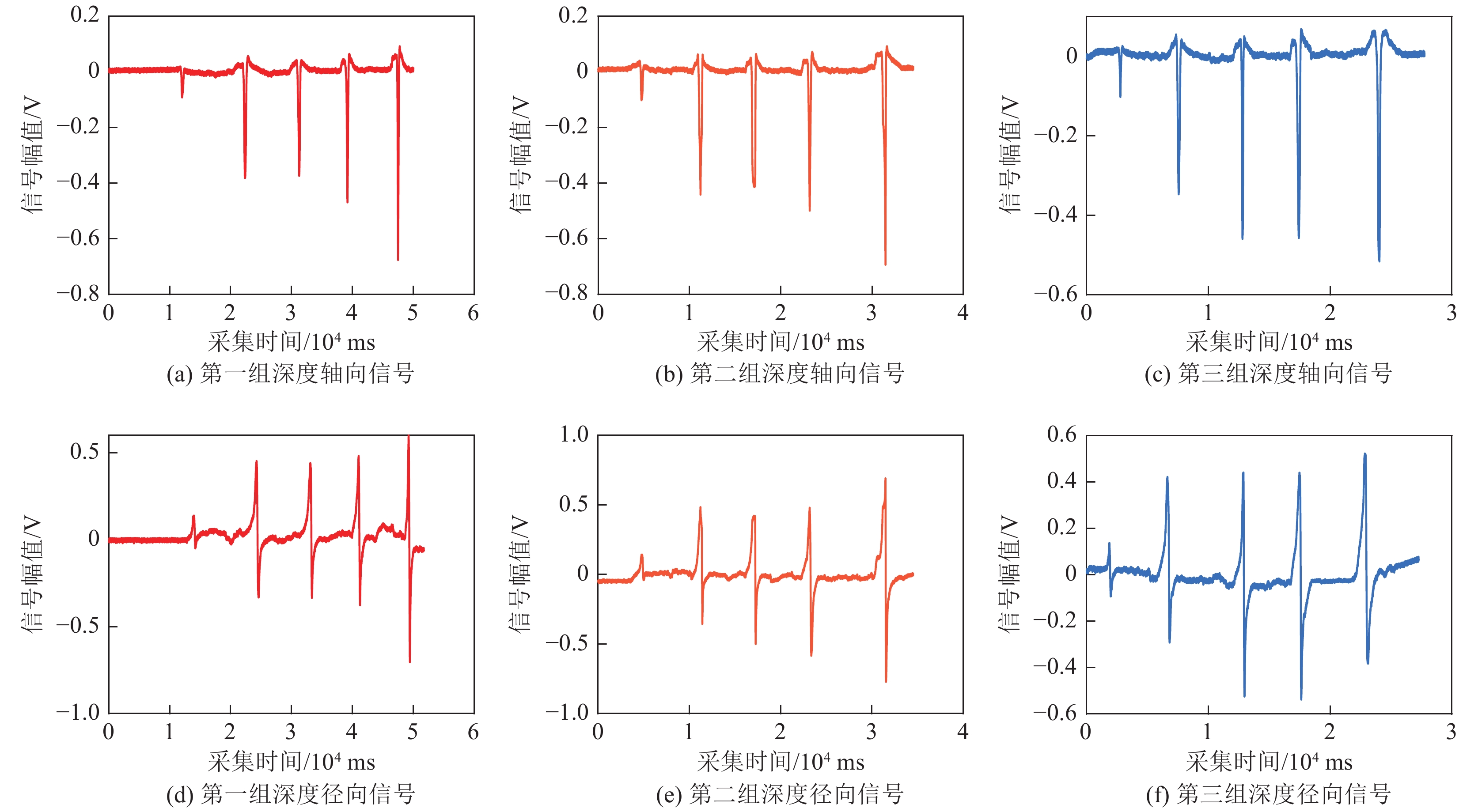

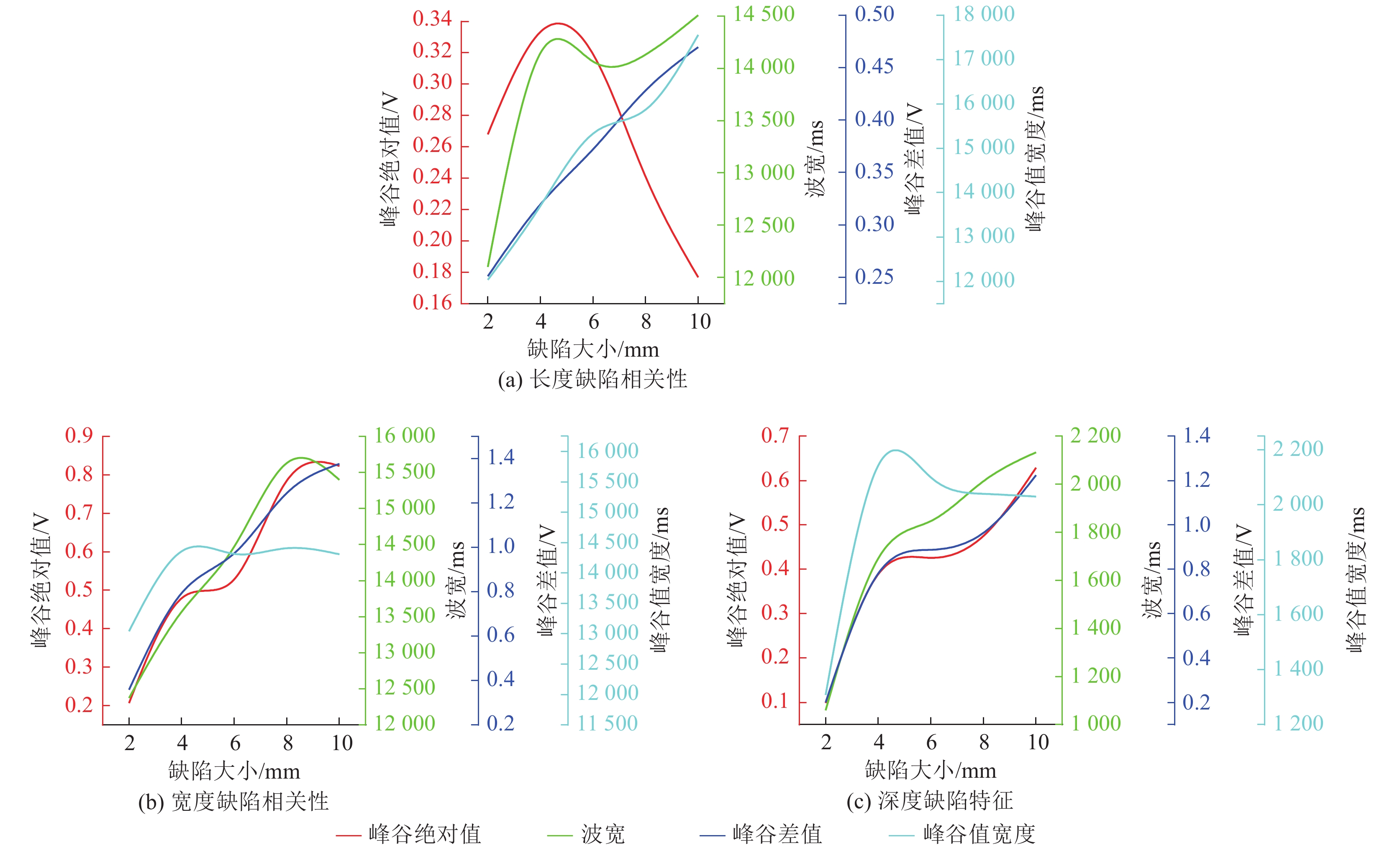

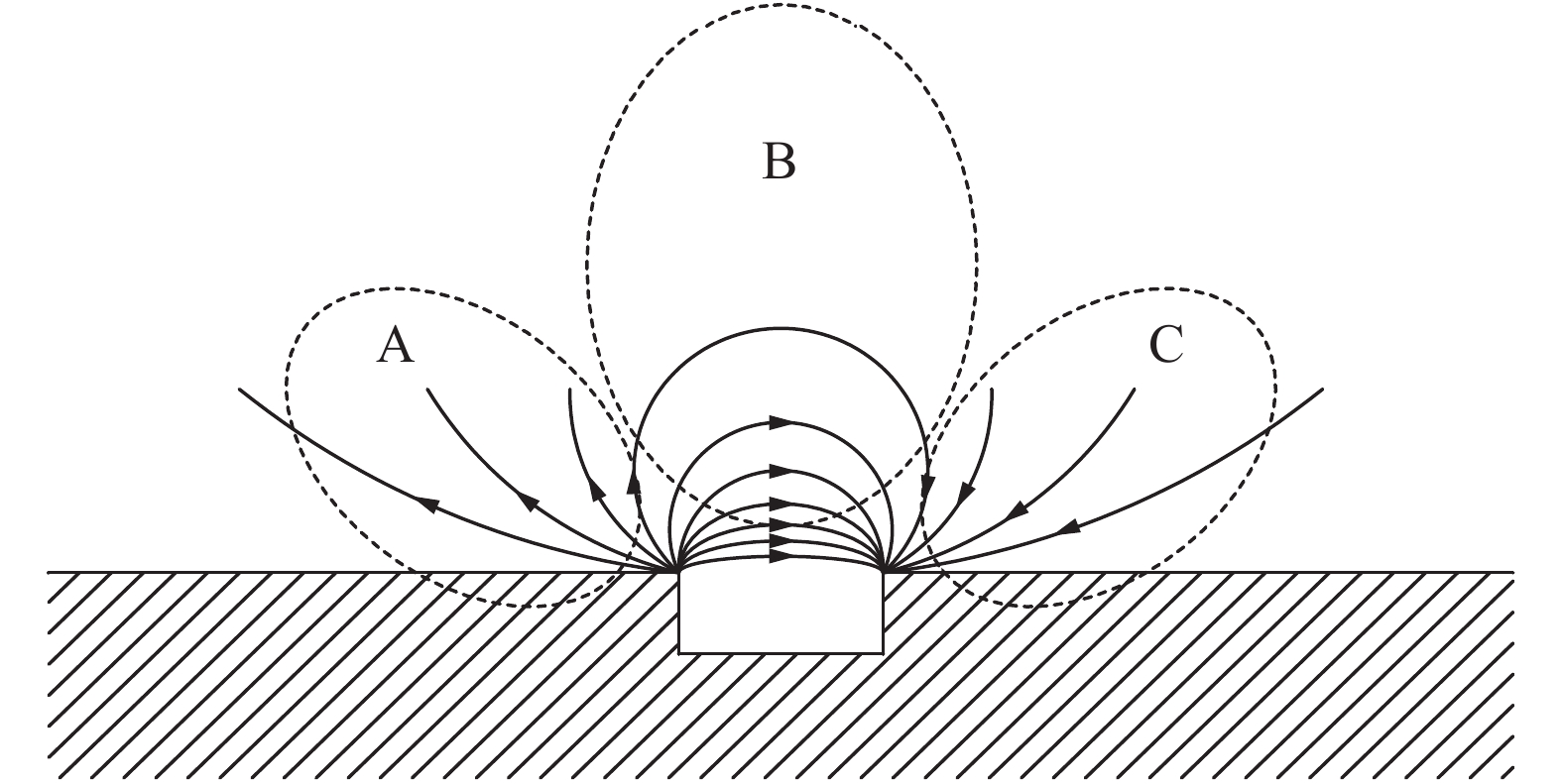

电磁检测是矿用钢丝绳缺陷可靠的检测手段之一。基于电磁法的矿用钢丝绳缺陷检测,目前存在缺陷与信号特性表征规律不明确的问题,定量识别时存在无关信号特性,影响识别准确性。采用三维磁偶极子理论计算、Maxwell模拟仿真与试验相互验证的方法,总结漏磁信号特性与缺陷变化之间的表征关系。首先建立磁场环境下的钢丝绳三维磁偶极子理论模型,应用模型对标准缺陷处进行磁场理论计算并进行Maxwell模拟仿真;分别提取理论值与仿真值的峰/谷绝对值、波宽、峰谷差值、峰谷值宽度四项信号特性,进行缺陷与信号的表征分析;最后设计缺陷进行试验验证,得到试验数值的斯皮尔曼相关系数。试验结果表明:缺陷的宽度、深度与峰/谷绝对值、波宽、峰谷差值3个信号特征值呈正相关,与峰谷值宽度无明显相关性;缺陷长度与峰/谷绝对值呈先上升后下降的趋势,与波宽、峰谷差值、峰谷值宽度呈正相关。并且发现宽度缺陷信号幅值最强,长度缺陷信号幅值最弱,深度信号幅值居中,峰谷差值和峰谷绝对值与缺陷相关性最高。该研究具有一定的工程指导价值。

Abstract:Electromagnetic detection is one of the reliable means of detecting mining wire rope defects. Based on the electromagnetic method of mining wire rope defect detection, there is a problem of unclear characterization law of defects and signal properties, and there are irrelevant signal properties in quantitative identification, which affects the accuracy of identification. The characterization relationship between the leakage signal characteristics and defect changes is summarized by using the method of three-dimensional magnetic dipole theory calculation, Maxwell simulation and experimental mutual verification. Firstly, the three-dimensional magnetic dipole theoretical model of steel wire rope under magnetic field environment is established, and the model is applied to the standard defects at the magnetic field theoretical calculations and Maxwell analog simulation; the peak/valley absolute value, wave width, peak/valley difference, peak/valley width of the theoretical and simulated values are extracted respectively, and the characterization analysis of the defects and the signals is carried out; finally, the design of defects is experimentally verified, and the experimental values of the Spearman correlation coefficients are obtained. The experimental results show that: the width and depth of defects are positively correlated with three signal eigenvalues of peak/valley absolute value, wave width and peak/valley difference, and there is no obvious correlation with peak/valley width; the length of defects shows a trend of increasing and then decreasing with peak/valley absolute value, and positively correlates with wave width, peak/valley difference and peak/valley width. And it is found that the width defect signal amplitude is the strongest, the length defect signal amplitude is the weakest, the depth signal amplitude is in the middle, and the peak/valley difference and peak/valley absolute value have the highest correlation with the defect. This study has certain engineering guidance value.

-

-

表 1 长度信号特征统计

Table 1 Statistics of length signal characteristics

缺陷深度/mm 峰/谷绝对值/V 波宽/ms 峰谷差值/V 峰谷值宽度/ms 第一组 第二组 第三组 平均值 第一组 第二组 第三组 平均值 第一组 第二组 第三组 平均值 第一组 第二组 第三组 平均值 2 0.2427 0.2973 0.2636 0.2679 16100 10170 9940 12070 0.2462 0.2677 0.2371 0.2503 14100 12090 9870 12020 4 0.3370 0.3195 0.3435 0.3333 17000 14000 11440 14147 0.3655 0.2927 0.2913 0.3165 15300 14600 11000 13633 6 0.3399 0.2742 0.3433 0.3191 19800 11300 11100 14067 0.4337 0.3311 0.3378 0.3675 17100 16600 11930 15210 8 0.2450 0.2177 0.2601 0.2409 19300 13300 9800 14133 0.4751 0.3678 0.4225 0.4218 16300 17200 13700 15733 10 0.2015 0.1623 0.1663 0.1767 19230 13600 10700 14510 0.5444 0.3986 0.4424 0.4618 20900 16800 14400 17367 表 2 宽度信号特征统计

Table 2 Statistics of width signal characteristics

缺陷深度/mm 峰/谷绝对值/V 波宽/ms 峰谷差值/V 峰谷值宽度/ms 第一组 第二组 第三组 平均值 第一组 第二组 第三组 平均值 第一组 第二组 第三组 平均值 第一组 第二组 第三组 平均值 2 0.1705 0.2822 0.1677 0.2068 12320 11280 13520 12373 0.3538 0.4080 0.3127 0.3582 15800 12000 11326 13042 4 0.3135 0.8110 0.3127 0.4791 13030 12200 15470 13567 0.5912 1.0724 0.7176 0.7937 13810 15200 14060 14357 6 0.3781 0.8265 0.3814 0.5287 14500 13320 15600 14473 0.9538 1.1364 0.8303 0.9735 14300 14650 14000 14317 8 0.6736 1.01 0.6727 0.7854 15800 15200 15900 15633 1.1318 1.2485 1.3554 1.2452 14400 13400 15430 14410 10 0.6390 1.076 0.7558 0.8236 14000 15500 16700 15400 1.2309 1.4344 1.4649 1.3767 14600 14730 13600 14310 表 3 深度信号特征统计

Table 3 Statistics of deep signal characteristics

缺陷深度/mm 峰/谷绝对值/V 波宽/ms 峰谷差值/V 峰谷值宽度/ms 第一组 第二组 第三组 平均值 第一组 第二组 第三组 平均值 第一组 第二组 第三组 平均值 第一组 第二组 第三组 平均值 2 0.0913 0.1022 0.1024 0.0986 1300 1122 755 1059 0.1890 0.1839 0.2294 0.2008 2070 1060 795 1308 4 0.3817 0.4415 0.3437 0.3890 2400 1060 1614 1691 0.7863 0.8403 0.7154 0.7807 2930 1800 1700 2143 6 0.3840 0.4346 0.4596 0.4261 1950 1970 1620 18467 0.7767 0.9205 0.9669 0.8880 2890 1760 1650 2100 8 0.4694 0.4994 0.4574 0.4754 2400 1880 1760 2013 0.8500 1.0655 0.9791 0.9649 2560 1830 1730 2040 10 0.6766 0.6939 0.5163 0.6289 2310 2050 2039 2133 1.3044 1.4628 0.9068 1.2247 2000 2110 1980 2030 表 4 斯皮尔曼分析

Table 4 Spearman analysis

缺陷特征 特征值 相关系数 显著性(P值) 双尾级别 长度 峰谷绝对值/V − 0.6001 0.018 0.05 波宽/ms — 0.587 — 峰谷差值/V 0.884 <0.001 0.01 峰谷值宽度/ms 0.611 0.016 0.05 宽度 峰谷绝对值/V 0.742 0.002 0.01 波宽/ms 0.720 0.002 0.01 峰谷差值/V 0.927 <0.001 0.01 峰谷值宽度/ms — 0.508 — 深度 峰谷绝对值/V 0.949 <0.001 0.01 波宽/ms 0.699 0.004 0.01 峰谷差值/V 0.873 <0.001 0.01 峰谷值宽度/ms — 0.173 — -

[1] 张 峰. 在役钢丝绳检测案例分析[J]. 中国特种设备安全,2021,37(11):103−107. doi: 10.3969/j.issn.1673-257X.2021.11.023 ZHANG Feng. Analysis of in-service steel wire rope inspection cases[J]. China Special Equipment Safety,2021,37(11):103−107 doi: 10.3969/j.issn.1673-257X.2021.11.023

[2] 阮锴燚,寇子明,王彦栋,等. 矿井提升系统数字孪生快速建模方法研究[J]. 煤炭科学技术,2023,51(9):219−230. RUAN Kaiyi,KOU Ziming,WANG Yandong,et al. Digital twin rapid construction method of a mining hoisting system[J]. Coal Science and Technology,2023,51(9):219−230.

[3] 庄吉庆,鲍久圣,刘 勇,等. 千米深井特大型箕斗直线电机辅助提升系统及控制策略[J]. 煤炭科学技术,2022,50(10):207−215. ZHUANG Jiqing,BAO Jiusheng,LIU Yong, et al. The linear motor auxiliary lifting system and control strategy for kilometers deep well extra large skip [J] Coal Science&Technolgy,2022,50 (10):207−215.

[4] TIAN J,WANG W,WANG H,et al. Enhancing Wire-Rope Damage Signals Based on a Radial Magnetic Concentrator Bridge Circuit[J]. Sensors,2022,22(10):3654. doi: 10.3390/s22103654

[5] LIU S ,SUN Y ,JIANG X , et al.A Review of Wire rope detection methods,sensors and signal processing techniques[J]. Journal of Nondestructive Evaluation,2020,39(4):1−18.

[6] ZHOU J,REN L,LIU Z. Instantaneous lift-off distance estimation in magnetic flux leakage testing of steel wire ropes[C]. Journal of Physics:Conference Series. IOP Publishing,2022,2184(1):012−051.

[7] 田 劼,孙钢钢,李睿峰,等. 基于正交试验的钢丝绳探伤仪结构参数优化[J]. 工矿自动化,2022,48(9):100−108. TIAN Jie,SUN Ganggang,LI Ruifeng et al Optimization of Structural Parameters for Steel Wire Rope Flaw Detectors Based on Orthogonal Testing [J]. Industrial and Mining Automation,2022,48 (9):100−108

[8] 张恩超. 钢丝绳多尺度缺陷定量磁检测技术研究[D]. 哈尔滨:哈尔滨工业大学,2021. ZHANG Enchao. Research on quantitative magnetic testing technology for multi-scale defects of steel wire rope [D]. Harbin:Harbin Institute of Technology,2021

[9] 张义清,谭继文,孟庆文,等. 基于迁移学习的钢丝绳断丝定量检测方法[J]. 振动与冲击,2022,41(12):261−266. ZHANG Yiqing,TAN Jiwen,MENG Qingwen,et al. Quantitative detection method for broken wire of steel wire rope based on Transfer learning[J]. Vibration and Impact,2022,41(12):261−266

[10] 黄松岭,彭丽莎,赵 伟,等. 缺陷漏磁成像技术综述[J]. 电工技术学报,2016,31(20):55−63. doi: 10.3969/j.issn.1000-6753.2016.20.005 HAUNG Songling,PENG Lisa,ZHAO Wei,et al. Overview of defect magnetic flux leakage imaging technology[J]. Journal of Electrical Engineering,2016,31(20):55−63 doi: 10.3969/j.issn.1000-6753.2016.20.005

[11] LONG Y,HUANG S,PENG L,et al. A characteristic approximation approach to defect opening profile recognition in magnetic flux leakage detection[J]. IEEE Transactions on Instrumentation and Measurement,2021,70:1−12.

[12] KANDROODI M R,ARAABI B N,BASSIRI M M,et al. Estimation of depth and length of defects from magnetic flux leakage measurements:verification with simulations,experiments,and pigging data[J]. IEEE Transactions on Magnetics,2016,53(3):1−10.

[13] ZAINI M A H P,SAARI M M,NADZRI N A I,et al. Extraction of flux leakage and eddy current signals induced by submillimeter backside slits on carbon steel plate using a low-field amr differential magnetic probe[J]. IEEE Access,2021,9:146755−146770. doi: 10.1109/ACCESS.2021.3123421

[14] 杨理践,梁成壮,高松巍,等. 管道漏磁内检测的管壁缺陷漏磁场解析模型[J]. 电子测量与仪器学报,2023,35(7):106−114. YANG Lijian,LIANG Chengzhuang,GAO Songwei, et al Analytical model for leakage magnetic field of pipe wall defects in pipeline magnetic leakage internal inspection [J] Journal of Electronic Measurement and Instrumentation,2023,35 (7):106−114

[15] 宿文耀. 基于无损检测的钢丝绳损伤定量识别研究[D]. 济南:山东大学,2023. SU Wenyao. Research on quantitative identification of wire rope damage based on nondestructive testing [D]. Jinan:Shandong University,2023.

[16] 杨叔子. 钢丝绳电磁无损检测[M]. 机械工业出版社,2017. YANG Shuzi. Electromagnetic nondestructive testing of steel wire rope [M] Mechanical Industry Press,2017

[17] 晏小兰. 钢丝绳金属截面积损伤定量检测关键技术研究[D]. 哈尔滨:哈尔滨工业大学,2019. YAN Xiaolan. Research on key technologies for quantitative detection of metal cross section damage in steel wire ropes [D] Harbin:Harbin Institute of Technology,2019

[18] 钟小勇,陈科安,张小红. 基于改进完备集成经验模态分解的钢丝绳缺陷漏磁检测方法[J]. 工矿自动化,2022,48(7):118−124. ZHONG Xiaoyong,CHEN Ke’an,ZHANG Xiaohong Magnetic flux leakage detection method for steel wire rope defects based on improved integrated empirical mode decomposition [J] Journal of Mine Automation,2022,48 (7):118−124.

[19] 周俊莹. 基于磁探伤原理的矿用钢丝绳局部缺陷检测方法研究[D]. 北京:中国矿业大学(北京),2019. ZHOU Junying. Research on local defect detection method for mining steel wire rope based on magnetic flaw detection principle [D] Beijing:China University of Mining and Technology -Beijing,2019

[20] PENG Q L,MCMURRY S M,COEY J M D. Axial magnetic field produced by axially and radially magnetized permanent rings[J]. Journal of magnetism and magnetic materials,2004,268(1−2):165−169. doi: 10.1016/S0304-8853(03)00494-3

[21] 时朋朋,郝 帅. 磁记忆检测的力磁耦合型磁偶极子理论及解析解[J]. 物理学报,2021,70(3):105−114. SHI Pengpeng,HAO Shuai Theory and Analytical expression of force magnetic coupling magnetic dipole for magnetic memory testing [J] Journal of Physics,2021,70 (3):105−114.

[22] 田 劼,宋 姗. 改进粒子群优化小波阈值的矿用钢丝绳损伤信号处理方法研究[J]. 煤炭工程,2020,52(4):103−107. TIAN Jie,SONG Shan Research on signal processing method of mining wire rope damage by improving Particle swarm optimization wavelet threshold [J] Coal Engineering,2020,52(4):103−107

[23] 郏荣荣,杨舒佩,郭泽虹,等. 基于有限元的钢丝绳漏磁检测定量仿真分析[J]. 大学物理,2023,42(2):59−65. JIA Rongrong,YANG Shupei,GUO Zehong, et al Quantitative simulation analysis of magnetic flux leakage detection for steel wire ropes based on finite element method [J] College Physics,2023,42 (2):59−65.

[24] 黄松岭. 现代漏磁无损检测[M]. 北京 机械工业出版社,2017. HUANG Songling. Modern magnetic flux leakage non-destructive testing [M] Beijing Mechanical Industry Press,2017

[25] 毛清华,李 晶,徐小龙,等. 矿用在役提升钢丝绳径向永磁环组合的励磁结构设计[J]. 工程科学与技术,2021,53(4):209−216. MAO Qinghua,LI Jing,XU Xiaolong,et al. Design of excitation structure of radial permanent magnet ring combination for in-service hoisting wire rope in mining[J]. Engineering Science and Technology,2021,53(4):209−216.

-

期刊类型引用(16)

1. 吴震, 高恒, 樊兆峰, 呼天亮, 王小虎, 王学刚, 姚金鹏. 鄂尔多斯矿区冲击地压致灾机制及动力显现防治. 煤矿安全. 2025(07)  百度学术

百度学术

2. 安成, 王静宜, 逯峰. 基于新一代信息技术提升煤矿物联感知和控制交互能力研究. 信息通信技术与政策. 2025(06)  百度学术

百度学术

3. 姚阳,刘猛,郭靖,李越. 采煤工作面高压环形供液系统研发设计. 煤矿现代化. 2025(03): 123-126+132 .  百度学术

百度学术

4. 郭文兵,吴东涛. 我国煤矿开采技术发展与人才培养需求分析. 河南理工大学学报(社会科学版). 2025(03): 92-103 .  百度学术

百度学术

5. 姚阳,王子亚,葛张一. 综采工作面液压支架性能提升应用研究. 中国设备工程. 2025(10): 106-108 .  百度学术

百度学术

6. 王雪峰,王佳,叶荣文,周剑,白德威. 德兴铜矿数字化智能矿山探索与应用实践. 有色金属(矿山部分). 2025(03): 111-118 .  百度学术

百度学术

7. 柴修伟,张龙,胡建华,肖红星,彭亚利,刘光俊,徐亮,赵祥波. 鄂西磷矿智能矿山建设现状与发展方向. 金属矿山. 2025(05): 137-144 .  百度学术

百度学术

8. 李伟,孙希奎. 深地煤炭资源安全高效智能化开采关键技术与实践. 煤炭科学技术. 2024(01): 52-64 .  本站查看

本站查看

9. 年立营,孙文佳,李肖飞,朱家强. 疏水改性对粗精煤泥助滤脱水效果的影响研究. 选煤技术. 2024(01): 18-23 .  百度学术

百度学术

10. 张运华,豆景乐,姚阳. 浅析液压支架应力测试与理论计算. 中国设备工程. 2024(11): 88-91 .  百度学术

百度学术

11. 邓双飞. 厚煤层综放工作面末采阶段火灾综合防治技术研究. 能源与节能. 2024(09): 197-199 .  百度学术

百度学术

12. 常冶衡,张令兰. 数据要素市场下山东省企业资本协同管理模式设计——来自坪效比、产权结构与区域经济模式的机理. 商业会计. 2024(22): 14-19 .  百度学术

百度学术

13. 于永宁,郭佳策. 采空区煤体自热效应及多元气体吸附研究. 山东煤炭科技. 2024(12): 71-75 .  百度学术

百度学术

14. 蔡峰,孔令华,程志恒. 大型煤炭企业煤矿智能化建设进展、问题和对策研究. 中国煤炭. 2023(06): 14-18 .  百度学术

百度学术

15. 文虎,黄剑,赵炬,张铎,黎杰. 基于FLUENT的气化灰渣灌浆输送特性模拟. 煤炭技术. 2023(09): 119-124 .  百度学术

百度学术

16. 雷亚军,闫少宏,王锐,申宇鹏,华照来,周小坡. 曹家滩煤矿大采高智能化综放面工艺优化. 煤炭工程. 2022(12): 7-12 .  百度学术

百度学术

其他类型引用(11)

下载:

下载: