Numerical simulation and application of phased cut blasting in hard rock Roadway in metal mine

-

摘要:

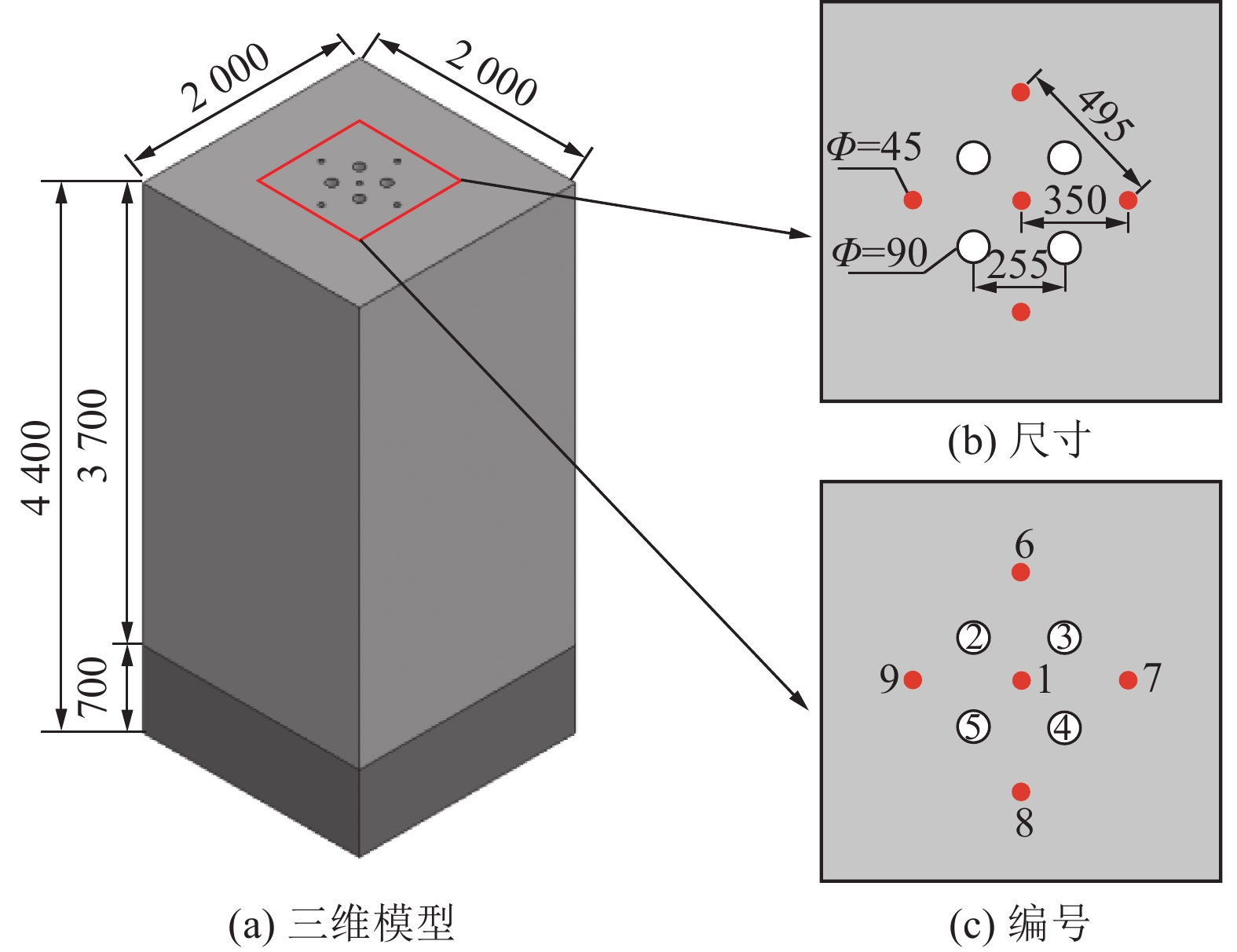

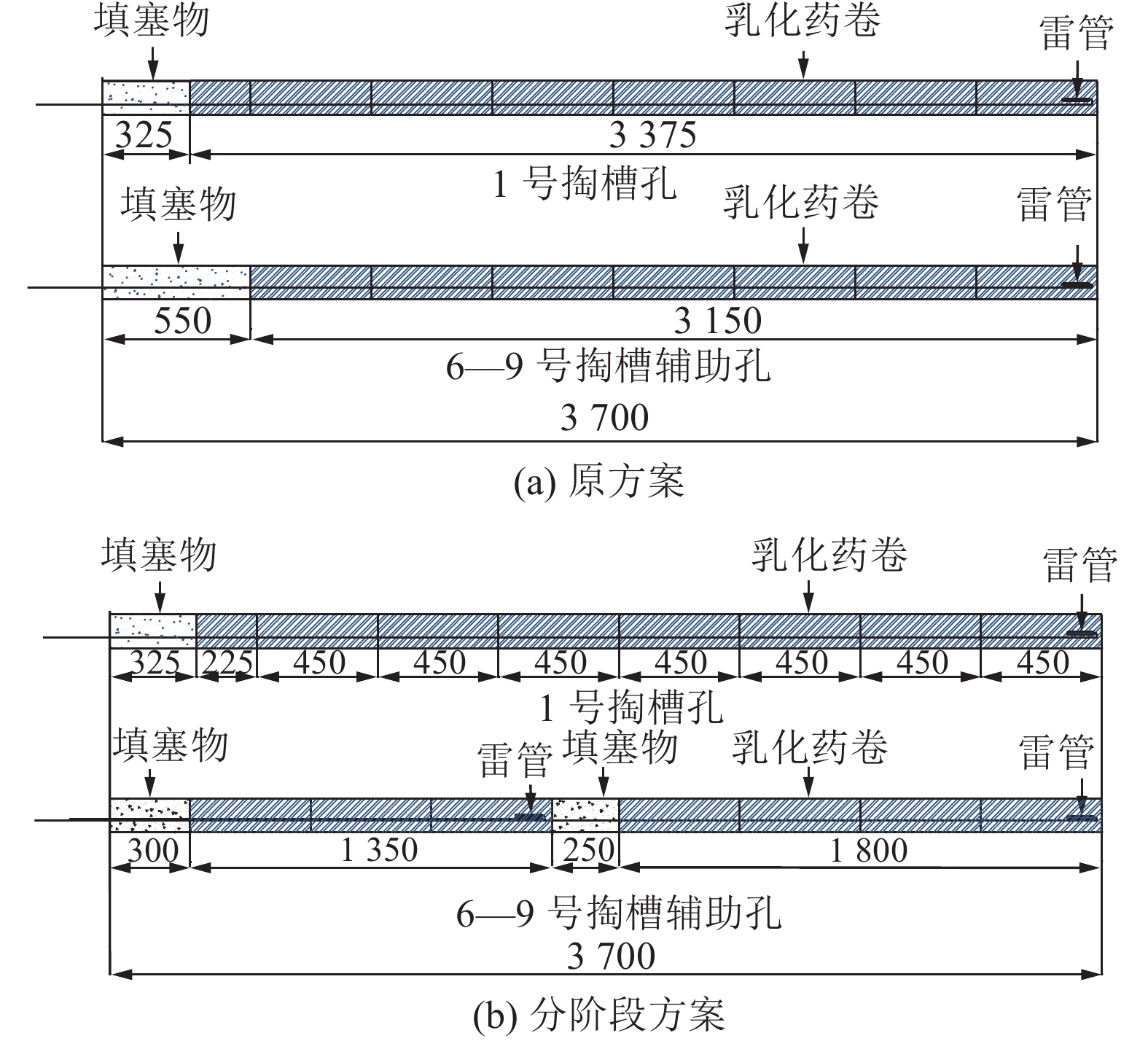

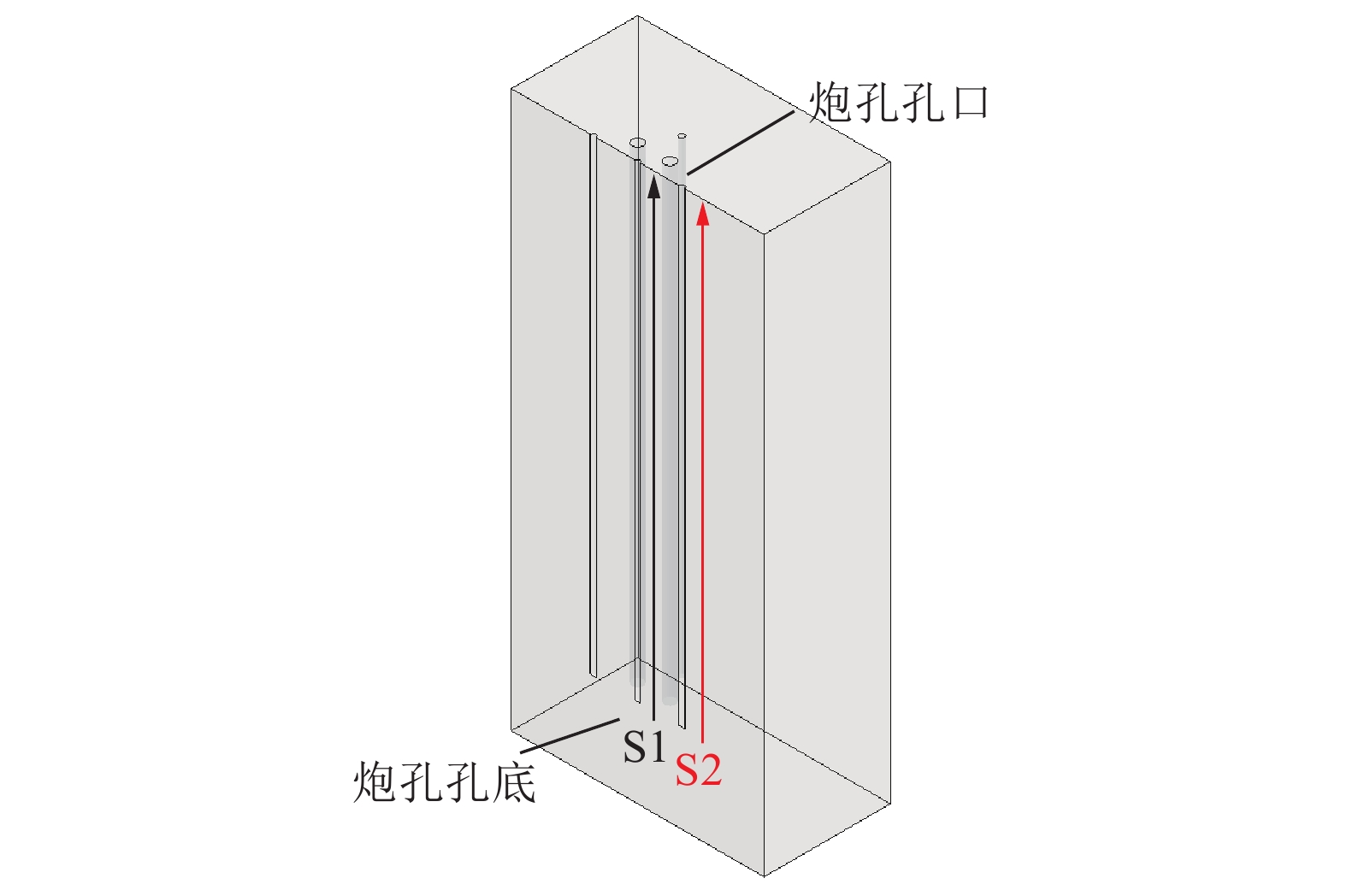

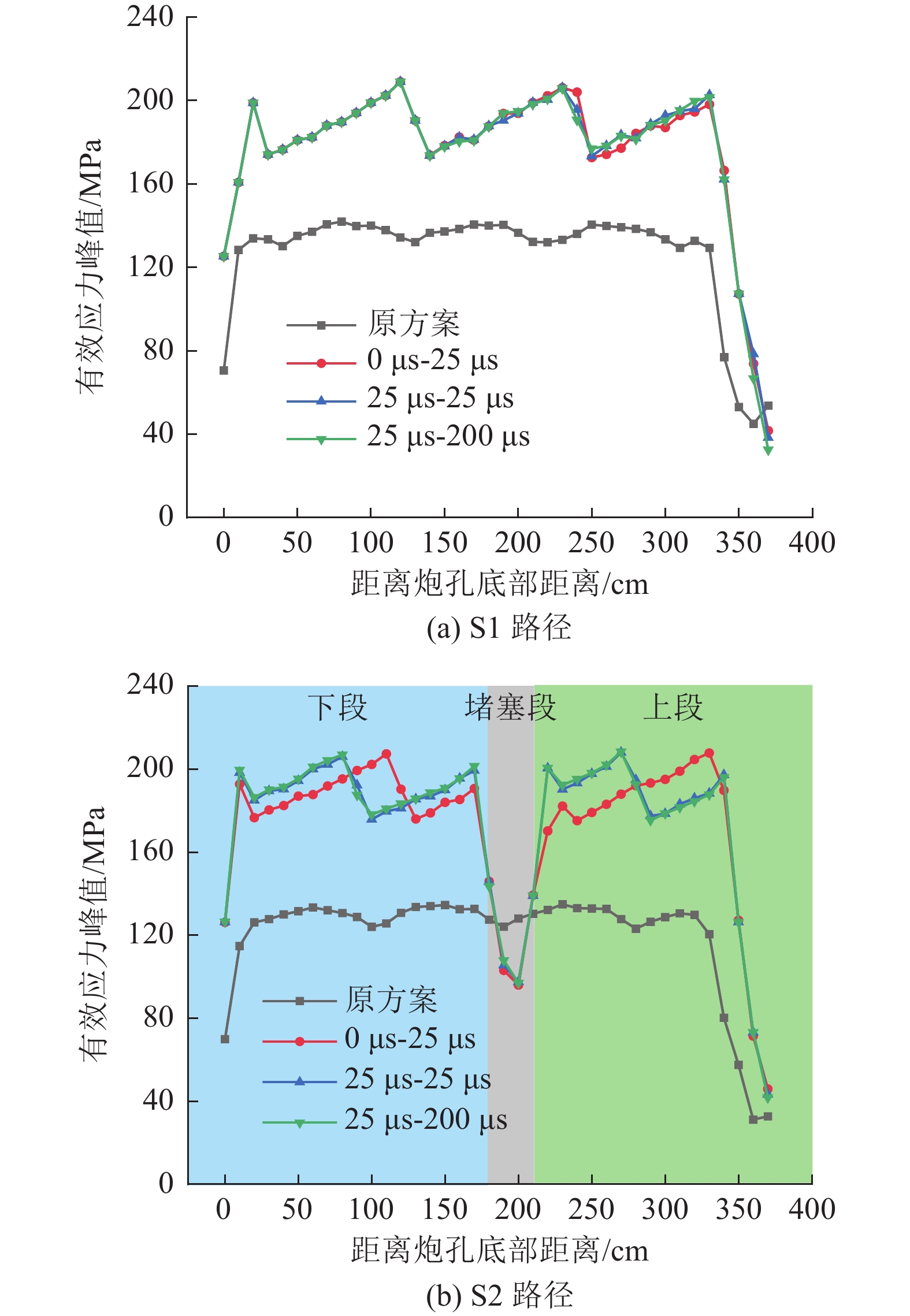

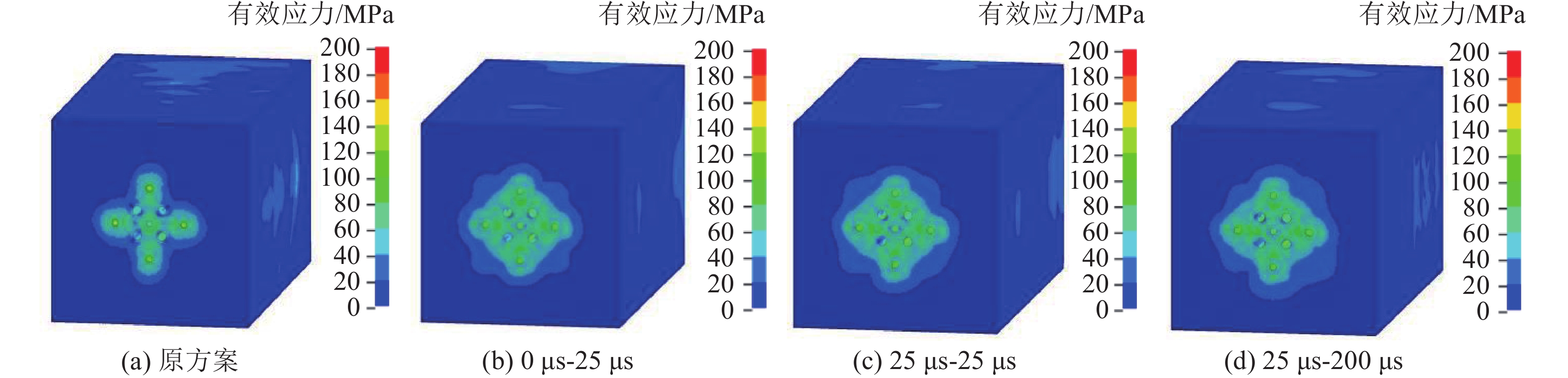

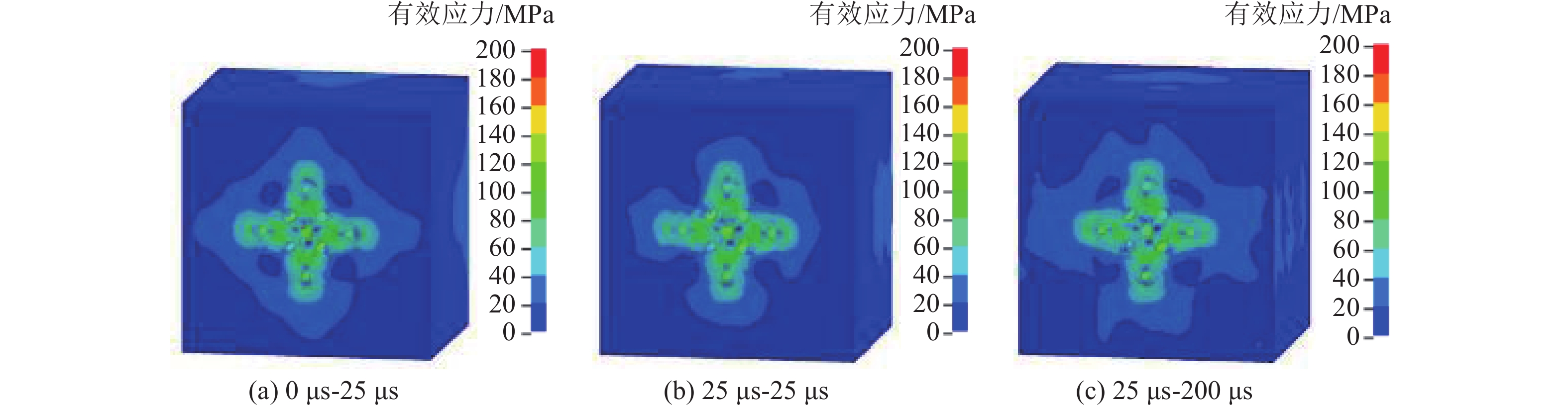

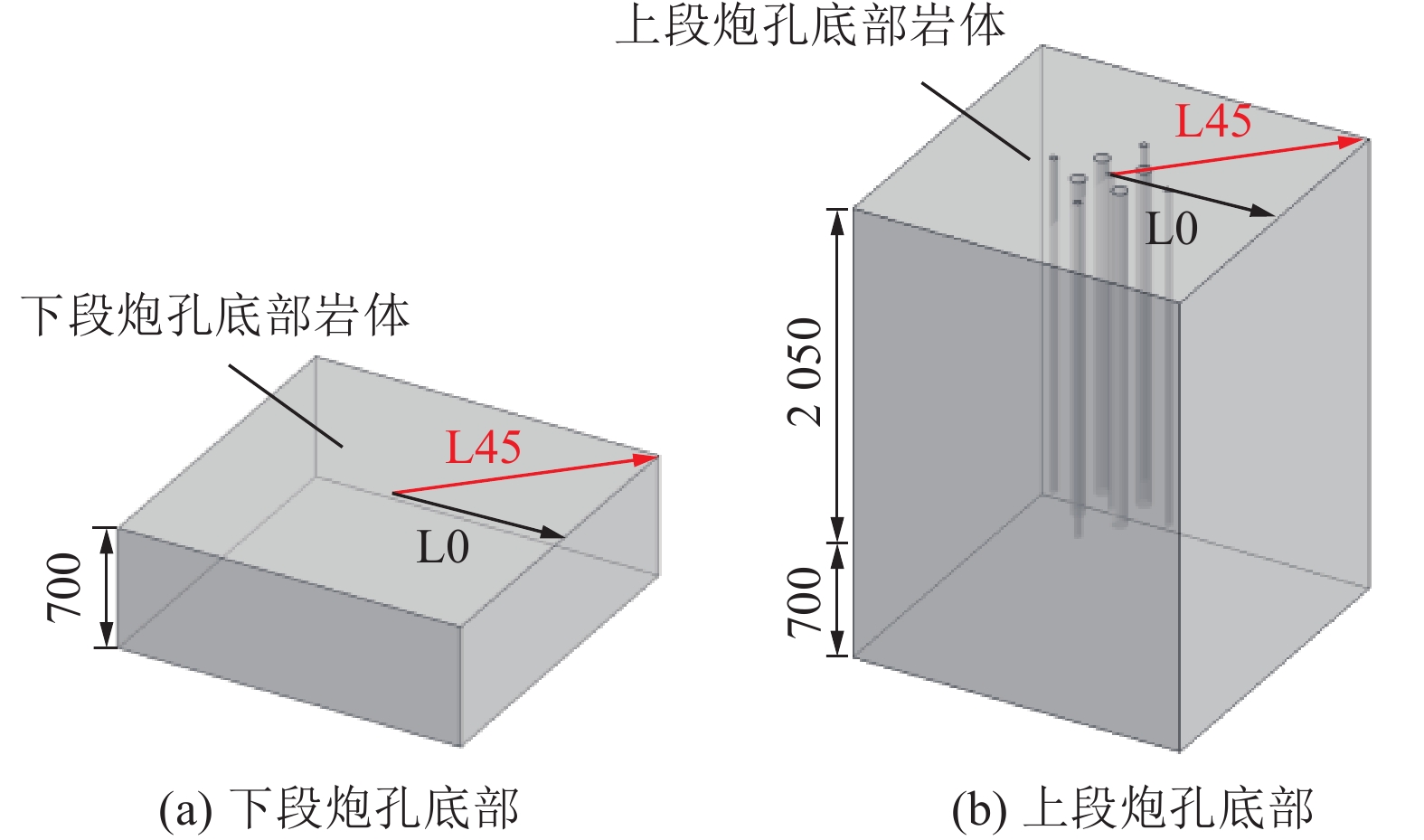

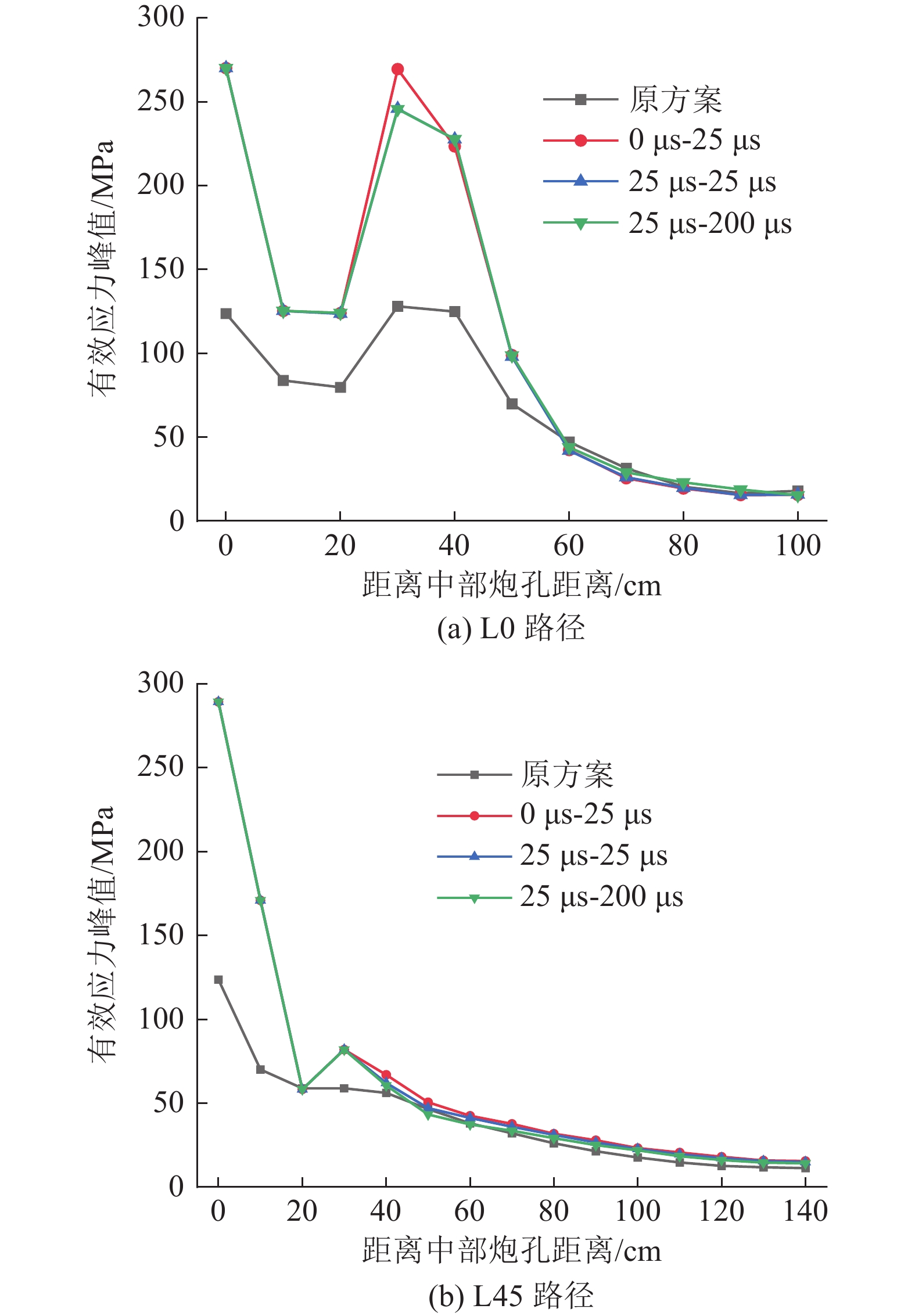

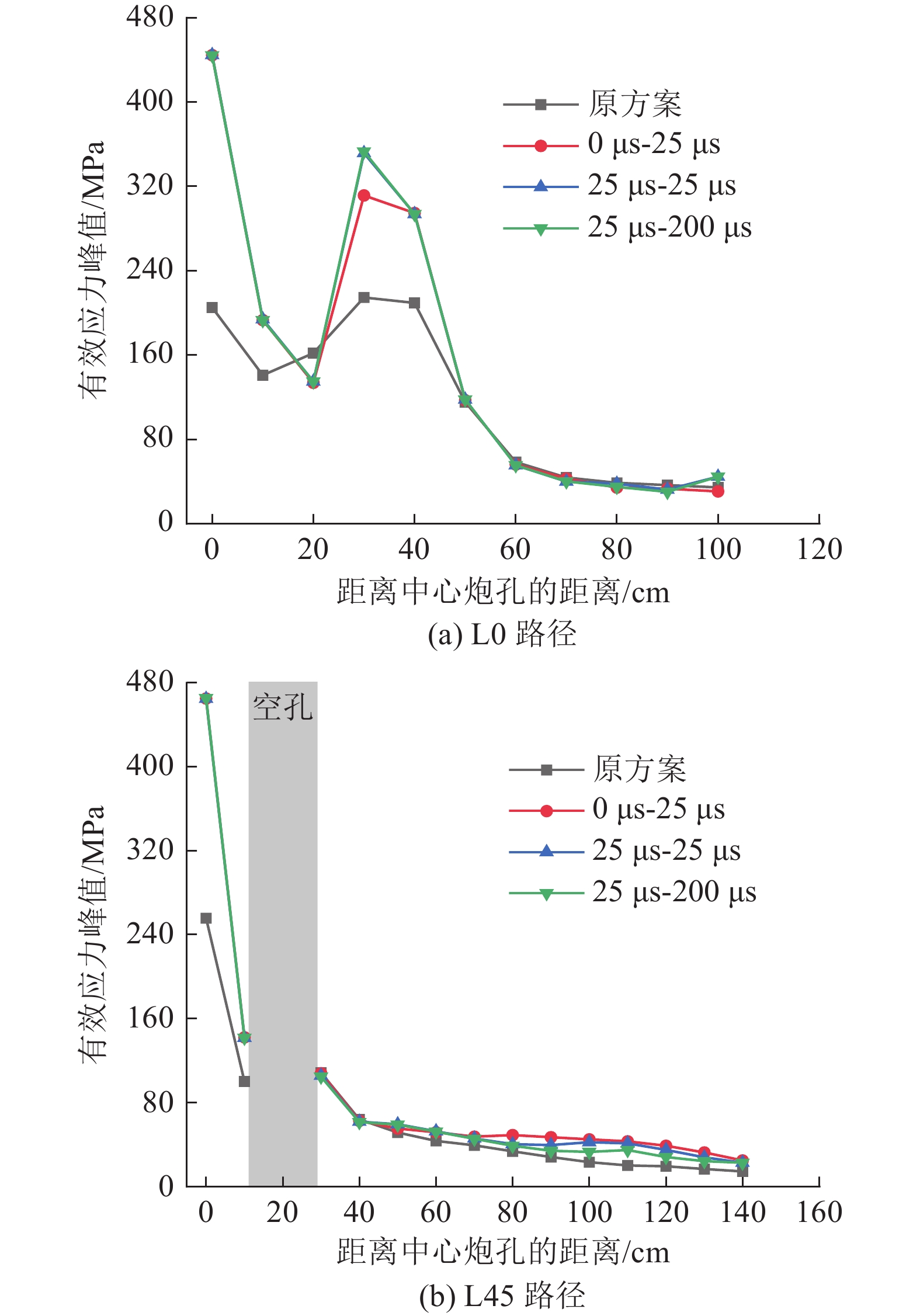

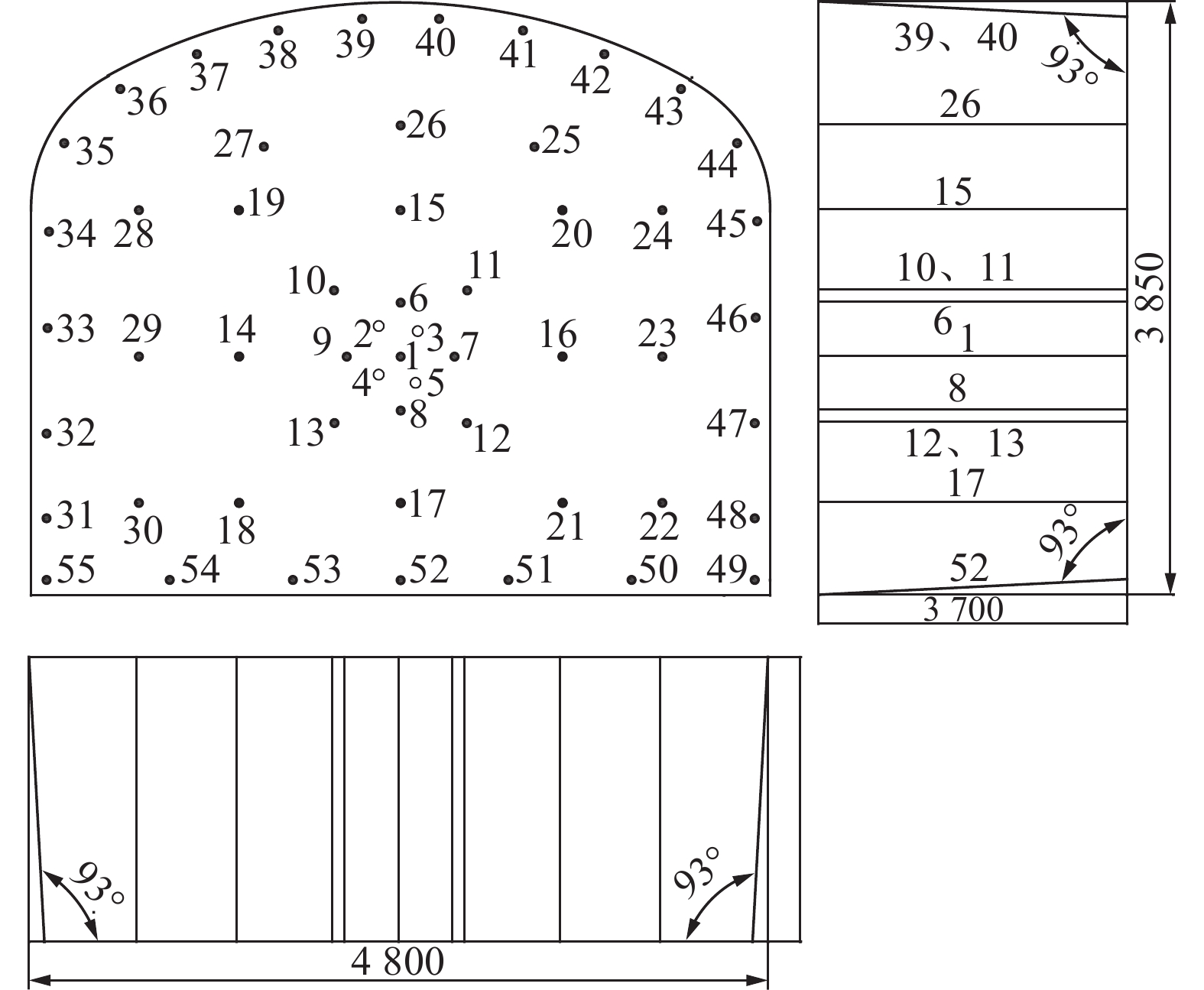

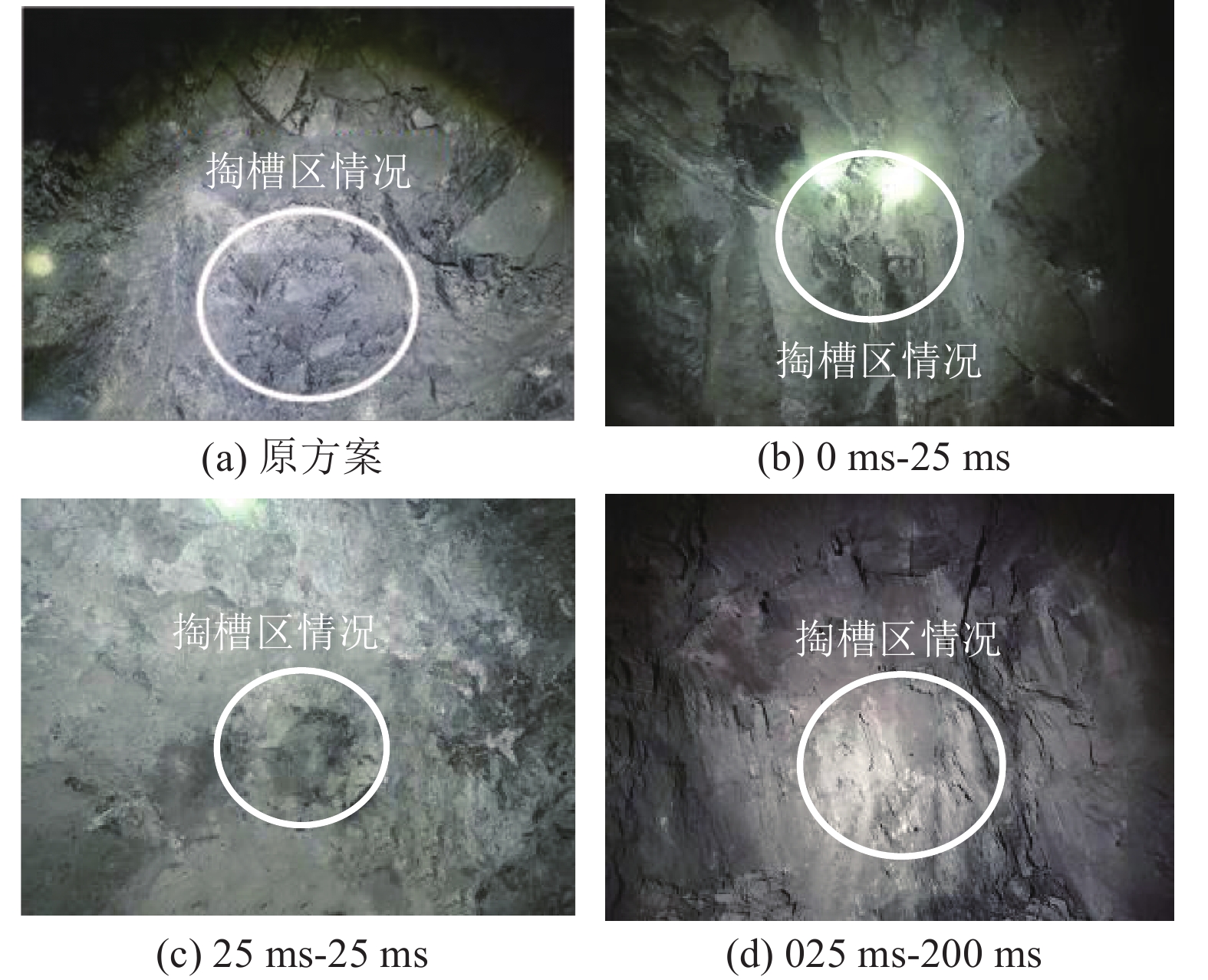

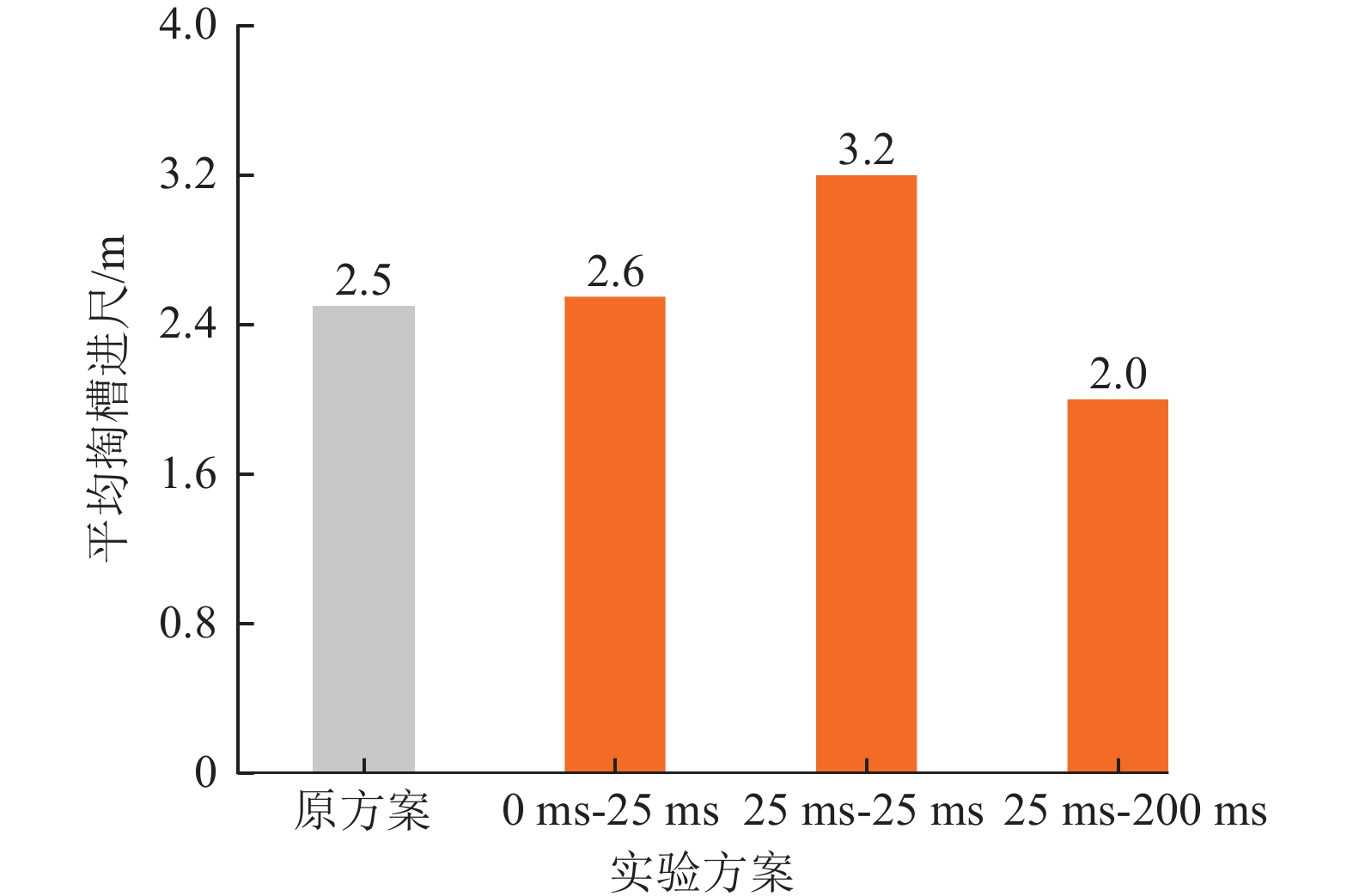

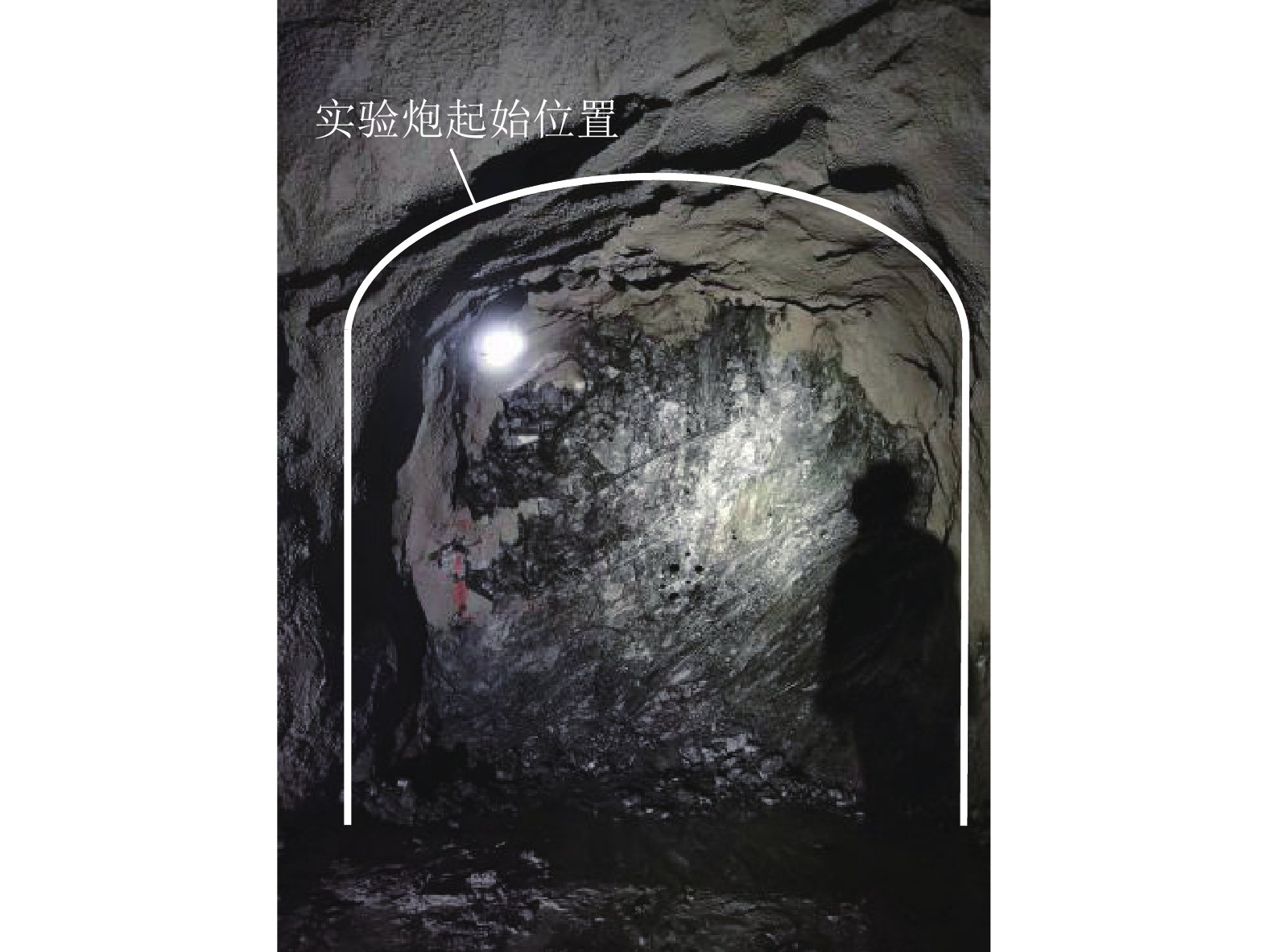

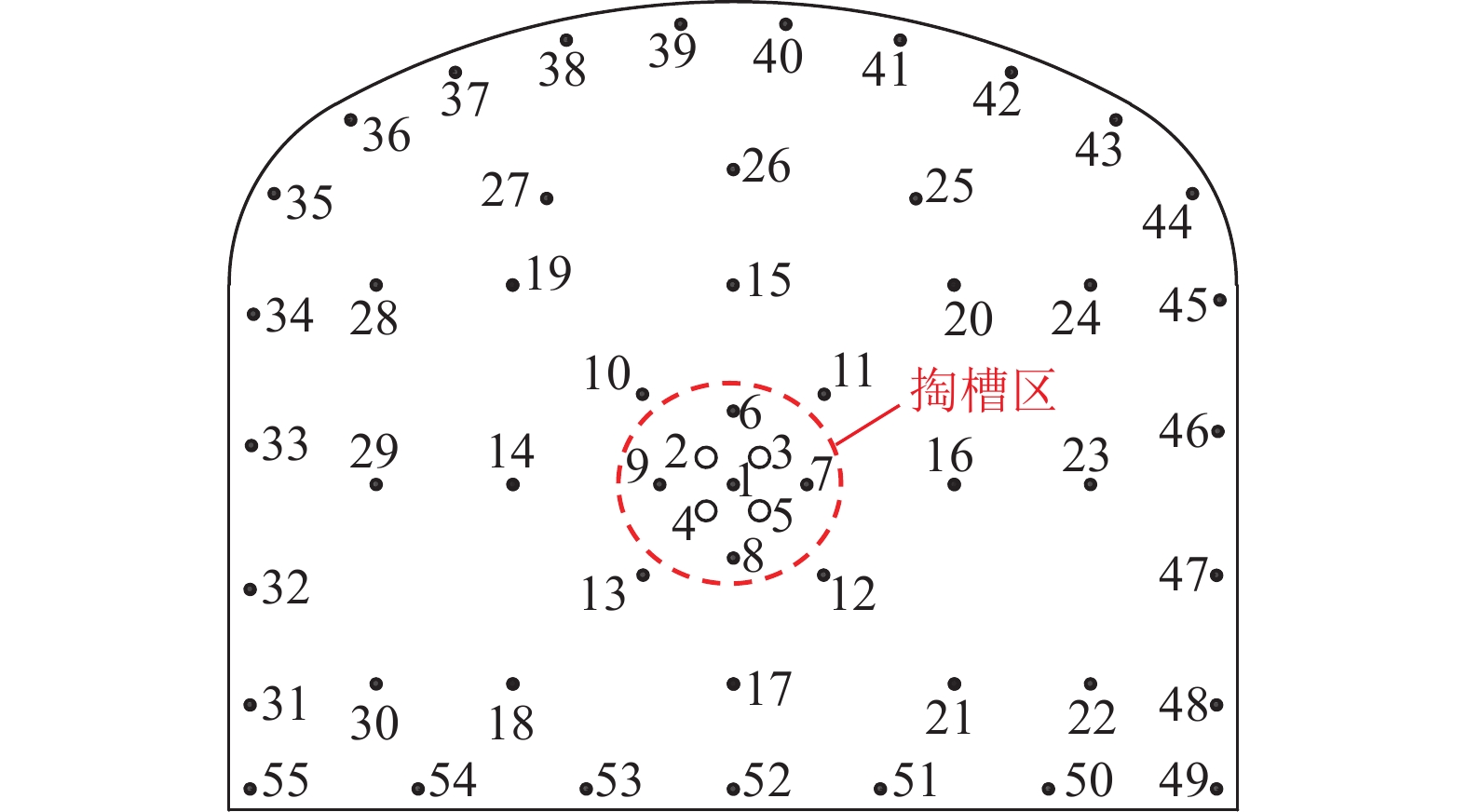

针对地下金属矿山深部硬岩强度高,掏槽难度大,掘进效率低下的问题,以首钢杏山地下铁矿巷道掘进项目为背景,基于数码电子雷管精准逐孔起爆,提出针对直眼桶形掏槽爆破的掏槽区孔内分段与孔间、孔内延时相结合的分阶段爆破方案。采用数值模拟以及现场试验方式,在现场原传统方案的基础上,对掏槽区炮孔进行孔内分段、孔间以及孔内微差起爆的分阶段起爆设置。通过LS-DYNA数值模拟软件建立掏槽区三维模型,设置了原传统方案和3种分阶段方案进行模拟计算,对比分析了原传统爆破方案和分阶段方案在掏槽区的有效应力峰值演化情况。数值模拟结果表明:采用孔间短延时分阶段爆破方案能够改变有效应力峰值波动形态,与原传统方案相比,掏槽区沿炮孔方向岩体的有效应力峰值状态提升40%~57%,炮孔底部0~30 cm半径岩体有效应力峰值状态提升幅度在84%~92%。在数值模拟结果的基础上,开展了现场试验验证,现场试验表明:在矿石点位掘进中,采用孔间短延时微差起爆能够改善碎石挤死的现象,采用孔内短延时微差起爆能够提高抛掷能力,改善上段炮孔爆破后产生碎石的抛掷效果,避免影响后续炮孔爆破,在硬岩爆破中二者结合可以明显改善爆破效果,掏槽进尺提高28%;在岩石点位掘进中,采用孔间短延时,孔内长延时设置能获得良好的掘进效果。

Abstract:In response to the challenges of high rock strength in deep underground metal mines, difficulty in slotting, and low efficiency in excavation, based on the tunneling project at Xingshan Underground Iron Mine of Shougang Corporation, and utilizing precise per-hole blasting with digital electronic detonators, we propose a phased blasting scheme for slotting areas of straight-eye barrel-shaped grooves, combining segmentation within and between holes, as well as delays within each hole. In combination with numerical simulations and field tests, it presents a trench domain gradient detonation configuration with differential detonation in the hole area, between holes and within holes on the basis of the original conventional scheme, builds a three-dimensional(3D) model of the trench domain μsing LS-DYNA numerical simulation software, sets up the original conventional scheme and three gradient schemes for modelling, and provides a comparative analysis of the evolution of the effective peak stress in the dredged-trench zone for the original conventional blasting solution and the staged solution. The results of the numerical simulations show that the μse of short-delay inter-hole blasting can change the fluctuation pattern of the peak effective stress, and compared to the original conventional scheme, the peak effective stress state of the rock in the dredged-trench zone along the direction of the shell hole is increased by 40% to 57%, while the peak effective stress state of the rock in the radiμs of 0-30 cm at the bottom of the shell hole is increased by 84% to 92%. In addition to the numerical simulation results, field experiments were carried out to verify the results. It is clear that the combination of short-delay differential detonation between holes can improve debris crowding in mine excavation, and short-delay differential detonation within holes can improve throwing capacity, improve debris throwing after blasting in the upper part of the shell hole, and avoid affecting the blasting of subsequent shell holes. Incorporating the two in hard rock blasting can significantly improve the blasting effect and increase the hollowing progress by 28%. And better results can be obtained in rock point-excavation by μsing short delay between holes and long delay within hole settings. The results of this paper could provide a reference for similar mine production.

-

Keywords:

- cut blasting /

- time delay between hole /

- tn-hole delay /

- segment straight cut /

- electronic detonator

-

-

表 1 各方案掏槽起爆顺序以及延时

Table 1 Cutting initiation sequence and delay time setting of each scheme

方案 孔内分段比例 孔间延期时间/μs 孔内延期时间/μs 1 原方案(不分段) — — 2 4.4/5.6 0 25 3 4.4/5.6 25 25 4 4.4/5.6 25 200 表 2 各方案孔间以及孔内时设置

Table 2 Inter-hole and in-hole delay settings of each scheme

炮孔编号 炮眼类型 原方案

起爆时间/μs不同延时/μs 0-25 μs

(上段、下段)25 μs

(上段、下段)25-200 μs

(上段、下段)1 掏槽孔 0 0 0 0 2~5 空孔 — — — — 6 掏槽辅助 490 500、525 500、525 500、700 7 掏槽辅助 990 500、525 525、550 525、725 8 掏槽辅助 520 500、525 550、575 550、750 9 掏槽辅助 1020 500、525 575、600 575、775 表 3 矿石材料特性参数

Table 3 Characteristic parameters of ore materials

ρ1/(g·cm−3) G1/GPa Fc/MPa T/MPa 3.46 32.09 130 6.8 表 4 炸药相关参数

Table 4 Related parameters of explosives

ρ2/(g·cm−3) D/(m·s−1) Pcj/GPa A/GPa B/GPa 1.12 4510 9.53 3.264 0.0581 R1 R2 ω E01 5.8 1.56 0.35 0.0323 表 5 原传统爆破方案

Table 5 Original traditional blasting scheme

炮孔编号 1 6 7 8 9 延期时间/ms 0 490 990 520 1 020 表 6 分阶段爆破试验方案

Table 6 Stage and subsection blasting test scheme

ms 炮孔

编号炮眼

类型0 ms-25 ms

(上段、下段)25 ms-25 ms

(上段、下段)25 ms-200 ms

(上段、下段)1 掏槽孔 0 0 0 2—5 空孔 6 掏槽孔 500、525 500、525 500、700 7 掏槽孔 500、525 525、550 525、725 8 掏槽孔 500、525 550、575 550、750 9 掏槽孔 500、525 575、600 575、775 注:表中时间为具体的起爆时间。0 ms即为第一个起爆,500 ms即为第500 ms起爆。同一格子中的2个时间分别为上段药卷起爆时间和下段药卷起爆时间。例:500 ms、525 ms即为上段药卷在第500 ms起爆,下段药卷在第525 ms起爆。其余同理。 -

[1] 何满潮,谢和平,彭苏萍,等. 深部开采岩体力学研究[J]. 岩石力学与工程学报,2005,24(16):2803−2813. doi: 10.3321/j.issn:1000-6915.2005.16.001 HE Manchao,XIE Heping,PENG Suping,et al. Study on rock mechanics in deep mining engineering[J]. Chinese Journal of Rock Mechanics and Engineering,2005,24(16):2803−2813. doi: 10.3321/j.issn:1000-6915.2005.16.001

[2] 谢和平. 深部岩体力学与开采理论研究进展[J]. 煤炭学报,2019,44(5):1283−1305. XIE Heping. Research review of the state key research development program of China:Deep rock mechanics and mining theory[J]. Journal of China Coal Society,2019,44(5):1283−1305.

[3] 李响,怀震,李夕兵,等. 基于裂纹扩展模型的深部硐室围岩致裂规律[J]. 煤炭学报,2019,44(5):1378−1390. LI Xiang,HUAI Zhen,LI Xibing,et al. Fracture patterns induced by deep underground excavation based on a crack propagation model[J]. Journal of China Coal Society,2019,44(5):1378−1390.

[4] 杨仁树. 我国煤矿岩巷安全高效掘进技术现状与展望[J]. 煤炭科学技术,2013,41(9):18−23. YANG Renshu. Present statusus and outlook on safety and high efficient heading technology of mine rock roadway in China[J]. Coal Science and Technology,2013,41(9):18−23.

[5] YANG,Jianhua,WU Zenan,SUN Wenbin,et al. Numerical simulation on radiation and energy of blast-induced seismic waves in deep rock masses[J]. Journal of Central South University,2022,29(2):645−662. doi: 10.1007/s11771-022-4908-x

[6] 罗勇,宫凤强. 深部硬岩巷道围岩板裂破坏试验研究进展与展望[J]. 煤炭科学技术,2022,50(6):46−60. LUO Yong,GONG Fengqiang. Research progress and prospect of laboratory test of rock spalling in deep hard rock roadway[J]. Coal Science and Technology,2022,50(6):46−60

[7] 单仁亮, 马军平, 赵华, 等. 分层分段直眼掏槽在石灰岩井筒爆破中的应用研究[J]. 岩石力学与工程学报, 2003(4): 636−640. doi: 10.3321/j.issn:1000-6915.2003.04.026 SHAN Renliang, MA Junping, ZHAO Hua, et al. Application of staged burn-cut in shaft blasting in limestone.[J]. Chinese Journal of Rock Mechanics and Engineering, 2003(4): 636−640. doi: 10.3321/j.issn:1000-6915.2003.04.026

[8] 杨国梁,姜琳琳,杨仁树. 复式楔形深孔掏槽爆破研究[J]. 中国矿业大学学报,2013,42(5):755−760. YANG Guoliang,JIANG Linlin,YANG Rernshu. Investigation of cut blasting with duplex wedge deep holes[J]. Journal of China University of Mining & Technology,2013,42(5):755−760.

[9] 宗琦,王从平. 深孔分段直眼掏槽试验研究[J]. 有色金属(矿山部分),2001(3):11−13. doi: 10.3969/j.issn.1671-4172.2001.03.004 ZHONG Qi,WANG Congping. Experimental study on deep hole segmented straight hole cutting[J]. Nonferrousus Metals(Mining Section),2001(3):11−13. doi: 10.3969/j.issn.1671-4172.2001.03.004

[10] 高全臣,杨永琦,宋浩,等. 岩巷中深孔光爆最佳掏槽方式探讨[J]. 建井技术,1996(4):28−32. GAO Quanchen,YANG Yongqi,SONG Hao,et al. Discusussion on the best cutting way of light explosion in deep hole in rock roadway[J]. Mine Construction Technology,1996(4):28−32.

[11] YANG Renshu,ZHENG Changda,YANG Liyun,et al. Study of two-step parallel cutting technology for deep-hole blasting in shaft excavation[J]. Shock and Vibration,2021(1):8815564.

[12] 倪昊. 竖井二氧化碳“二阶二段”筒形掏槽爆破技术及应用[J]. 煤炭科学技术,2023,51(10):65−71. NI Hao. Application and carbon dioxide two-step barrel cut blasting technology in coal mine shaft[J]. Coal Science and Technology,2023,51(10):65−71.

[13] LENG Zhendong,SUN Jinshan,LU Wenbo,et al. Mechanism of the in-hole detonation wave interactions in dual initiation with electronic detonators in bench blasting operation[J]. Computers and Geotechnics 2021,129:103873

[14] KATSABANIS P D,TAWADROUSΜS A,BRAUN C,et al. Timing effects on the fragmentation of small scale blocks of granodiorite[J]. Fragblast,2006,10(1-2):83−93. doi: 10.1080/13855140600858339

[15] MA Jun,LI Xianglong,WANG Jiangguo,et al. Numerical simulation on selection of optimal delay time for precise delay blasting[J]. Shock and Vibration,2021,2021:4593221,9.

[16] SAADATMAND H,KATSABANIS A P. The effect of stress wave interaction and delay timing on blast-induced rock damage and fragmentation[J]. Rock Mechanics and Rock Engineering,2020,53(5):2327−2346. doi: 10.1007/s00603-019-02043-9

[17] CHEN Xudong,XU Lingyu,ZHU Qiao. Mechanical behavior and damage evolution for concrete subjected to multiple impact loading[J]. Ksce Journal of Civil Engineering. 2017,21(6):2351-2359.

[18] MANUAL,K U S. LS-DYNA keyword user’s manual. LSTC Co.,Livermore,CA[Z] . 2007.

[19] 李志鹏,吴顺川,严琼,等. 瓦斯剧烈爆炸隧道衬砌损伤数值模拟与机理分析[J]. 煤炭学报,2018,43(S1):167−177. LI Zhipeng,WU Shunchuan,YAN Qiong,et al. Numerical simulation and mechanism analysis of tunnel lining structure damage subjected to severe gas explosion[J]. Journal of China Coal Society,2018,43(S1):167−177.

[20] 霍晓锋,史秀志,苟永刚. 边帮控制爆破裂纹扩展模拟及参数优化[J]. 爆破,2019,36(1):21−28. doi: 10.3963/j.issn.1001-487X.2019.01.004 HUO Xiaofeng,SHI Xiuzhi,GOU Yonggang. Simulation of crack growth in sidewall controlled blasting and parameter optimization[J]. Blasting,2019,36(1):21−28. doi: 10.3963/j.issn.1001-487X.2019.01.004

下载:

下载: