Technology and application of coal and CBM co-mining in east fifth panel of sihe mine

-

摘要:

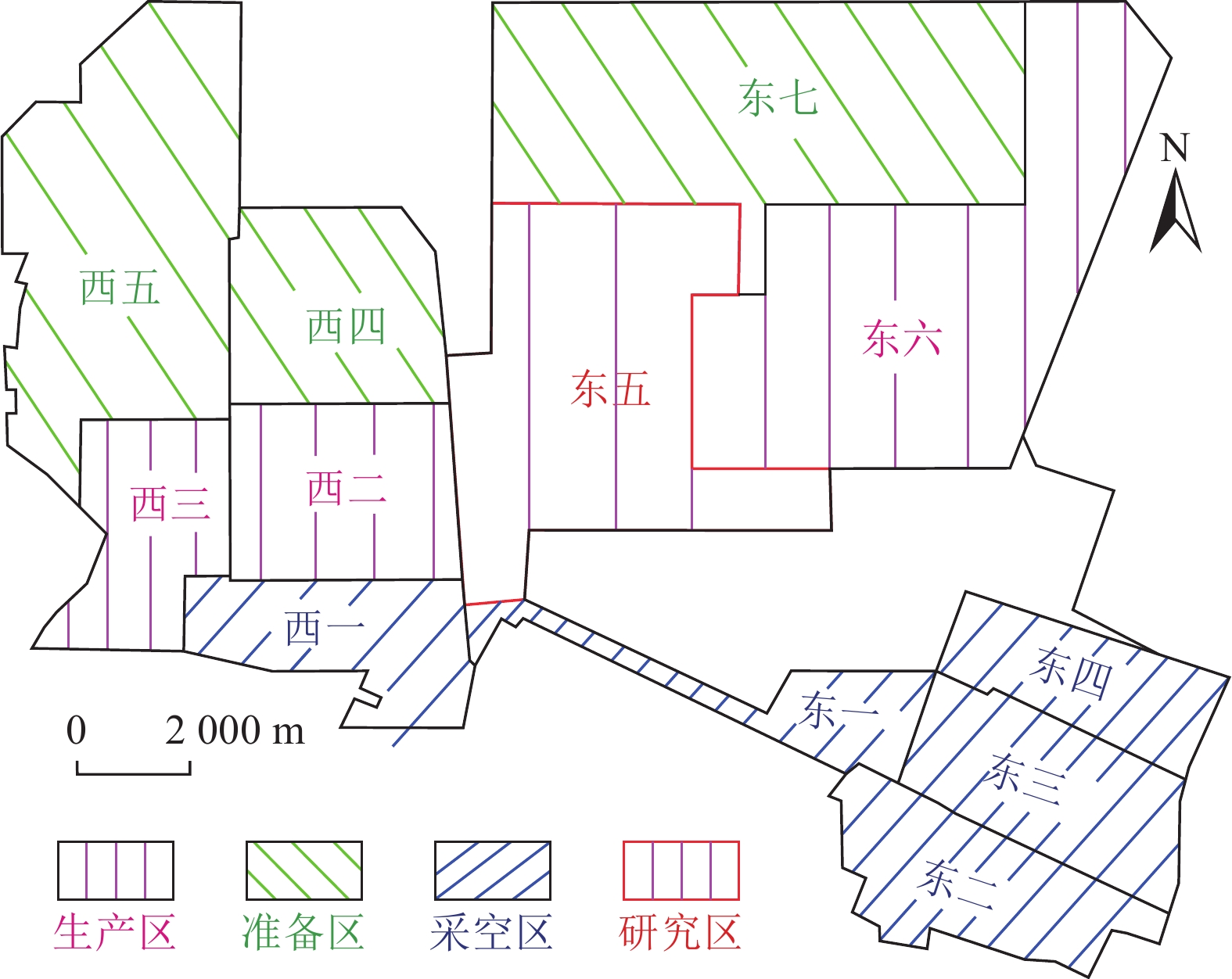

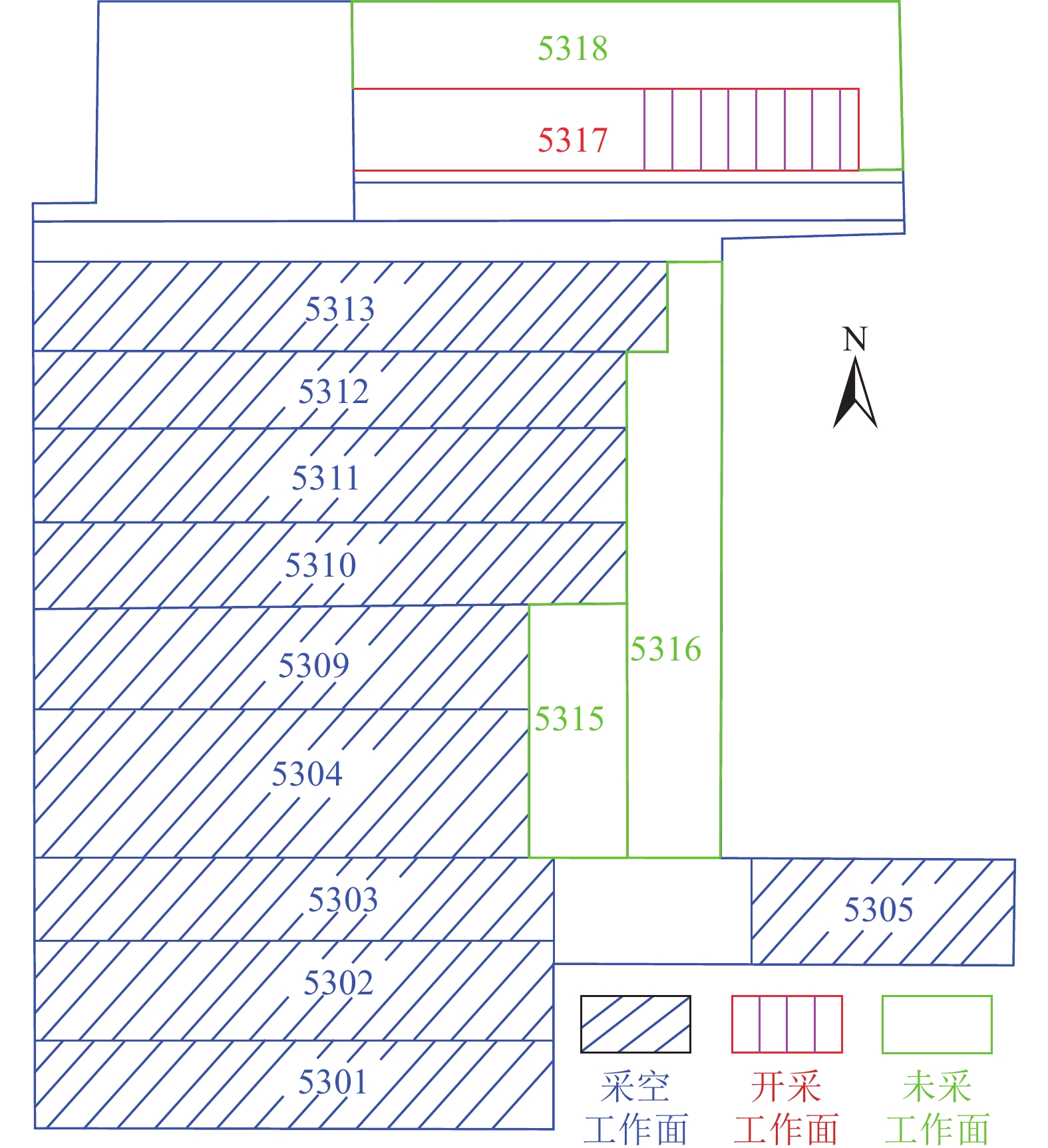

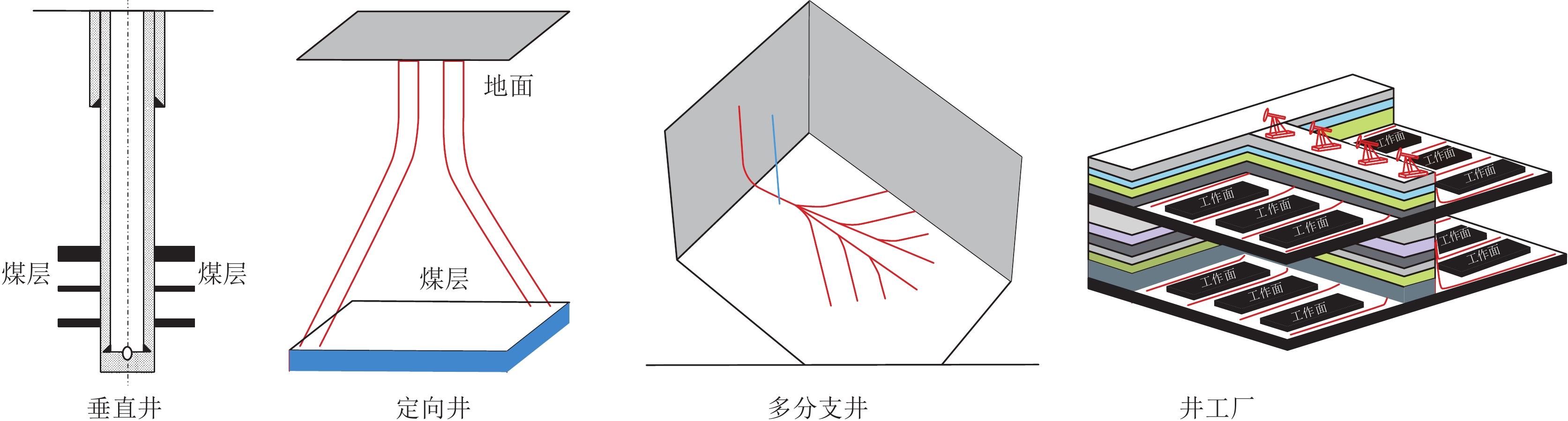

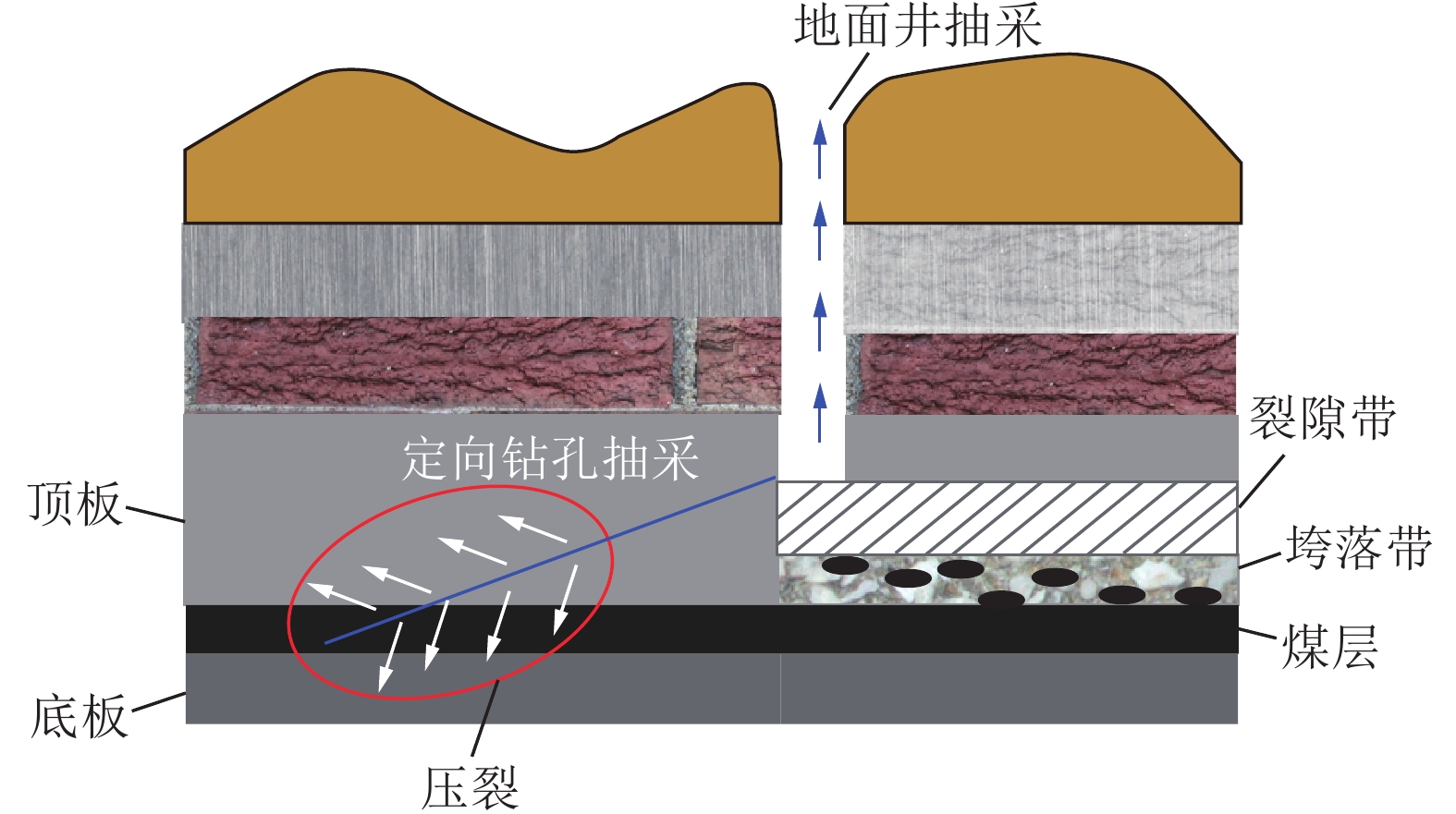

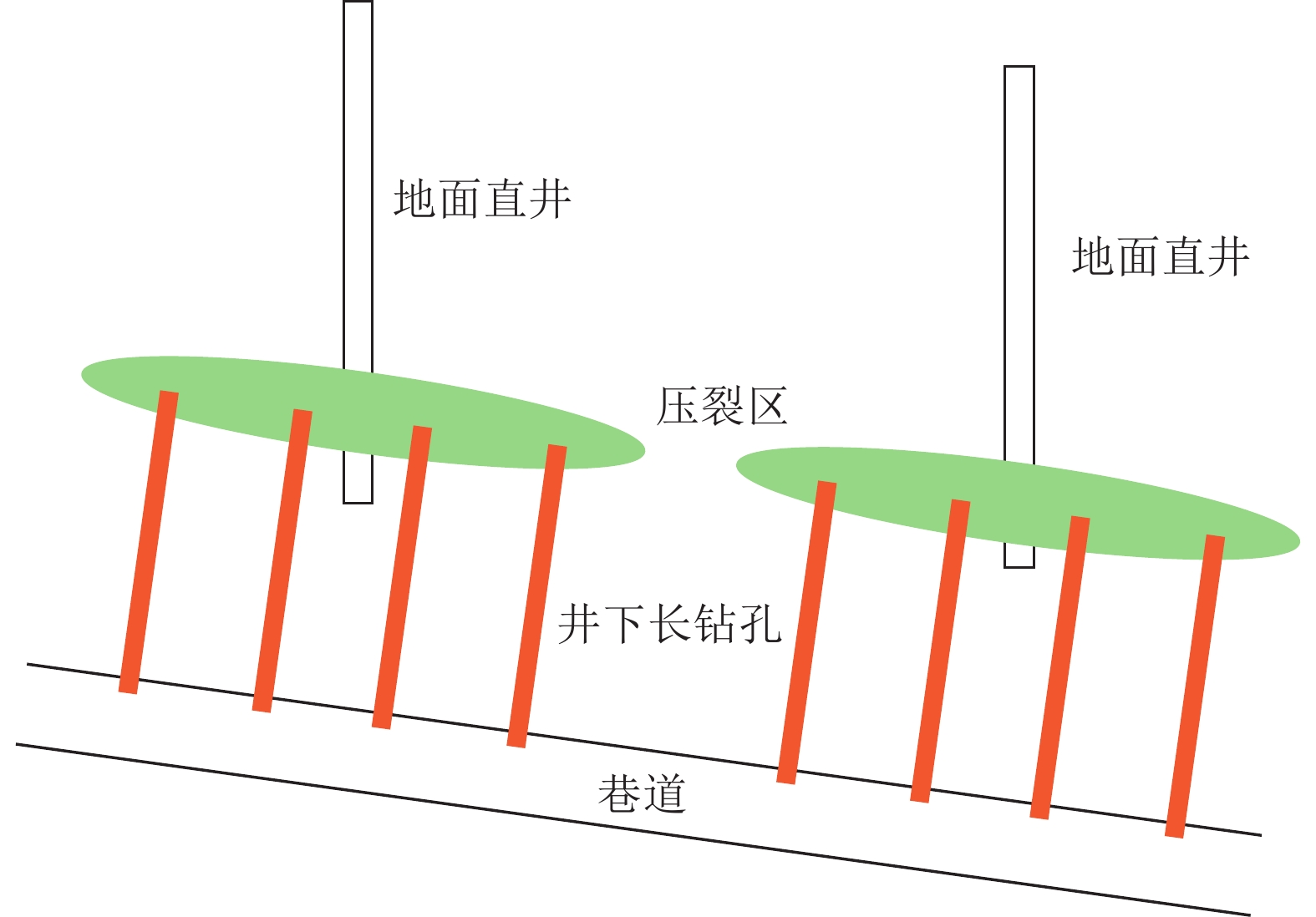

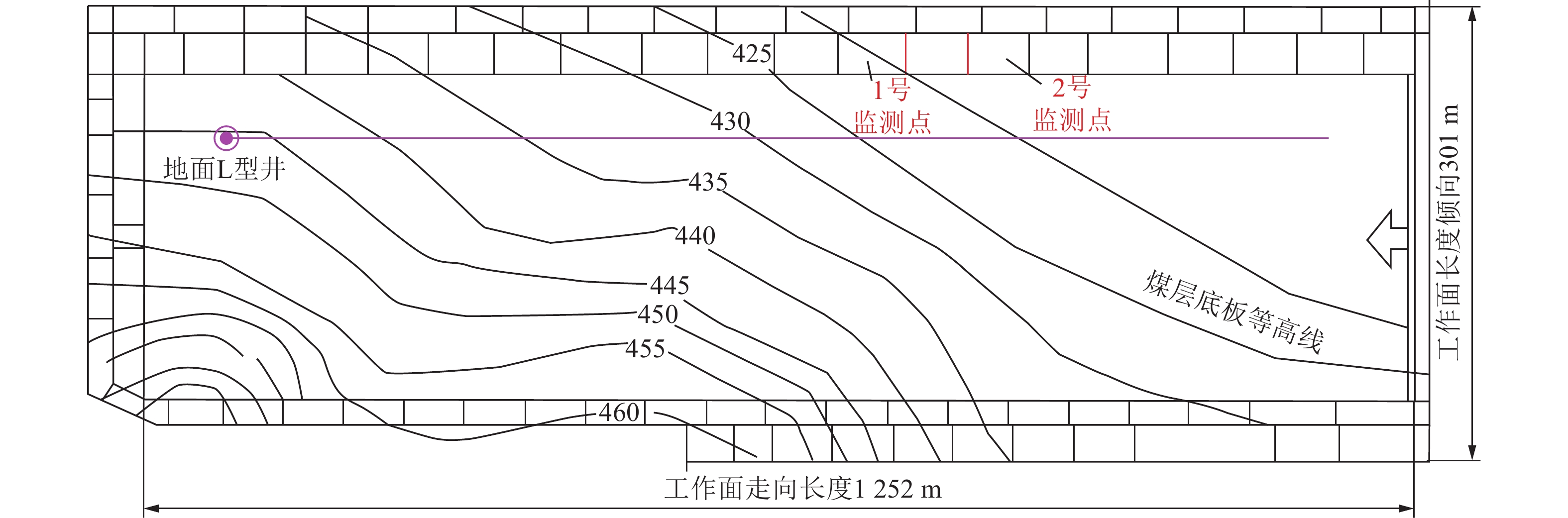

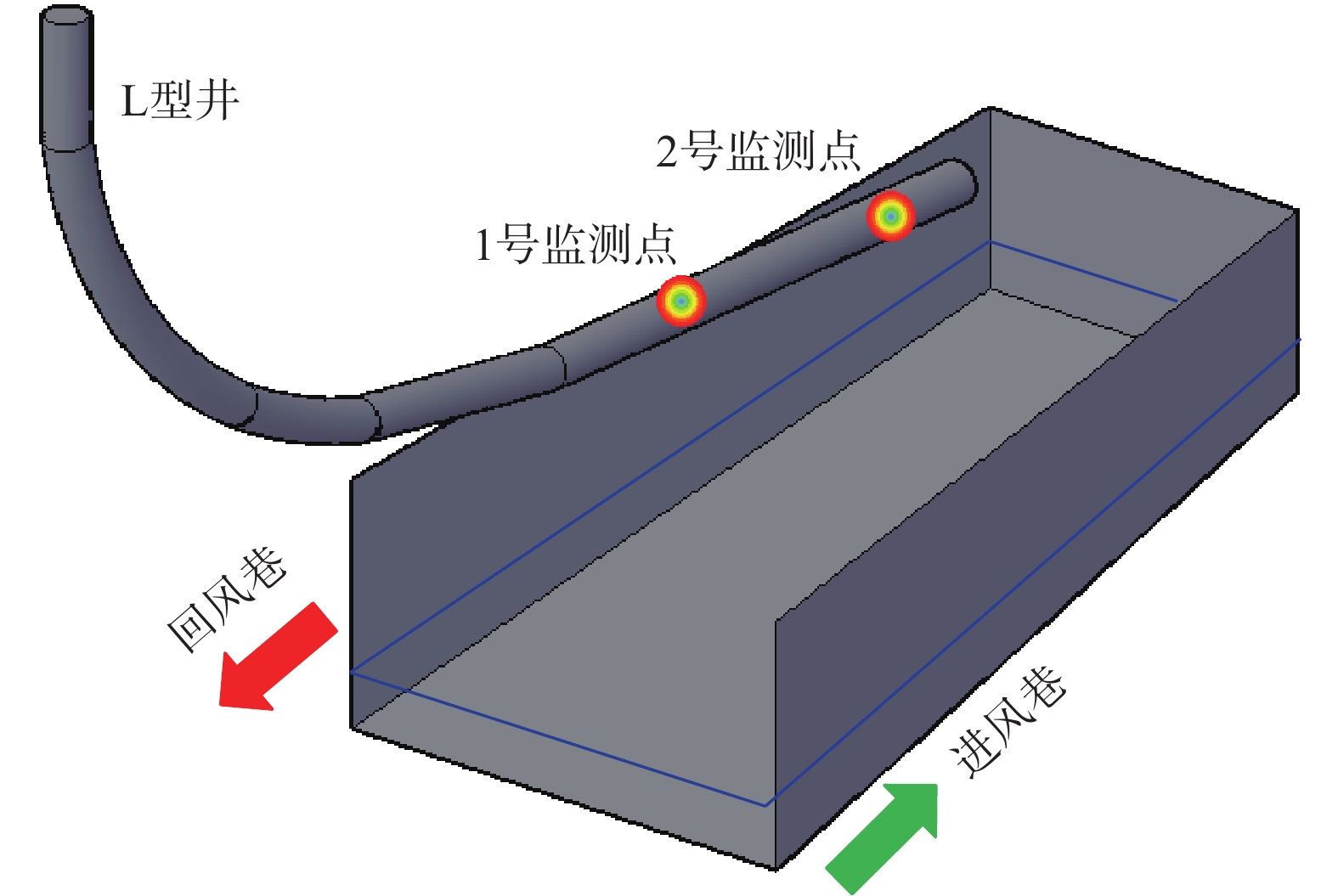

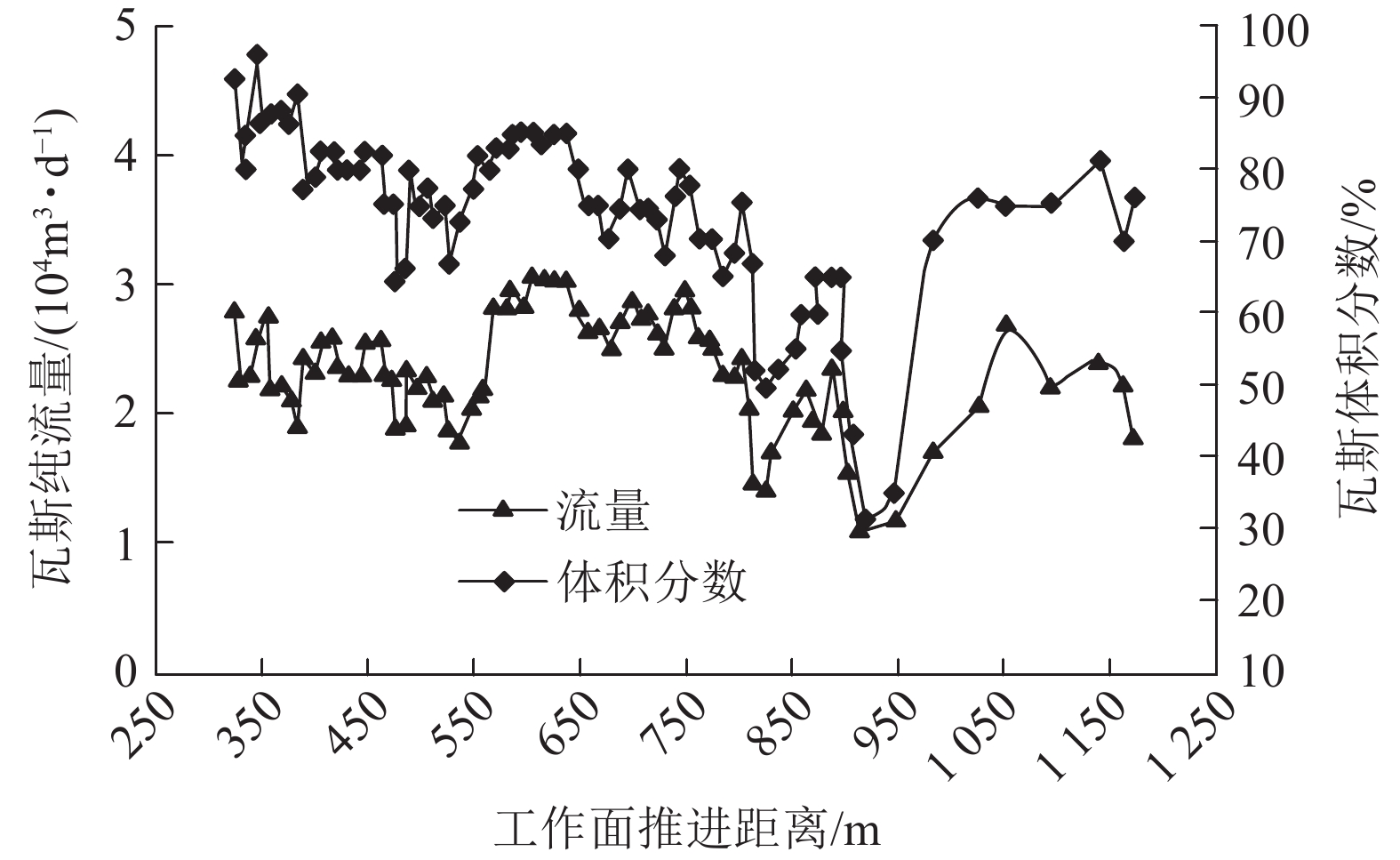

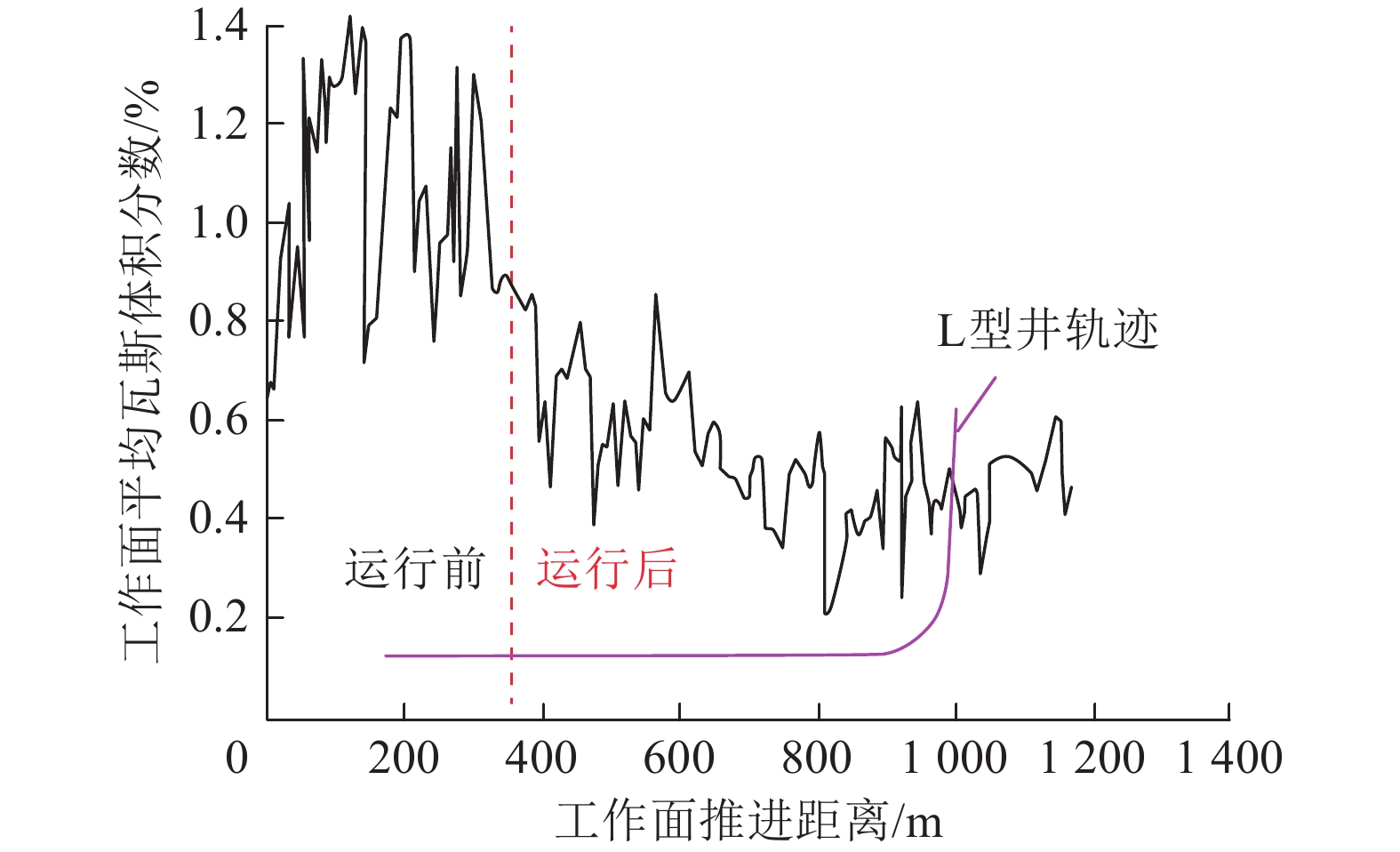

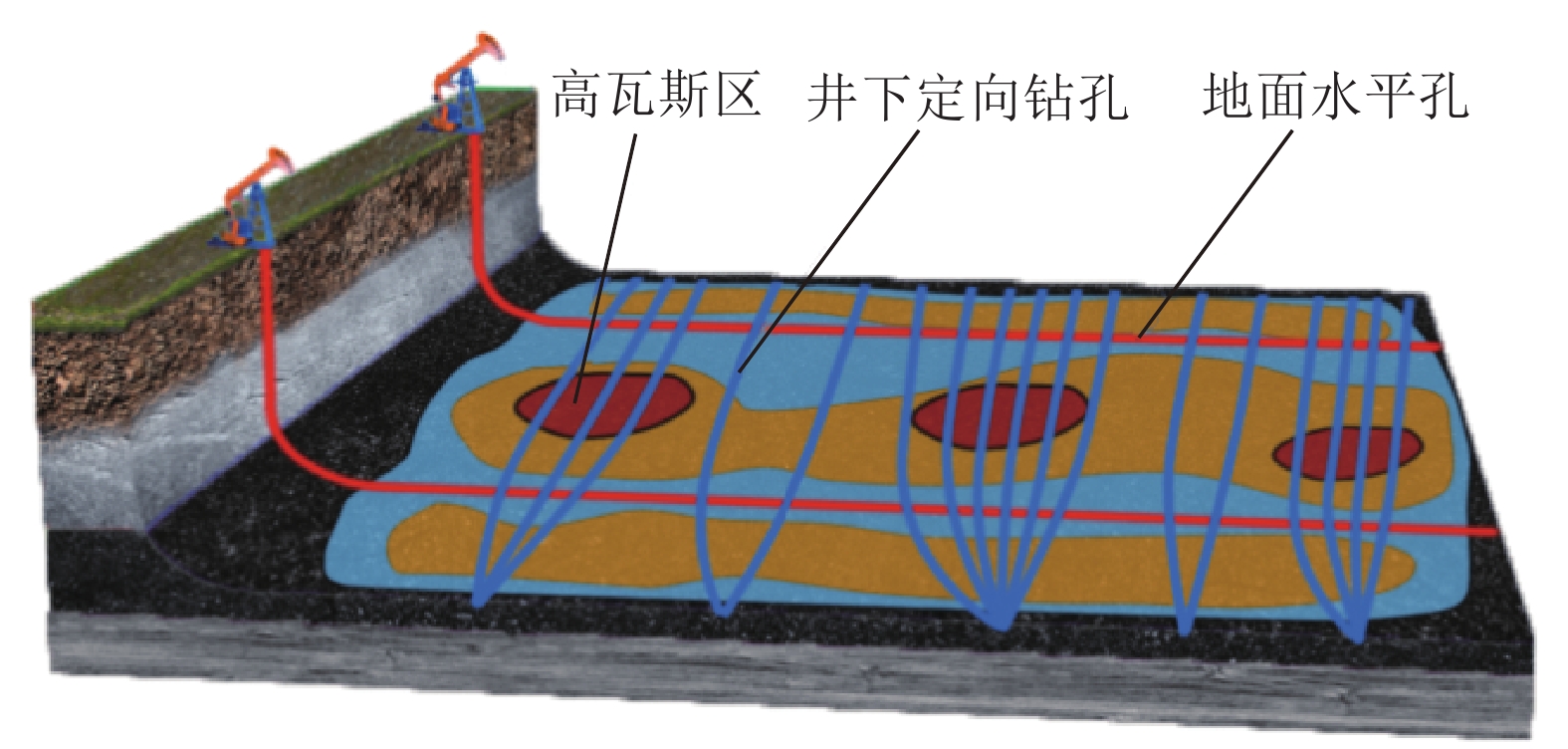

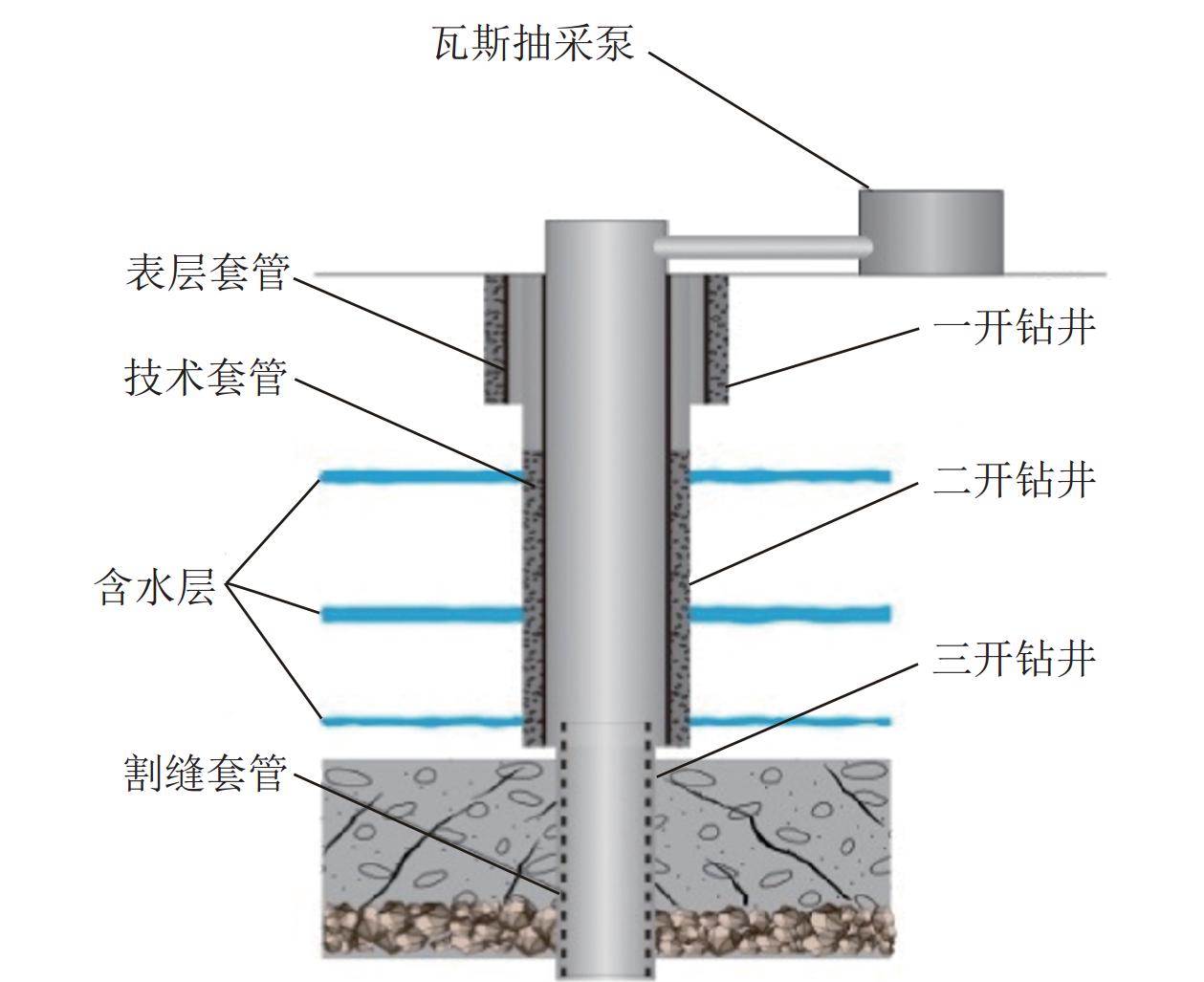

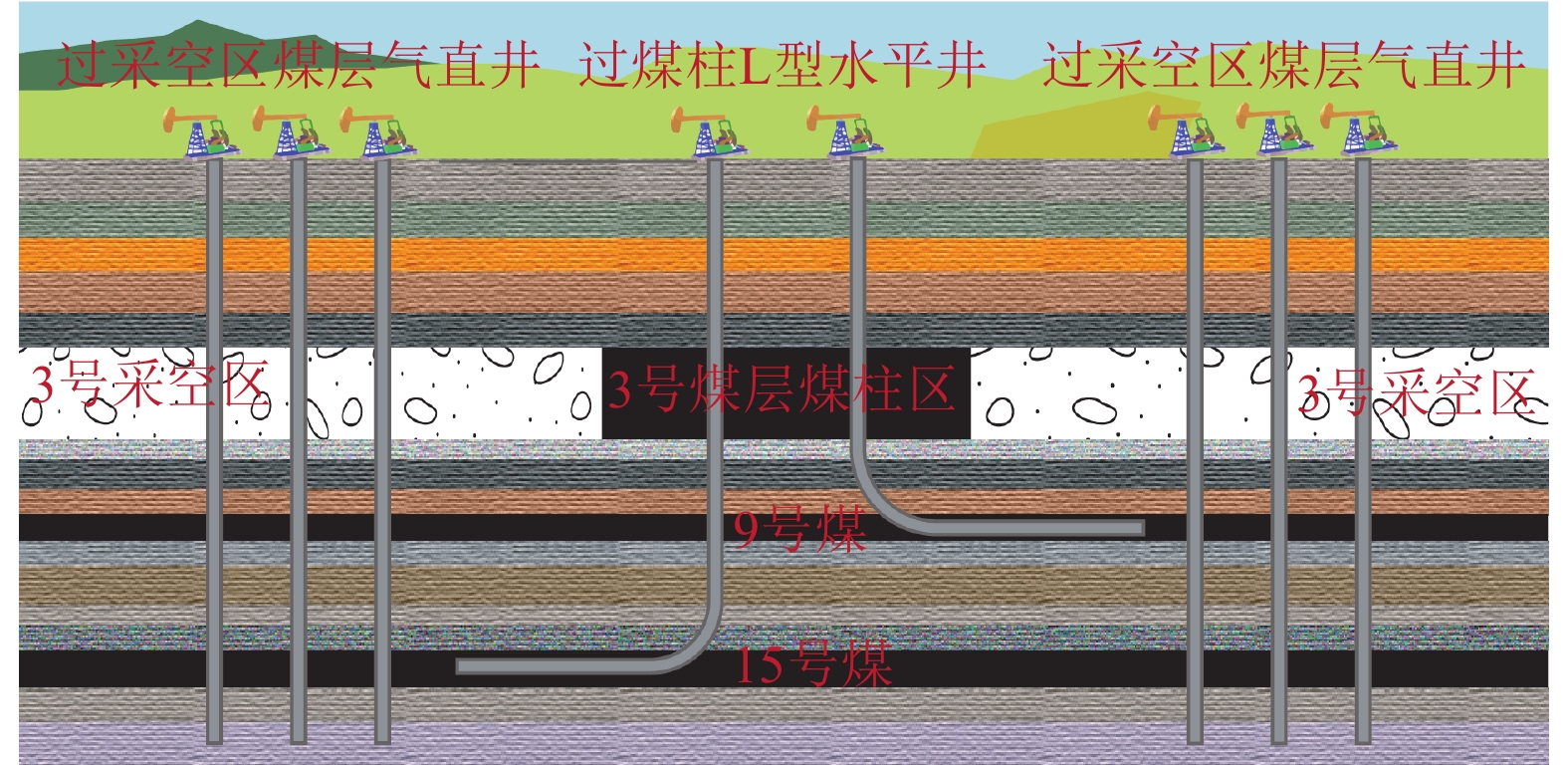

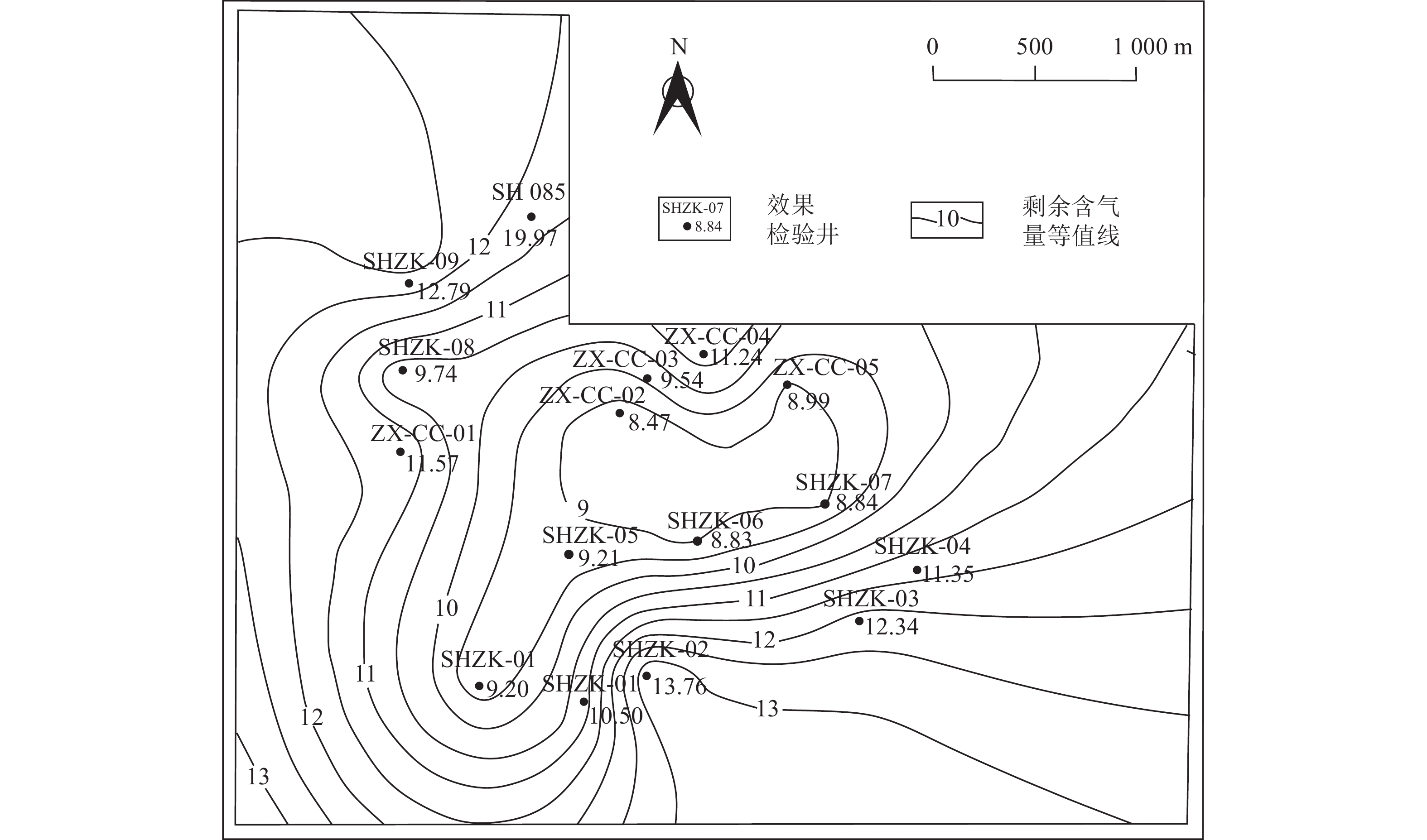

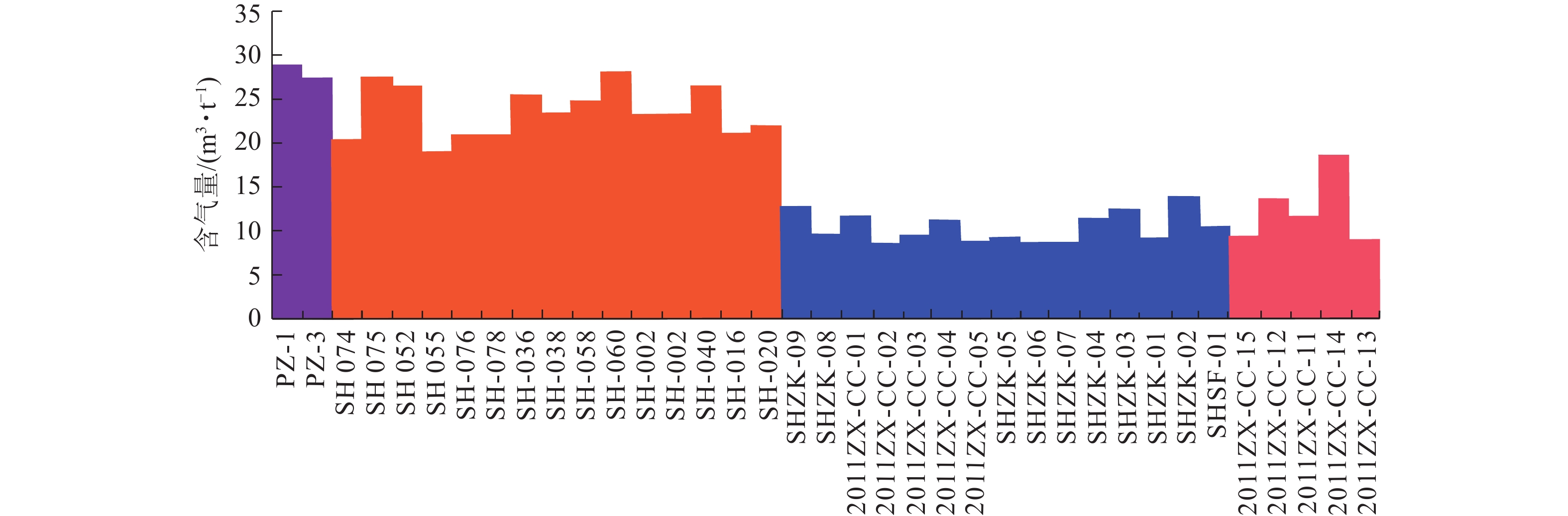

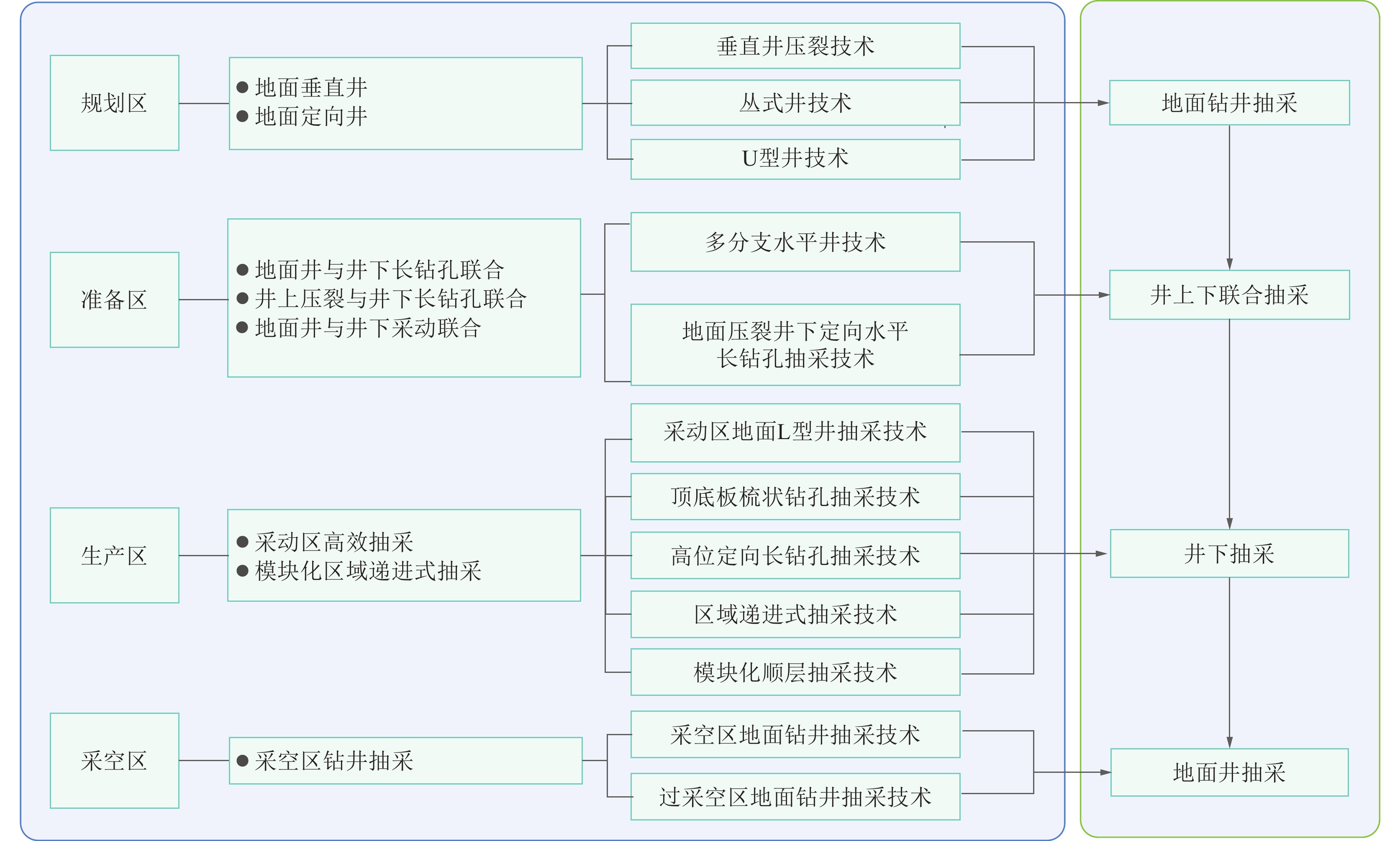

高瓦斯矿井煤层含气量大,单纯的井下瓦斯抽采受时间及空间制约,导致井下抽采效果受限。同时,由于井下通常仅依靠钻孔进行负压抽采,煤层增透手段和改造方式缺乏,导致抽采不充分,煤层含气量总体降幅小,无法快速实现工作面消突、达到保障矿井安全生产的要求。运用油气开发技术在地面进行煤层气抽采,煤层增透措施不受空间限制,可采用多种手段进行煤层改造,提升储层渗透性。同时,根据采掘规划,在地面超前布置煤层气抽采工程,对煤层进行长时间超前预抽,可减少井下瓦斯抽采工程量,缩短井下瓦斯抽采和达标时间,保障矿井安全生产。为大幅降低高瓦斯煤层含气量,提升煤炭开采效率与安全生产水平,针对寺河矿东五盘区煤层气地质特征,结合盘区采掘衔接规划,开展相适应的煤层气地面与井下抽采技术与工艺研究,探索高瓦斯矿井的煤与煤层气高效协调开发。采用理论分析与现场测试相结合的方式,对东五盘区开展多种煤层气地面与井下抽采尝试,综合降低煤层含气量。并通过地面抽采效果检验井,评价东五盘区煤层气抽采实际效果。经过近20 a的井上下连续抽采,东五盘区规划区3号煤层剩余含气量降到8 m3/t以下,平均降幅在50%以上;准备区抽采达标时间缩短了15%以上,保障了矿井高产高效;生产区井下精准抽采甲烷浓度提高5%以上,工作面抽采率提高5%以上,确保井下高效抽采。东五盘区地面大规模超前预抽已基本实现高瓦斯煤层的低瓦斯采掘。煤与煤层气共采既通过地面超前预抽大幅度降低了煤层含气量、增加了煤层气产量,又通过井下精准抽采填补了地面抽采盲区,实现了煤层气抽采的全覆盖,节约了井下瓦斯抽采成本。寺河矿东五盘区煤与煤层气共采的成功实施,不仅有效保障了高瓦斯煤层的低瓦斯开采,也大幅度降低了甲烷排空污染大气环境,同时还促进了沁南煤层气产业基地的建设,为其他高瓦斯矿井的煤与煤层气共采提供了参考与借鉴,对煤与煤层气共采技术的推广具有重要的意义。

Abstract:The gas content of coal seam in high gas mine is large. and the simple underground gas extraction is restricted by time and space, which leads to the limited effect of underground gas extraction. At the same time, because the underground usually only rely on drilling for negative pressure extraction, the lack of coal seam anti-reflection means and transformation methods leads to insufficient gas extraction. The overall gas reduction is small, which couldn’t meet the requirements of working face gas outburst elimination and ensure mine safety production. The use of oil and gas development technology for coal seam gas extraction on the ground, coal seam permeability improvement measures are not limited by space. Various means could be used to stimulate coal seams and improve reservoir permeability. At the same time, according to the mining plan, the gas extraction project is arranged in advance on the ground. The coal seam gas is pre-extracted for a long time. Which could reduce the underground gas extraction project, shorten the underground gas extraction and standard time, and ensure the safe production of the mine. In order to greatly reduce the gas content and improve the efficiency of coal mining and the level of safe production, according to the gas geological characteristics of the east fifth plate of Sihe mine, combined with the mining and excavation connection planning of the plate, the corresponding surface and underground gas extraction technology and process research are carried out to explore the efficient and coordinated development of coal and CBM in high gas mines. By combining theoretical analysis and field test, a variety of ground and underground gas extraction attempts are carried out in the east fifth plate to comprehensively reduce the gas content of the coal seam. And through the ground extraction effect test well, the gas extraction effect of the east fifth plate is evaluated. After nearly 20 years of continuous extraction, the remaining gas content of No.3 coal seam in the planning area is reduced to less than 8 m3/t, with an average decrease above 50%. The extraction time of the preparation area is shortened by more than 15%, which ensure the high yield and high efficiency of the mine. The methane concentration of underground precise extraction in the production area is increased by more than 5%, and the extraction rate of working face is increased by more than 5%, which ensure the efficient extraction of underground. The large-scale advance pre-extraction on the ground in the east fifth plate have basically realized low-gas mining in high-gas coal seam. The co-mining of coal and CBM not only greatly reduces the gas content and increases the production of CBM through ground advanced pre-extraction, but also fills the blind area of ground extraction through underground precise extraction. Which realize the full coverage of gas extraction and save the cost of underground gas extraction. The successful implementation of the co-mining of coal and CBM in the east fifth plate of Sihe coal mine not only effectively guarantees the low-gas mining in high-gas coal seam, but also greatly reduces the atmospheric environment polluted by CBM emptying. At the same time, it also promotes the construction of the Qinnan CBM industrial base, and provides reference for the co-mining of coal and CBM in other high-gas mines. It has important value for the promotion of coal and CBM co-mining.

-

-

表 1 可采煤层特征

Table 1 Characteristics of mineable coal seam

煤层 煤层厚度/m 可采性 顶底板岩性 顶板 底板 3号 4.95~7.22

6.14全区可采 泥岩、砂质泥岩 泥岩、砂质泥岩、粉砂岩 9号 0~1.35

0.86大部可采 粉砂岩 泥岩、粉砂岩 15 1.20~4.00

2.52全区可采 石灰岩 泥岩 注:数据格式为$\dfrac{最小值 \sim 最大值}{平均值} $;3号煤层与9号煤层层间距为$\dfrac{ {43.00\sim 59.28}}{48.01} $,m;9号煤层与15号煤层层间距为$\dfrac{{24.15 \sim 52.15}}{36.53} $,m。 -

[1] 王国法,任世华,庞义辉,等. 煤炭工业“十三五” 发展成效与“双碳” 目标实施路径[J]. 煤炭科学技术,2021,49(9):1−8. WANG Guofa,REN Shihua,PANG Yihui,et al. Development achievements of China’s coal industry during the 13th Five-Year Plan period and implementation path of “dual carbon” target[J]. Coal Science and Technology,2021,49(9):1−8.

[2] 刘峰,郭林峰,赵路正. 双碳背景下煤炭安全区间与绿色低碳技术路径[J]. 煤炭学报,2022,47(1):1−15. LIU Feng,GUO Linfeng,ZHAO Luzheng. Research on coal safety range and green low-carbon technology path under the dual-carbon background[J]. Journal of China Coal Society,2022,47(1):1−15.

[3] 刘见中,孙海涛,雷毅,等. 煤矿区煤层气开发利用新技术现状及发展趋势[J]. 煤炭学报,2020,45(1):258−267. LIU Jianzhong,SUN Haitao,LEI Yi,et al. Current situation and development trend of coalbed methane development and utilization technology in coal mine area[J]. Journal of China Coal Society,2020,45(1):258−267.

[4] 张群,降文萍,姜在炳,等. 我国煤矿区煤层气地面开发现状及技术研究进展[J]. 煤田地质与勘探,2023,51(1):139−158. ZHANG Qun,JIANG Wenping,JIANG Zaibing,et al. Present situation and technical research progress of coalbed methane surface development in coal mining areas of China[J]. Coal Geology & Exploration,2023,51(1):139−158.

[5] 陈本良,袁亮,薛生,等. 淮南矿区煤层顶板分段压裂水平井抽采技术及效果研究[J]. 煤炭科学技术,2024,52(4):155−163. CHEN Benliang,YUAN Liang,XUE Sheng,et al. Study on technology and effect of gas extraction in horizontal well with segmental hydraulic fracture in roof of coal seam in Huainan mining area[J]. Coal Science and Technology,2024,52(4):155−163.

[6] 苏现波,赵伟仲,王乾,等. 煤层气井地联合抽采全过程低负碳减排关键技术研究进展[J]. 煤炭学报,2023,48(1):335−356. SU Xianbo,ZHAO Weizhong,WANG Qian,et al. Conception of key technologiesfor low-negative carbon emission reduction in the process of coalbed methane development from the CBM well,coal mine and goaf[J]. Journal of China Coal Society,2023,48(1):335−356.

[7] 降文萍,柴建禄,张群,等. 基于煤层气与煤炭协调开发的地面抽采工程部署关键技术进展[J]. 煤炭科学技术,2022,50(12):50−61. JIANG Wenping,CHAI Jianlu,ZHANG Qun,et al. Key technology progress of surface extraction project deployment based on coordinated development of CBM and coal[J]. Coal Science and Technology,2022,50(12):50−61.

[8] 王耀锋. 中国煤矿瓦斯抽采技术装备现状与展望[J]. 煤矿安全,2020,51(10):67−77. WANG Yaofeng. Current situation and prospect of gas extraction technology and equipment for coal mines in China[J]. Safety in Coal Mines,2020,51(10):67−77.

[9] 唐永志,周俊. 中国煤矿典型瓦斯治理模式与技术[M]. 北京:应急管理出版社,2020. [10] 朱庆忠. 沁水盆地高煤阶煤层气高效开发关键技术与实践[J]. 天然气工业,2022,42(6):87−96. doi: 10.3787/j.issn.1000-0976.2022.06.008 ZHU Qingzhong. Key technologies and practices for efficient development of high-rank CBM in the Qinshui Basin[J]. Natural Gas Industry,2022,42(6):87−96. doi: 10.3787/j.issn.1000-0976.2022.06.008

[11] 王魁军,张兴华. 中国煤矿瓦斯抽采技术发展现状与前景[J]. 中国煤层气,2006,3(1):13−16,39. doi: 10.3969/j.issn.1672-3074.2006.01.004 WANG Kuijun,ZHANG Xinghua. Current status and prospects of CMM drainage technologies in China[J]. China Coalbed Methane,2006,3(1):13−16,39. doi: 10.3969/j.issn.1672-3074.2006.01.004

[12] 冯三利,叶建平. 中国煤层气勘探开发技术研究进展[J]. 中国煤田地质,2003,15(6):19−23,29. FENG Sanli,YE Jianping. Progress in China’s CBM exploration and exploitation technical researches[J]. Coal Geology of China,2003,15(6):19−23,29.

[13] 李国富,李波,焦海滨,等. 晋城矿区煤层气三区联动立体抽采模式[J]. 中国煤层气,2014,11(1):3−7. LI Guofu,LI Bo,JIAO Haibin,et al. Three-region integrated CBM stereo-extraction in Jincheng mining area[J]. China Coalbed Methane,2014,11(1):3−7.

[14] 叶建平. 中国煤层气勘探开发及其科技进步历程回顾与思考[J]. 煤田地质与勘探,2025,53(1):114−127. doi: 10.12363/issn.1001-1986.24.11.0723 YE Jianping. China’s CBM exploration and production and associated technological advancements:A review and reflections[J]. Coal Geology & Exploration,2025,53(1):114−127. doi: 10.12363/issn.1001-1986.24.11.0723

[15] 梁运培,朱拴成,陈亮,等. 倾斜碎软煤层群煤层气协调开发关键技术:以艾维尔沟矿区为例[J]. 煤炭科学技术,2024,52(1):211−220. LIANG Yunpei,ZHU Shuancheng,CHEN Liang,et al. Key technologies for coordinated development of coalbed methane in inclined soft coal seam groups:A case study of Aiweigou Mining Area[J]. Coal Science and Technology,2024,52(1):211−220.

[16] 张千贵,李权山,范翔宇,等. 中国煤与煤层气共采理论技术现状及发展趋势[J]. 天然气工业,2022,42(6):130−145. ZHANG Qiangui,LI Quanshan,FAN Xiangyu,et al. Current situation and development trend of theories and technologies for coal and CBM co-mining in China[J]. Natural Gas Industry,2022,42(6):130−145.

[17] 李丹,苏现波. 煤与煤层气资源开发全过程阶段划分及其开发效果评价[J]. 煤炭科学技术,2023,51(3):137−147. LI Dan,SU Xianbo. Stage division and development effect evaluation of whole process of coal and coalbed methane resources development[J]. Coal Science and Technology,2023,51(3):137−147.

[18] 孙海涛,舒龙勇,姜在炳,等. 煤矿区煤层气与煤炭协调开发机制模式及发展趋势[J]. 煤炭科学技术,2022,50(12):1−13. SUN Haitao,SHU Longyong,JIANG Zaibing,et al. Progress and trend of key technologies of CBM development and utilization in China coal mine areas[J]. Coal Science and Technology,2022,50(12):1−13.

[19] 桑树勋,韩思杰,周效志,等. 华东地区深部煤层气资源与勘探开发前景[J]. 油气藏评价与开发,2023,13(4):403−415. SANG Shuxun,HAN Sijie,ZHOU Xiaozhi,et al. Deep coalbed methane resource and its exploration and development prospect in East China[J]. Petroleum Reservoir Evaluation and Development,2023,13(4):403−415.

[20] 张群,孙四清,降文萍. 碎软低渗煤层煤矿区煤层气勘探开发关键技术及发展方向[J]. 石油学报,2024,45(5):855−865. doi: 10.7623/syxb202405007 ZHANG Qun,SUN Siqing,JIANG Wenping. Key technologies and development direction of CBM exploration and development in coal mine area of fractured soft and low permeablity coal seams[J]. Acta Petrolei Sinica,2024,45(5):855−865. doi: 10.7623/syxb202405007

[21] 吴建国,李伟. 淮北矿区煤层气抽采利用技术探讨[J]. 中国煤层气,2005,2(4):16−19. doi: 10.3969/j.issn.1672-3074.2005.04.004 WU Jianguo,LI Wei. Discussion on technology for drainage and utilization of CBM in Huibei mining area[J]. China Coalbed Methane,2005,2(4):16−19. doi: 10.3969/j.issn.1672-3074.2005.04.004

[22] 孙景来. 煤与煤层气协调开发机制研究[J]. 煤炭科学技术,2014,42(10):62−65,70. SUN Jinglai. Study on coordinative development mechanism of coal and coalbed methane[J]. Coal Science and Technology,2014,42(10):62−65,70.

[23] 崔刚. 低透气性煤层群井下增透技术[J]. 煤炭科学技术,2016,44(5):151−154. CUI Gang. Permeability improved technology of low permeability seams group in underground mine[J]. Coal Science and Technology,2016,44(5):151−154.

[24] 李日富. 松藻矿区采动稳定区煤层气地面井抽采试验及应用效果[J]. 矿业安全与环保,2018,45(2):44−48. doi: 10.3969/j.issn.1008-4495.2018.02.010 LI Rifu. Drainage test of cbm ground well in mining stability area of Songzao coal mine[J]. Mining Safety & Environmental Protection,2018,45(2):44−48. doi: 10.3969/j.issn.1008-4495.2018.02.010

[25] 张培河,张明山. 煤层气不同开发方式的应用现状及适应条件分析[J]. 煤田地质与勘探,2010,38(2):9−13. doi: 10.3969/j.issn.1001-1986.2010.02.003 ZHANG Peihe,ZHANG Mingshan. Analysis of application status and adapting conditions for different methods of CBM development[J]. Coal Geology & Exploration,2010,38(2):9−13. doi: 10.3969/j.issn.1001-1986.2010.02.003

[26] 张群,冯三利,杨锡禄. 试论我国煤层气的基本储层特点及开发策略[J]. 煤炭学报,2001,26(3):230−235. ZHANG Qun,FENG Sanli,YANG Xilu. Basic reservoir characteristics and development strategy of coalbed methane resource in China[J]. Journal of China Coal Society,2001,26(3):230−235.

[27] 李树刚,林海飞,赵鹏翔,等. 采动裂隙椭抛带动态演化及煤与甲烷共采[J]. 煤炭学报,2014,39(8):1455−1462. LI Shugang,LIN Haifei,ZHAO Pengxiang,et al. Dynamic evolution of mining fissure elliptic paraboloid zone and extraction coal and gas[J]. Journal of China Coal Society,2014,39(8):1455−1462.

[28] 黄昌文, 杨良智. 松藻矿区瓦斯抽采的现状和发展方向[J]. 矿业安全与环保,2009,36(4):69−72. [29] 刘彦青,赵灿,李国富,等. 晋城矿区煤与煤层气协调开发模式优化决策方法[J]. 煤炭学报,2020,45(7):2575−2589. LIU Yanqing,ZHAO Can,LI Guofu,et al. Optimized decision method of coordinated development mode of coal and coalbed methane in Jincheng mining area[J]. Journal of China Coal Society,2020,45(7):2575−2589.

[30] 李国富,张遂安,季长江,等. 煤矿区煤层气“四区联动” 井上下联合抽采模式与技术体系[J]. 煤炭科学技术,2022,50(12):14−25. LI Guofu,ZHANG Suian,JI Changjiang,et al. Mechanism and technical system of ground and underground combined drainage of CBM in “four region linkage” in coal mining area[J]. Coal Science and Technology,2022,50(12):14−25.

[31] 孙东玲,梁运培,黄旭超,等. 新疆大倾角多煤组煤矿区煤层气开发利用进展与前景[J]. 煤炭科学技术,2023,51(S1):162−172. SUN Dongling,LIANG Yunpei,HUANG Xuchao,et al. Development and prospect of coalbed methane in coal mining areas with large dip angle and multi-coal groups in Xinjiang[J]. Coal Science and Technology,2023,51(S1):162−172.

[32] 韦波,杨曙光,李鑫,等. 倾斜煤层煤层气与煤炭地下气化协调开发技术构想[J]. 煤炭科学技术,2024,52(5):152−165. doi: 10.12438/cst.2024-0265 WEI Bo,YANG Shuguang,LI Xin,et al. Conception of coordinated development technology system for coalbed methane and underground coal gasification in inclined coal seams[J]. Coal Science and Technology,2024,52(5):152−165. doi: 10.12438/cst.2024-0265

下载:

下载: