A three-dimensional reconstruction method of coal mine tunnel fused with LiDAR and IMU

-

摘要:

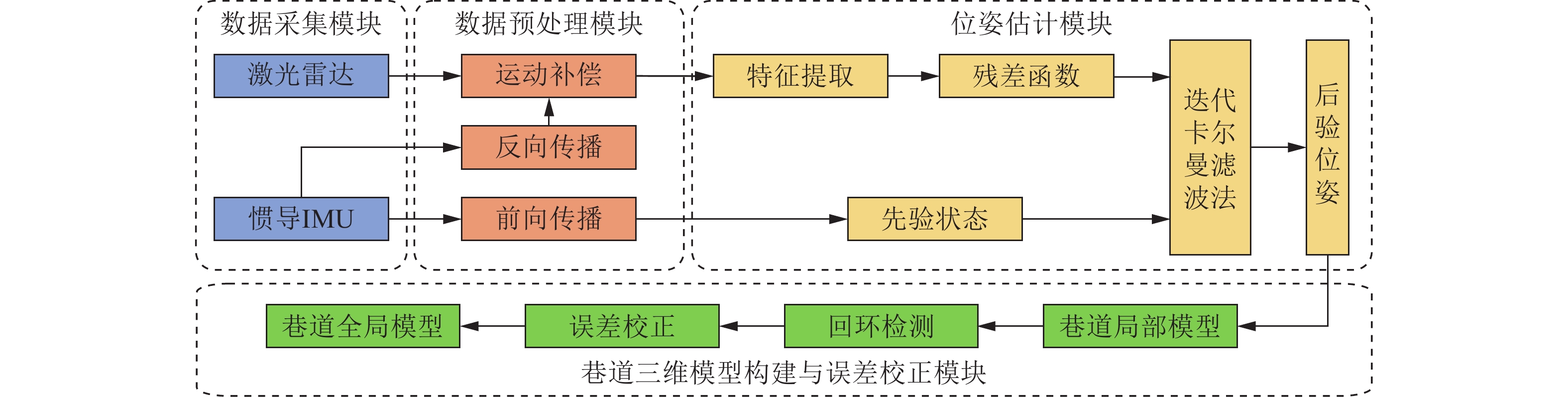

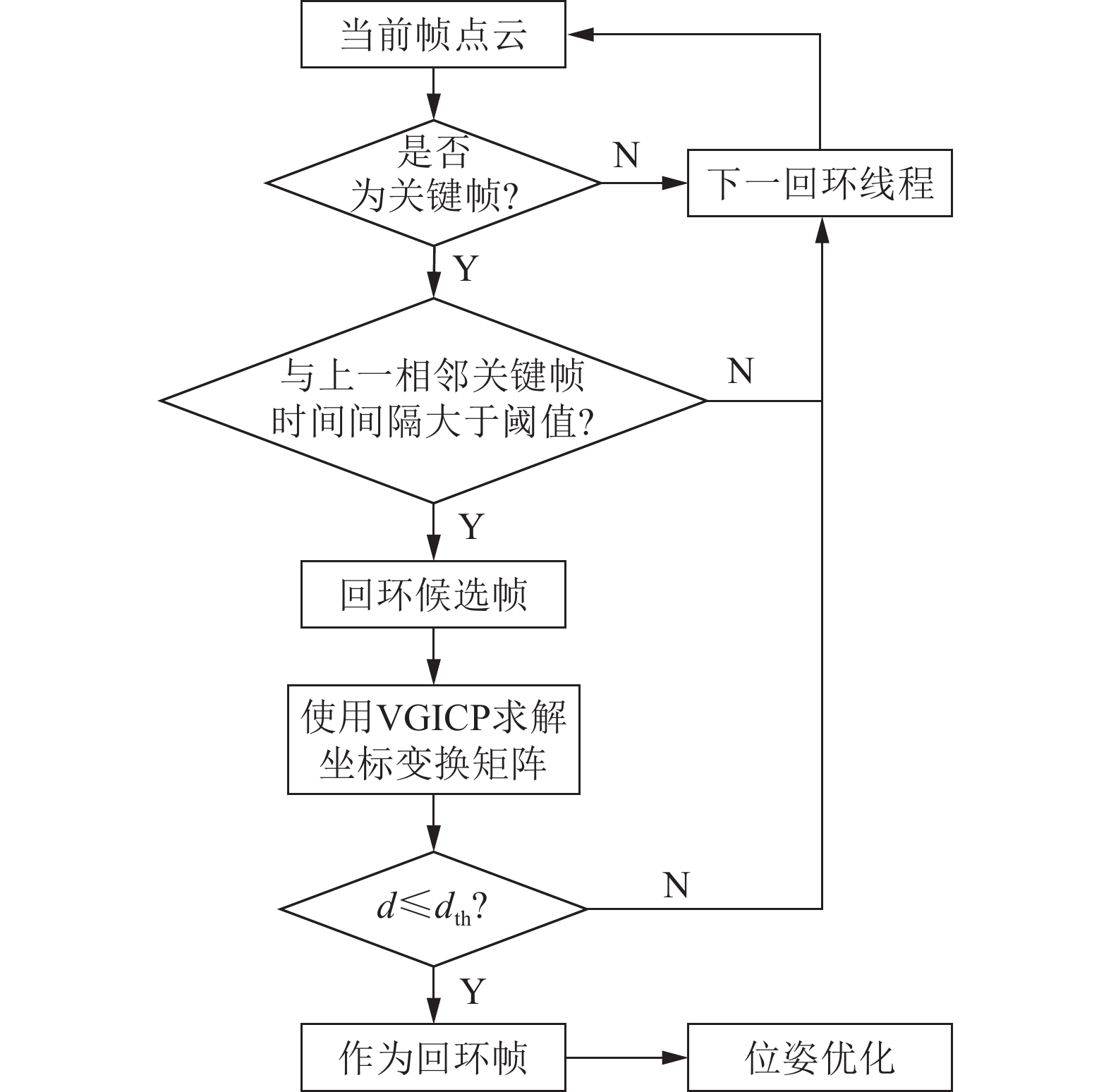

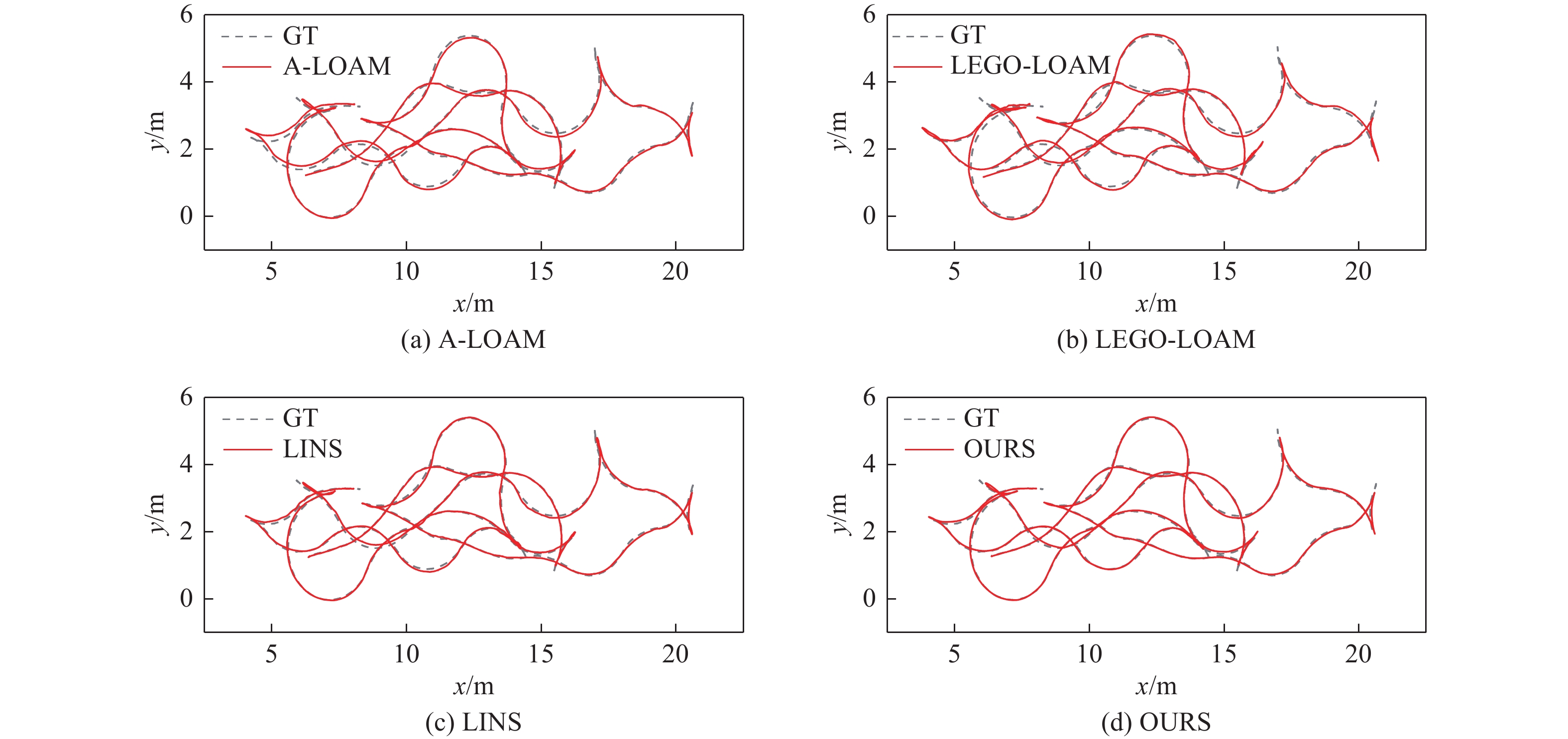

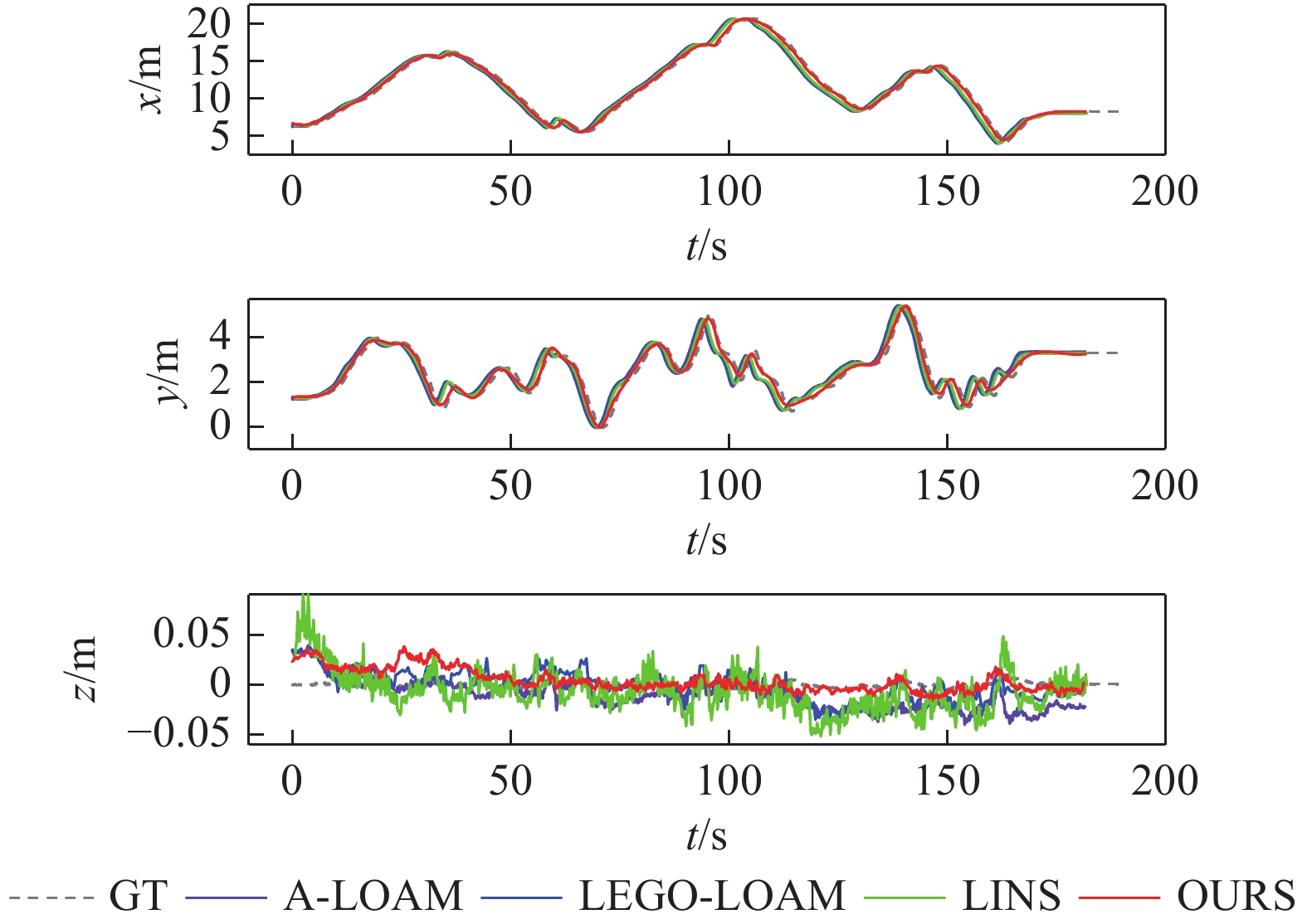

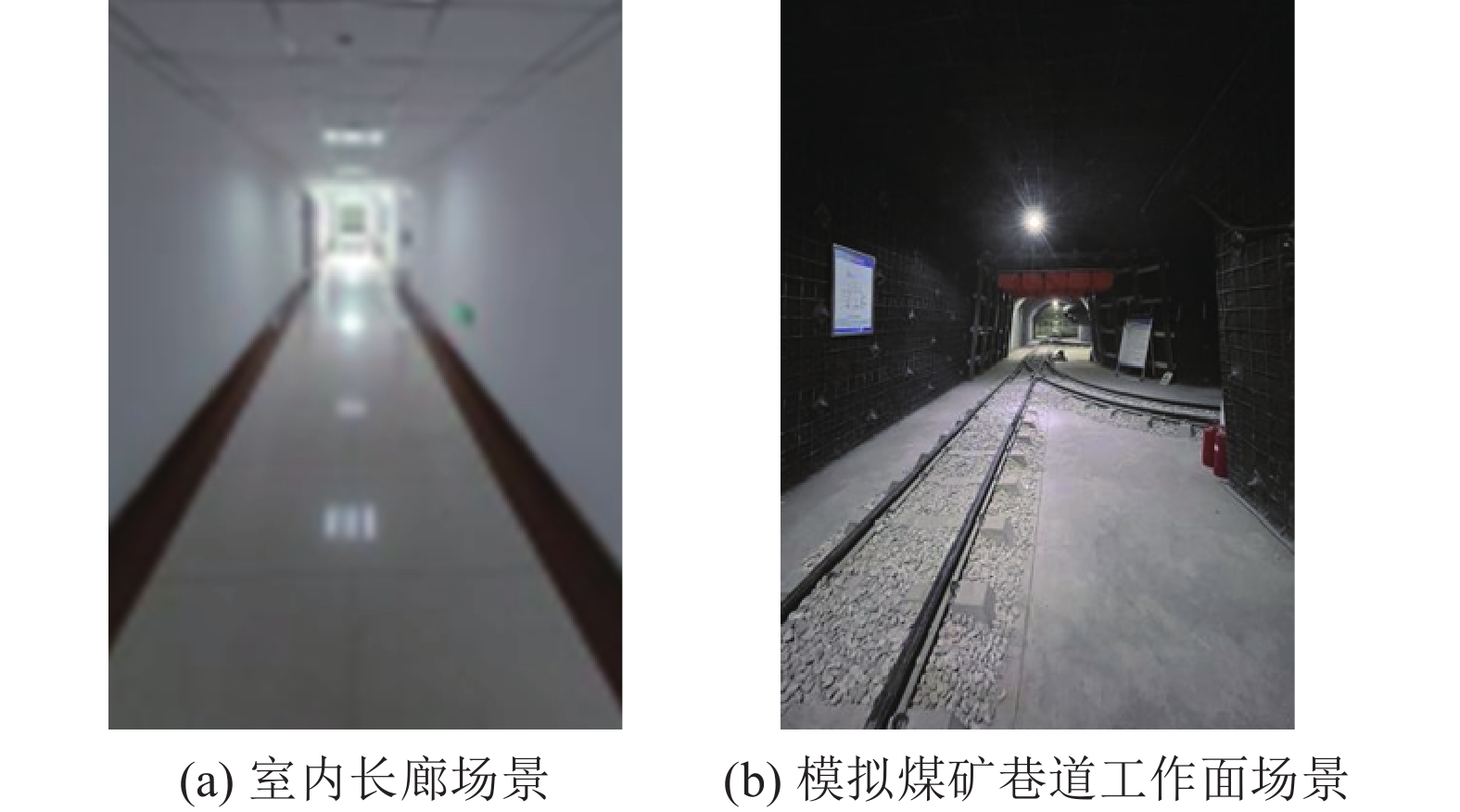

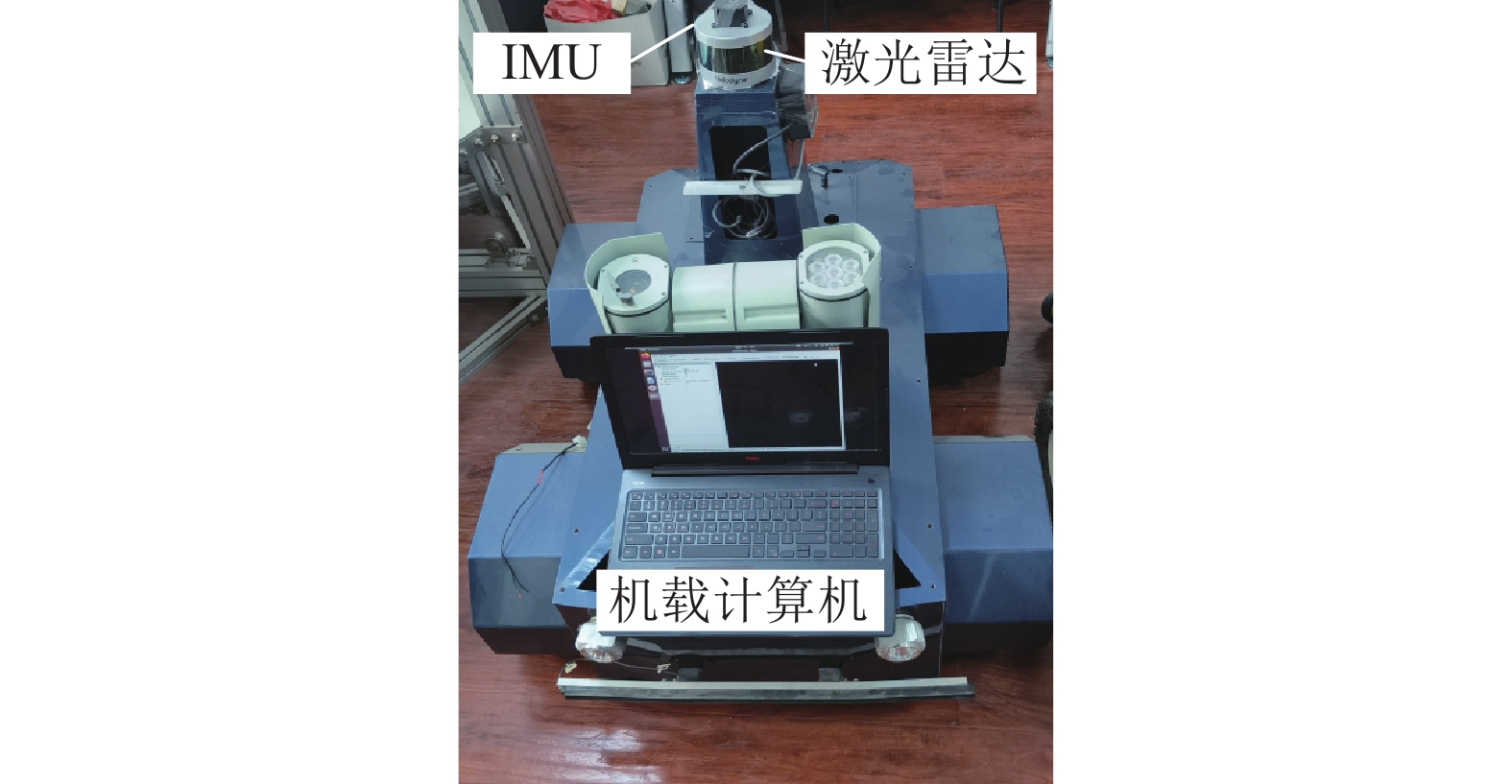

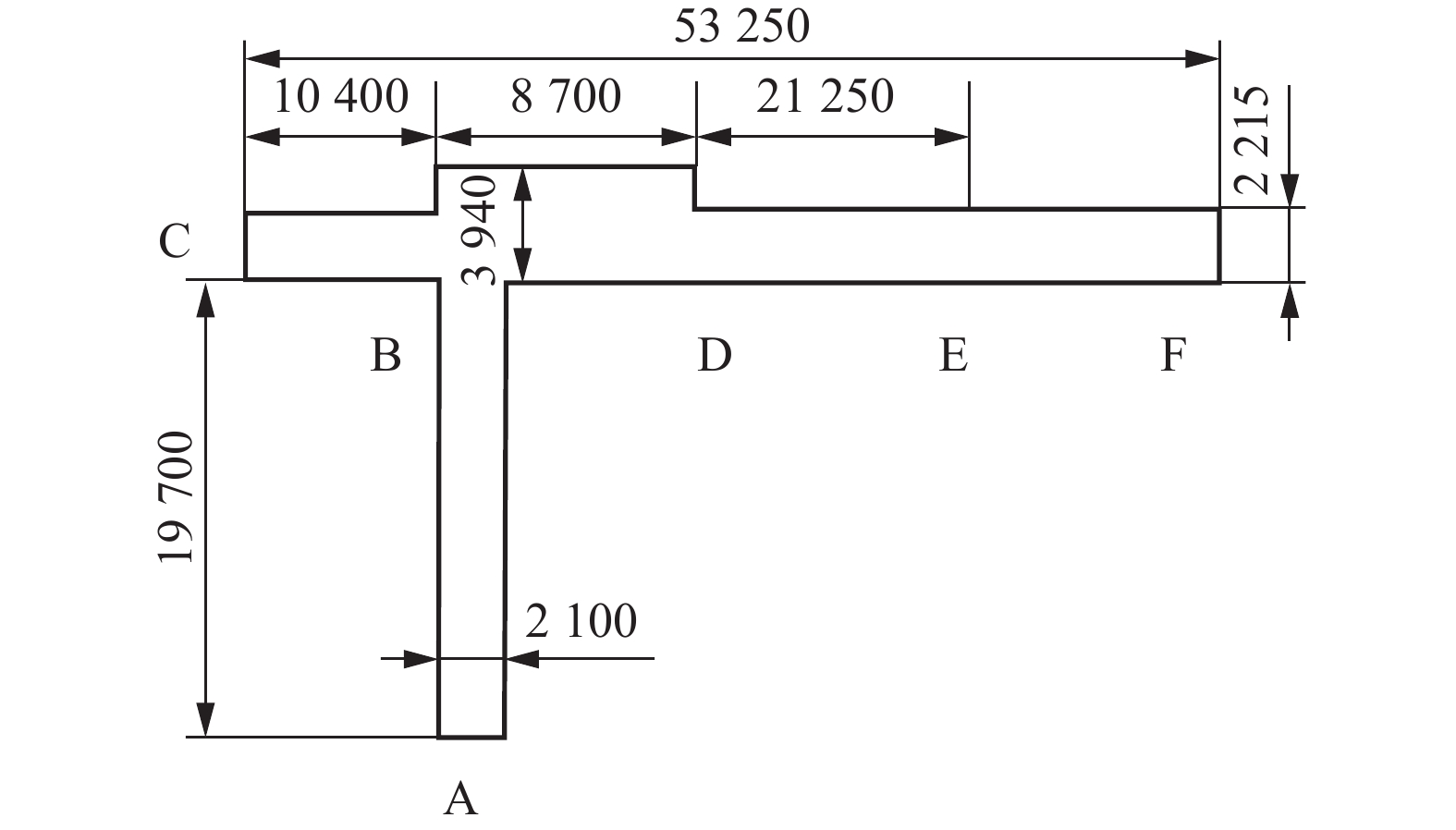

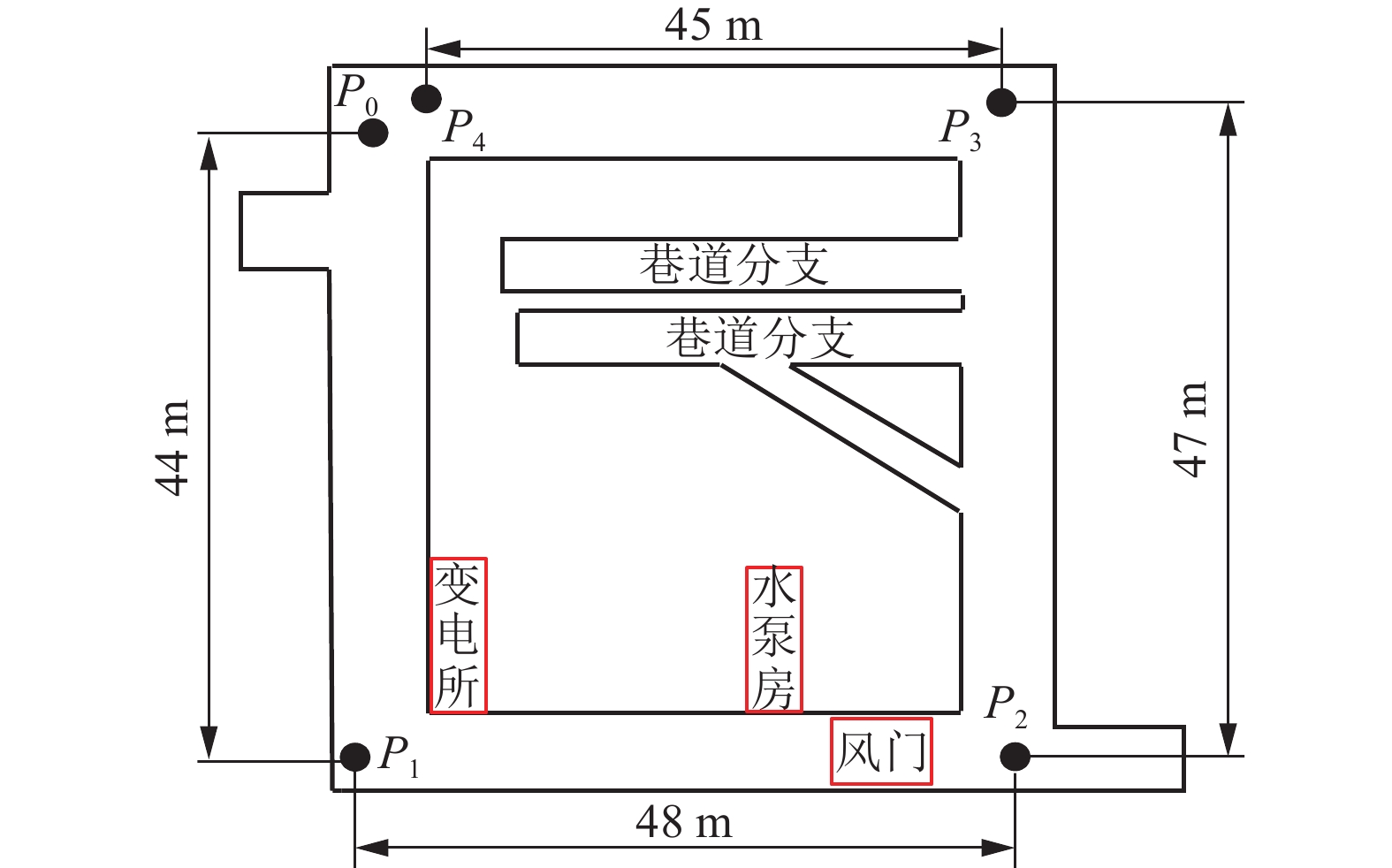

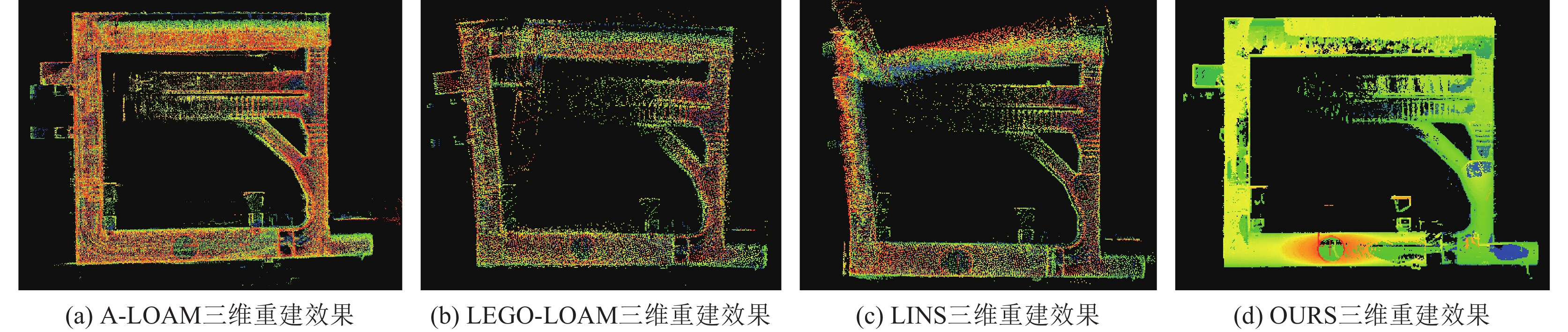

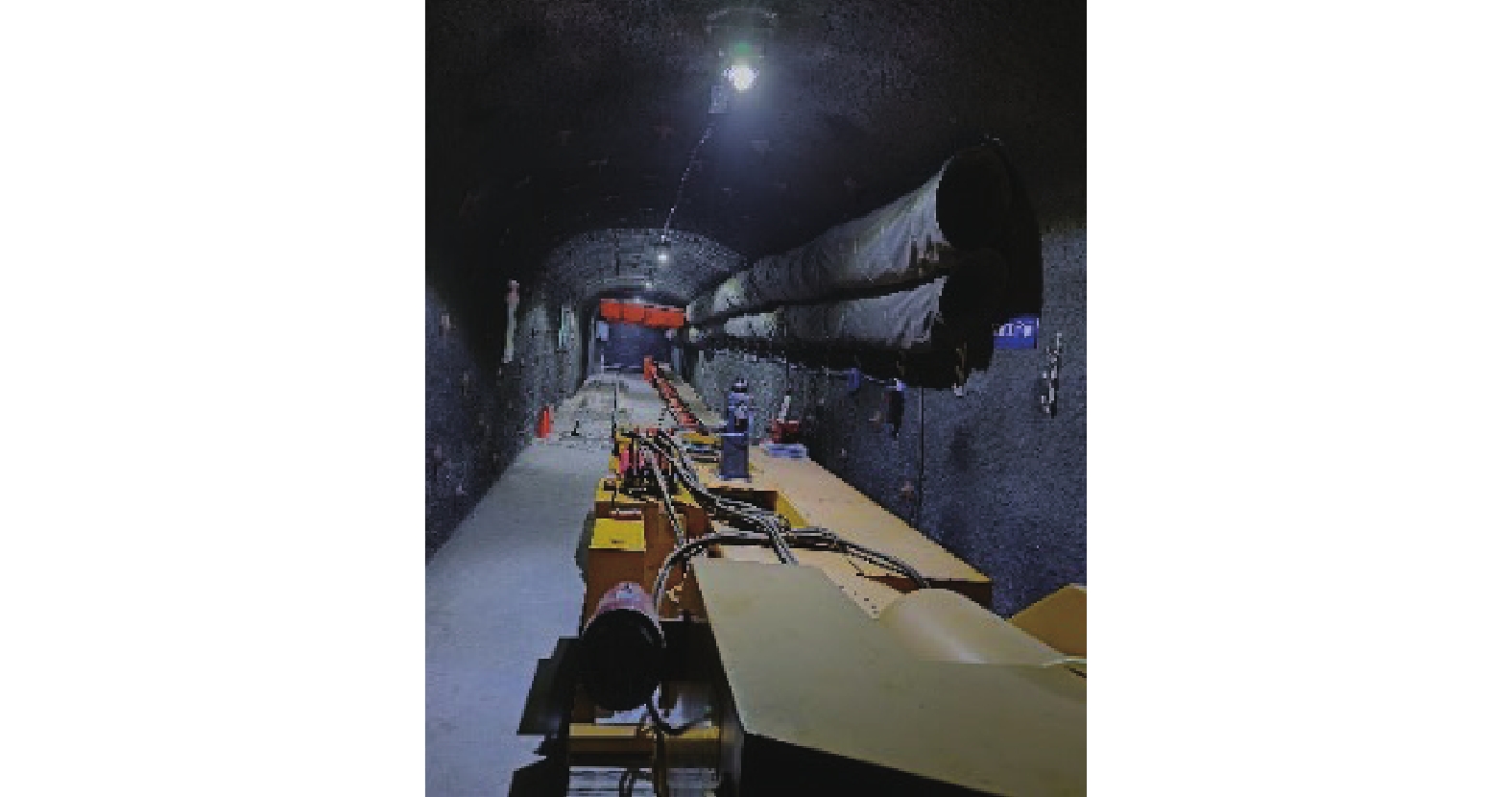

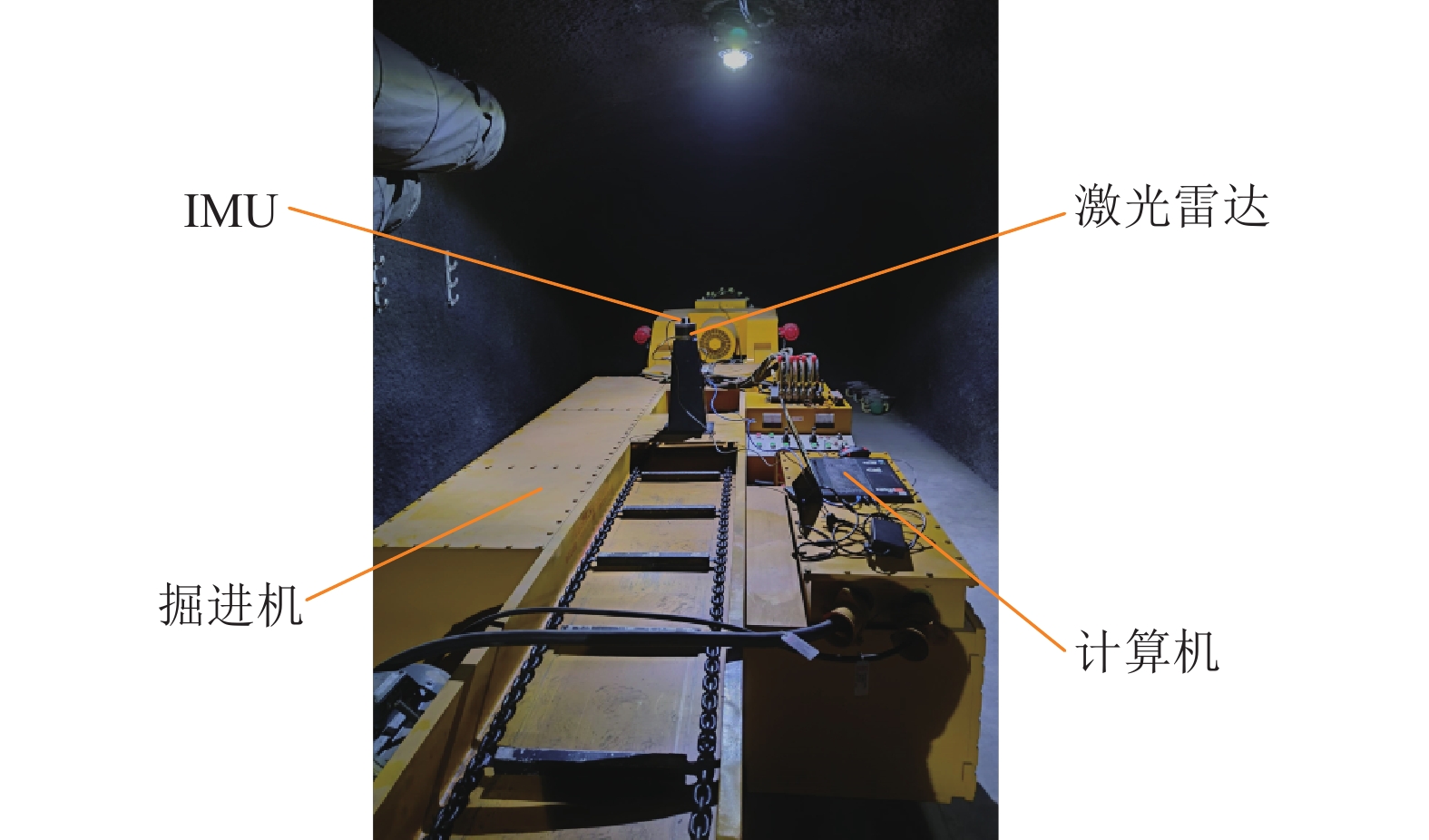

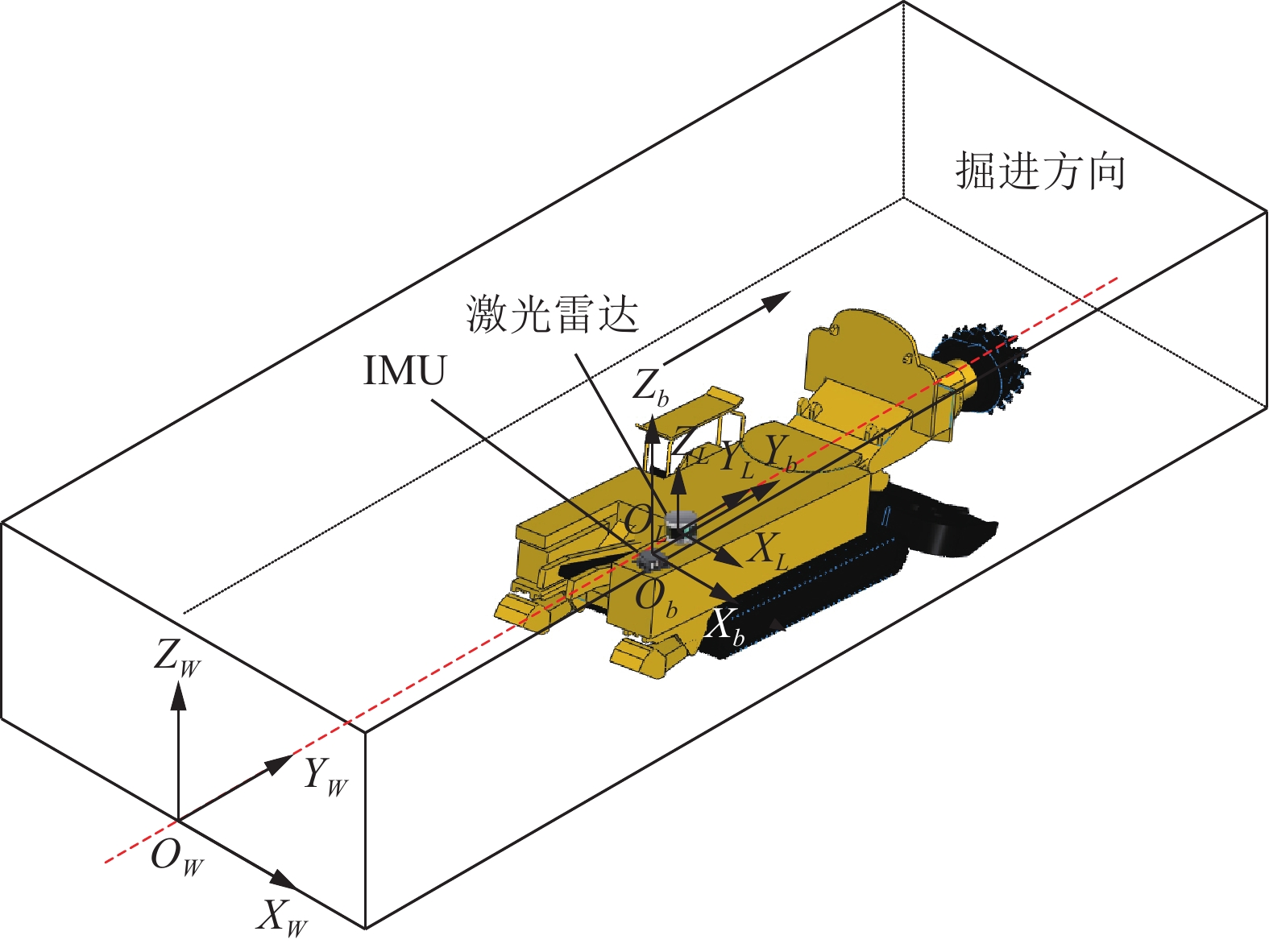

针对煤矿掘进巷道存在典型非结构化、特征退化、大尺度环境,巷道三维重建易出现位姿估计精度低、累计漂移误差大等问题,提出了一种激光雷达和惯导(Inertial Measurement Unit,IMU)融合的煤矿掘进巷道三维重建方法。该方法通过迭代卡尔曼滤波将激光雷达观测模型的残差函数和IMU预测模型的先验状态偏差紧耦合,经状态更新得到更为精确的后验状态,提升了退化环境下的位姿估计精度。为降低巷道三维模型重建过程中的累计漂移误差,提出基于体素化广义迭代最近点(Voxelized Generalized ICP,VGICP)的回环检测算法,以基于体素的单分布到多分布的方式进行配准,完成对回环帧的选取及精确匹配,实现回环帧的全局位姿校正,有效降低煤矿巷道三维重建的累计漂移误差。相比于A-LOAM、LEGO-LOAM、LINS算法,所提算法在位姿估计精度和全局一致性方面显著提升。公开数据集试验结果表明:所提算法的RPE和APE均方根误差分别为

0.2718 和0.5008 ,与其他算法相比分别降低了53.14%、50.97%、48.31%,和50.41%、47.99%、47.49%。开展了2种模拟巷道场景三维重建试验,结果表明所提算法构建的室内长廊模型各区域在长度、宽度和高度方向的误差均在1.2%以内;所提算法构建的煤矿巷道三维模型与真实巷道空间分布一致,总体距离退化误差仅为2.46%,较其他3种算法重建性能分别提升了66.12%、65.30%、70.43%。在煤矿主体实验室掘进巷道进行三维重建试验,结果表明三维重建结果在长度、宽度和高度方向的平均误差百分比分别为0.47%、0.75%和0.67%,可以实现掘进巷道三维精确建模。Abstract:In view of the problems of typical unstructured, degraded characteristics and large-scale environment in coal mine tunnel, and the 3D reconstruction of coal mine tunnel is prone to low pose estimation accuracy and large cumulative drift error, a 3D reconstruction method of coal mine tunnel fused with lidar and inertial measurement unit (IMU) is proposed. In this method, the residual function of the lidar observation model and the prior state deviation of the IMU prediction model are tightly coupled through iterative kalman filter, and a more accurate posteriori state is obtained through state update, which provides reliable pose estimation for the degraded environment. In order to reduce the cumulative drift error in the process of tunnel 3D model reconstruction, a loopback detection algorithm based on Voxelized Generalized ICP (VGICP) is proposed. It is registered in a voxel-based single to multi-distribution mode, so as to complete the selection and accurate matching of loopback keyframes, realize the global pose correction of loopback keyframes, and effectively reduce the cumulative drift error of 3D reconstruction of coal mine tunnel. Compared with the A-LOAM and LEGO-LOAM algorithms, the proposed algorithm has significantly improved the accuracy and global consistency of pose estimation. Experimental results on public datasets show that the root mean square errors of RPE and APE of the proposed algorithm are

0.2718 and0.5008 , respectively, which are reduced by 53.14%, 50.97%, 48.31%, and 50.41%, 47.99% 47.49% respectively compared with other algorithms. Two experiments of simulated coal mine tunnel are carried out. The results show that the error percentage of each area of the indoor corridor model constructed by the proposed algorithm in the directions of length, width and height was within 1.2%. The three-dimensional model of coal mine tunnel constructed by the proposed algorithm is consistent with the spatial distribution of the real coal mine tunnel. The overall distance degradation error is only 2.46%, which is 66.12%, 65.30% and 70.43% higher than that of the other three algorithms, respectively. Three-dimensional reconstruction experiments are carried out in the roadway excavation in the main laboratory of the coal mine. The results show that the average error percentages in the length, width and height directions are 0.47%, 0.75% and 0.67%, respectively. It can realize the accurate three-dimensional modeling of the tunnel.-

Keywords:

- coal mine tunnel /

- 3D reconstruction /

- lidar /

- inertial navigation /

- iterative kalman filter /

- loopback detection

-

-

表 1 各算法轨迹误差统计

Table 1 Trajectory error statistics of each algorithm

算法 A-LOAM LEGO-LOAM LINS OURS RPE 最大值 2.7500 2.5402 2.3449 1.0224 平均值 0.3815 0.3715 0.3517 0.2197 最小值 0.0023 0.0027 0.0112 0.0067 均方根误差 0.5800 0.5543 0.5258 0.2718 标准差 0.4368 0.4262 0.3909 0.1599 APE 最大值 1.9418 1.8644 1.8088 1.5932 平均值 0.9199 0.8655 0.8555 0.4276 最小值 0.1587 0.1382 0.1308 0.0020 均方根误差 1.0099 0.9628 0.9537 0.5008 标准差 0.4416 0.4167 0.4004 0.2610 表 2 室内长廊三维模型重建误差统计

Table 2 Statistics of reconstruction error of the 3D model of indoor corridor

测量区域 A-LOAM LINS OURS 长度 宽度 长度 宽度 长度 宽度 高度 AB段 模型尺寸/mm 18717 — 19176 2132 19629 2119 2324 实际尺寸/mm 19700 2100 19700 2100 19700 2100 2300 误差值/mm −983 — −524 32 −71 19 24 误差/% 4.99 — 2.66 1.52 0.36 0.90 1.04 BC段 模型尺寸/mm 10504 2265 10577 2251 10447 2236 2479 实际尺寸/mm 10400 2215 10400 2215 10400 2215 2450 误差值/mm 104 50 177 36 47 21 29 误差/% 1.00 2.26 1.70 1.63 0.45 0.95 1.18 BD段 模型尺寸/mm 8828 3877 — 4005 8736 3973 2476 实际尺寸/mm 8700 3940 8700 3940 8700 3940 2450 误差值/mm 128 −63 — 65 36 33 26 误差/% 1.47 1.60 — 1.65 0.41 0.84 1.06 DE段 模型尺寸/mm 18746 — 19296 2263 21175 2231 2473 实际尺寸/mm 21250 2215 21250 2215 21250 2215 2450 误差值/mm − 2504 — − 1954 48 −75 16 23 误差/% 11.78 — 9.20 2.17 0.35 0.72 0.94 EF段 模型尺寸/mm 12996 2286 13005 2256 12952 2235 2478 实际尺寸/mm 12900 2215 12900 2215 12900 2215 2450 误差值/mm 96 71 105 41 52 20 28 误差/% 0.74 3.21 0.81 1.85 0.40 0.90 1.14 表 3 各算法距离退化误差统计

Table 3 Distance degradation error statistics of each algorithm

方法 P0-P1/m P1-P2/m P2-P3/m P3-P4/m 总距离/m 误差/% 真实值 44.00 48.00 47.00 45.00 184.00 − A-LOAM 41.30 45.77 40.84 42.74 170.65 7.26 LEGO-LOAM 40.33 43.14 44.88 42.61 170.96 7.09 LINS 42.52 43.90 40.31 41.96 168.69 8.32 OURS 43.46 46.91 45.98 43.13 179.48 2.46 表 4 掘进巷道场景三维重建误差

Table 4 Reconstruction error of the tunnel scene

参数 实际尺寸/m 模型尺寸/m 误差/m 误差/% 长度 23.42 23.31 0.11 0.47 宽度 4.00 3.97 0.03 0.75 高度 3.00 2.98 0.02 0.67 -

[1] 王国法,王虹,任怀伟,等. 智慧煤矿2025情景目标和发展路径[J]. 煤炭学报,2018,43(2):295−305. WANG Guofa,WANG Hong,REN Huaiwei,et al. 2025 scenarios and development path of intelligent coal mine[J]. Journal of China Coal Society,2018,43(2):295−305.

[2] 毛君,杨润坤,谢苗,等. 煤矿智能快速掘进关键技术研究现状及展望[J]. 煤炭学报,2024,49(2):1214−1229. MAO Jun,YANG Runkun,XIE Miao,et al. Research status and prospects of key technologies for intelligent rapid excavation in coal mines[J]. Journal of China Coal Society,2024,49(2):1214−1229.

[3] 王国法. 《煤矿智能化建设指南(2021年版)》解读:从编写组视角进行解读[J]. 智能矿山,2021,2(4):2−9. [4] 胡兴涛,朱涛,苏继敏,等. 煤矿巷道智能化掘进感知关键技术[J]. 煤炭学报,2021,46(7):2123−2135. HU Xingtao,ZHU Tao,SU Jimin,et al. Key technology of intelligent drivage perception in coal mine roadway[J]. Journal of China Coal Society,2021,46(7):2123−2135.

[5] 马宏伟,王岩,杨林. 煤矿井下移动机器人深度视觉自主导航研究[J]. 煤炭学报,2020,45(6):2193−2206. MA Hongwei,WANG Yan,YANG Lin. Research on depth vision based mobile robot autonomous navigation in underground coal mine[J]. Journal of China Coal Society,2020,45(6):2193−2206.

[6] 杨林,马宏伟,王岩. 基于激光惯性融合的煤矿井下移动机器人SLAM算法[J]. 煤炭学报,2022,47(9):3523−3534. YANG Lin,MA Hongwei,WANG Yan. LiDAR-Inertial SLAM for mobile robot in underground coal mine[J]. Journal of China Coal Society,2022,47(9):3523−3534.

[7] ZHANG J,SINGH S. LOAM:Lidar odometry and mapping in real-time[C]//Robotics:Science and Systems X. Robotics:Science and Systems Foundation,2014.

[8] SHAN T X,ENGLOT B. LeGO-LOAM:Lightweight and ground-optimized lidar odometry and mapping on variable terrain[C]//2018 IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS). Piscataway,NJ:IEEE,2018:4758−4765.

[9] YANG L,MA H W,WANG Y,et al. A tightly coupled LiDAR-inertial SLAM for perceptually degraded scenes[J]. Sensors,2022,22(8):3063. doi: 10.3390/s22083063

[10] YANG X,LIN X H,YAO W Q,et al. A robust LiDAR SLAM method for underground coal mine robot with degenerated scene compensation[J]. Remote Sensing,2023,15(1):186.

[11] 刘峰,王宏伟,刘宇. 基于多传感融合的巷道三维空间映射[J]. 煤炭学报,2024,49(9):4019−4026 LIU Feng,WANG Hongwei,LIU Yu. Research on 3D Spatial Mapping of Road ways Based on Multi-sensor Fusion[J]. Journal of Coal Industry,2024,49(9):4019−4026

[12] SHAN T X,ENGLOT B,MEYERS D,et al. LIO-SAM:Tightly-coupled lidar inertial odometry via smoothing and mapping[C]//2020 IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS). Piscataway,NJ:IEEE,2020:5135−5142.

[13] 马庆禄,汪军豪,张杰,等. 激光雷达与惯性测量单元同步融合下的园区三维建图[J]. 光学 精密工程,2024,32(3):422−434. doi: 10.37188/OPE.20243203.0422 MA Qinglu,WANG Junhao,ZHANG Jie,et al. Three-dimensional mapping of park based on synchronous fusion of lidar and inertial measurement unit[J]. Optics and Precision Engineering,2024,32(3):422−434. doi: 10.37188/OPE.20243203.0422

[14] XU W,CAI Y X,HE D J,et al. FAST-LIO2:Fast direct LiDAR-inertial odometry[J]. IEEE Transactions on Robotics,2022,38(4):2053−2073. doi: 10.1109/TRO.2022.3141876

[15] 张福斌,王凯,廖伟飞,等. 激光雷达/MEMS IMU/里程计紧组合导航算法[J]. 仪器仪表学报,2022,43(7):139−148. ZHANG Fubin,WANG Kai,LIAO Weifei,et al. Lidar/MEMS IMU/Odometer integrated tightly navigation algorithm[J]. Chinese Journal of Scientific Instrument,2022,43(7):139−148.

[16] 任好玲,吴江东,林添良,等. 基于多传感器紧耦合的工程机械定位与建图系统[J]. 机械工程学报,2023,59(24):323−333. doi: 10.3901/JME.2023.24.323 REN Haoling,WU Jiangdong,LIN Tianliang,et al. Construction machinery localization and mapping system based on multi-sensor tight coupling[J]. Journal of Mechanical Engineering,2023,59(24):323−333. doi: 10.3901/JME.2023.24.323

[17] REN Z L,WANG L G,BI L. Robust GICP-based 3D LiDAR SLAM for underground mining environment[J]. Sensors,2019,19(13):2915. doi: 10.3390/s19132915

[18] REN Z L,WANG L G. Accurate real-time localization estimation in underground mine environments based on a distance-weight map (DWM)[J]. Sensors,2022,22(4):1463. doi: 10.3390/s22041463

[19] JI X L,ZUO L,ZHANG C H,et al. LLOAM:LiDAR odometry and mapping with loop-closure detection based correction[C]//2019 IEEE International Conference on Mechatronics and Automation (ICMA). Piscataway,NJ:IEEE,2019:2475−2480.

[20] JIANG J W,WANG J K,WANG P,et al. LiPMatch:LiDAR point cloud plane based loop-closure[J]. IEEE Robotics and Automation Letters,2020,5(4):6861−6868. doi: 10.1109/LRA.2020.3021374

[21] 徐晓苏,李诺,姚逸卿. 基于快速回环检测的室外环境下激光雷达SLAM算法[J]. 中国惯性技术学报,2022,30(6):716−722. XU Xiaosu,LI Nuo,YAO Yiqing. Lidar SLAM algorithm in outdoor environment based on fast loop detection[J]. Journal of Chinese Inertial Technology,2022,30(6):716−722.

[22] 马宝良,崔丽珍,李敏超,等. 露天煤矿环境下基于LiDAR/IMU的紧耦合SLAM算法研究[J]. 煤炭科学技术,2024,52(3):236−244. doi: 10.12438/cst.2023-0538 MA Baoliang,CUI Lizhen,LI Minchao,et al. Study on tightly coupled LiDAR-Inertial SLAM for open pit coal mine environment[J]. Coal Science and Technology,2024,52(3):236−244. doi: 10.12438/cst.2023-0538

[23] 薛光辉,李瑞雪,张钲昊,等. 基于激光雷达的煤矿井底车场地图融合构建方法研究[J]. 煤炭科学技术,2023,51(8):219−227. XUE Guanghui,LI Ruixue,ZHANG Zhenghao,et al. Lidar based map construction fusion method for underground coal mine shaft bottom[J]. Coal Science and Technology,2023,51(8):219−227.

[24] 李芳威,鲍久圣,王陈,等. 基于LD改进Cartographer建图算法的无人驾驶无轨胶轮车井下SLAM自主导航方法及试验[J/OL]. 煤炭学报,1−12[2024−02−15]. https://doi.org/10.13225/j.cnki.jccs.2023.0731. LI Fangwei,BAO Jiusheng,WANG Chen,et al. Unmanned trackless rubber wheeler based on LD improved Cartographer mapping algorithm Underground SLAM autonomous navigation method and test[J/OL]. Journal of Coal Industry,1−12[2024−02−15]. https://doi.org/10.13225/j.cnki.jccs.2023.0731.

[25] 邱佳月,赖际舟,方玮,等. 一种基于动态剔除和场景匹配的Robust SLAM方法[J]. 仪器仪表学报,2022,43(3):249−257. QIU Jiayue,LAI Jizhou,FANG Wei,et al. A Robust SLAM method based on eliminating dynamic points and matching scenes[J]. Chinese Journal of Scientific Instrument,2022,43(3):249−257.

[26] 郝宇,张亿,黄磊,等. 基于改进图优化的移动机器人二维激光SLAM算法研究[J/OL]. 激光与光电子学进展,1−13[2024−02−15]. http://kns.cnki.net/kcms/detail/31.1690.TN.20240517.1421.004.html. HAO Yu,ZHANG Yi,HUANG Lei,et al. Research on Mobile Robot 2D Laser SLAM Algorithm Based on Improved Graph Optimization [J/OL]. Laser & Optoelectronics Progress,1−13[2024−02−15]. http://kns.cnki.net/kcms/detail/31.1690.TN.20240517.1421.004.html.

[27] 薛光辉,张钲昊,张桂艺,等. 煤矿井下点云特征提取和配准算法改进与激光SLAM研究[J/OL]. 煤炭科学技术,1−12[2024−02−15]. http://kns.cnki.net/kcms/detail/11.2402.TD.20240722.1557.003.html. XU Guanghui,ZHANG Zhenghao,ZHANG Guiyi,et al. Improvement of Point Cloud Feature Extraction and Alignment Algorithms and LiDAR SLAM in Coal Mine Underground [J/OL]. Coal Science and Technology, 1−12[2024−02−15]. http://kns.cnki.net/kcms/detail/11.2402.TD.20240722.1557.003.html.

下载:

下载: