Simulation and experimental study on energy absorption components of advanced hydraulic support for mining

-

摘要:

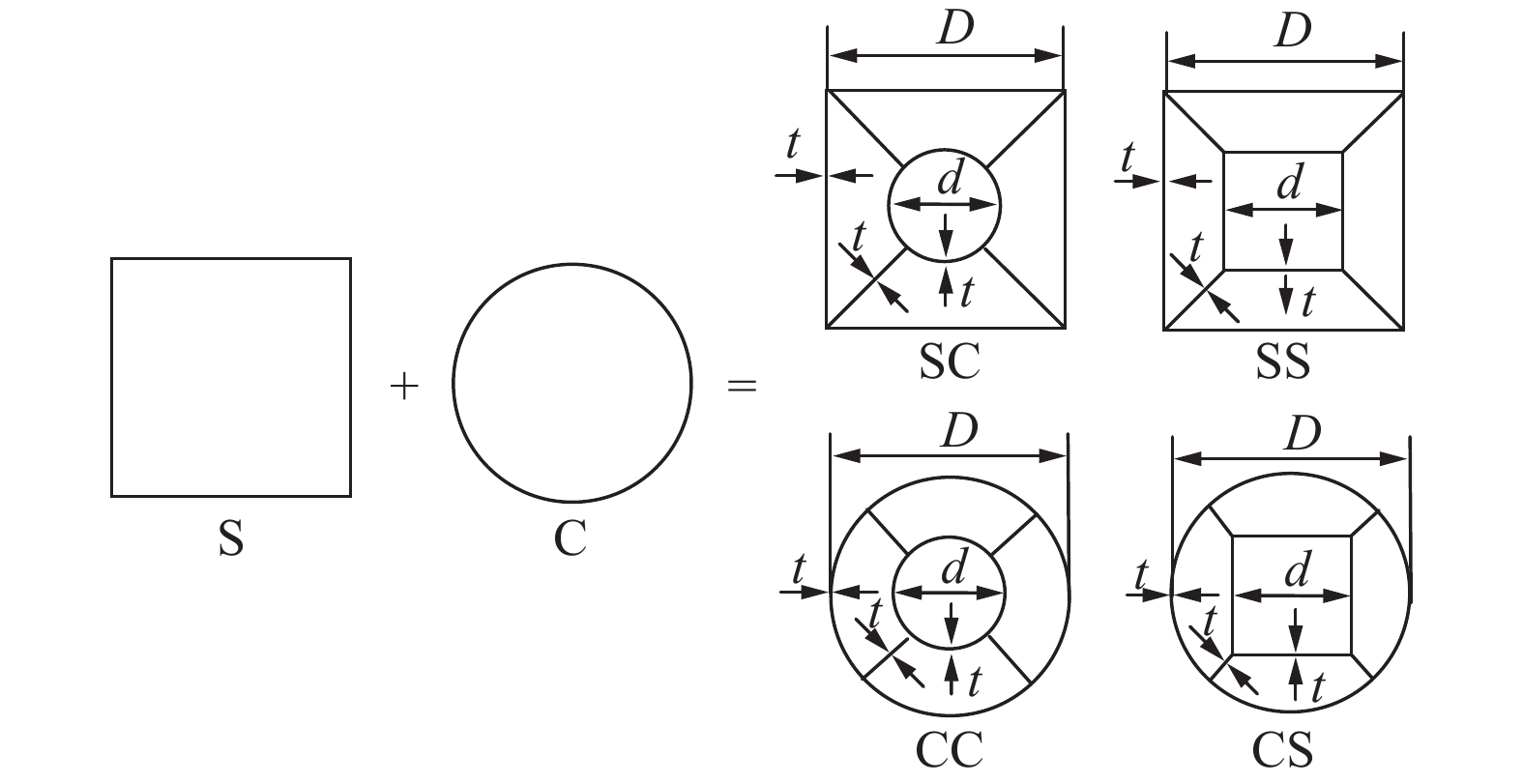

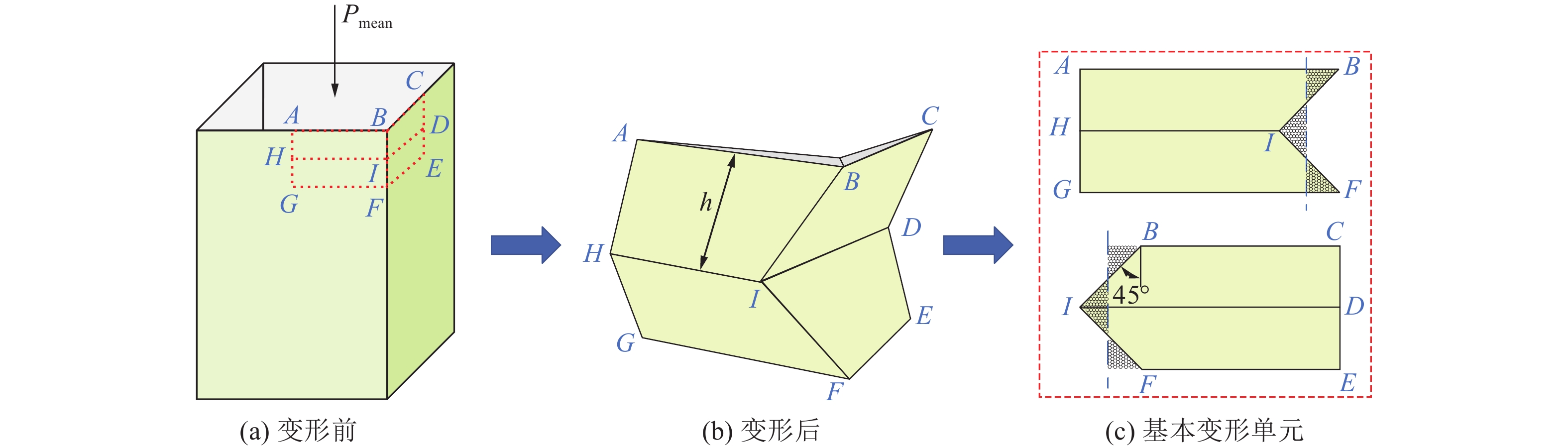

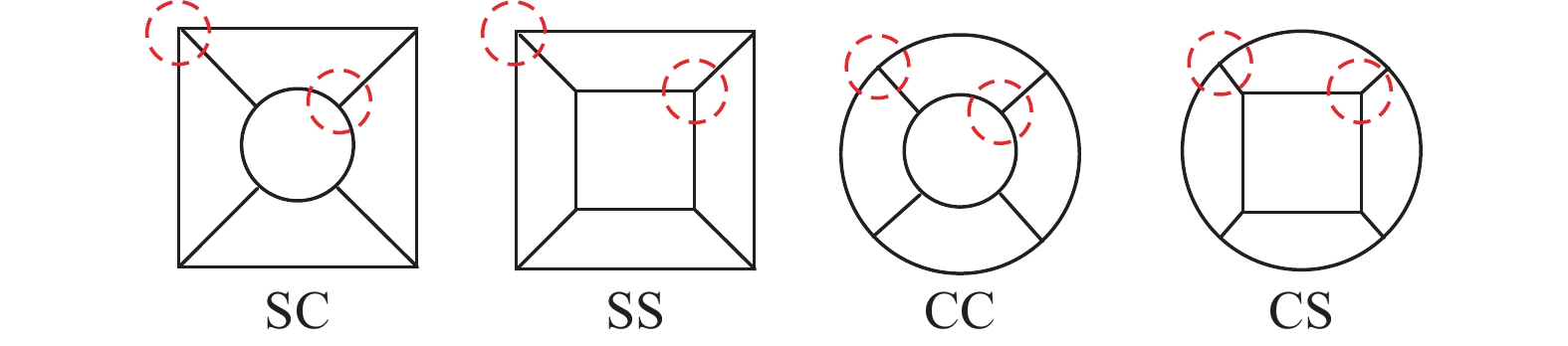

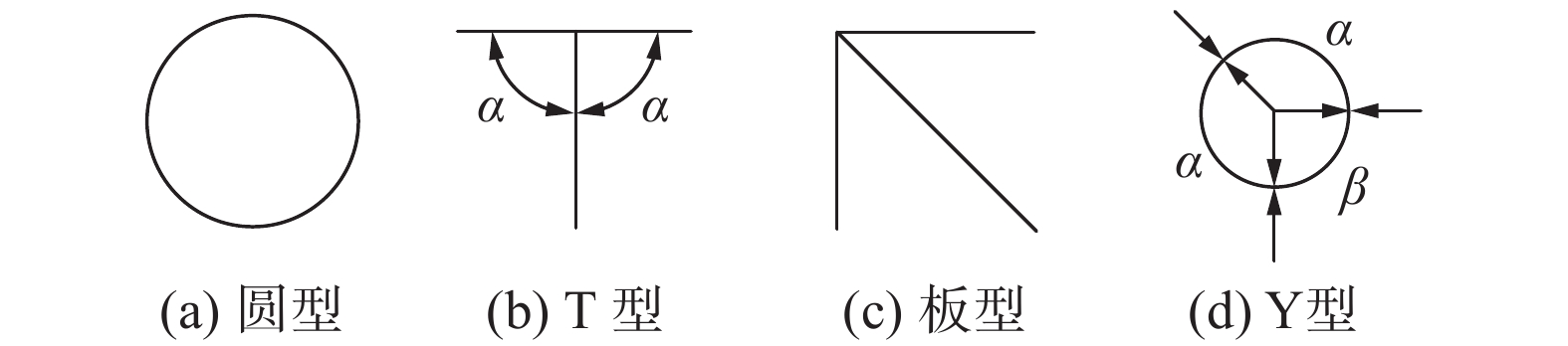

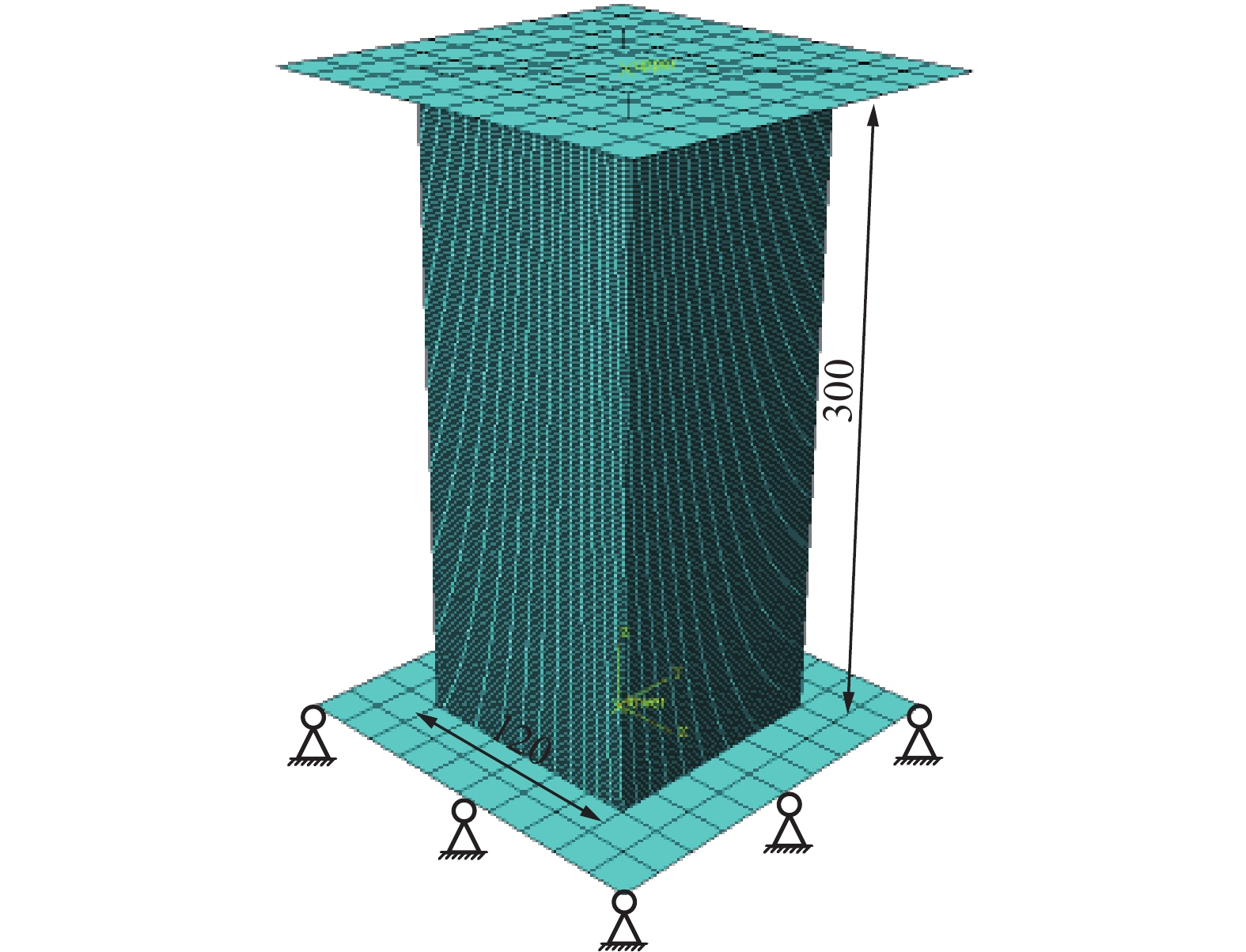

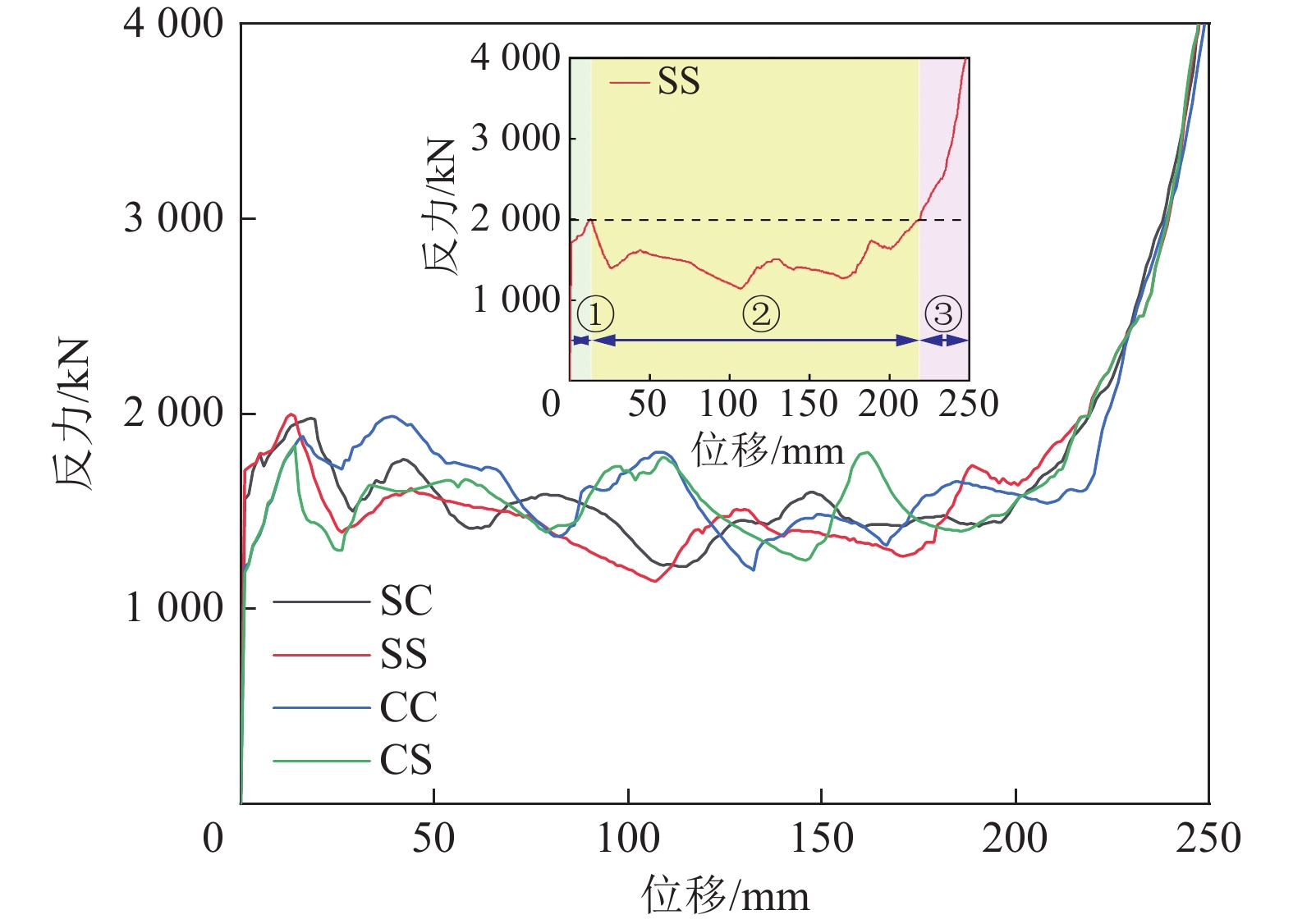

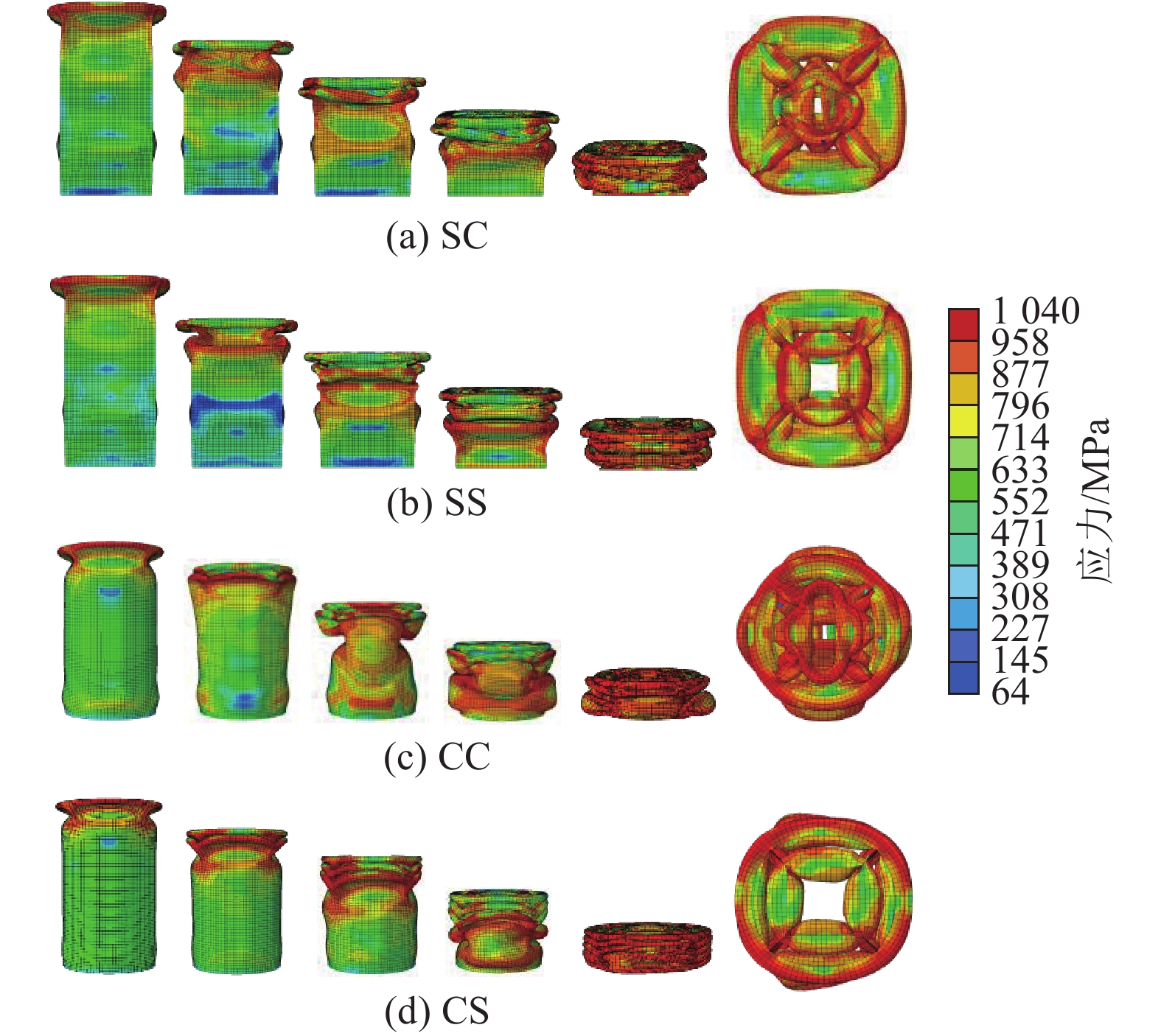

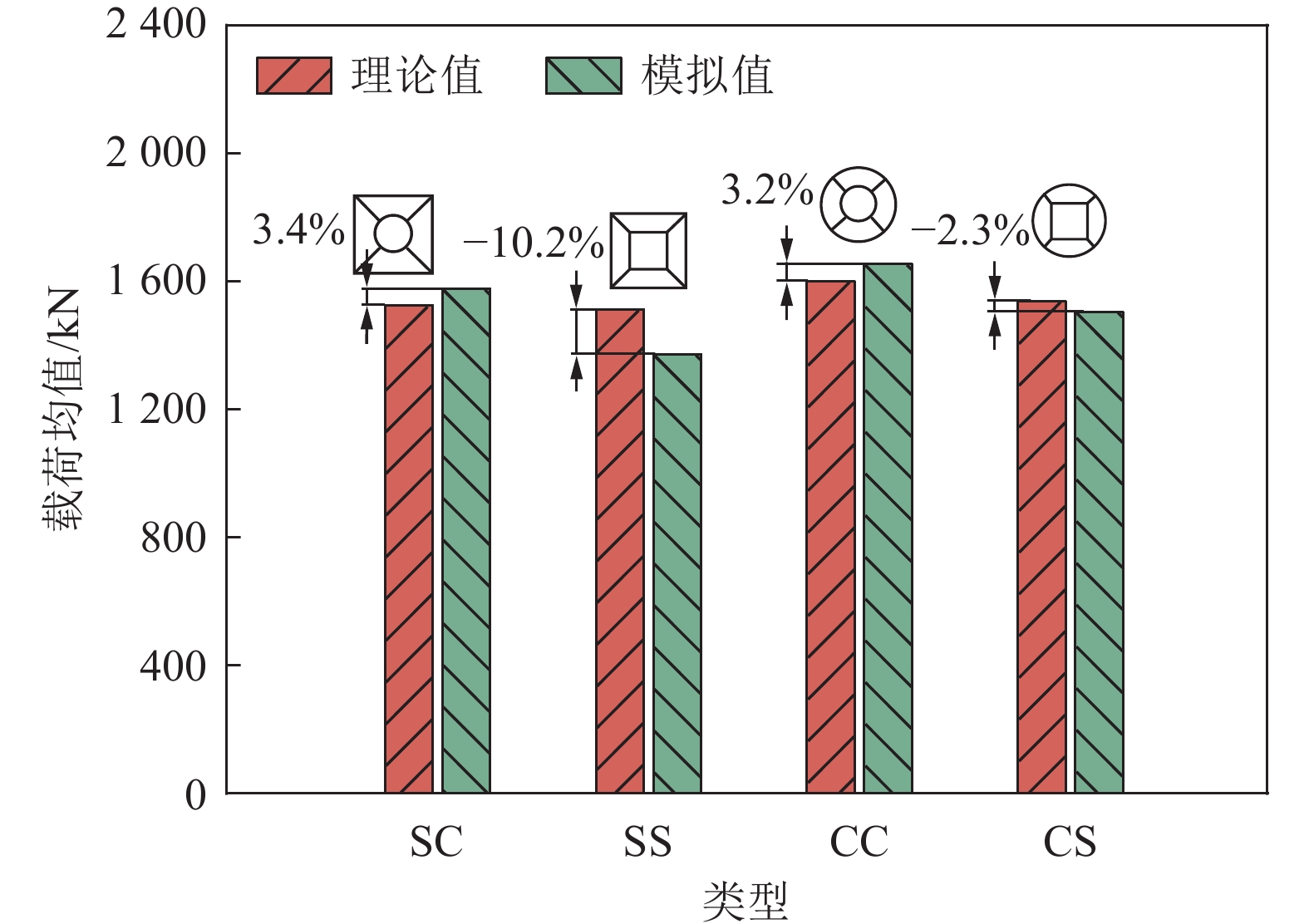

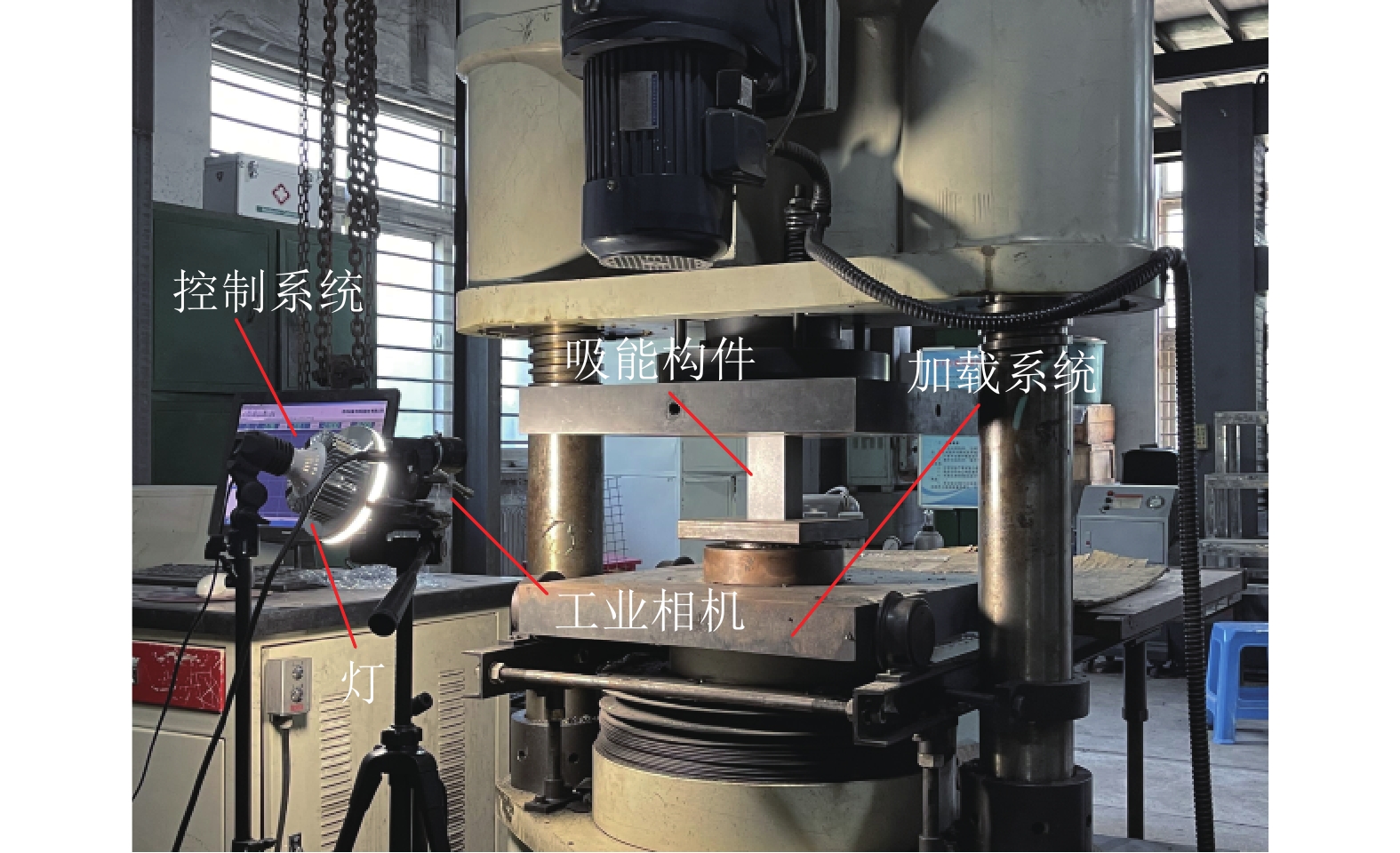

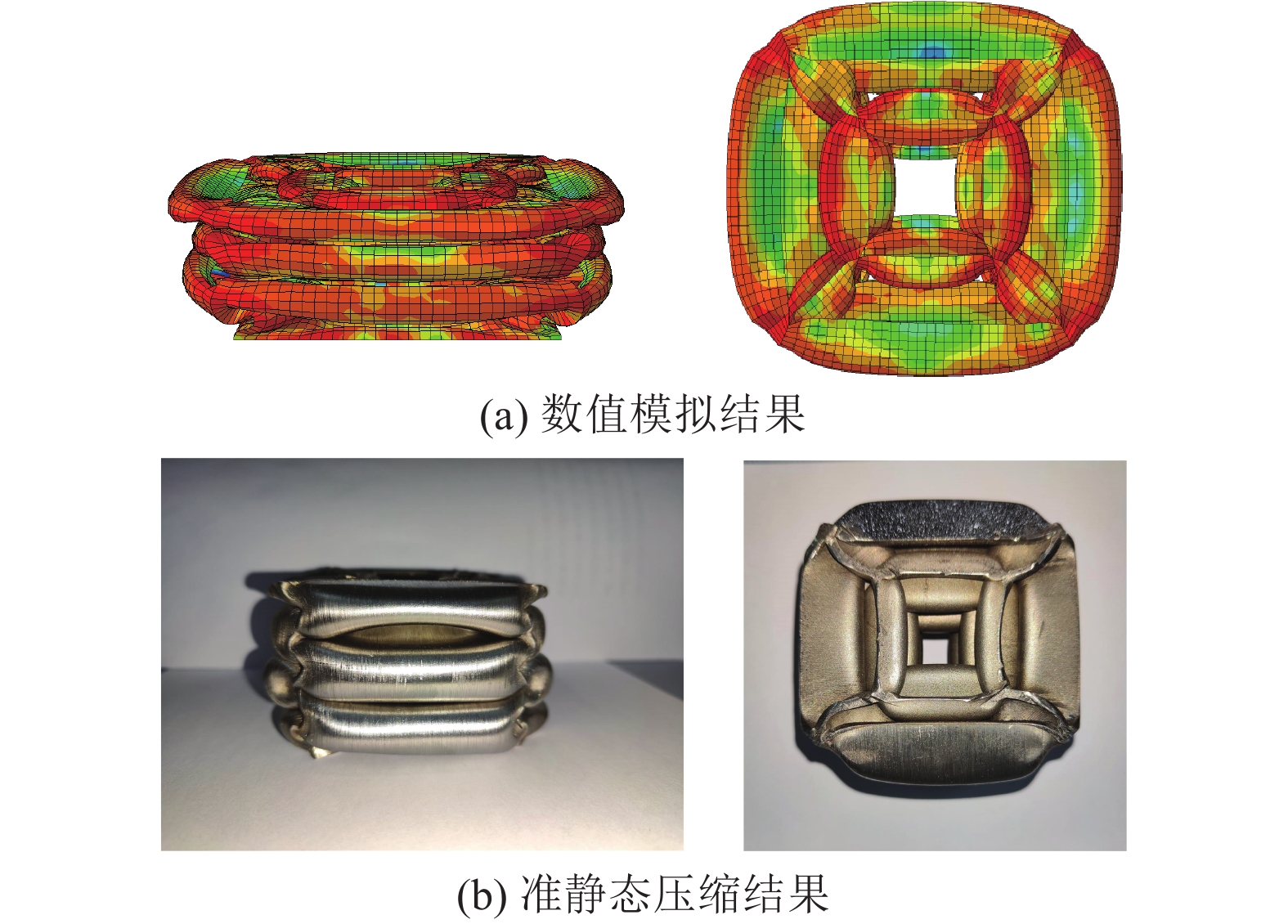

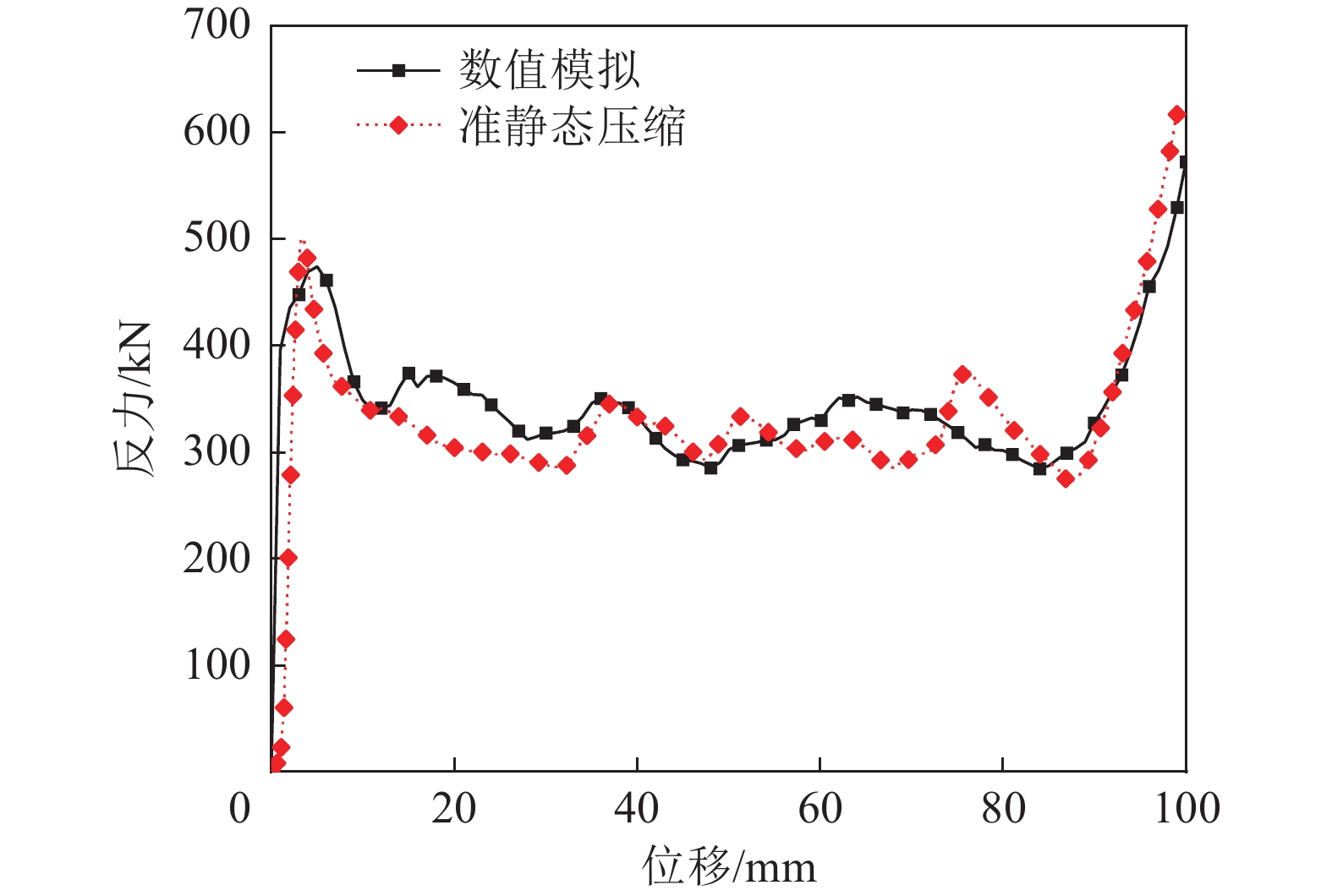

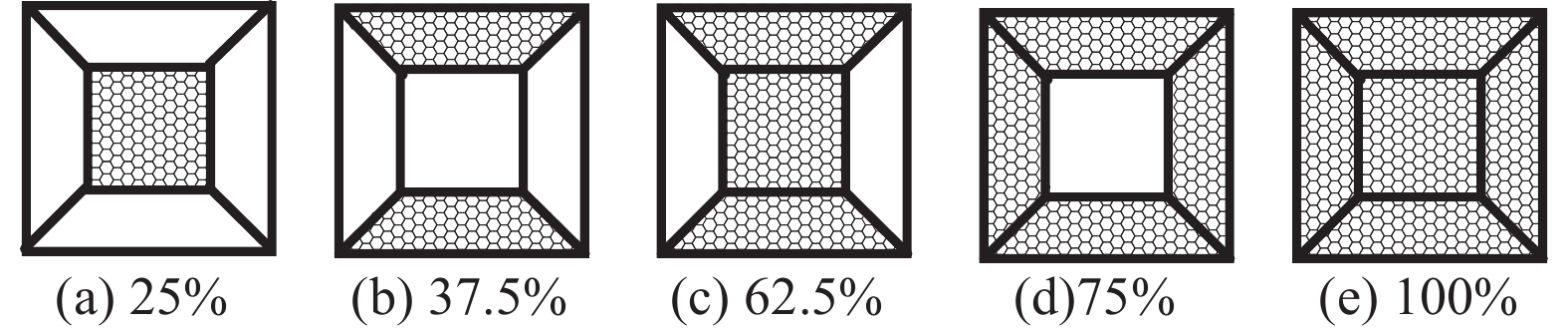

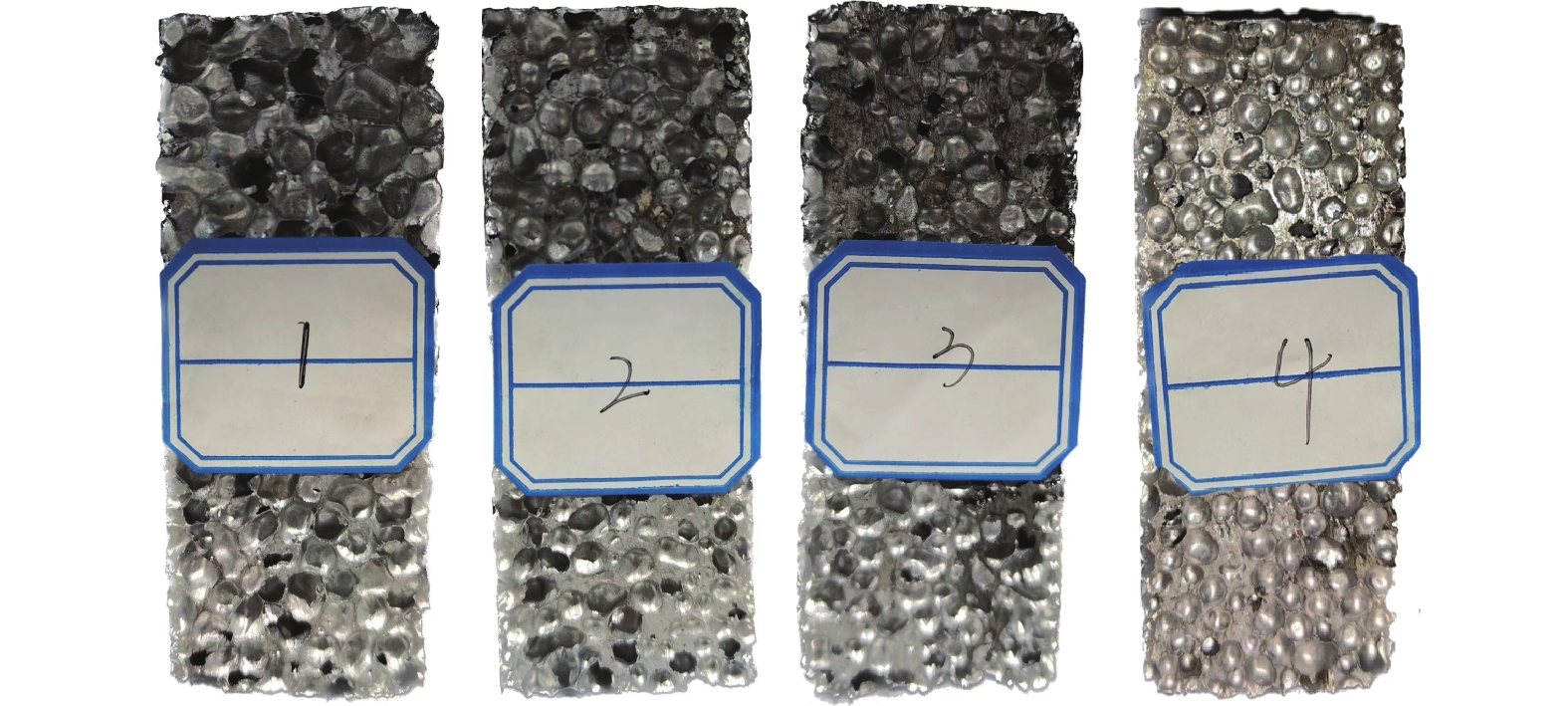

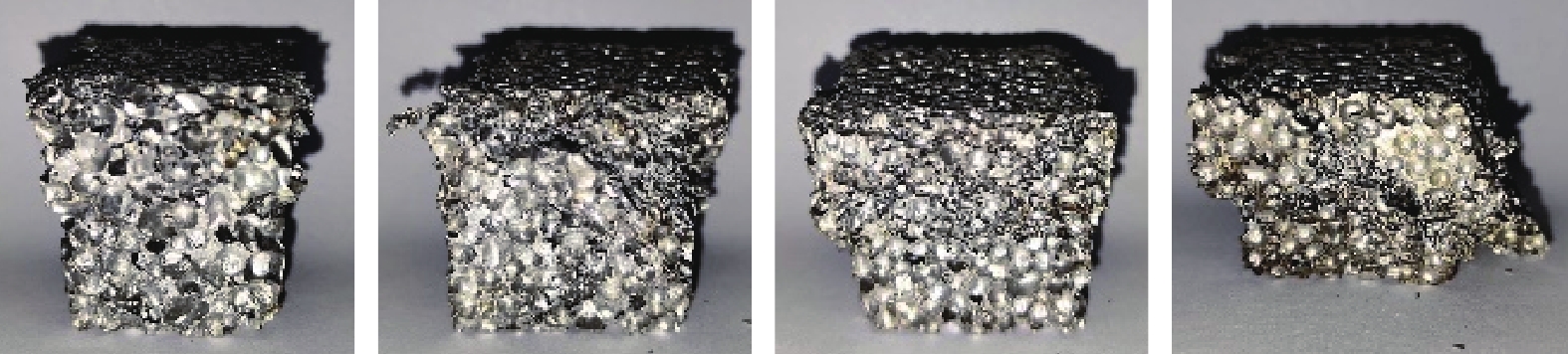

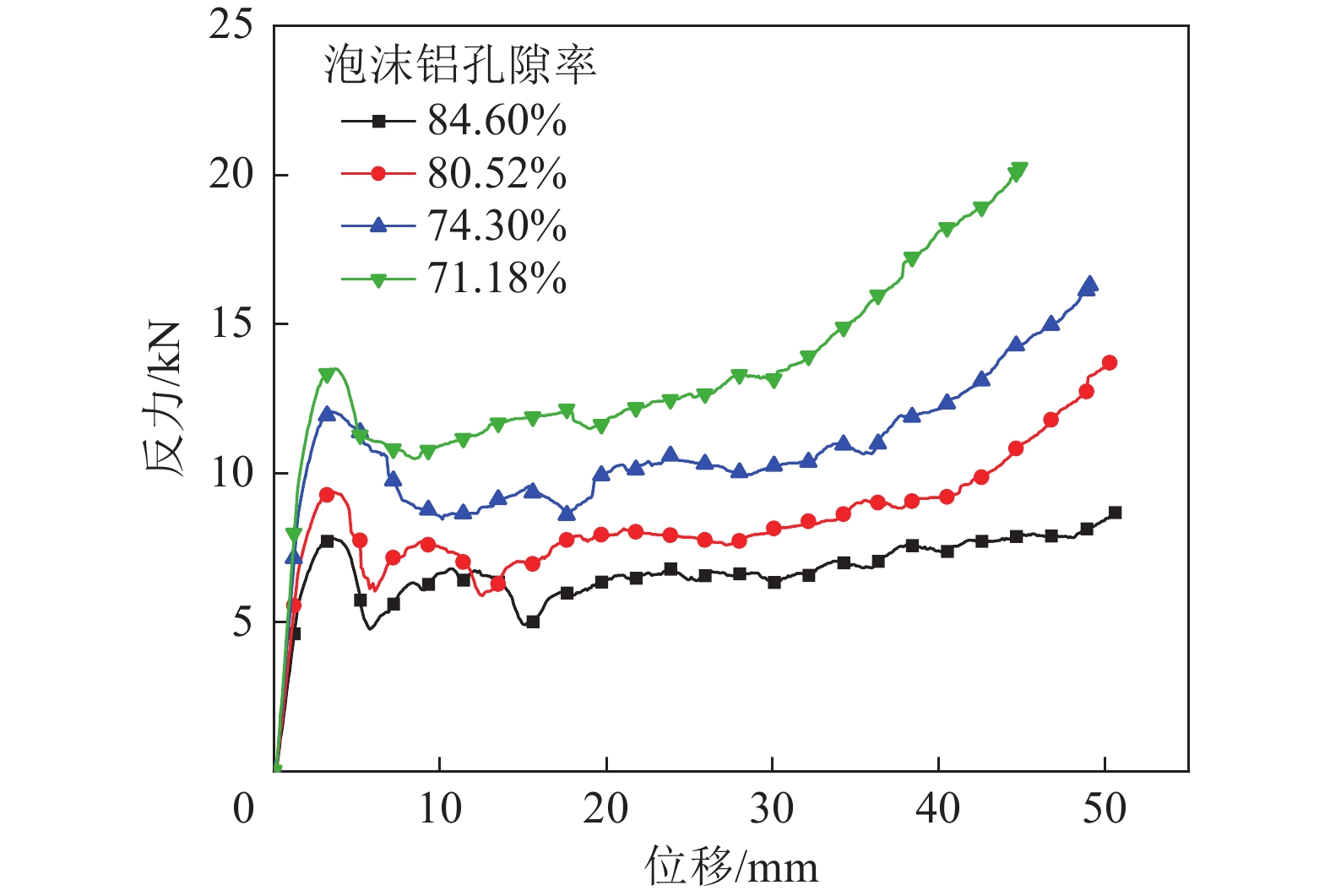

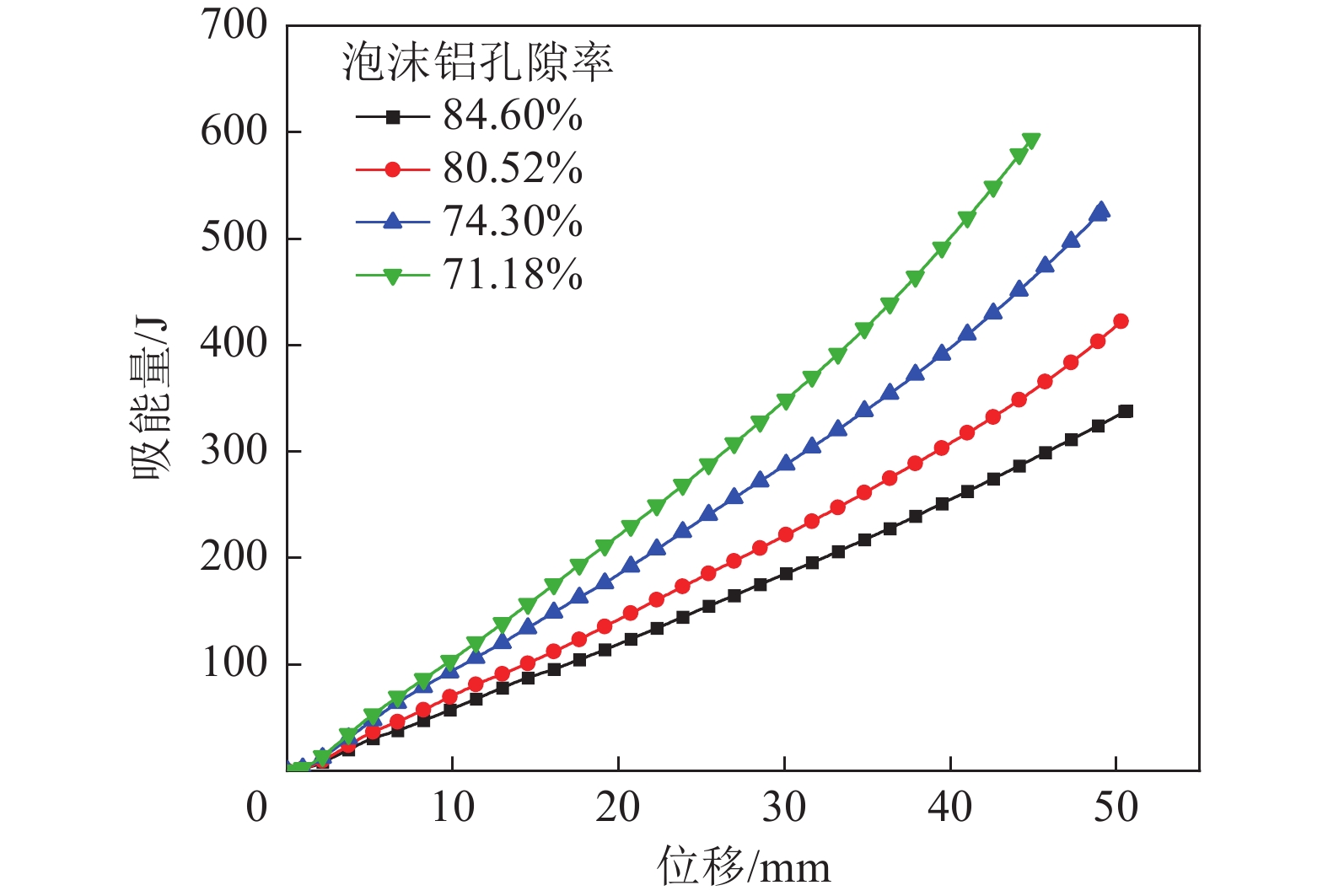

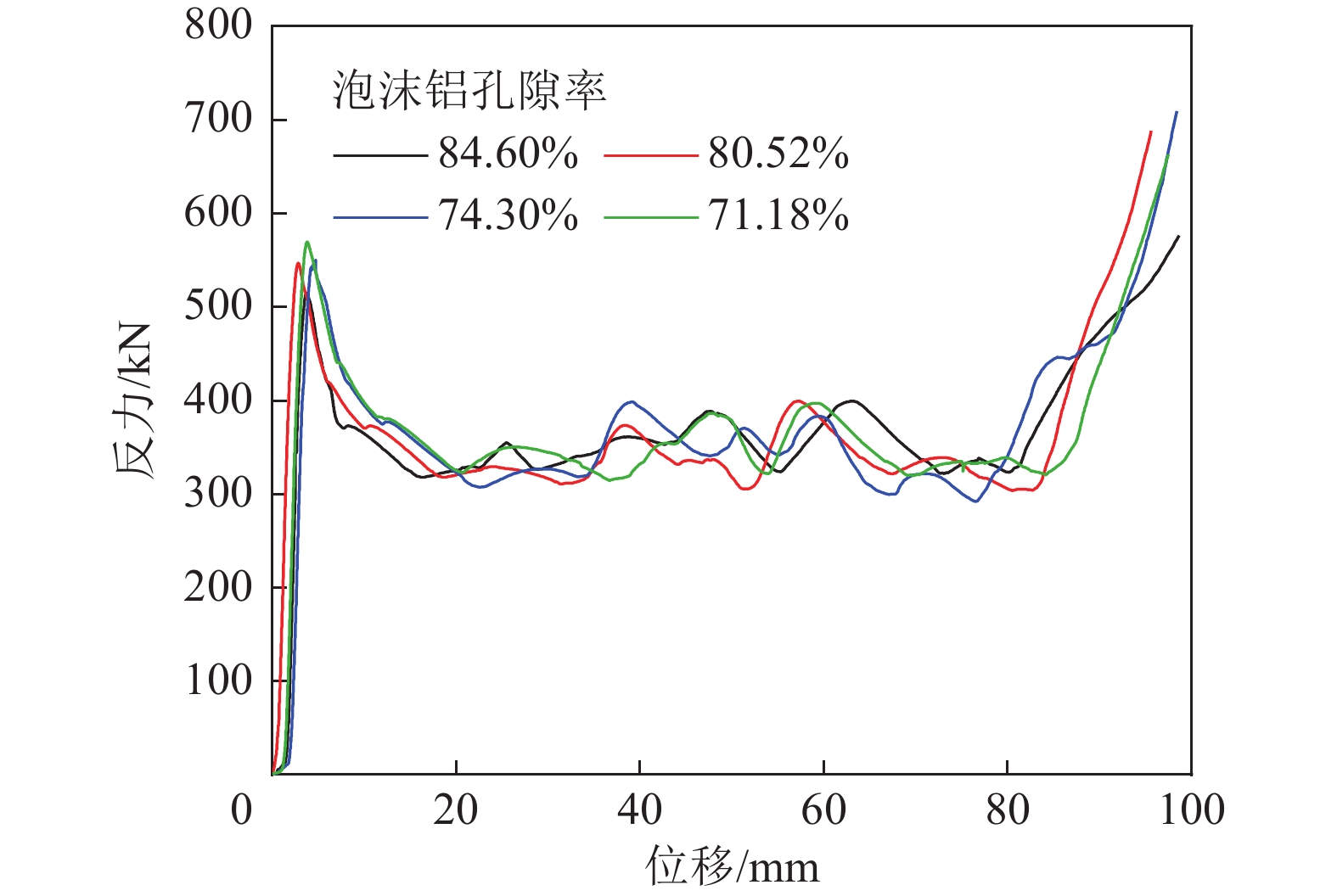

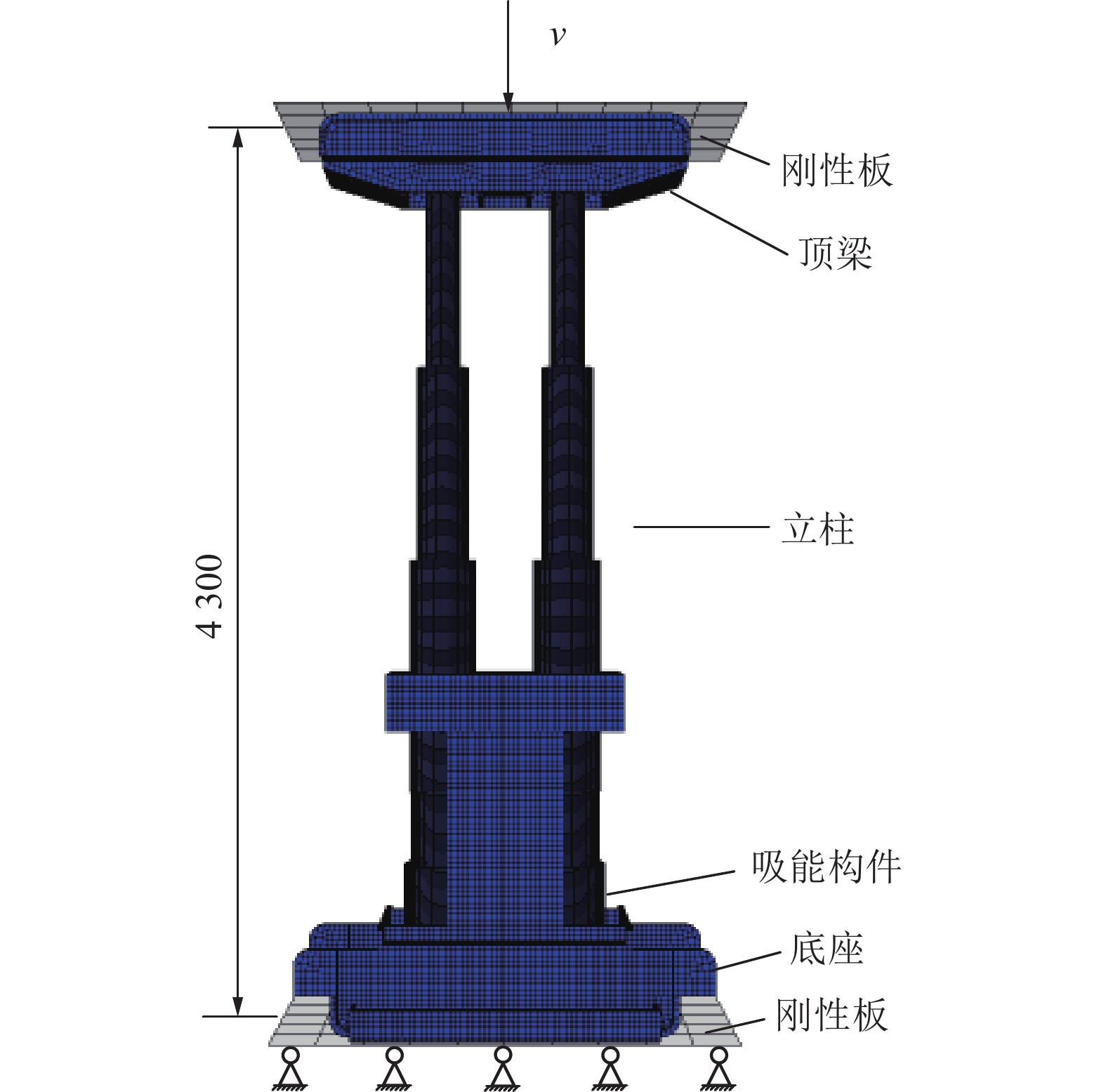

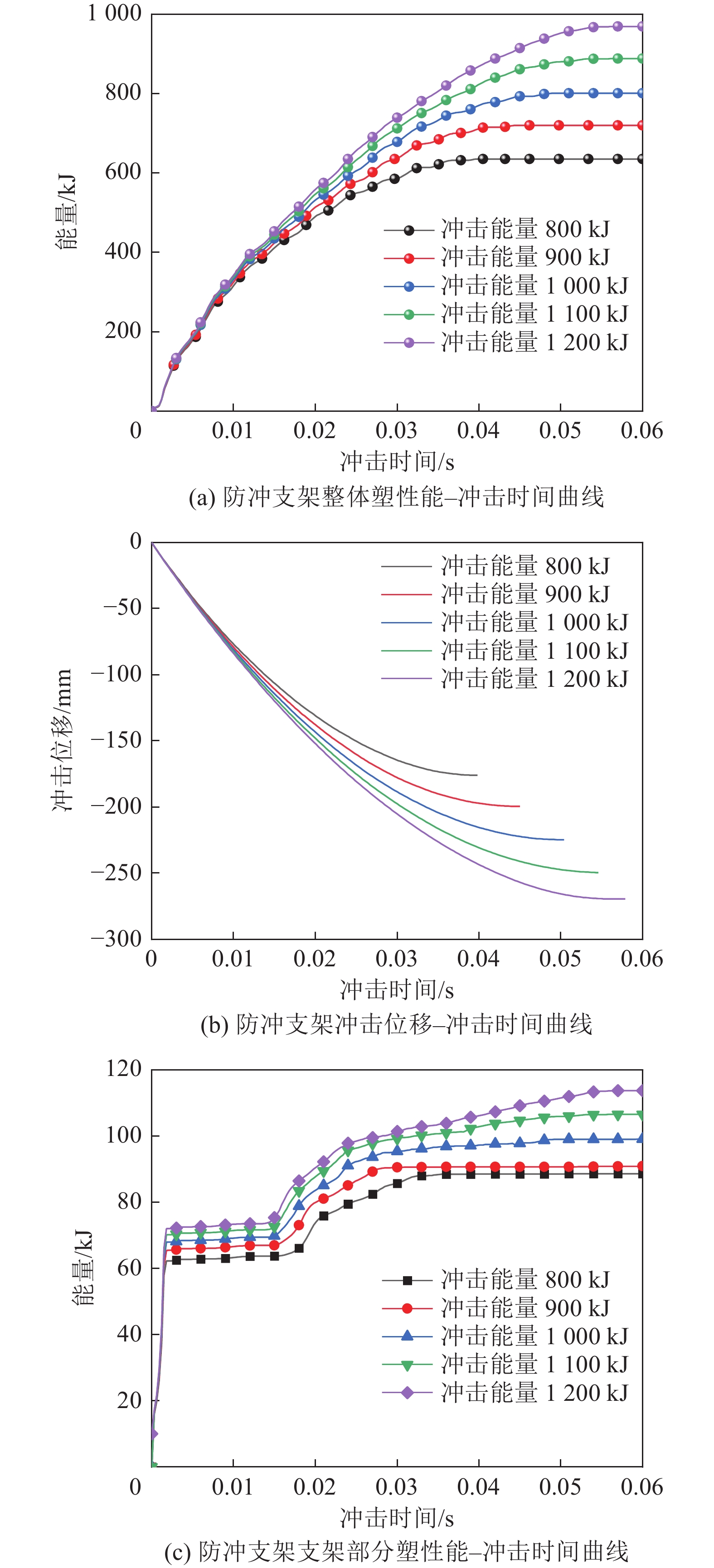

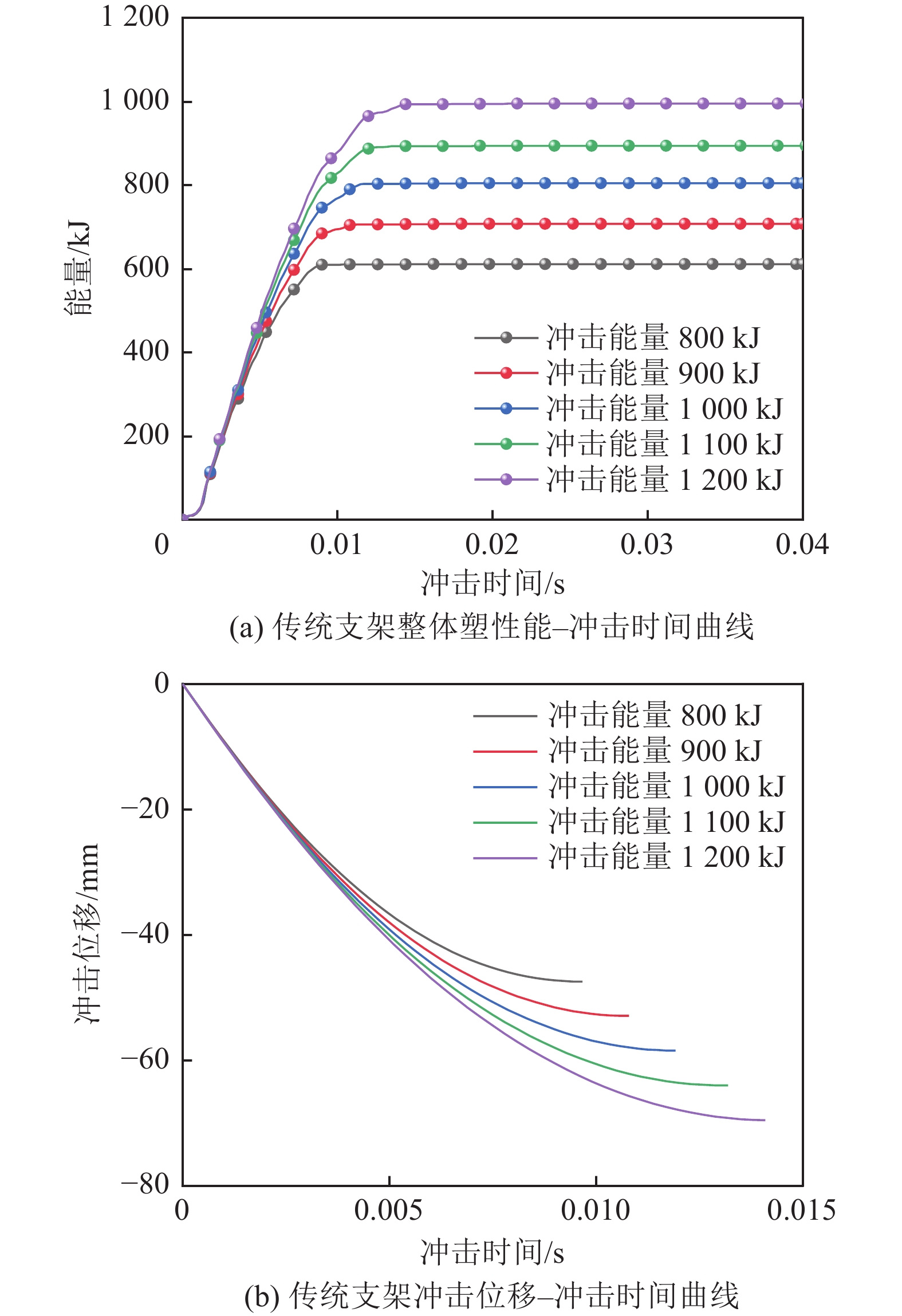

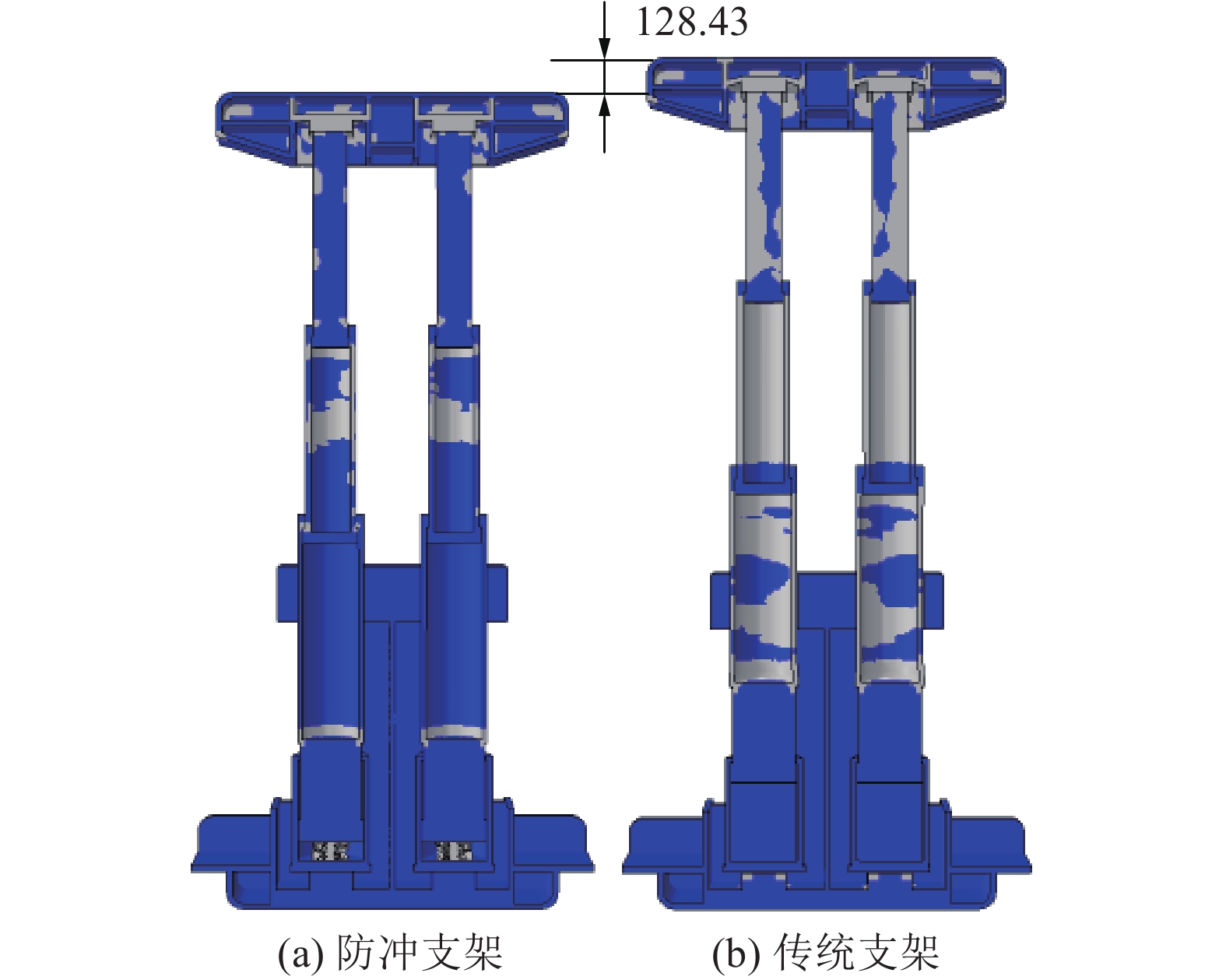

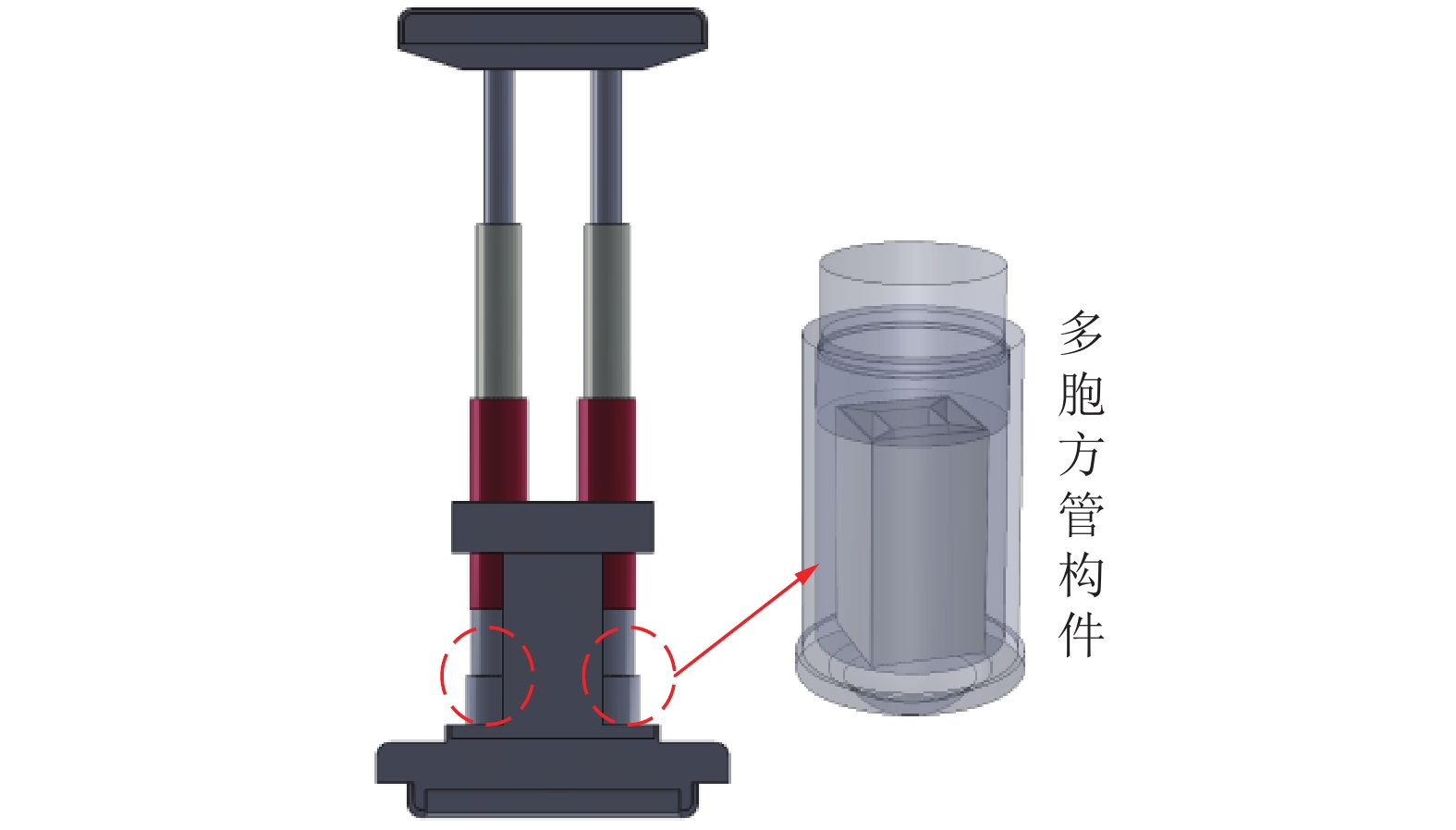

为了提高液压支架的能量吸收性能以解决巷道冲击地压发生时支架立柱爆缸等问题,提出了将一种方管与圆管互相嵌套的多胞管吸能构件与立柱串联应用于液压支架中。基于简化的超折叠单元理论剖析了多胞管的能量耗散途径,推导出了不同截面形状多胞管的等效轴向载荷预测公式;采用数值模拟获得了不同截面形状多胞管在轴向压溃作用下的能量吸收性能及其屈曲变形形态,发现多胞方管(SS类型)具备相对吸能优势,并通过试验验证了数值模拟的可靠性,同时将数值模拟与试验得到载荷均值与理论预测的等效轴向载荷进行对比,验证了等效轴向载荷预测公式具有较高的预测精度;依托课题组多胞方管中泡沫铝填充方式研究基础,选择具备相对吸能优势的25%填充率的填充方式,开展不同孔隙度泡沫铝填充多胞方管的轴向准静态压缩试验。结果表明:泡沫铝的填充有助于提升多胞方管抵抗变形的能力,其中71.18%孔隙度泡沫铝填充多胞方管载荷波动最小,有效变形长度和吸能量最大,能量吸收效果最好,可使吸能让位过程更加稳定;当冲击速度保持不变时,在不同冲击能量条件下,泡沫铝填充多胞方管防冲支架与未添加吸能构件的传统液压支架相比,支架部分的塑性能降低了87%左右,冲击时间延长了307%左右,让位距离增加了282%左右,通过吸能构件的屈曲变形有效减少了防冲支架的塑性变形,为支架立柱安全阀的开启提供了充足的时间。泡沫铝填充多胞方管的应用减小了支架立柱发生爆缸的危险性,提高了立柱的抗冲击性能。

Abstract:In order to improve the energy absorption performance of hydraulic support and solve the problems such as cylinder explosion of support column when roadway rock burst occurs, a kind of multi-cell tube energy absorption component with square tube and round tube nested with each other is proposed and applied in series to the hydraulic support. Based on the simplified super folding element theory, the energy dissipation path of multi-cell tubes is analyzed, and the equivalent axial load prediction formula of multi-cell tubes with different section shapes is derived. The energy absorption performance and buckling deformation morphology of multi-cell tubes with different section shapes under axial crushing were obtained by numerical simulation. It was found that multi-cell square tubes (SS type) had relative energy absorption advantages, and the reliability of numerical simulation was verified by experiments. Meanwhile, the average load obtained by numerical simulation and experiment was compared with the equivalent axial load predicted by theory. It is proved that the equivalent axial load prediction formula has high prediction accuracy. Based on the research foundation of aluminum foam filling method in multi-cell square tube, the filling method with 25% filling rate with relative energy absorption advantage was selected to carry out axial quasi-static compression test of aluminum foam filling multi-cell square tube with different porosity. The results show that the aluminum foam filling can improve the deformation resistance of the multicellular square tube. Among them, the load fluctuation of the multi-cell square tube with 71.18% porosity is the smallest, the effective deformation length and energy absorption are the largest, and the energy absorption effect is the best, which can make the energy absorption and displacement process more stable. When the impact velocity remains unchanged, under different impact energy conditions, compared with the with the traditional hydraulic support without adding energy absorbing components, the plastic energy of the support part is reduced by about 87%, the impact time is extended by about 307%, and the yield distance is increased by about 282%. The plastic deformation of the support is effectively reduced through the buckling deformation of the energy absorption component. Sufficient time is provided for the opening of the support column safety valve. The application of aluminum foam filled multi-cell square tube reduces the risk of cylinder explosion of the support column and improves the impact resistance of the column.

-

-

表 1 不同结构多胞管等效轴向载荷预测公式

Table 1 Equivalent axial load prediction formula for multi-cell tubes with different structures

类型 圆型单元 T型单元 板型单元 Y型单元 Pmean SC 1 4 4 — $ 6.40\dfrac{{{\sigma _0}}}{k}\sqrt {4D + \pi d + 2\sqrt 2 D - 2d} {T^{1.5}} $ SS — — 4 4 $ 5.56\dfrac{{{\sigma _0}}}{k}\sqrt {4D + 4d + \sqrt 2 D} {T^{1.5}} $ CC 2 8 — — $ 7.64\dfrac{{{\sigma _0}}}{k}\sqrt {\pi D + \pi d + 2D - 2d} {T^{1.5}} $ CS 1 4 — 4 $ 6.94\dfrac{{{\sigma _0}}}{k}\sqrt {\pi D + 4d + 2D - 2\sqrt 2 d} {T^{1.5}} $ 表 2 不同结构多胞管能量吸收性能

Table 2 Energy absorption performance of multi-cell tubes with different structures

类型 Pmax/kN Pmean/kN Etotal/kJ σ/kN δ/mm SC 1 980 1 523 330 205 217 SS 1 989 1 511 331 200 219 CC 1 885 1 549 342 216 221 CS 1 839 1 538 330 207 215 表 3 SS型多胞方管数值模拟与准静态压缩试验的吸能性能

Table 3 Energy absorption performance of SS-type multi-cell square tube under numerical simulation and quasi-static compression experiment

Pmax Pmean Etotal σ δ 仿真/kN 试验/kN 误差/% 仿真/kN 试验/kN 误差/% 仿真/kJ 试验/kJ 误差/% 仿真/kN 试验/kN 误差/% 仿真/mm 试验/mm 误差/% 474.52 501.64 5.41 338.14 309.50 9.25 32.91 30.87 6.61 55.67 65.32 14.77 97.12 96.31 0.84 表 4 不同孔隙率泡沫铝填充多胞方管能量吸收性能

Table 4 Energy absorption performance of multi-cellular square tubes filled with aluminum foam with different porosity

孔隙率/% Pmax/kN Pmean/kN σ/kN Etotal/kJ δ/mm 84.60 514.65 330.27 54.78 31.21 94.51 80.52 546.40 340.50 54.73 32.12 94.33 74.30 550.08 345.09 57.64 32.67 94.68 71.18 569.70 354.60 54.14 33.55 94.61 表 5 泡沫铝填充多胞方管防冲支架与传统支架防冲性能对比

Table 5 Comparison of anti-impact performance of aluminum foam filled multi-cell square tube support and traditional support

冲击能量/kJ 冲击时间 冲击位移 支架部分塑性能 传统支架/s 防冲支架/s 提升量/% 传统支架/mm 防冲支架/mm 提升量/% 传统支架/kJ 防冲支架/kJ 降低量/% 800 0.009 7 0.035 8 269 47.48 175.91 270 611 89 85 900 0.010 8 0.045 0 317 52.93 199.50 277 707 91 87 1 000 0.011 9 0.050 4 324 58.47 224.67 284 804 99 88 1 100 0.013 2 0.054 6 314 64.00 249.47 290 895 107 88 1 200 0.014 1 0.057 9 311 69.56 269.38 287 998 114 89 -

[1] 王国法,潘一山,赵善坤,等. 冲击地压煤层如何实现安全高效智能开采[J]. 煤炭科学技术,2024,52(1):1−14. WANG Guofa,PAN Yishan,ZHAO Shankun,et al. How to realize safe-efficient-intelligent mining of rock burst coal seam[J]. Coal Science and Technology,2024,52(1):1−14.

[2] 王国法. 煤矿智能化最新技术进展与问题探讨[J]. 煤炭科学技术,2022,50(1):1−27. WANG Guofa. New technological progress of coal mine intelligence and its problems[J]. Coal Science and Technology,2022,50(1):1−27.

[3] 姜福兴,张翔,朱斯陶. 煤矿冲击地压防治体系中的关键问题探讨[J]. 煤炭科学技术,2023,51(1):203−213. JIANG Fuxing,ZHANG Xiang,ZHU Sitao. Discussion on key problems in prevention and control system of coal mine rock burst[J]. Coal Science and Technology,2023,51(1):203−213.

[4] 姜耀东,赵毅鑫. 我国煤矿冲击地压的研究现状:机制、预警与控制[J]. 岩石力学与工程学报,2015,34(11):2188−2204. JIANG Yaodong,ZHAO Yixin. State of the art:investigation on mechanism,forecast and control of coal bumps in China[J]. Chinese Journal of Rock Mechanics and Engineering,2015,34(11):2188−2204.

[5] 潘一山,肖永惠,李忠华,等. 冲击地压矿井巷道支护理论研究及应用[J]. 煤炭学报,2014,39(2):222−228. PAN Yishan,XIAO Yonghui,LI Zhonghua,et al. Study of tunnel support theory of rockburst in coal mine and its application[J]. Journal of China Coal Society,2014,39(2):222−228.

[6] 马箫,潘一山,张建卓,等. 防冲支架的核心吸能构件设计与吸能性能研究[J]. 煤炭学报,2018,43(4):1171−1178. MA Xiao,PAN Yishan,ZHANG Jianzhuo,et al. Design and performance research on core energy absorption component of anti-impact support[J]. Journal of China Coal Society,2018,43(4):1171−1178.

[7] MA X,PAN Y S,XIAO Y H. Study on application of the mine anti-impact and energy-absorption device[J]. Applied Mechanics and Materials,2013,470:598−603. doi: 10.4028/www.scientific.net/AMM.470.598

[8] 田立勇,周禹鹏,孙业新,等. 防冲支架立柱多胞薄壁吸能构件能量吸收性能[J]. 煤炭学报,2023,48(5):2224−2235. TIAN Liyong,ZHOU Yupeng,SUN Yexin,et al. Energy absorption performance of multicellular thin-walled energy-absorbing components of anti-shock support columns[J]. Journal of China Coal Society,2023,48(5):2224−2235.

[9] 郝志勇,刘亚强,潘一山. 矿用缓冲吸能装置及其填充材料试验研究[J]. 采矿与安全工程学报,2018,35(3):620−628. HAO Zhiyong,LIU Yaqiang,PAN Yishan. Experimental study on filling material of mining buffer energy absorption device[J]. Journal of Mining & Safety Engineering,2018,35(3):620−628.

[10] GUO C H,HAN J Q. Research on energy absorbing components of ZQL hydraulic support[J]. Journal of the Brazilian Society of Mechanical Sciences and Engineering,2023,45(3):176. doi: 10.1007/s40430-022-03999-6

[11] 王春华,安达,韩冲,等. 冲击地压新型加肋板圆管式吸能防冲构件的仿真与试验[J]. 振动与冲击,2019,38(11):203−210,241. WANG Chunhua,AN Da,HAN Chong,et al. Simulation and tests for new tubular type energy-absorbing and anti-impact members with stiffened plate under rock burst[J]. Journal of Vibration and Shock,2019,38(11):203−210,241.

[12] 张建卓,刘欢,王洁. 直纹管外翻式构件设计与吸能特性研究[J]. 振动与冲击,2020,39(9):49−56. ZHANG Jianzhuo,LIU Huan,WANG Jie. Design and energy-absorbing properties of the everting components of straight corrugated tubes[J]. Journal of Vibration and Shock,2020,39(9):49−56.

[13] LIU Q,MA J B,HE Z H,et al. Energy absorption of bio-inspired multi-cell CFRP and aluminum square tubes[J]. Composites Part B:Engineering,2017,121:134−144. doi: 10.1016/j.compositesb.2017.03.034

[14] CHEN J X,XIE J,ZHU H,et al. Integrated honeycomb structure of a beetle forewing and its imitation[J]. Materials Science and Engineering:C,2012,32(3):613−618.

[15] CHEN J X,GU C L,GUO S J,et al. Integrated honeycomb technology motivated by the structure of beetle forewings[J]. Materials Science and Engineering:C,2012,32(7):1813−1817.

[16] CHEN J X,HE C L,GU C L,et al. Compressive and flexural properties of biomimetic integrated honeycomb plates[J]. Materials & Design,2014,64:214−220.

[17] CHEN W G,WIERZBICKI T. Relative merits of single-cell,multi-cell and foam-filled thin-walled structures in energy absorption[J]. Thin-Walled Structures,2001,39(4):287−306. doi: 10.1016/S0263-8231(01)00006-4

[18] 潘一山,齐庆新,王爱文,等. 煤矿冲击地压巷道三级支护理论与技术[J]. 煤炭学报,2020,45(5):1585−1594. PAN Yishan,QI Qingxin,WANG Aiwen,et al. Theory and technology of three levels support in bump-prone roadway[J]. Journal of China Coal Society,2020,45(5):1585−1594.

[19] 煤矿用液压支架 第1部分:通用技术条件:GB 25974.1—2010[S]. [20] JIN M Z,YIN G S,HAO W Q,et al. Energy absorption characteristics of multi-cell tubes with different cross-sectional shapes under quasi-static axial crushing[J]. International Journal of Crashworthiness,2022,27(2):565−580. doi: 10.1080/13588265.2020.1826825

[21] QIU N,GAO Y K,FANG J G,et al. Theoretical prediction and optimization of multi-cell hexagonal tubes under axial crashing[J]. Thin-Walled Structures,2016,102:111−121. doi: 10.1016/j.tws.2016.01.023

[22] WIERZBICKI T,ABRAMOWICZ W. On the crushing mechanics of thin-walled structures[J]. Journal of Applied Mechanics,1983,50:727. doi: 10.1115/1.3167137

[23] 潘一山,李忠华,章梦涛. 我国冲击地压分布、类型、机理及防治研究[J]. 岩石力学与工程学报,2003,22(11):1844−1851. doi: 10.3321/j.issn:1000-6915.2003.11.019 PAN Yishan,LI Zhonghua,ZHANG Mengtao. Distribution,type,mechanism and prevention of rockbrust in China[J]. Chinese Journal of Rock Mechanics and Engineering,2003,22(11):1844−1851. doi: 10.3321/j.issn:1000-6915.2003.11.019

[24] 肖晓春,朱恒,徐军,等. 含泡沫铝填充多胞方管吸能立柱防冲特性数值研究[J]. 煤炭科学技术,2023,51(10):302−311. XIAO Xiaochun,ZHU Heng,XU Jun,et al. Numerical study on anti-impact characteristics of energy absorbing column with multicellular square tube filled with aluminum foam[J]. Coal Science and Technology,2023,51(10):302−311.

[25] 宋嘉祺. 冲击地压巷道支架防冲性能及优化设计[D]. 北京:北方工业大学,2020. SONG Jiaqi. Anti-scour performance and optimal design of roadway support in rockburst[D]. Beijing:North China University of Technology,2020.

下载:

下载: