Study on coal permeability evolution considering adsorptive deformation characteristics of matrix

-

摘要:

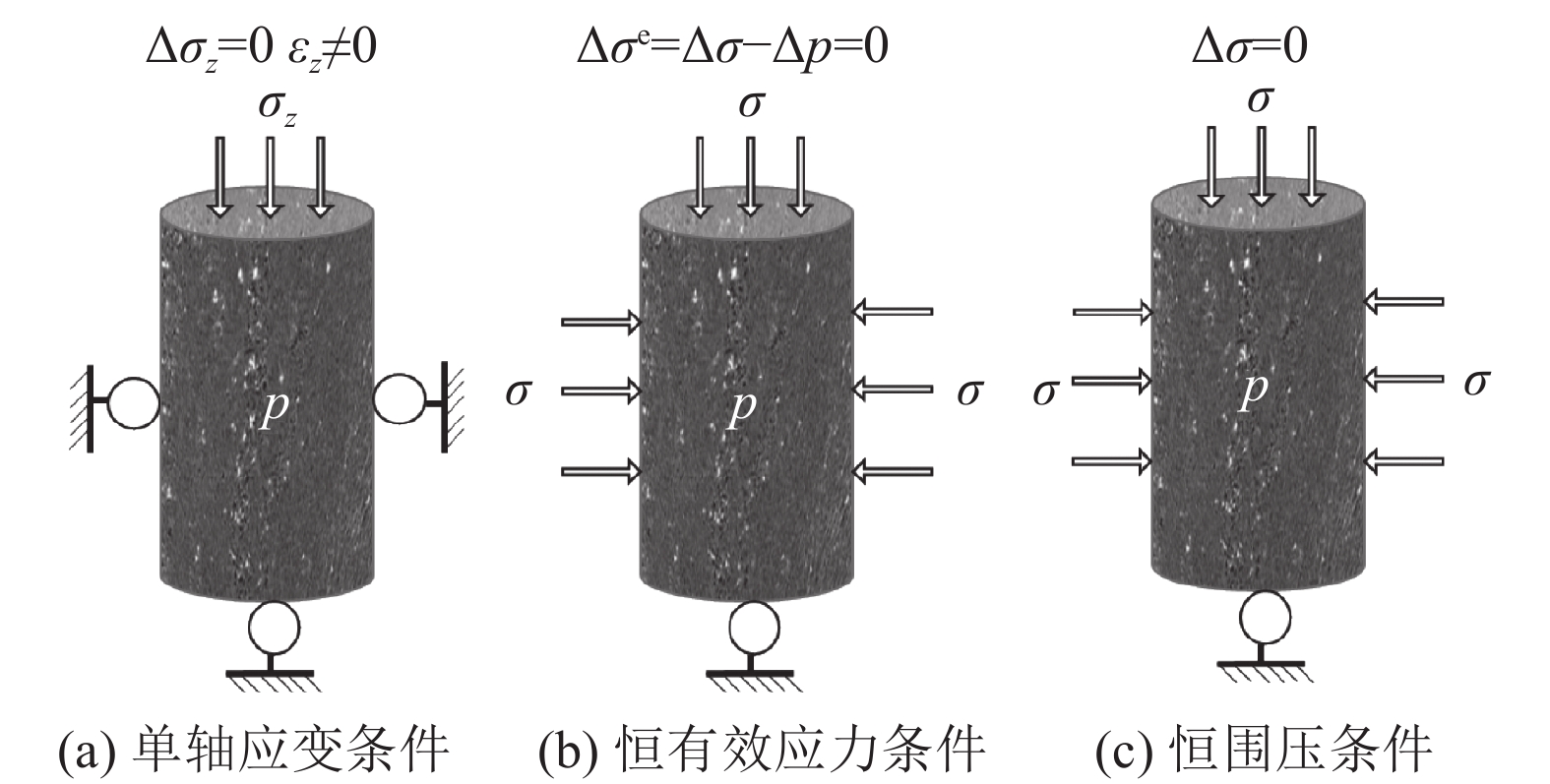

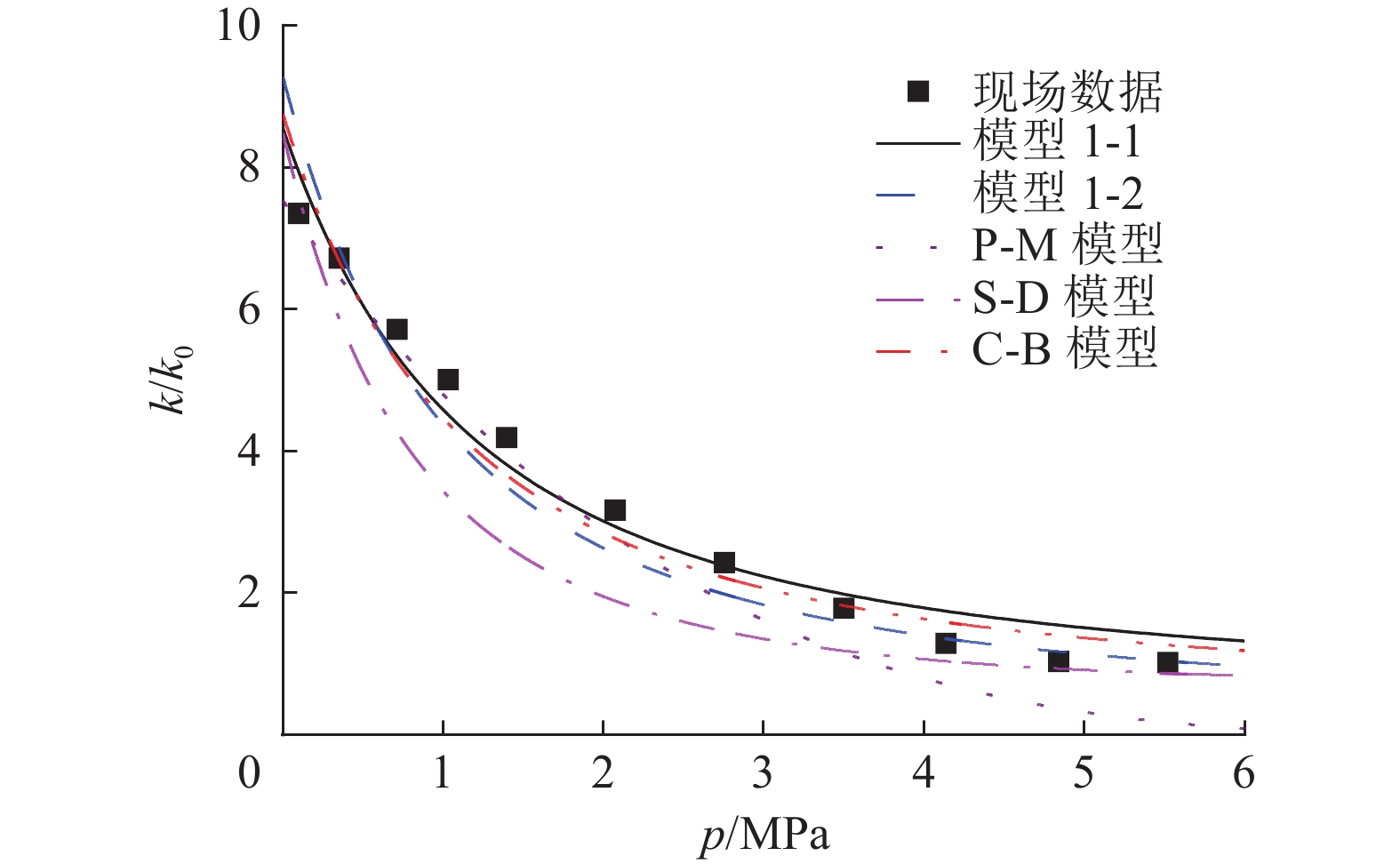

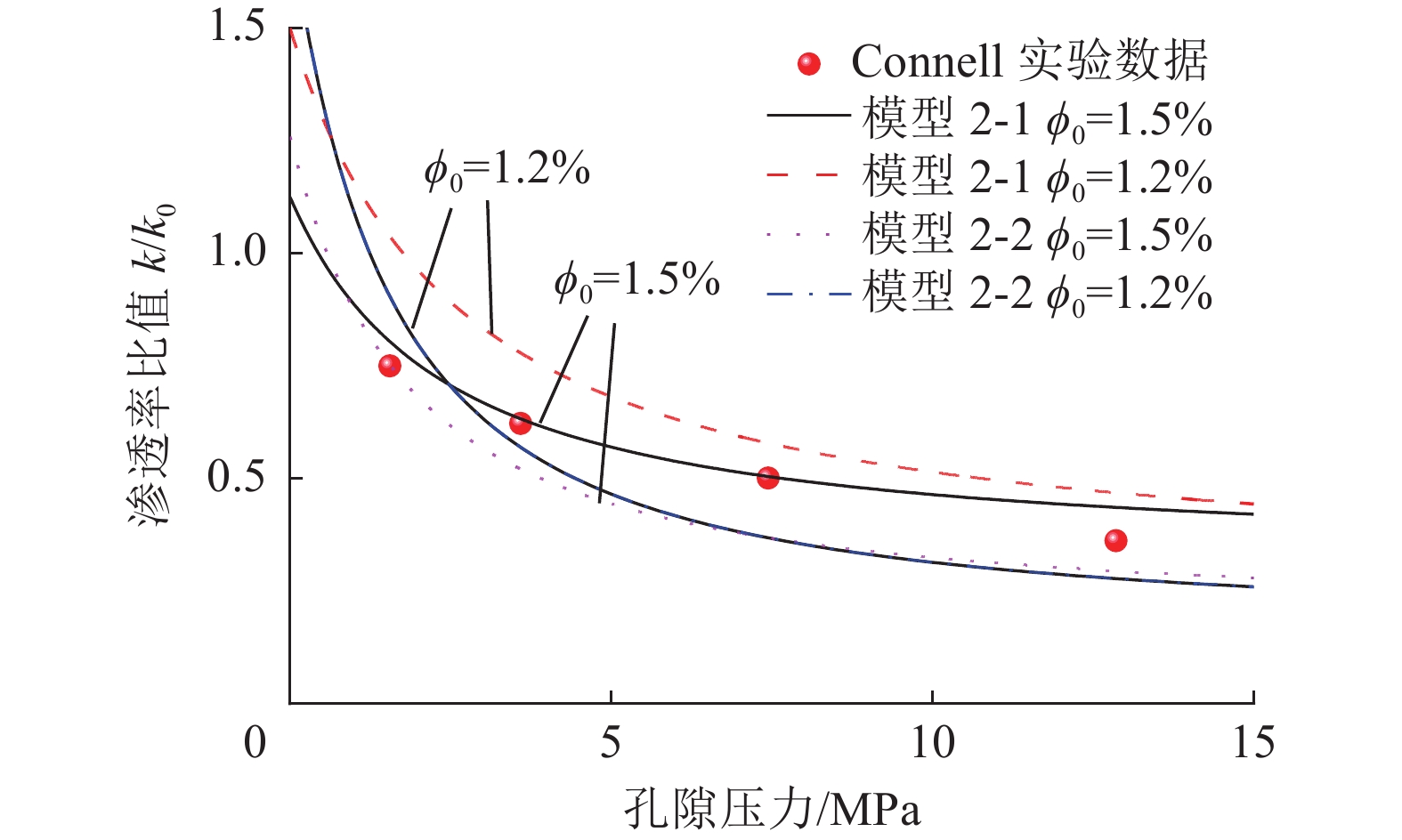

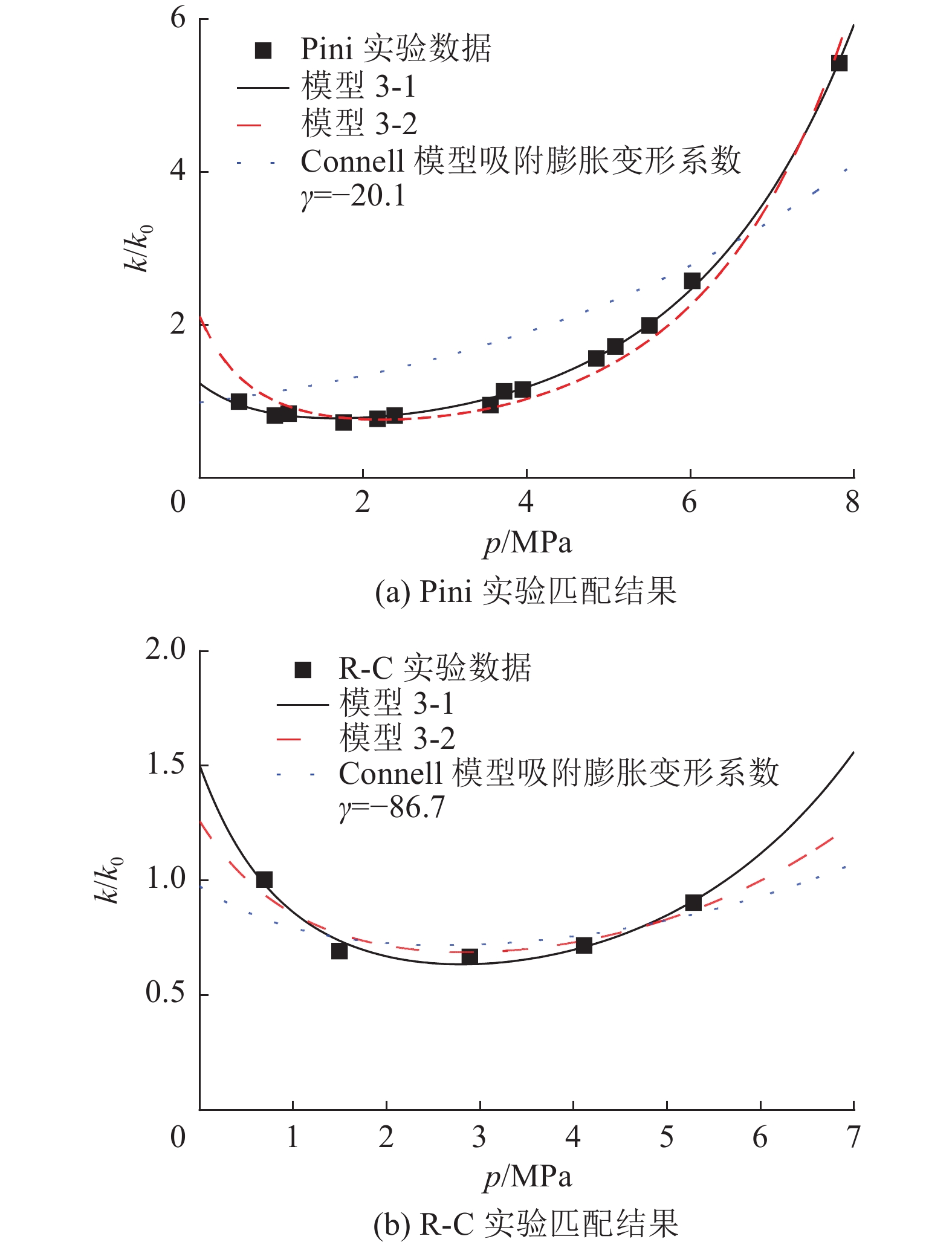

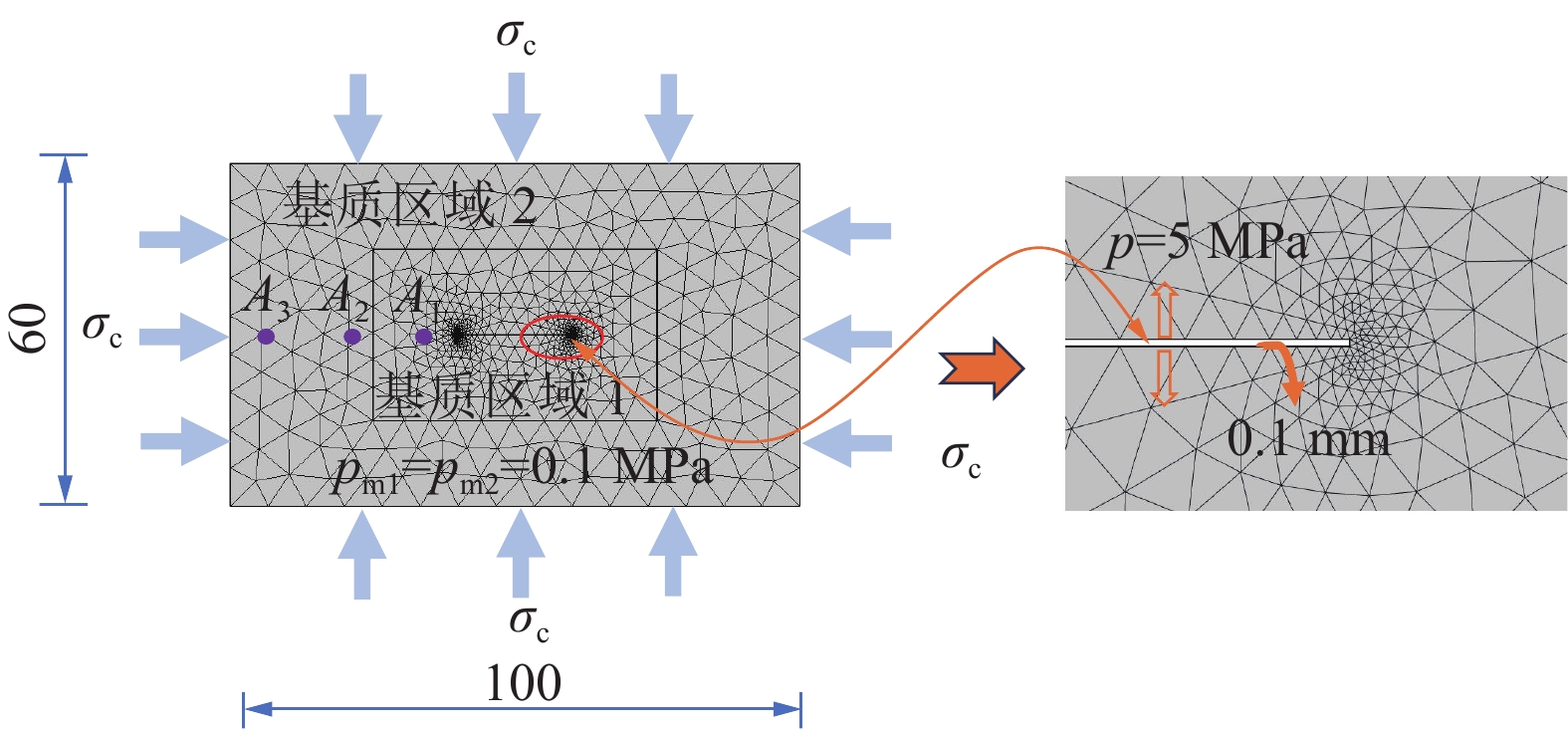

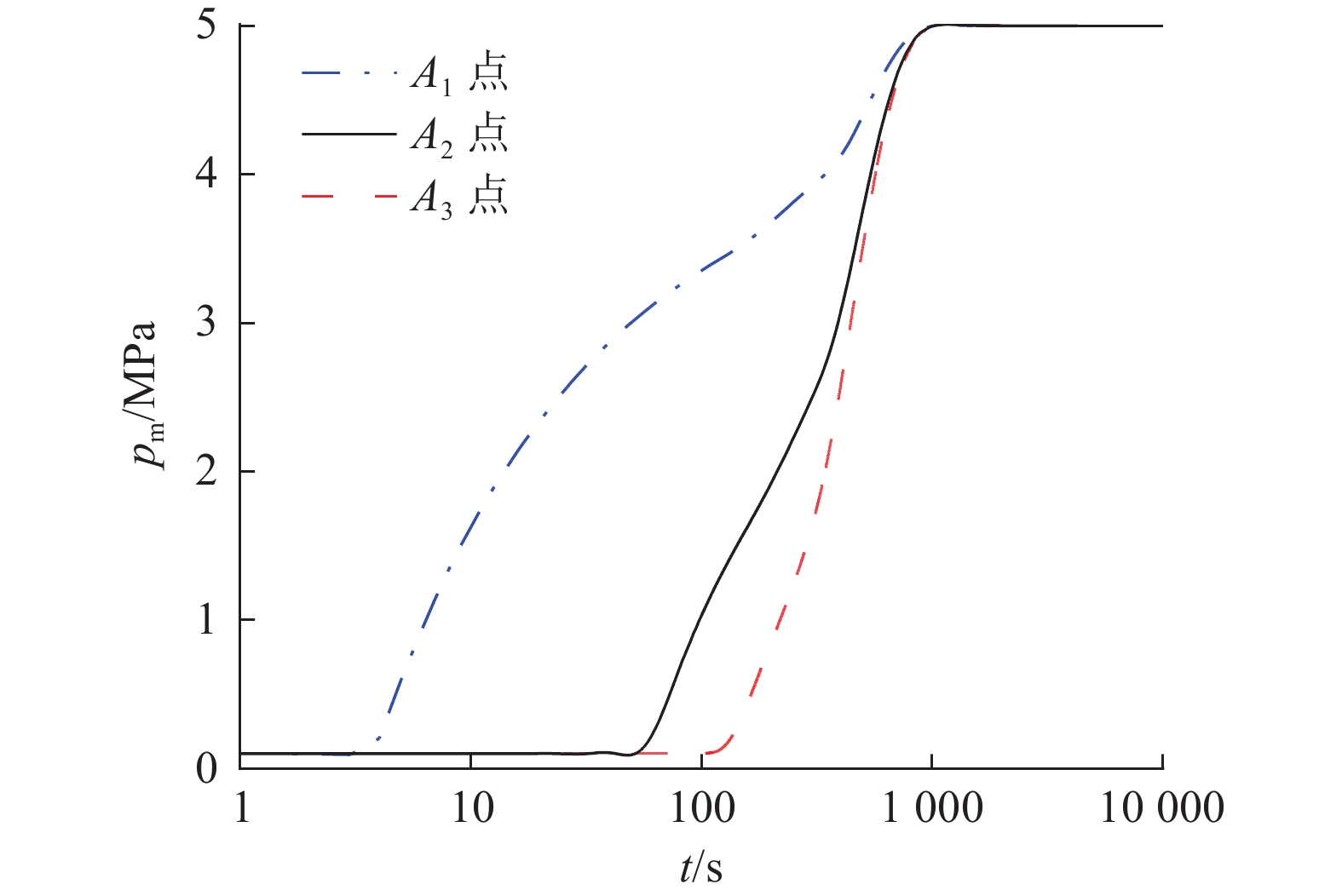

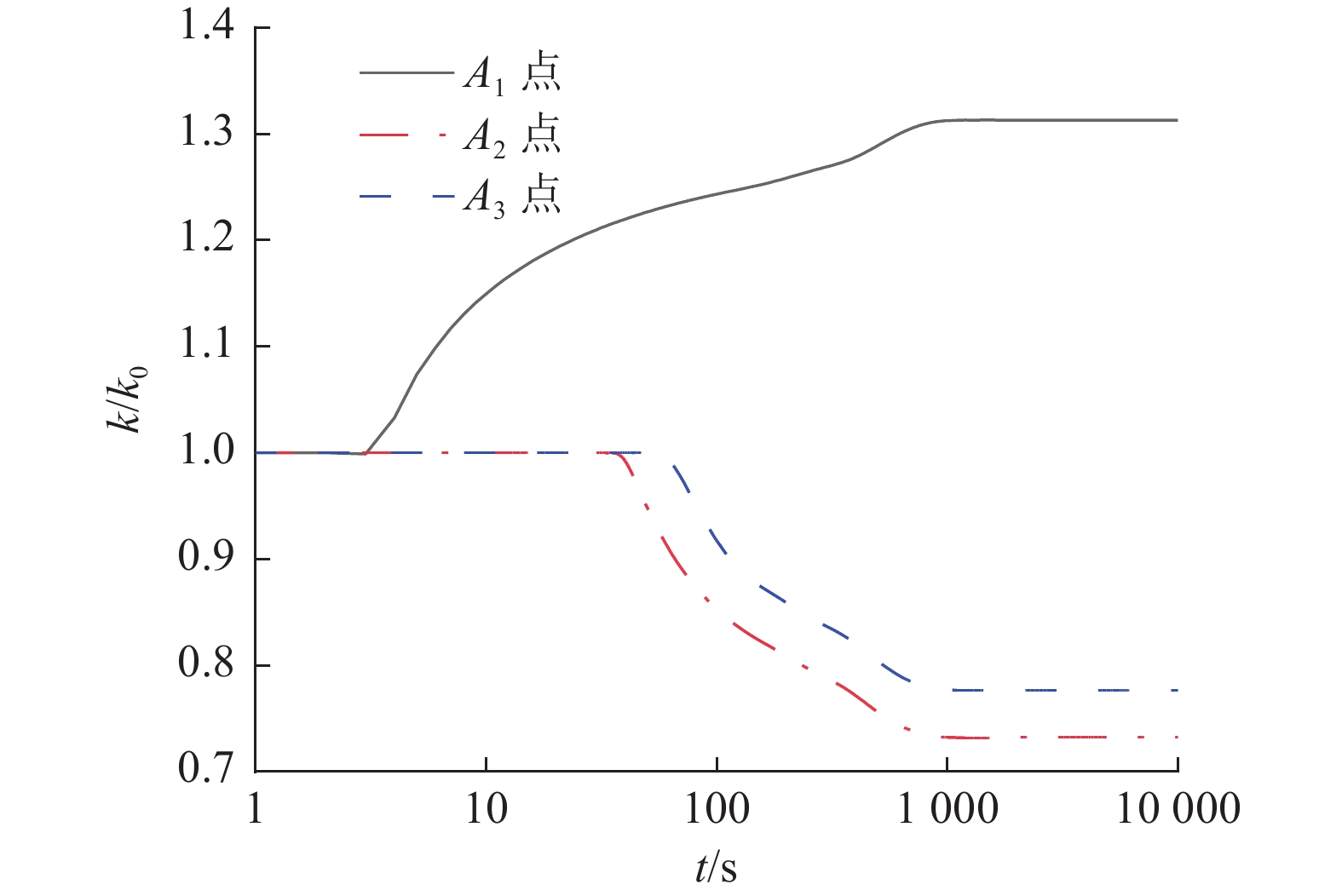

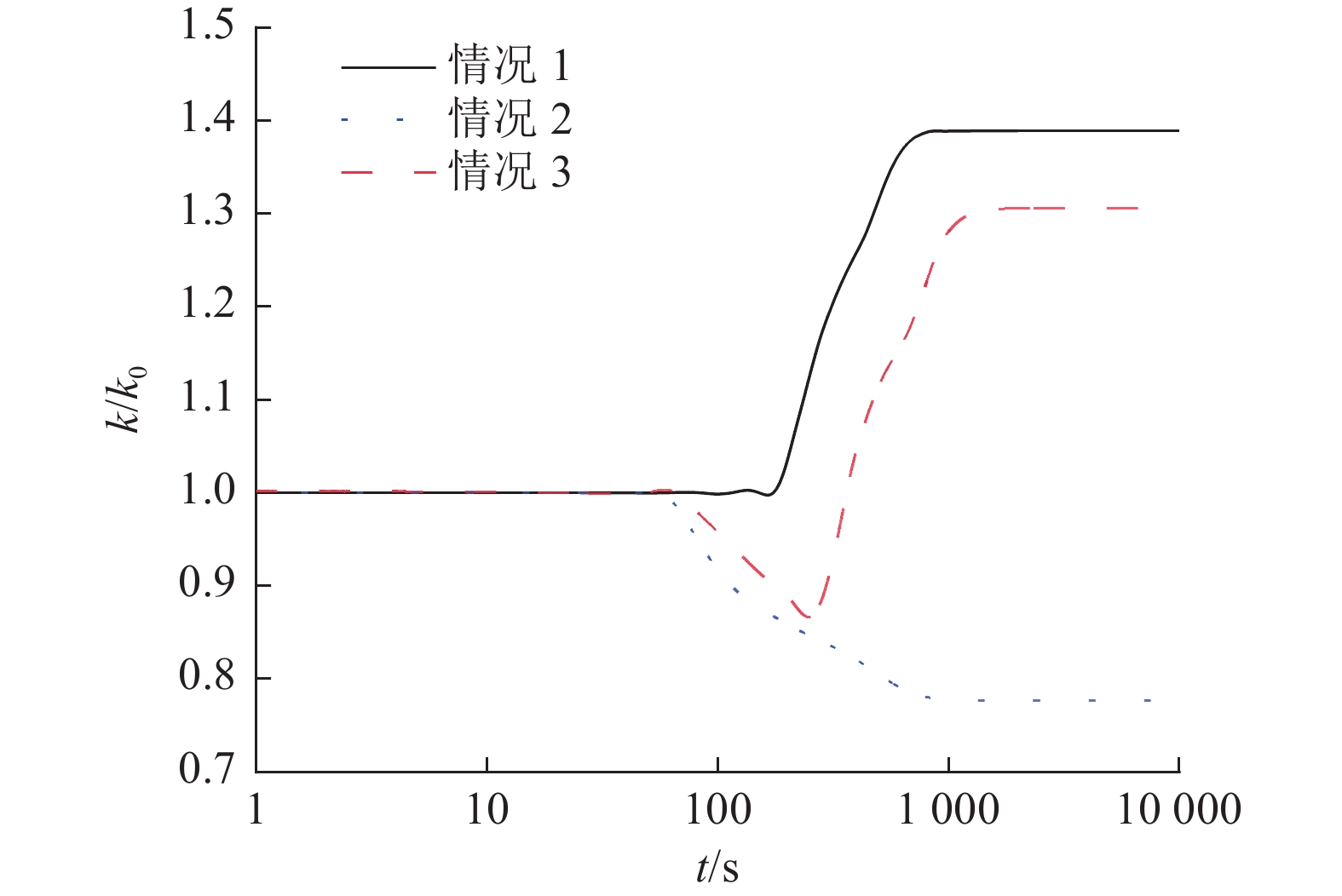

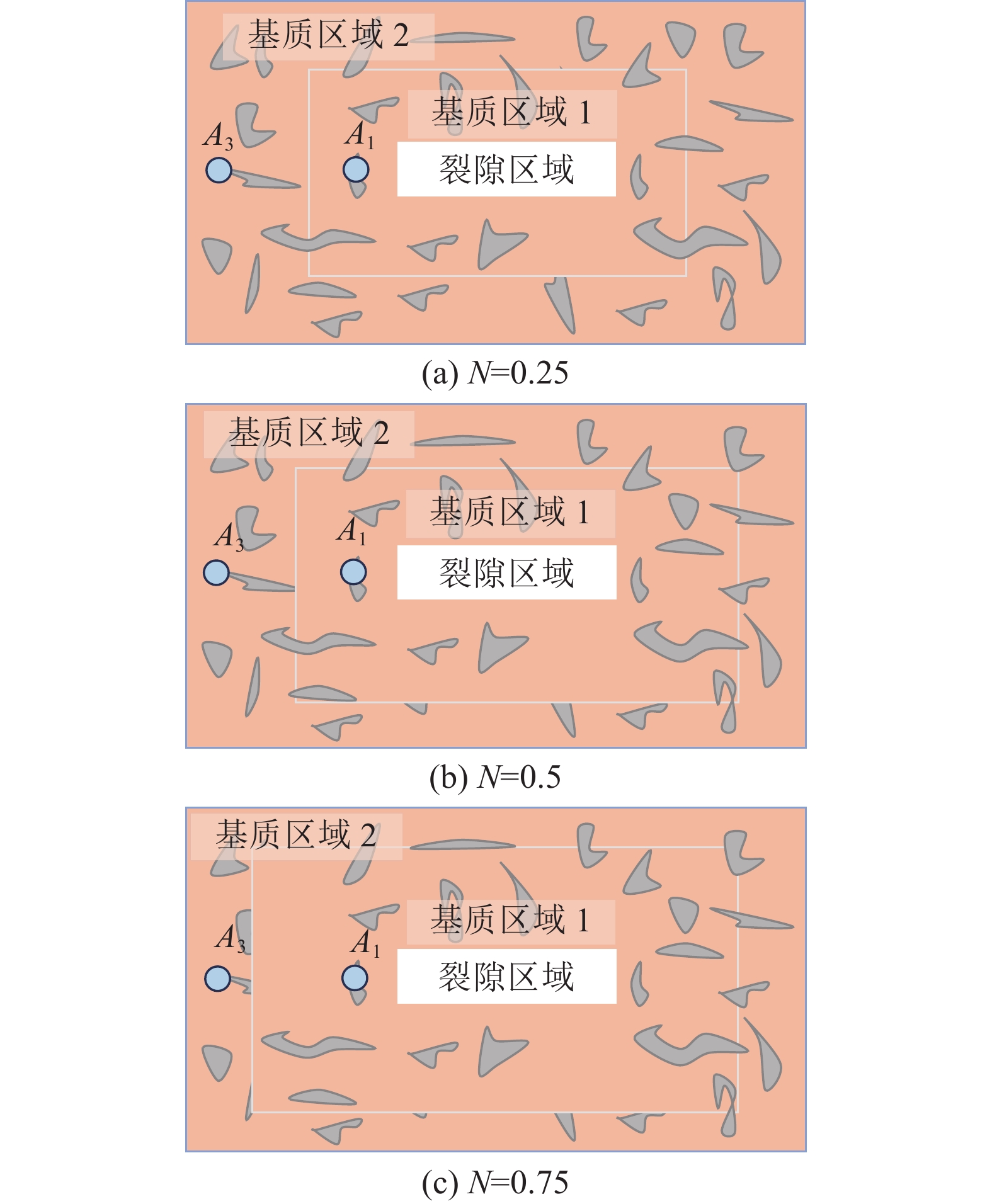

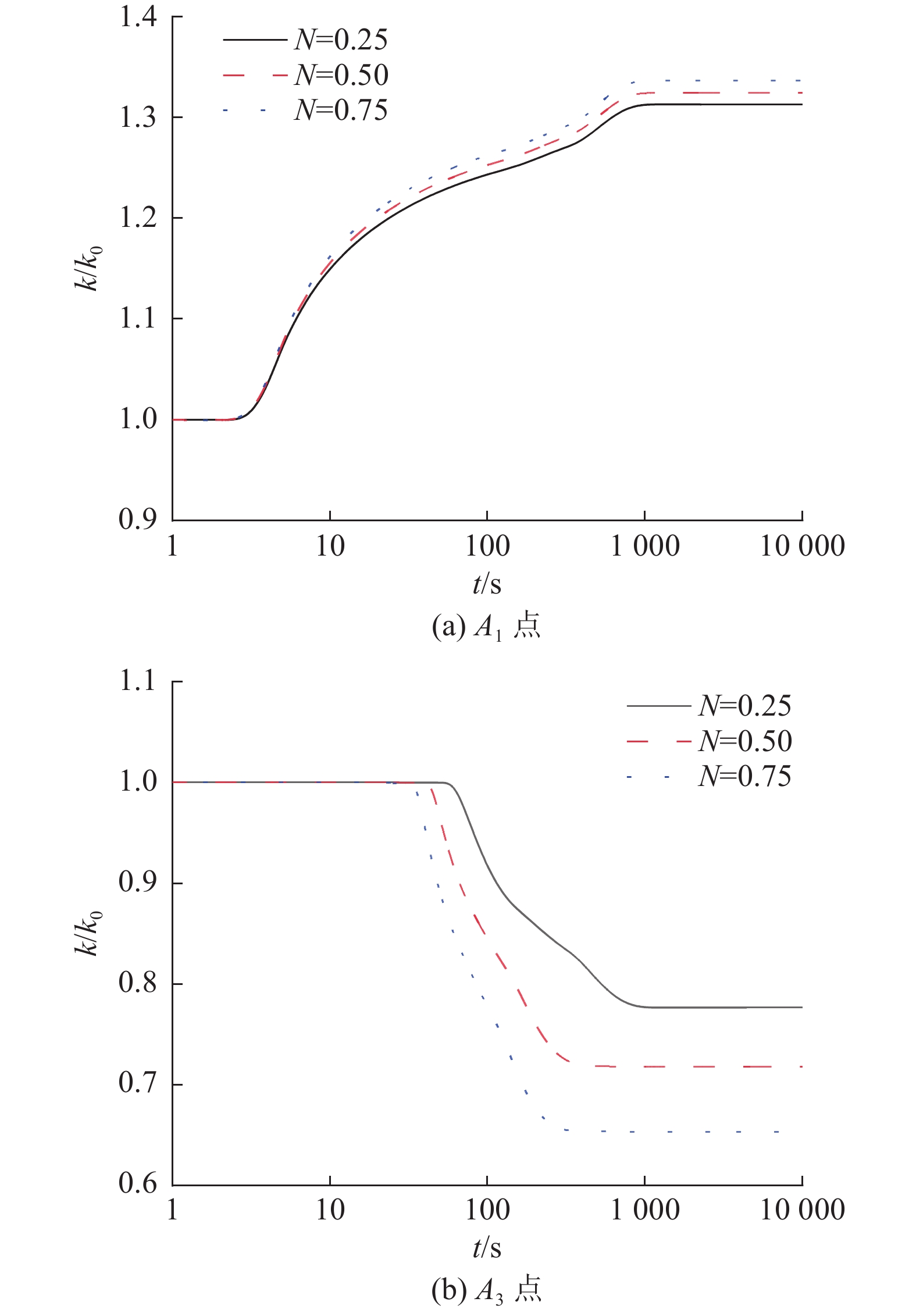

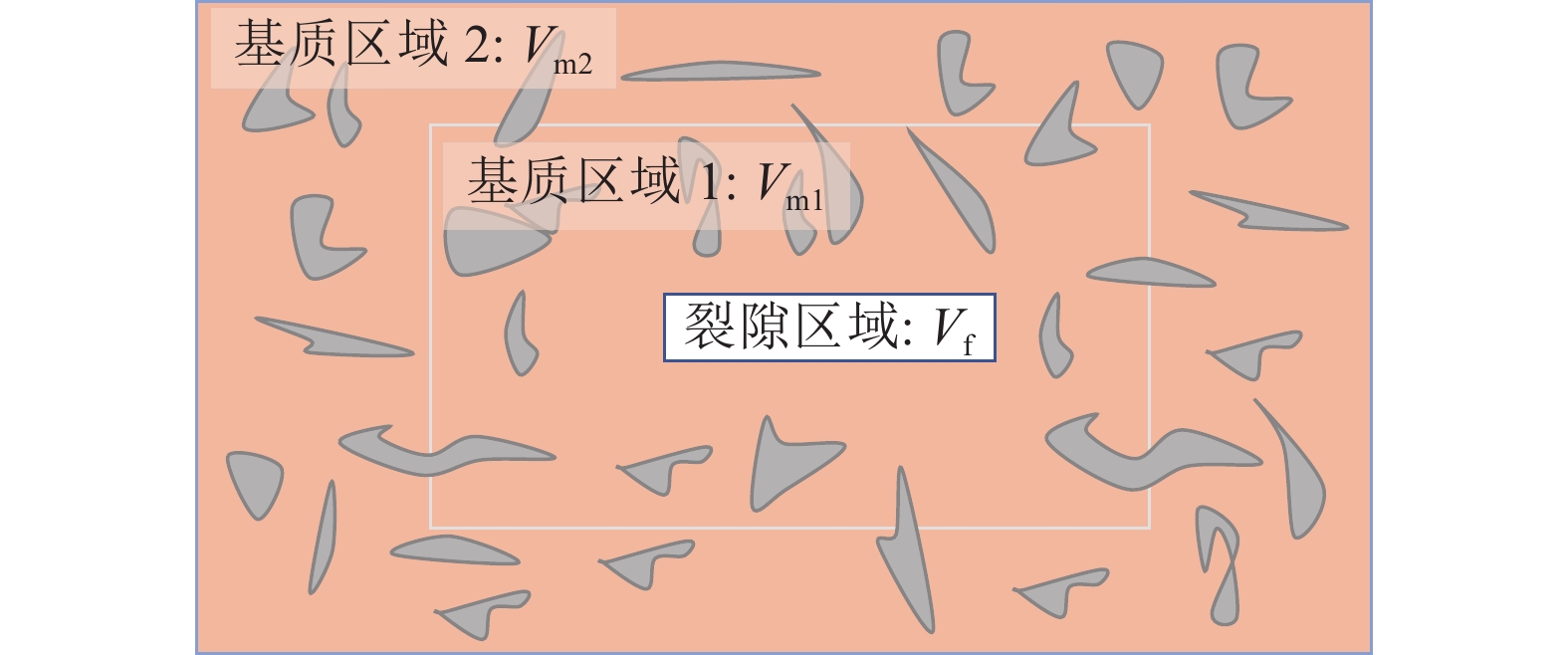

渗透率是煤层气勘探与温室气体存储中必不可少的参数,准确认识煤层内气体流动不仅能够合理预测煤层气产量,还能提高CO2地质封存的效率。一般的煤岩渗透率预测模型都是从有效应力以及气体吸附的角度出发进行模型的相关理论推导,但在实际情况中,煤岩的基质内部构造复杂不定,与吸附相关的矿物成分分布存在不均匀的现象,这就往往会忽略基质区域非均匀吸附变形这一因素的影响。因此,通过将煤岩的基质区域划分为2个吸附能力不同的区域,重新推导了煤岩渗透率模型,利用现场数据以及实验室数据对提出的模型进行比较验证,并通过有限元软件分析了基质区域的非均匀吸附对渗透率演化的影响,结果表明:① 提出的模型与现场及实验室实验数据具有较高的匹配度,不同边界条件下的渗透率预测数据具有较高的可靠性。② 基质的非吸附膨胀区域的渗透率会在吸附膨胀区域的挤压效应下降低,并且越靠近吸附膨胀变形区域处,受到的挤压效果越强,非吸附膨胀区域渗透率降低程度越明显。③ 随着基质吸附区域面积的增加会使相邻基质区域受到的应力扰动越早,并使得受挤压的基质区域平衡时气体渗透率越低。改进的渗透率模型可以更加深入地了解煤岩内部基质区域相互作用对渗透率产生的影响,对煤层气开采具有一定的理论指导意义。

Abstract:Permeability is an essential parameter in CBM exploration and greenhouse gas storage. Accurate understanding of gas flow in coal seam can not only reasonably predict CBM production, but also improve the efficiency of CO2 geological storage. The general coal rock permeability prediction model is from the effective stress and gas adsorption point of view for the theoretical derivation of the model, but in practice, the complexity and uncertainty of the internal structure of the matrix of the coal rock, and adsorption related to the distribution of the mineral constituents of the phenomenon of inhomogeneous, which tends to ignore the matrix region of non-uniform adsorption deformation of the influence of this factor. Therefore, in this paper, the matrix region of coal and rock is divided into two regions with different adsorption capacity, and the permeability model of coal and rock is re-derived. The field data and laboratory data are used to compare and verify the proposed model, and the influence of non-uniform adsorption of matrix region on permeability evolution is analyzed by finite element software. The results show that: ① The proposed model has a high matching degree with field and laboratory experimental data, and the permeability prediction data under different boundary conditions have high reliability. ② The permeability of the non-adsorption expansion area of the matrix will be reduced by the squeezing effect of the adsorption expansion area, and the closer to the adsorption expansion deformation area, the stronger the squeezing effect, and the more obvious the reduction in permeability of the non-adsorption expansion area. ③ With the increase of the adsorption area of the matrix, the stress disturbance of the adjacent matrix region will be earlier, and the gas permeability will be lower when the compressed matrix region is in equilibrium. The improved permeability model can better understand the influence of regional matrix interaction in coal and rock on permeability, and has certain theoretical guiding significance for coalbed methane exploitation.

-

Keywords:

- coal bed gas /

- permeability /

- gas pressure /

- heterogeneity /

- adsorption swelling strain /

- matrix ratio factor

-

-

表 1 圣胡安盆地 Fruitland 煤岩力学参数[32]及煤层拟合参数

Table 1 Mechanical parameters of Fruitland coal rock and Fitting parameters of Fruitland coal seam in San Juan Basin[32]

参数 值 煤岩力学参数 煤的弹性模量/MPa 2200 煤的泊松比 0.3 煤层拟合参数 朗缪尔体积应变常数 0.02258 朗缪尔压力/MPa 5.9 初始孔隙率/% 1.46 基质区域占比系数 0.5935 巷道基质区域占比系数 0.5822 参数 值 煤的初始渗透率/% 1.2~1.5 煤的初始渗透率/10−15m2 1.5 朗缪尔体积应变常数 0.001 朗缪尔压力/MPa 8.9 基质占比系数 0.5747 表 3 ROBERTSON and CHRISTIANSEN[34]、PINI实验拟合参数[35]

Table 3 Fitting parameters of ROBERTSON and CHRISTIANSEN[34], PINI[35] experiment

参数 数值 Robertson and Christiansen

实验拟合参数煤的初始孔隙率/% 0.1 朗缪尔体积应变常数 0.0077 朗缪尔压力/MPa 6.1 煤的压缩系数/MPa−1 0.2462 基质占比系数 0.928 Pini实验拟合参数 煤的初始孔隙率/% 0.42 朗缪尔体积应变 0.057 朗缪尔压力/MPa 3.53 煤的压缩系数/MPa−1 0.1947 基质占比系数 0.7256 表 4 数值模拟参数

Table 4 Parameter of numerical simulation

表 5 基质不同区域吸附情况

Table 5 Adsorption in different regions of the matrix

基质区域 情况1 情况2 情况3 1 无吸附 含吸附 含吸附 2 含吸附 无吸附 含吸附 -

[1] 琚宜文,李清光,颜志丰,等. 煤层气成因类型及其地球化学研究进展[J]. 煤炭学报,2014,39(5):806−815. JU Yiwen,LI Qingguang,YAN Zhifeng,et al. Origin types of CBM and their geochemical research progress[J]. Journal of China Coal Society,2014,39(5):806−815.

[2] 王佟,刘峰,赵欣,等. “双碳” 背景下我国煤炭资源保障能力与勘查方向的思考[J]. 煤炭科学技术,2023,51(12):1−8. doi: 10.12438/cst.2023-0095 WANG Tong,LIU Feng,ZHAO Xin,et al. Reflection on China’s coal resource guarantee capacity and exploration work under the background of “double carbon”[J]. Coal Science and Technology,2023,51(12):1−8. doi: 10.12438/cst.2023-0095

[3] PERERA M S A,RANJITH P G,CHOI S K. Coal cleat permeability for gas movement under triaxial,non-zero lateral strain condition:A theoretical and experimental study[J]. Fuel,2013,109:389−399. doi: 10.1016/j.fuel.2013.02.066

[4] HARPALANI S,SCHRAUFNAGEL R A. Shrinkage of coal matrix with release of gas and its impact on permeability of coal[J]. Fuel,1990,69(5):551−556. doi: 10.1016/0016-2361(90)90137-F

[5] CHEN Z W,PAN Z J,LIU J S,et al. Effect of the effective stress coefficient and sorption-induced strain on the evolution of coal permeability:Experimental observations[J]. International Journal of Greenhouse Gas Control,2011,5(5):1284−1293. doi: 10.1016/j.ijggc.2011.07.005

[6] 刘曰武,苏中良,方虹斌,等. 煤层气的解吸/吸附机理研究综述[J]. 油气井测试,2010,19(6):37−44,83. doi: 10.3969/j.issn.1004-4388.2010.06.007 LIU Yuewu,SU Zhongliang,FANG Hongbin,et al. Review on CBM desorption/adsorption mechanism[J]. Well Testing,2010,19(6):37−44,83. doi: 10.3969/j.issn.1004-4388.2010.06.007

[7] 丁云娜,李波波,成巧耘,等. 考虑动态滑脱的页岩微裂隙表观渗透率演化机制[J]. 煤炭科学技术,2023,51(11):129−138. doi: 10.12438/cst.2023-0090 DING Yunna,LI Bobo,CHENG Qiaoyun,et al. Evolution mechanism of shale microfracture apparent permeability considering dynamic slippage[J]. Coal Science and Technology,2023,51(11):129−138. doi: 10.12438/cst.2023-0090

[8] SOMERTON W H,SÖYLEMEZOḠLU I M,DUDLEY R C. Effect of stress on permeability of coal[J]. International Journal of Rock Mechanics and Mining Sciences & Geomechanics Abstracts,1975,12(5-6):129−145.

[9] GRAY I. Reservoir engineering in coal seams:Part 1—the physical process of gas storage and movement in coal seams[J]. SPE Reservoir Engineering,1987,2(1):28−34. doi: 10.2118/12514-PA

[10] PALMER I,MANSOORI J. How permeability depends on stress and pore pressure in coalbeds:A new model[J]. SPE Reservoir Evaluation & Engineering,1998,1(6):539−544.

[11] SHI J Q,DURUCAN S. Drawdown induced changes in permeability of coalbeds:A new interpretation of the reservoir response to primary recovery[J]. Transport in Porous Media,2004,56(1):1−16. doi: 10.1023/B:TIPM.0000018398.19928.5a

[12] CUI X J,BUSTIN R M. Volumetric strain associated with methane desorption and its impact on coalbed gas production from deep coal seams[J]. AAPG Bulletin,2005,89(9):1181−1202. doi: 10.1306/05110504114

[13] ZHU W C,WEI C H,LIU J,et al. A model of coal–gas interaction under variable temperatures[J]. International Journal of Coal Geology,2011,86(2-3):213−221. doi: 10.1016/j.coal.2011.01.011

[14] BAI M,ELSWORTH D,ROEGIERS J C. Multiporosity/multipermeability approach to the simulation of naturally fractured reservoirs[J]. Water Resources Research,1993,29(6):1621−1633. doi: 10.1029/92WR02746

[15] WANG C G,FENG J L,LIU J S,et al. Direct observation of coal–gas interactions under thermal and mechanical loadings[J]. International Journal of Coal Geology,2014,131:274−287. doi: 10.1016/j.coal.2014.06.021

[16] QU H Y,LIU J S,PAN Z J,et al. Impact of matrix swelling area propagation on the evolution of coal permeability under coupled multiple processes[J]. Journal of Natural Gas Science and Engineering,2014,18:451−466. doi: 10.1016/j.jngse.2014.04.007

[17] WU Y,LIU J S,ELSWORTH D,et al. Dual poroelastic response of a coal seam to CO2 injection[J]. International Journal of Greenhouse Gas Control,2010,4(4):668−678. doi: 10.1016/j.ijggc.2010.02.004

[18] WU Y,LIU J S,CHEN Z W,et al. A dual poroelastic model for CO2-enhanced coalbed methane recovery[J]. International Journal of Coal Geology,2011,86(2-3):177−189. doi: 10.1016/j.coal.2011.01.004

[19] 肖智勇,王长盛,王刚,等. 基质-裂隙相互作用对渗透率演化的影响:考虑基质变形和应力修正[J]. 岩土工程学报,2021,43(12):2209−2219. doi: 10.11779/CJGE202112007 XIAO Zhiyong,WANG Changsheng,WANG Gang,et al. Influences of matrix-fracture interaction on permeability evolution:Considering matrix deformation and stress correction[J]. Chinese Journal of Geotechnical Engineering,2021,43(12):2209−2219. doi: 10.11779/CJGE202112007

[20] 王刚,肖智勇,王长盛,等. 基于非平衡状态的煤层中气体运移规律研究[J]. 岩土工程学报,2022,44(8):1512−1520. doi: 10.11779/CJGE202208016 WANG Gang,XIAO Zhiyong,WANG Changsheng,et al. Gas transport in coal seams based on non-equilibrium state[J]. Chinese Journal of Geotechnical Engineering,2022,44(8):1512−1520. doi: 10.11779/CJGE202208016

[21] WANG C G,ZHANG J D,ZANG Y X,et al. Time-dependent coal permeability:Impact of gas transport from coal cleats to matrices[J]. Journal of Natural Gas Science and Engineering,2021,88:103806. doi: 10.1016/j.jngse.2021.103806

[22] PENG Y,LIU J S,PAN Z J,et al. Impact of coal matrix strains on the evolution of permeability[J]. Fuel,2017,189:270−283. doi: 10.1016/j.fuel.2016.10.086

[23] KARACAN C Ö. Swelling-induced volumetric strains internal to a stressed coal associated with CO2 sorption[J]. International Journal of Coal Geology,2007,72(3-4):209−220. doi: 10.1016/j.coal.2007.01.003

[24] LEVINE J R. Model study of the influence of matrix shrinkage on absolute permeability of coal bed reservoirs[J]. Geological Society of London Special Publications,1996,109(1):197−212. doi: 10.1144/GSL.SP.1996.109.01.14

[25] JIANG C Z,ZHAO Z F,ZHANG X W,et al. Controlling effects of differential swelling index on evolution of coal permeability[J]. Journal of Rock Mechanics and Geotechnical Engineering,2020,12(3):461−472. doi: 10.1016/j.jrmge.2020.02.001

[26] LIU J S,WANG J G,CHEN Z W,et al. Impact of transition from local swelling to macro swelling on the evolution of coal permeability[J]. International Journal of Coal Geology,2011,88(1):31−40. doi: 10.1016/j.coal.2011.07.008

[27] DETOURNAY E,CHENG A H. Fundamentals of poroelasticity[M]//Analysis and design methods. Amsterdam:Elsevier,1993:113-171.

[28] ZHANG H B,LIU J S,ELSWORTH D. How sorption-induced matrix deformation affects gas flow in coal seams:A new FE model[J]. International Journal of Rock Mechanics and Mining Sciences,2008,45(8):1226−1236. doi: 10.1016/j.ijrmms.2007.11.007

[29] LU S Q,CHENG Y P,LI W. Model development and analysis of the evolution of coal permeability under different boundary conditions[J]. Journal of Natural Gas Science and Engineering,2016,31:129−138. doi: 10.1016/j.jngse.2016.02.049

[30] GUO H J,TANG H L,WU Y C,et al. Gas seepage in underground coal seams:application of the equivalent scale of coal matrix-fracture structures in coal permeability measurements[J]. Fuel,2021,288:119641. doi: 10.1016/j.fuel.2020.119641

[31] GAO Q,LIU J S,HUANG Y F,et al. A critical review of coal permeability models[J]. Fuel,2022,326:125124. doi: 10.1016/j.fuel.2022.125124

[32] LIU S M,HARPALANI S. Permeability prediction of coalbed methane reservoirs during primary depletion[J]. International Journal of Coal Geology,2013,113:1−10. doi: 10.1016/j.coal.2013.03.010

[33] CONNELL L D,LU M,PAN Z J. An analytical coal permeability model for tri-axial strain and stress conditions[J]. International Journal of Coal Geology,2010,84(2):103−114. doi: 10.1016/j.coal.2010.08.011

[34] ROBERTSON E P,CHRISTIANSEN R L. Modeling laboratory permeability in coal using sorption-induced-strain data[J]. SPE Reservoir Evaluation & Engineering,2007,10(3):260−269.

[35] PINI R,OTTIGER S,BURLINI L,et al. Role of adsorption and swelling on the dynamics of gas injection in coal[J]. Journal of Geophysical Research:Solid Earth,2009,114(B4):B04203.

[36] SHI J Q Q,DURUCAN S. Exponential growth in San Juan Basin fruitland coalbed permeability with reservoir drawdown:model match and new insights[J]. SPE Reservoir Evaluation & Engineering,2010,13(6):914−925.

下载:

下载: