Research on design of small diameter TBM cutterhead in gas control roadway of Well 1 Bailongshan Coal Mine

-

摘要:

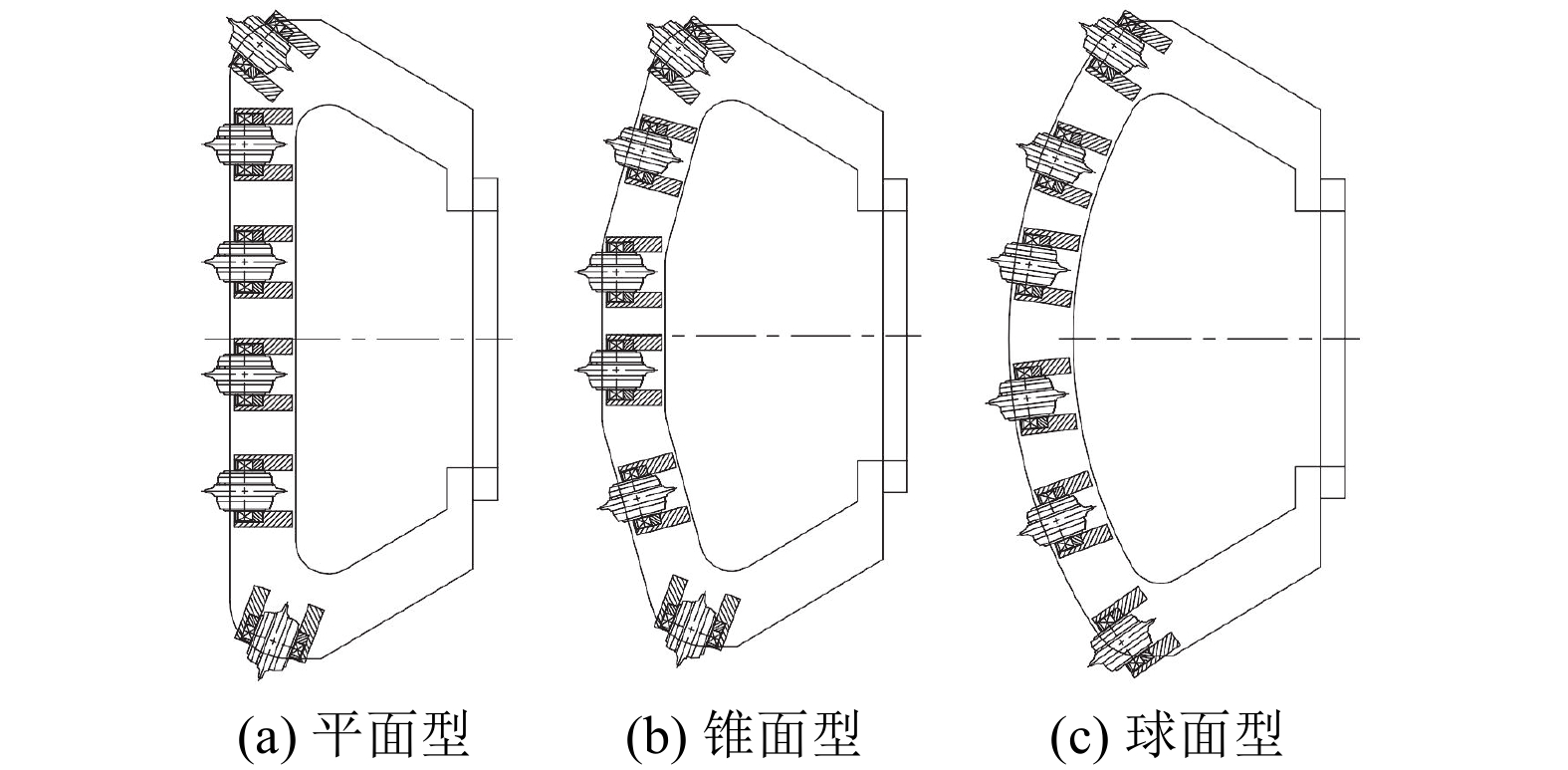

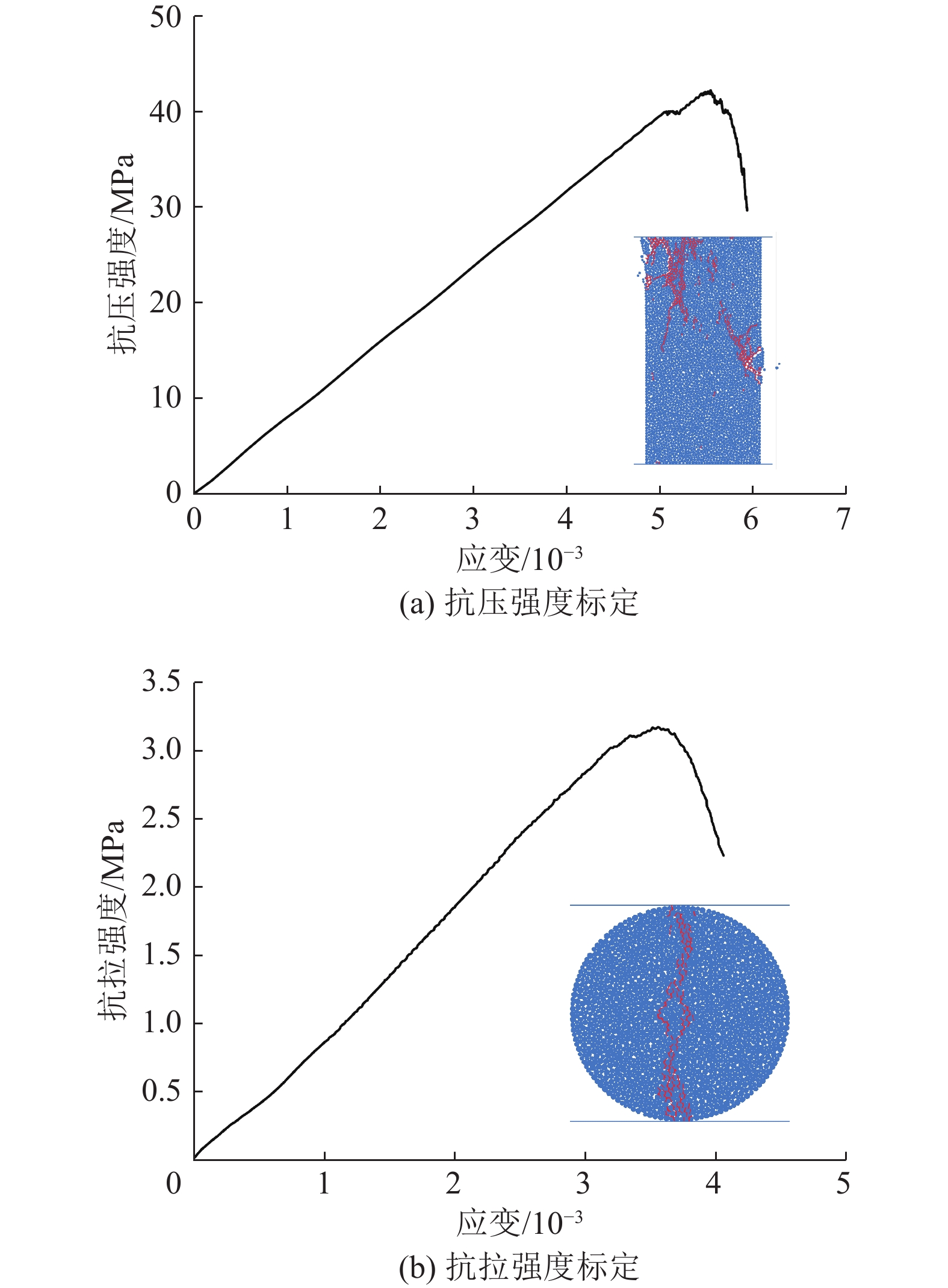

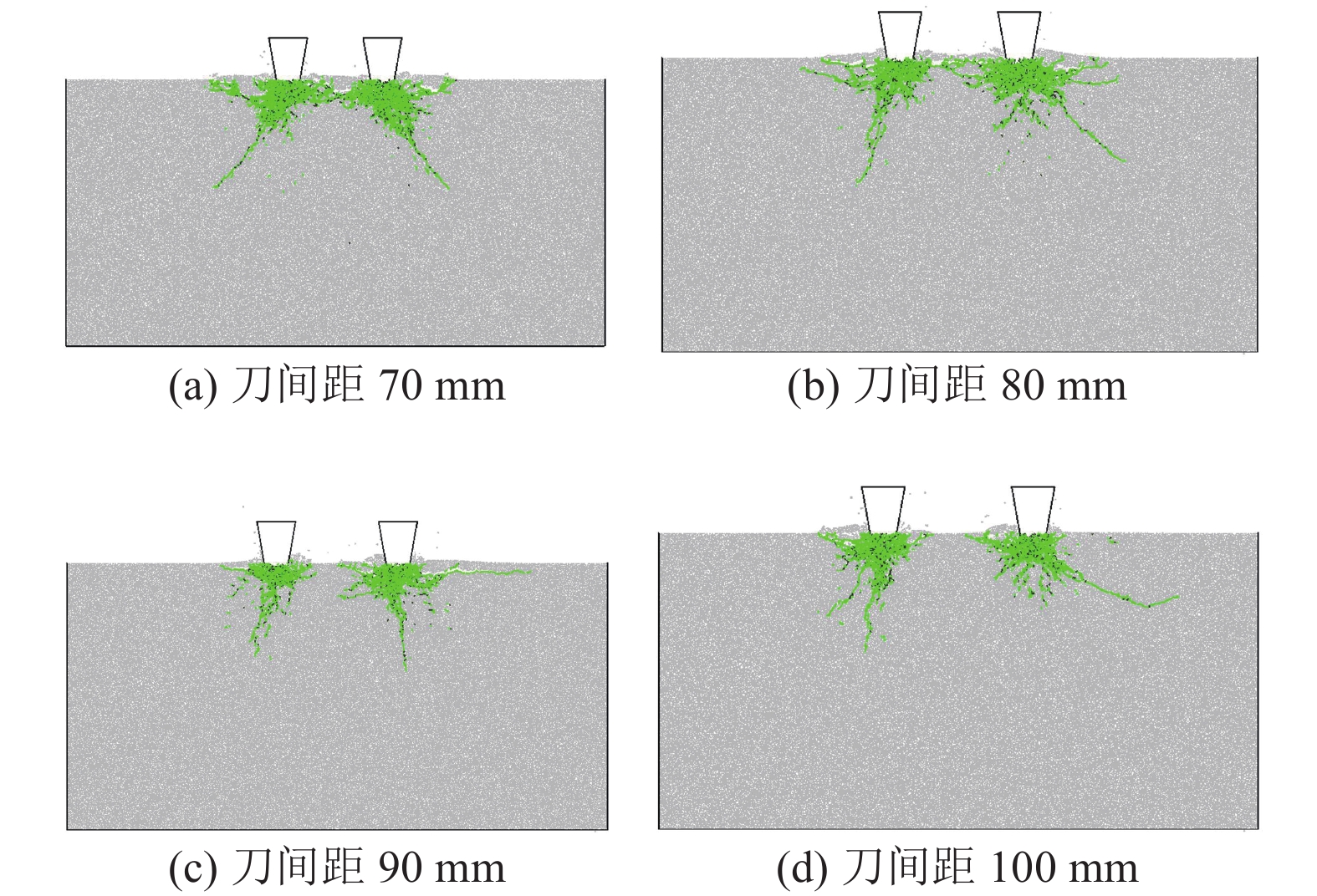

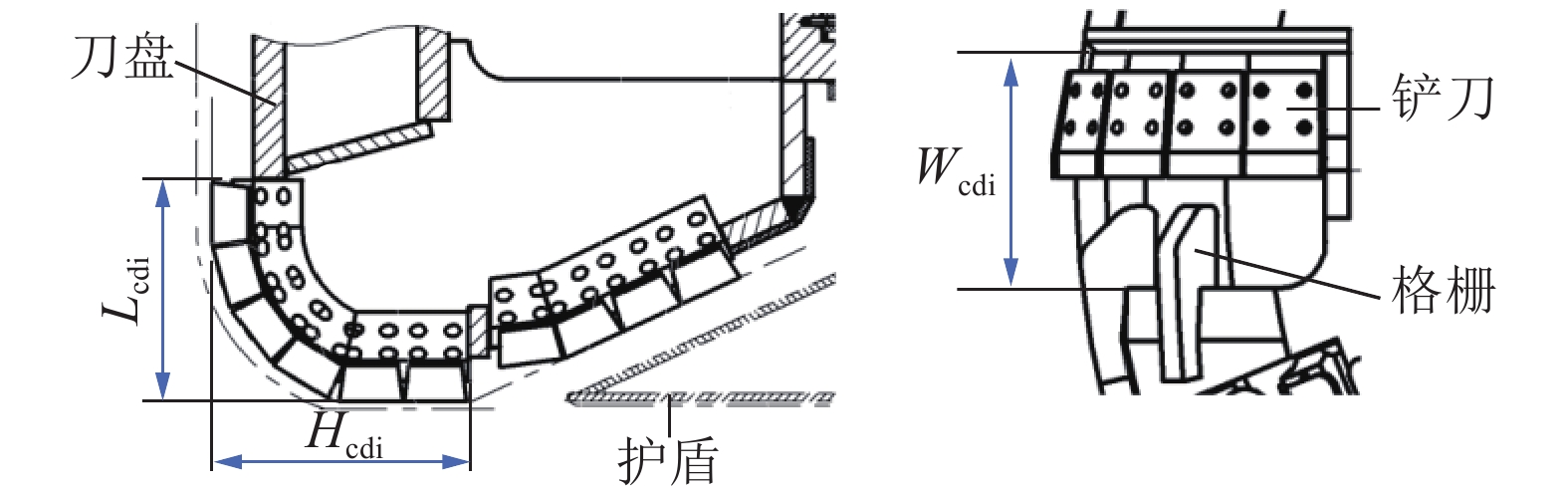

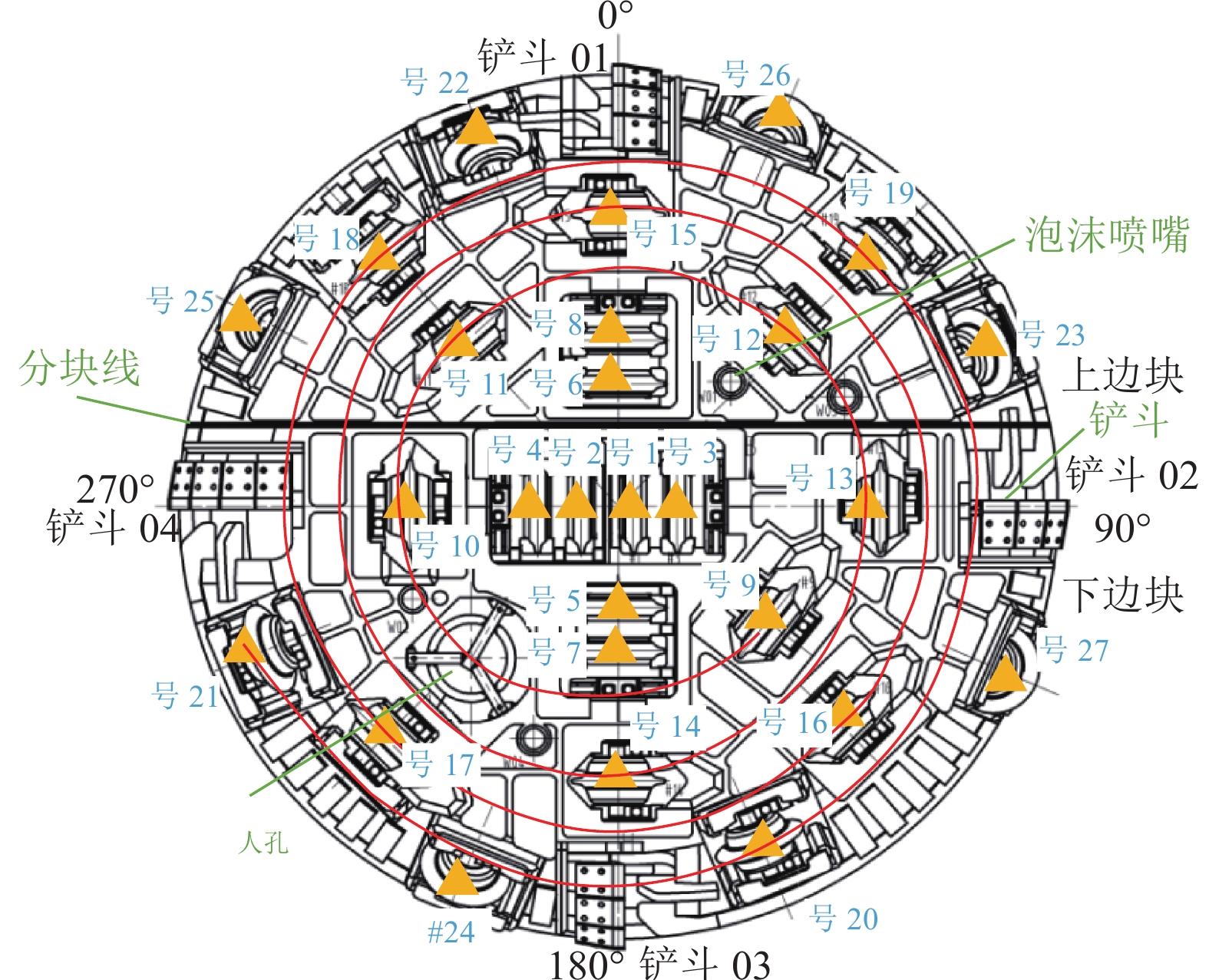

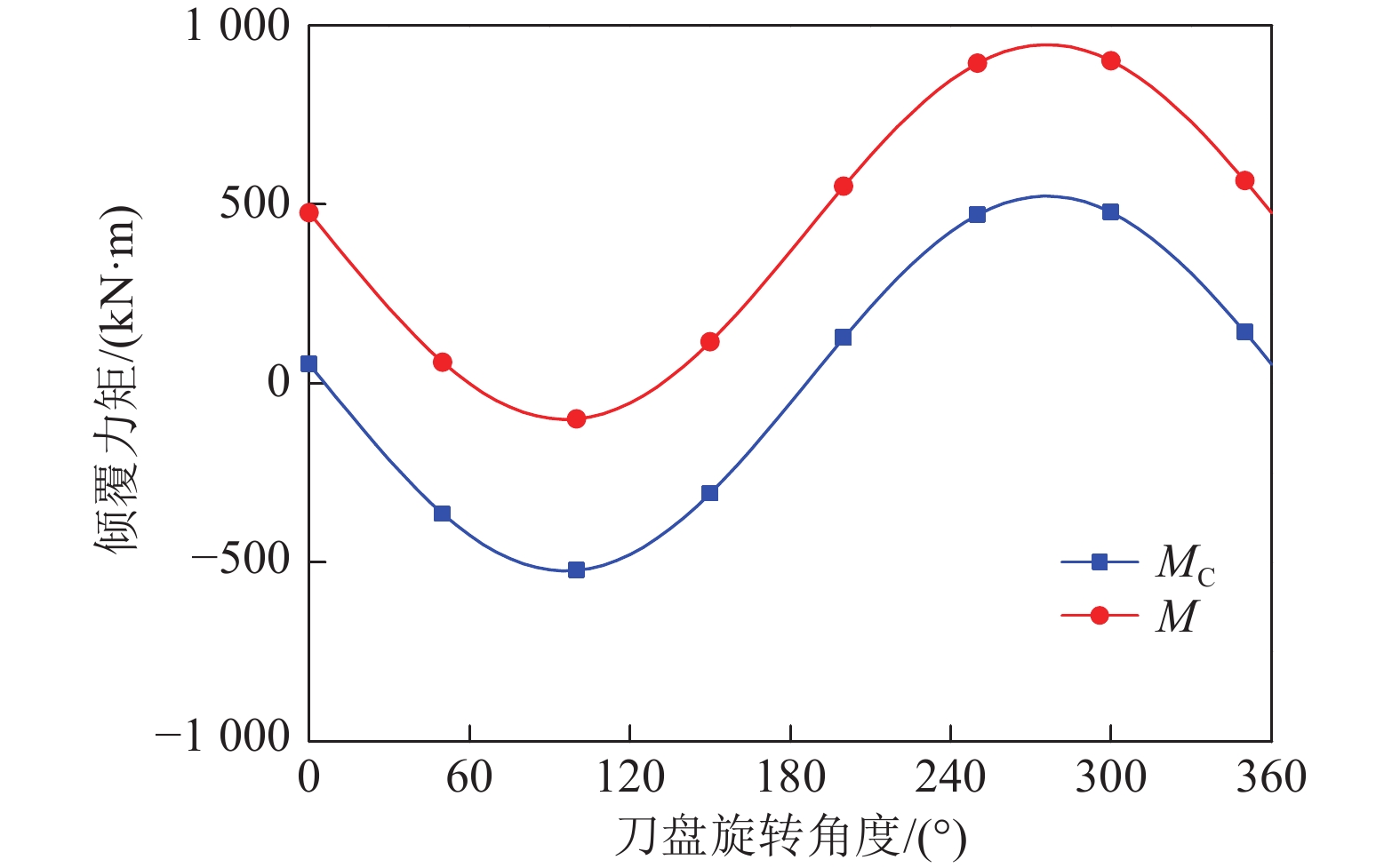

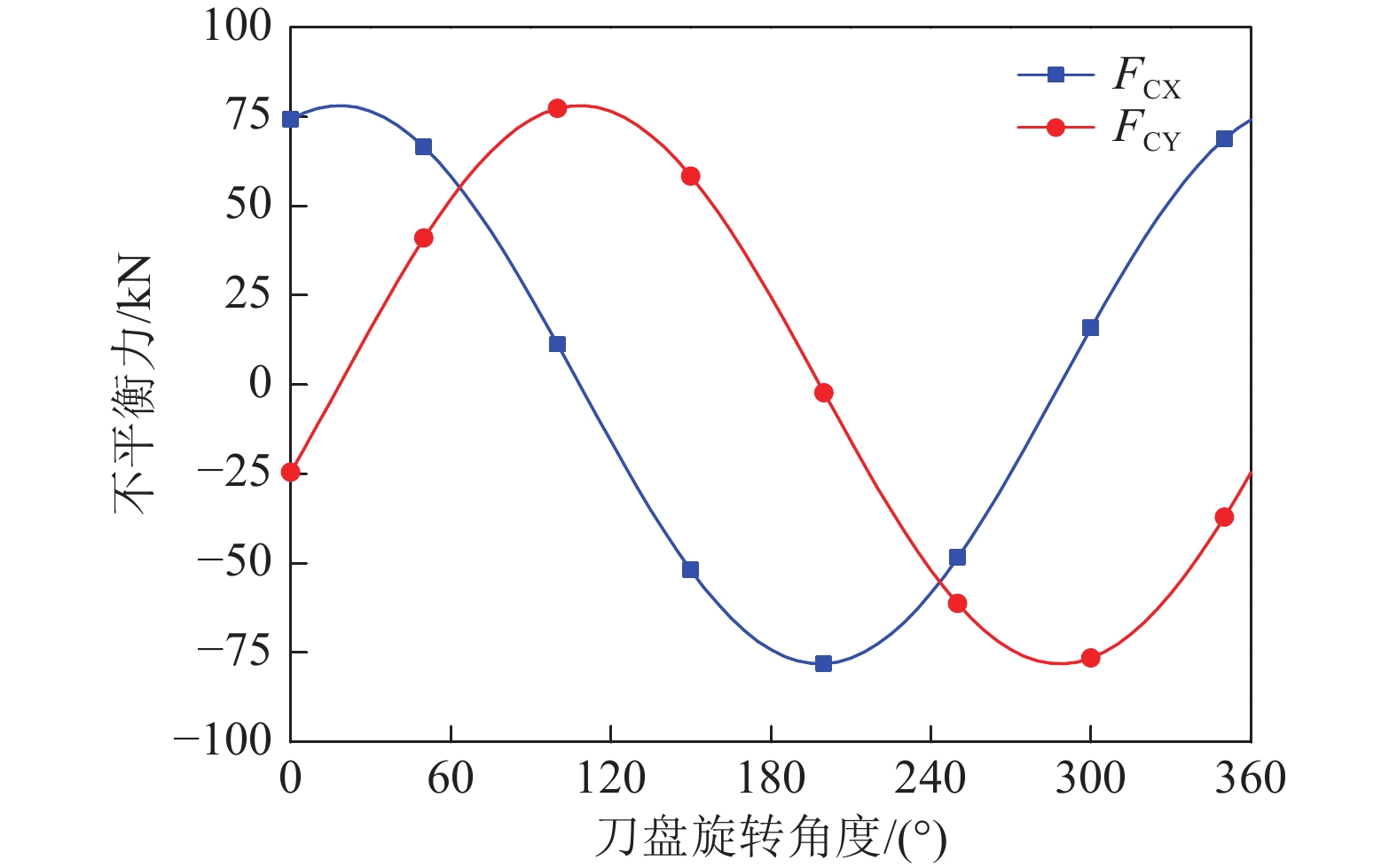

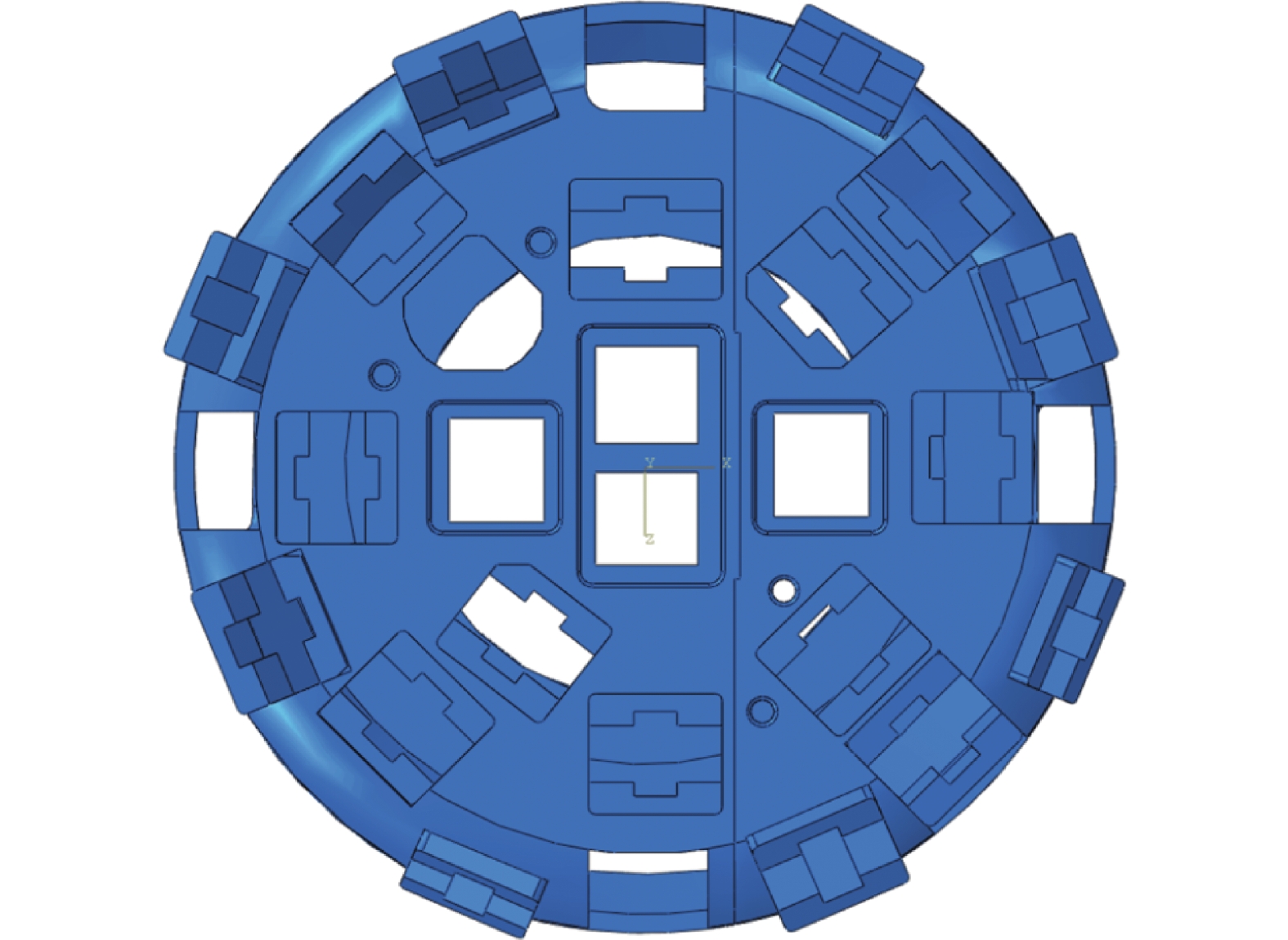

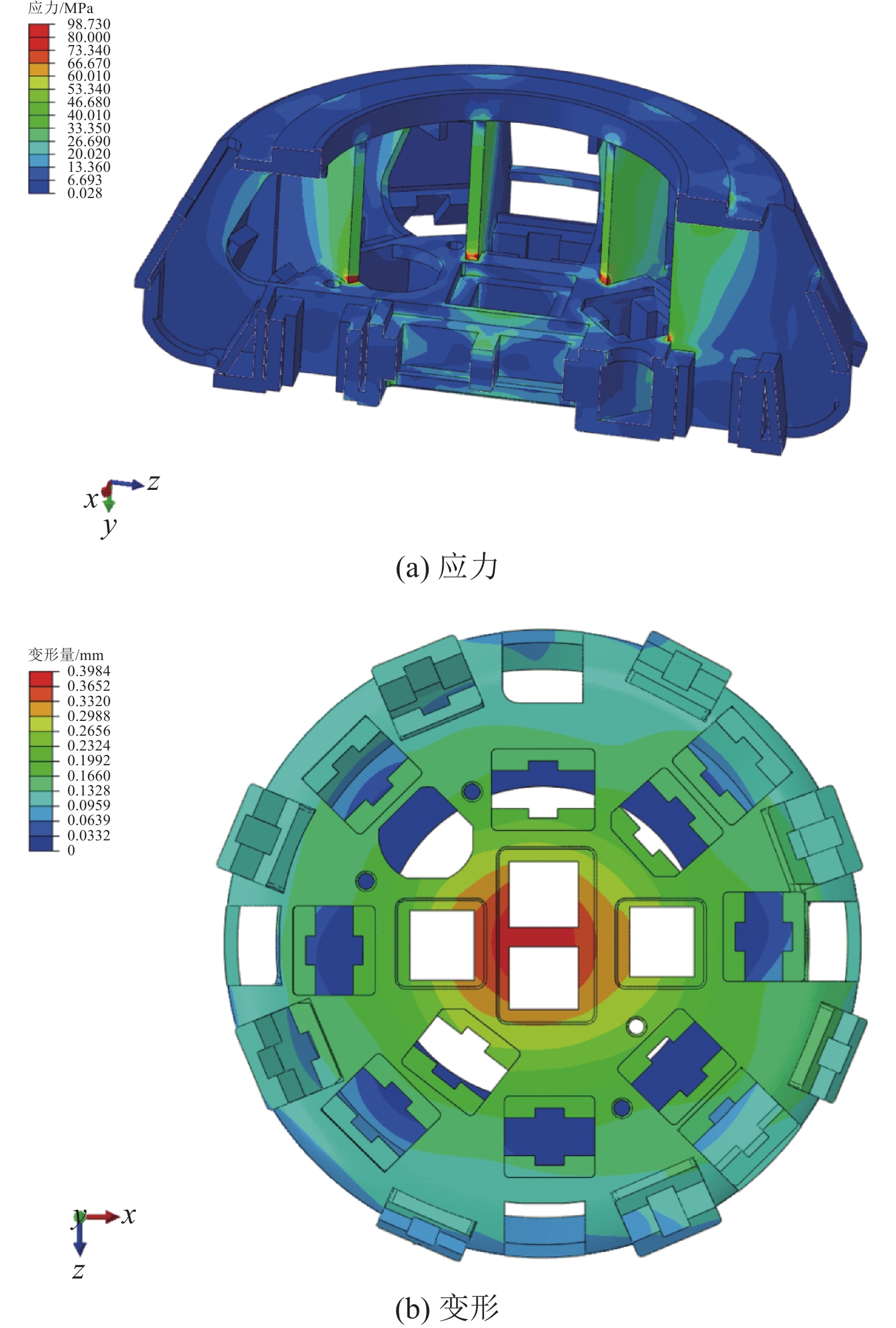

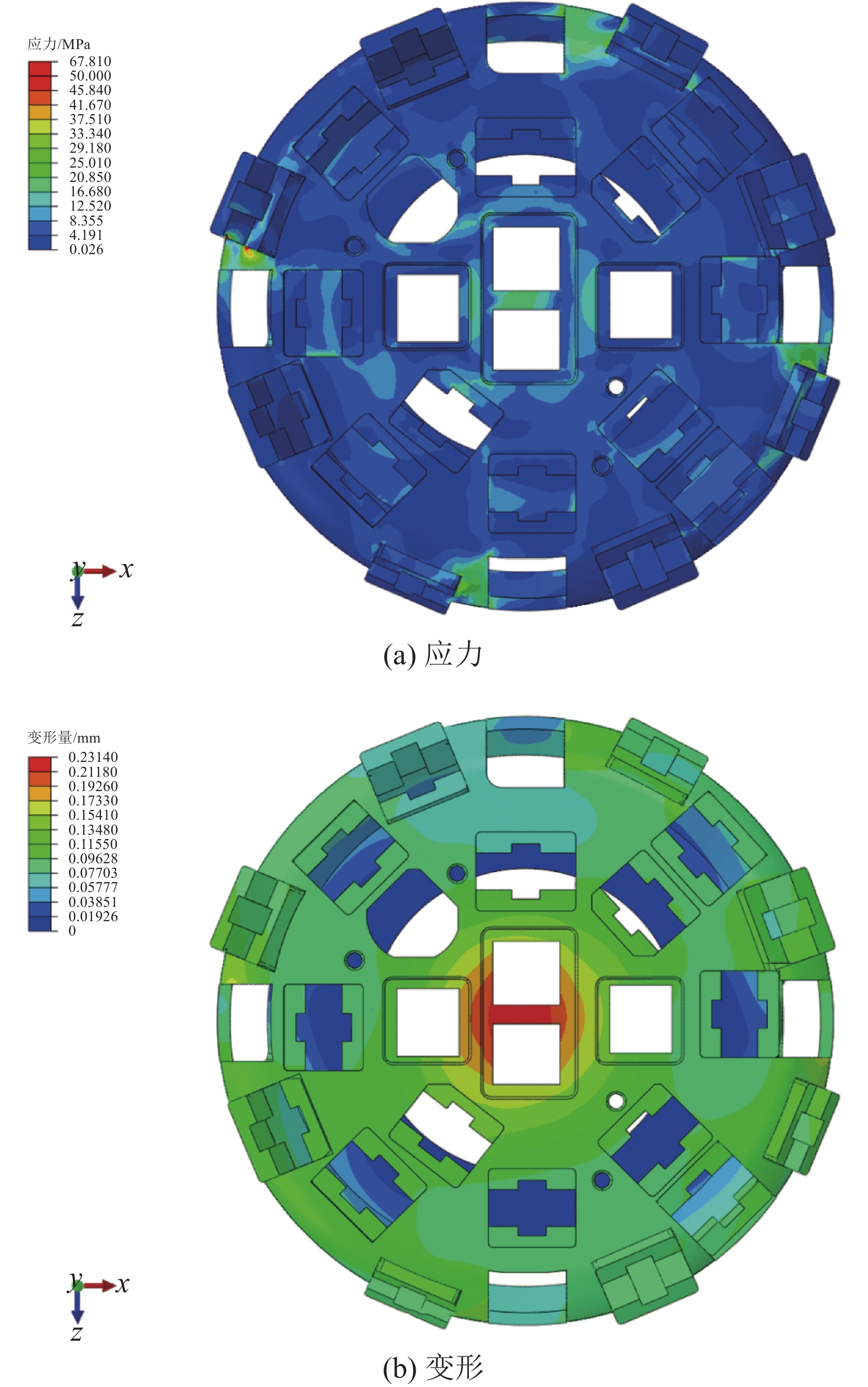

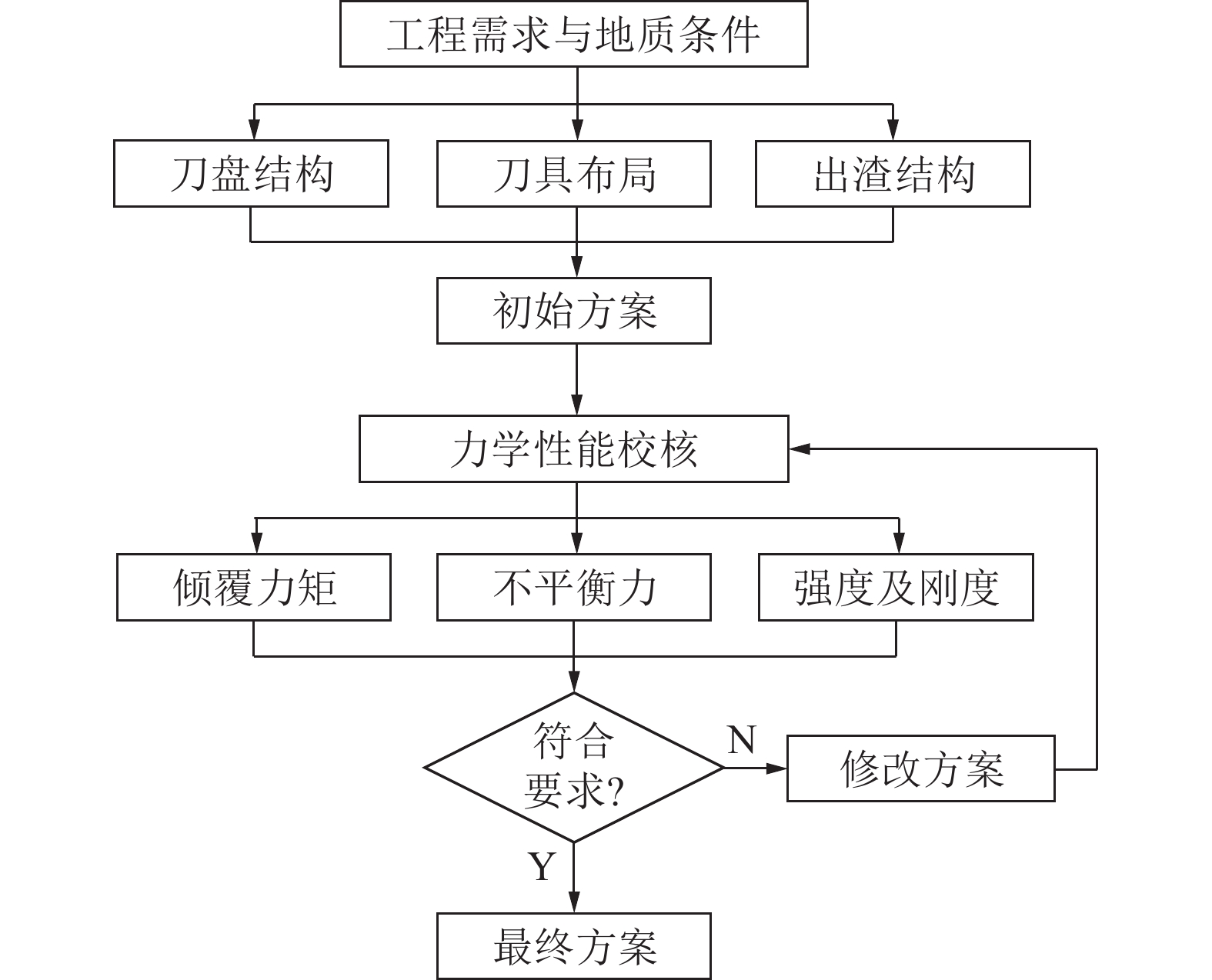

白龙山煤矿一井为煤与瓦斯双突矿井,采用全断面岩石隧道掘进机(Tunnel Boring Machine, TBM)施工能更好地满足煤矿安全、高效和环保的建设需要,刀盘是决定TBM掘进效率和施工安全的关键部件,其设计是否合理对保障TBM施工效率与煤矿高效生产至关重要。通过分析煤矿瓦斯治理巷道与非煤矿领域隧道工程要求和地质特点差异,总结了煤矿瓦斯治理巷TBM刀盘设计需求,阐述了瓦斯治理巷TBM刀盘的设计流程。针对白龙山煤矿一井瓦斯治理巷开展小直径TBM刀盘设计,从刀盘盘体结构、刀具布置、出渣结构等3个主要方面确定刀盘初始方案,结合倾覆力矩、不平衡力、强度及刚度校核形成刀盘最终设计方案。白龙山煤矿一井瓦斯治理巷TBM刀盘选取平面型二分块结构,采用单螺旋线刀具布置形式,滚刀刀间距设计根据离散元仿真分析确定,铲斗均布在刀盘外周,铲斗尺寸根据出渣量确定。刀盘最大倾覆力矩为946.53 kN·m,由刀具产生的倾覆力矩为523.28 kN·m,占比为55.3%,刀具产生的水平与竖直不平衡力最大值为78.12 kN,仅为刀盘重力产生的竖直不平衡力的17.2%,刀盘最大应力为99 MPa,最大变形为0.4 mm,相当于刀盘整体厚度应变量为0.027%,满足设计要求。面向白龙山煤矿一井瓦斯治理巷提出的刀盘设计流程能够为同类工程TBM刀盘设计提供借鉴。

-

关键词:

- 瓦斯治理巷 /

- 岩石隧道掘进机(TBM) /

- 刀盘设计 /

- 滚刀布置 /

- 性能校核

Abstract:Well 1 of Bailongshan Coal Mine is a coal and gas blow-out mine, the use of full-face tunnel boring machine (TBM) can better meet the needs of safe, efficient and environmentally friendly construction of coal mines. The cutterhead is a key component to determine the efficiency of TBM construction, and its reasonable design is essential to ensure the safety of coal mine production. Based on the analysis of the differences in engineering demands and geological characteristics between coal mine gas control roadway and non-coal mine tunnel, the design requirements of TBM cutterhead in coal mine gas control roadway are summarized, and the design process of TBM cutter head in gas control roadway is illustrated. The small diameter TBM cutterhead is designed for the gas control roadway in Well 1 of Bailongshan Coal Mine, and the initial scheme of the cutterhead is determined from three main aspects: the body structure, the layout of the cutters, and muck removal structure, then, the scheme of cutterhead is finally formed in combination with the verification of overturning moment, unbalanced force, strength and stiffness. The TBM cutterhead of gas control roadway in Well 1 Bailongshan Coal Mine adopts a planar two-part structure, the cutters are arranged in the form of single helix cutter layout, and the cutter spacing design is determined according to the discrete element simulation analysis. The scraper bucket is uniform distributed around the cutterhead, and its size is determined according to the volume of muck removal. The analysis of mechanical properties shows that the maximum overturning torque of the cutterhead is 946.53 kNm, and the overturning torque generated by the cutters is 523.28 kNm, accounting for 55.3%. The maximum horizontal and vertical unbalanced force generated by the cutters is 78.12 kN, which is only accounts for 17.2% of the vertical unbalanced force generated by the cutterhead gravity. The maximum stress of the cutterhead is 99 MPa and the maximum deformation is 0.4 mm, which is equivalent to that the overall thickness strain of the cutterhead is about 0.27‰, its performance meeting the design requirements. The cutterhead design process for gas control roadway in Well 1 of Bailongshan Coal Mine can provide reference for TBM cutterhead design of similar projects.

-

-

表 1 离散元细观参数

Table 1 Micro parameters of DEM

颗粒密度/(kg·m−3) 有效模量/GPa 刚度比 摩擦因数 平行黏结有效模量/GPa 平行黏结刚度比 抗拉强度/GPa 黏结强度/GPa 内摩擦角/(°) 2660 5.0 2.5 0.577 5.0 2.5 27 20 23 表 2 不同网格精度下刀盘最大应力

Table 2 Maximum stress of cutterhead under different grid accuracy

网格模型 网格数量/万 最大应力/MPa 模型1 20 92.31 模型2 35 98.73 模型3 70 97.84 -

[1] 徐腾飞,王学兵. 近十年我国低瓦斯煤矿瓦斯爆炸事故统计与规律分析[J]. 矿业安全与环保,2021,48(3):126−130. XU Tengfei,WANG Xuebing. Statistics and regularity analysis of gas explosion accidents in domestic low-gas coal mines in recent ten years[J]. Mining Safety & Environmental Protection,2021,48(3):126−130.

[2] 王杜娟,贺 飞,王 勇,等. 煤矿岩巷全断面掘进机(TBM)及智能化关键技术[J]. 煤炭学报,2020,45(6):2031−2044. WANG Dujuan,HE Fei,WANG Yong,et al. Tunnel boring machine (TBM) in coal mine and its intelligent key technnology[J]. Journal of China Coal Society,2020,45(6):2031−2044.

[3] 刘泉声,黄 兴,潘玉丛,等. TBM在煤矿巷道掘进中的技术应用和研究进展[J]. 煤炭科学技术,2023,51(1):242−260. LIU Quansheng,HUANG Xing,PAN Yucong,et al. Application and research progress of TBM tunneling in coal mine roadway[J]. Coal Science and Technology,2023,51(1):242−260.

[4] 代恩虎,王 勇,鲁义强,等. 云贵地区煤矿建设中TBM施工技术应用研究[J]. 煤炭科学技术,2022,50(10):10−18. DAI Enhu,WANG Yong,LU Yiqiang,et al. Application and study of TBM construction technology for coal mine construction in Yunnan and Guizhou Provinces[J]. Coal Science and Technology,2022,50(10):10−18.

[5] GENG Qi,ZHANG Huijian,LIU Xiaohui,et al. Numerical study on the rock muck transfer process of TBM cutterhead with clump strategy based on discrete element method[J]. Tunnelling and Underground Space Technology,2019,91:103000. doi: 10.1016/j.tust.2019.103000

[6] 刘志杰,滕弘飞,史彦军,等. TBM刀盘设计若干关键技术[J]. 中国机械工程,2008(16):1980−1985. doi: 10.3321/j.issn:1004-132X.2008.16.021 LIU Zhijie,TENG Hongfei,SHI Yanjun,et al. Cutterhead design key issues of a full face rock tunnel boring machine(TBM)[J]. China Mechanical Engineering,2008(16):1980−1985. doi: 10.3321/j.issn:1004-132X.2008.16.021

[7] ROSTAMI Jamal,CHANG Soo-Ho. A closer look at the design of cutterheads for hard rock tunnel-boring machines[J]. Engineering,2017,3(6):892−904. doi: 10.1016/j.eng.2017.12.009

[8] 程永亮,钟 掘,暨智勇,等. TBM刀盘地质适应性设计方法及其应用[J]. 机械工程学报,2018,54(1):1−9. CHENG Yongliang,ZHONG Jue,JI Zhiyong,et al. Geological adaptaive design method and application of TBM cutterhead[J]. Journal of Mechanical Engineering,2018,54(1):1−9.

[9] 霍军周,史彦军,滕弘飞,等. 全断面岩石掘进机刀具布置设计方法[J]. 中国机械工程,2008(15):1832−1836. HUO Junzhou,SHI Yanjun,TENG Hongfei,et al. Cutter layout design of full-face rock tunnel boring machine(TBM)[J]. Journal of Mechanical Engineering,2008(15):1832−1836.

[10] 郭 伟,孙红艳,刘建琴,等. 基于TBM刀盘剖面轮廓的滚刀极径优化布置设计[J]. 天津大学学报(自然科学与工程技术版),2016,49(12):1303−1311. GUO Wei,SUN Hongyan,LIU Jianqin,et al. Optimal layout design for disc cutters’ assembled radii based on TBM cutterhead profile[J]. Journal of Tianjin University(Science and Technology),2016,49(12):1303−1311.

[11] 郭 伟,刘小庆,刘建琴,等. 基于破岩比能的刀盘滚刀优化布置设计[J]. 东北大学学报(自然科学版),2018,39(2):242−247,253. GUO Wei,LIU Xiaoqing,LIU Jianqin,et al. Optimized layout design for cutterhead’s disc cutters based on rock-breaking specific energy[J]. Journal of Northeastern University(Natural Science),2018,39(2):242−247,253.

[12] 刘建琴,邢振华,宾怀成,等. 复合岩层地质下硬岩隧道掘进机滚刀布局方法[J]. 浙江大学学报(工学版),2019,53(1):166−173. LIU Jianqin,XING Zhenhua,BIN Huaicheng,et al. Cutters’ layout method of tunnel boring machine cutter-head under mixed-face rock ground[J]. Journal of Zhejiang University(Engineering Science),2019,53(1):166−173.

[13] 刘亚迪,齐文聪,刘浩飞,等. 多滚刀协同破岩过程数值模拟与滚刀布置规律研究[J]. 煤炭科学技术,2023,51(5):232−244. LIU Yadi,QI Wencong,LIU Haofei,et al. Numerical simulation of cooperative breaking rock by multi-cutter and research on the layout law of disc cutter on cutterhead[J]. Coal Science and Technology,2023,51(5):232−244.

[14] 谭 青,李建芳,夏毅敏,等. 盘形滚刀破岩过程的数值研究[J]. 岩土力学,2013,34(9):2707−2714. TAN Qing,LI Jianfang,XIA Yimin,et al. Numerical research on rock fragmentation process by disc cutter[J]. Rock and Soil Mechanics,2013,34(9):2707−2714.

[15] 谭 青,易念恩,夏毅敏,等. TBM滚刀破岩动态特性与最优刀间距研究[J]. 岩石力学与工程学报,2012,31(12):2453−2464. doi: 10.3969/j.issn.1000-6915.2012.12.009 TAN Qing,YI Nianen,XIA Yimin,et al. Research on rock dynamic fragmentation characteristics by TBM cutters and cutter spacing optimization[J]. Chinese Journal of Rock Mechanics and Engineering,2012,31(12):2453−2464. doi: 10.3969/j.issn.1000-6915.2012.12.009

[16] 林赉贶,夏毅敏,贾连辉,等. TBM边缘滚刀组合破岩特性及其影响因素敏感性评价[J]. 机械工程学报,2018,54(1):18−26. doi: 10.3901/JME.2018.01.018 LIN Laikuang,XIA Yimin,JIA Lianhui,et al. Rock-breaking characteristics of TBM gage disc cutters and sensitivity analysis of their influencing factors[J]. Journal of Mechanical Engineering,2018,54(1):18−26. doi: 10.3901/JME.2018.01.018

[17] 刘立鹏,汪小刚,刘海舰,等. TBM滚刀破岩机理与影响因素数值模拟研究[J]. 中国水利水电科学研究院学报,2017,15(5):346−353,359. LIU Lipeng,WANG Xiaogang,LIU Haijian,et al. Numerical simulation research on rock Breakage mechanism and influence TBM cutters[J]. Journal of China Institute of Water Resources and Hydropower Research,2017,15(5):346−353,359.

[18] 赵振威,郑康泰,李 楠,等. 不同几何结构的TBM刀盘静力学性能对比分析[J]. 隧道建设,2016,36(1):102−107. doi: 10.3973/j.issn.1672-741X.2016.01.016 ZHAO Zhenwei,ZHENG Kangtai,LI Nan,et al. Analysis on static mechanical performances of TBM cutterhead with different geometries[J]. Tunnel Construction,2016,36(1):102−107. doi: 10.3973/j.issn.1672-741X.2016.01.016

[19] 曾文宇,管会生,宋颖鹏,等. 煤矿斜井双模式盾构刀盘的受力特性研究[J]. 工程设计学报,2017,24(1):77−82. ZENG Wenyu,GUAN Huisheng,SONG Yingpeng,et al. Study on stress characteristics of cutter head of dual-mode shield machine used for inchlined shaft of colliery[J]. Chinese Journal of Engineering Design,2017,24(1):77−82.

[20] 荆留杰,张 娜,杨 晨,等. 基于最小破碎比能TBM滚刀间距设计方法研究[J]. 铁道学报,2018,40(12):123−129. doi: 10.3969/j.issn.1001-8360.2018.12.016 JING Liujie,ZHANG Na,YANG Chen,et al. A design method research on TBM face cutter spacing layout based on mnimum specific energy[J]. Journal of The China Railway Society,2018,40(12):123−129. doi: 10.3969/j.issn.1001-8360.2018.12.016

[21] 石 崇,张 强,王盛年. 颗粒流(PFC5.0)数值模拟技术及应用[M]. 北京:中国建筑工业出版社,2018:262−286. SHI Chong,ZHANG Qiang,WANG Shengnian. Numerical simulation technology and application with particle flow code(PFC5.0) [M]. Beijing:China Architecture & Building Press,2018:262−286.

[22] YANG Mei,XIA Yimin,LIN Laikuang,et al. Optimal design for buckets layout based on muck removal analysis of TBM cutterhead[J]. Journal of Central South University,2020,27(6):1729−1741. doi: 10.1007/s11771-020-4403-1

[23] 吕建乐. TBM 扩挖方式及其对比分析[J]. 隧道建设(中英文),2021,41(6):1058−1064. LYU Jianle. Comparison and analysis of tunnel boring machine overcutting methods[J]. Tunnel Construction,2021,41( 6):1058−1064.

[24] XIA Yimin,TIAN Yanchao,TAN Qing,et al. Side force formation mechanism and change law of TBM center cutter[J]. Journal of Central South University,2016,23:1115−1122. doi: 10.1007/s11771-016-0361-z

[25] 夏毅敏,吴才章,兰 浩,等. 典型TBM刀盘力学性能分析与对比[J]. 哈尔滨工程大学学报,2016,37(8):1136−1142. XIA Yimin,WU Caizhang,LAN Hao,et al. Mechanical performance analysis and comparison of typical TBM cutterhead[J]. Journal of Harbin Engineering University,2016,37( 8):1136−1142.

-

期刊类型引用(22)

1. 许波,杨鹏军. 深部矿区巷道围岩力学参数测试及反演研究. 采矿技术. 2024(01): 1-5 .  百度学术

百度学术

2. 张杰,孙建平,何义峰,张一铭,庞海波,武浩昊,张建辰,彭冰. 近距离煤层底板应力分布规律及巷道布置研究. 煤炭科学技术. 2024(08): 11-22 .  本站查看

本站查看

3. 纪金池,董显业. 空间交叉型巷道围岩控制技术研究. 煤炭技术. 2024(12): 98-101 .  百度学术

百度学术

4. 王鹏,王虎伟,王帅,王鹏程. 孤岛工作面回采巷道围岩破坏机理及差异化控制技术. 金属矿山. 2024(12): 96-105 .  百度学术

百度学术

5. 潘忠德,张珂,顾成富,张启航. 近距离煤层采动影响及巷道合理位置研究. 煤炭技术. 2023(04): 43-47 .  百度学术

百度学术

6. 朱宗奎,鲁岩. 基于锚固应力叠加控制原理的多层支护数值模拟实验研究. 实验技术与管理. 2023(04): 125-132 .  百度学术

百度学术

7. 贺相乾. 高应力煤巷围岩多维预应力锚索桁架应用研究. 山西冶金. 2023(04): 207-208 .  百度学术

百度学术

8. 王向来,曹晓杰,温颖远. 动载扰动开切巷支护设备及工艺改造研究. 煤矿机械. 2023(08): 103-106 .  百度学术

百度学术

9. 任帅,鲁德超,罗勇,肖殿才. 滞弹性应变恢复法地应力测量及地质信息可视化研究. 采矿技术. 2023(05): 46-50 .  百度学术

百度学术

10. 娄杰,张迎春,温慧,杨玉顺,韦四江. 采动影响下全煤回采巷道围岩稳定性模拟研究. 能源与环保. 2023(09): 257-265 .  百度学术

百度学术

11. 陈朋磊,陈鑫源,刘欢欢,王丹,梁洁,杨景景. 近距离煤层回采巷道合理位置确定应用研究. 能源与环保. 2022(05): 262-269 .  百度学术

百度学术

12. 高玉军,康庆涛,殷帅峰. 条带煤柱下近距离煤层巷道围岩控制. 华北科技学院学报. 2022(02): 26-31 .  百度学术

百度学术

13. 冯根民. 台头煤矿3206工作面动压巷道围岩控制技术与试验. 山东煤炭科技. 2022(05): 24-26 .  百度学术

百度学术

14. 姚直书,王晓云,王要平,程桦,唐彬,冯依赞,徐火祥,刘小虎,包蓓蓓,方玉. 煤矿TBM掘进巷道围岩时效变形分析及支护参数优化研究. 煤炭工程. 2022(07): 31-37 .  百度学术

百度学术

15. 李桂臣,杨森,孙元田,许嘉徽,李菁华. 复杂条件下巷道围岩控制技术研究进展. 煤炭科学技术. 2022(06): 29-45 .  本站查看

本站查看

16. 石文朋,魏宝贞,李楠,谭浩,陈兆生. 缩面影响下辅助巷道变形特征及控制技术. 煤矿现代化. 2022(05): 1-4 .  百度学术

百度学术

17. 李松峰,陈军锋. 高地应力巷道围岩变形控制方法. 煤炭技术. 2022(10): 33-35 .  百度学术

百度学术

18. 陈康,杨张杰,王福海,王威,王庆牛. 富水弱胶结顶板巷道支护优化设计研究. 煤炭工程. 2022(11): 79-83 .  百度学术

百度学术

19. 郑光辉,刘宇飞,吉格买提·吉布森. 东沟煤矿浅埋煤层群采空区下巷道最佳布置. 煤矿安全. 2022(12): 192-200 .  百度学术

百度学术

20. 杨鹏,马平,赵俊达. 高强度开采条件下煤炭巷道锚杆支护技术. 煤炭工程. 2022(S1): 44-48 .  百度学术

百度学术

21. 王伟,弓仲标. 近距离煤层群煤柱下开采动压巷道围岩变形规律及控制. 煤炭科学技术. 2022(S2): 143-152 .  本站查看

本站查看

22. 卞涛,陆浩. 浅埋近距离厚煤层开采对上覆采空区影响规律. 煤炭科学技术. 2021(S2): 40-45 .  本站查看

本站查看

其他类型引用(4)

下载:

下载: