Vibration reduction method and device of shearer inertial measurement unit

-

摘要:

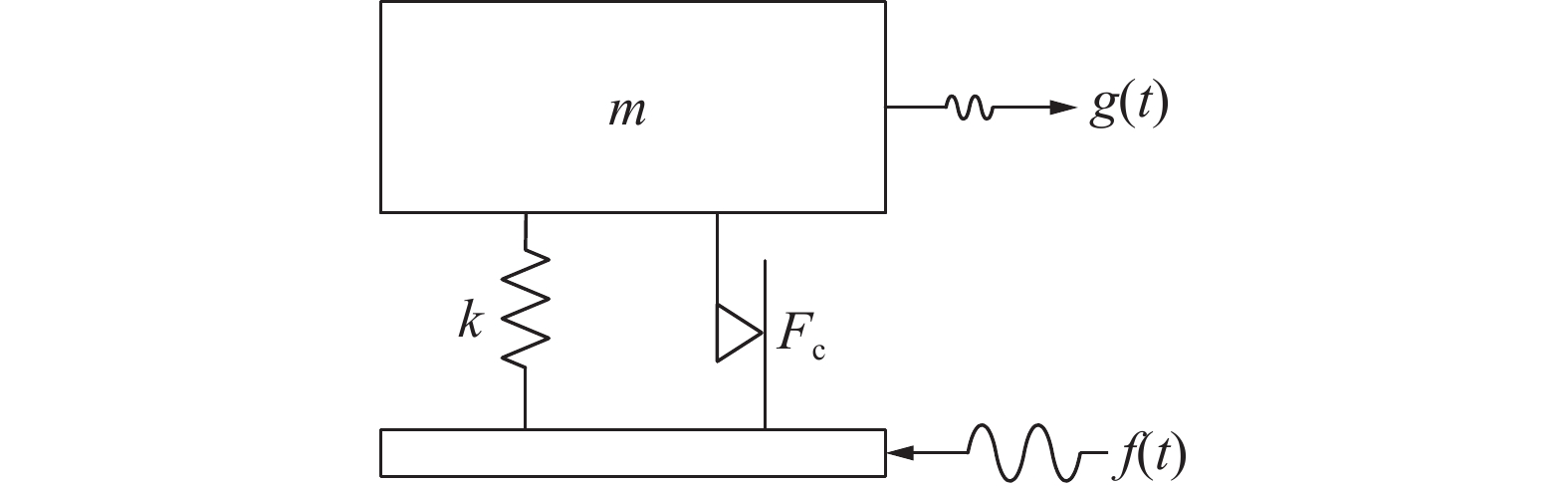

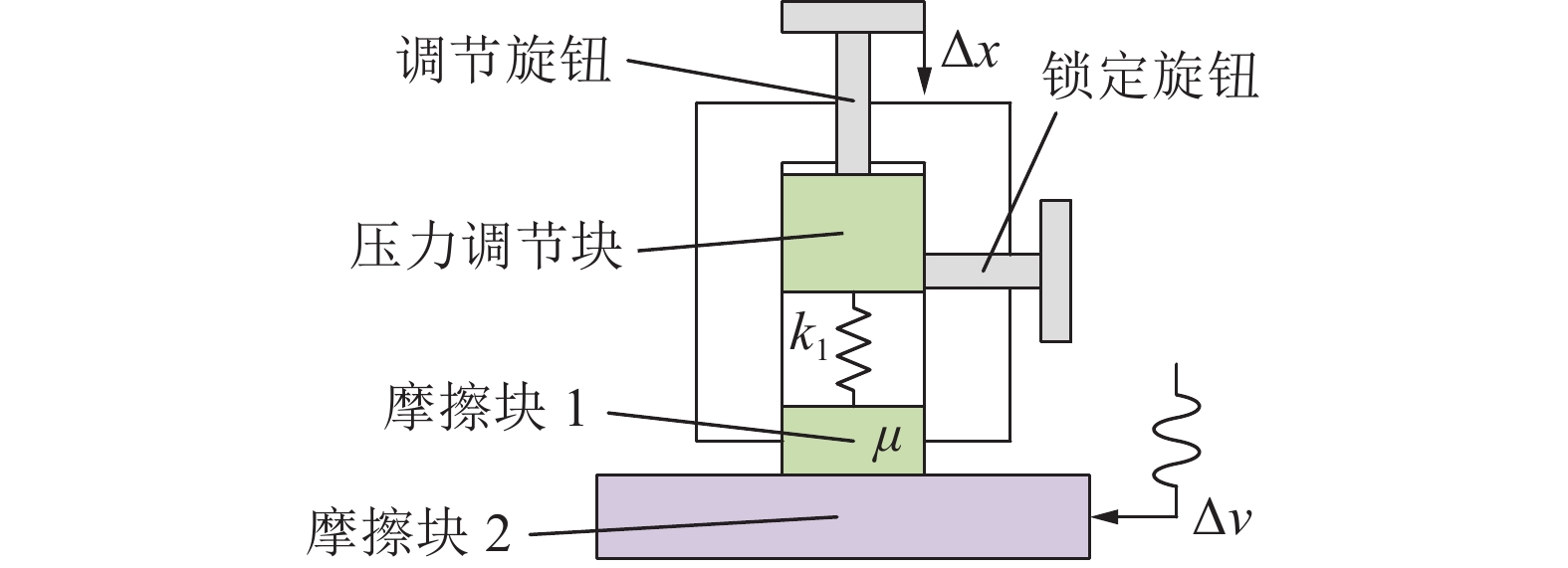

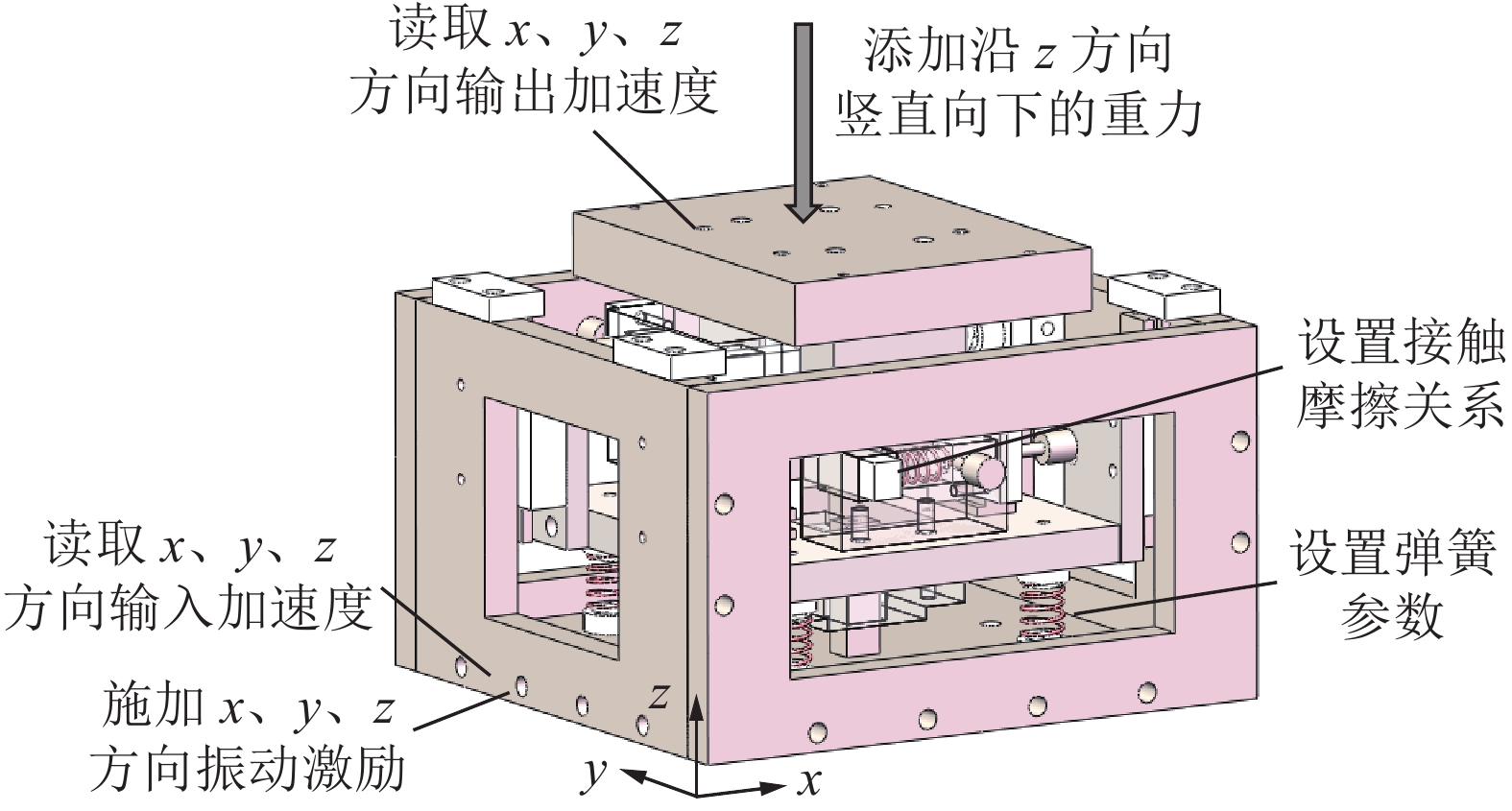

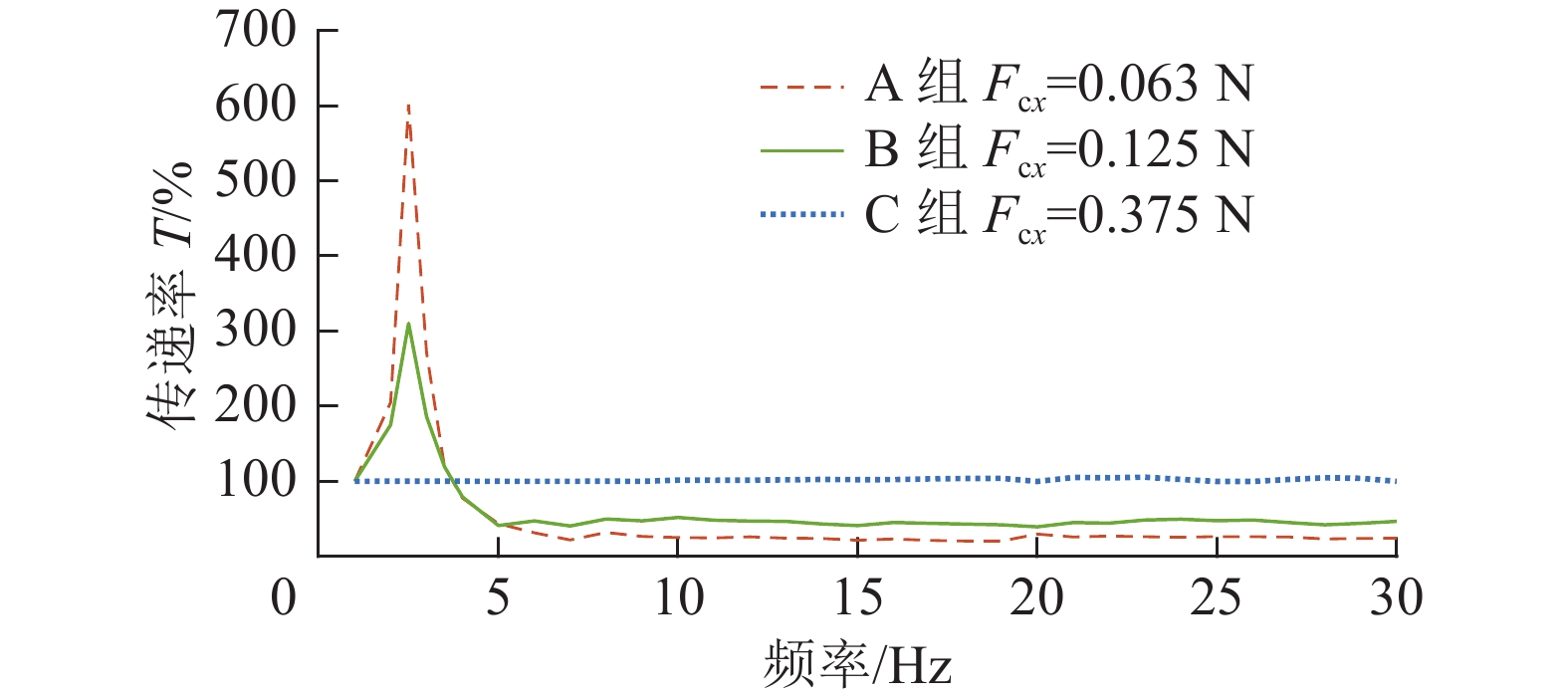

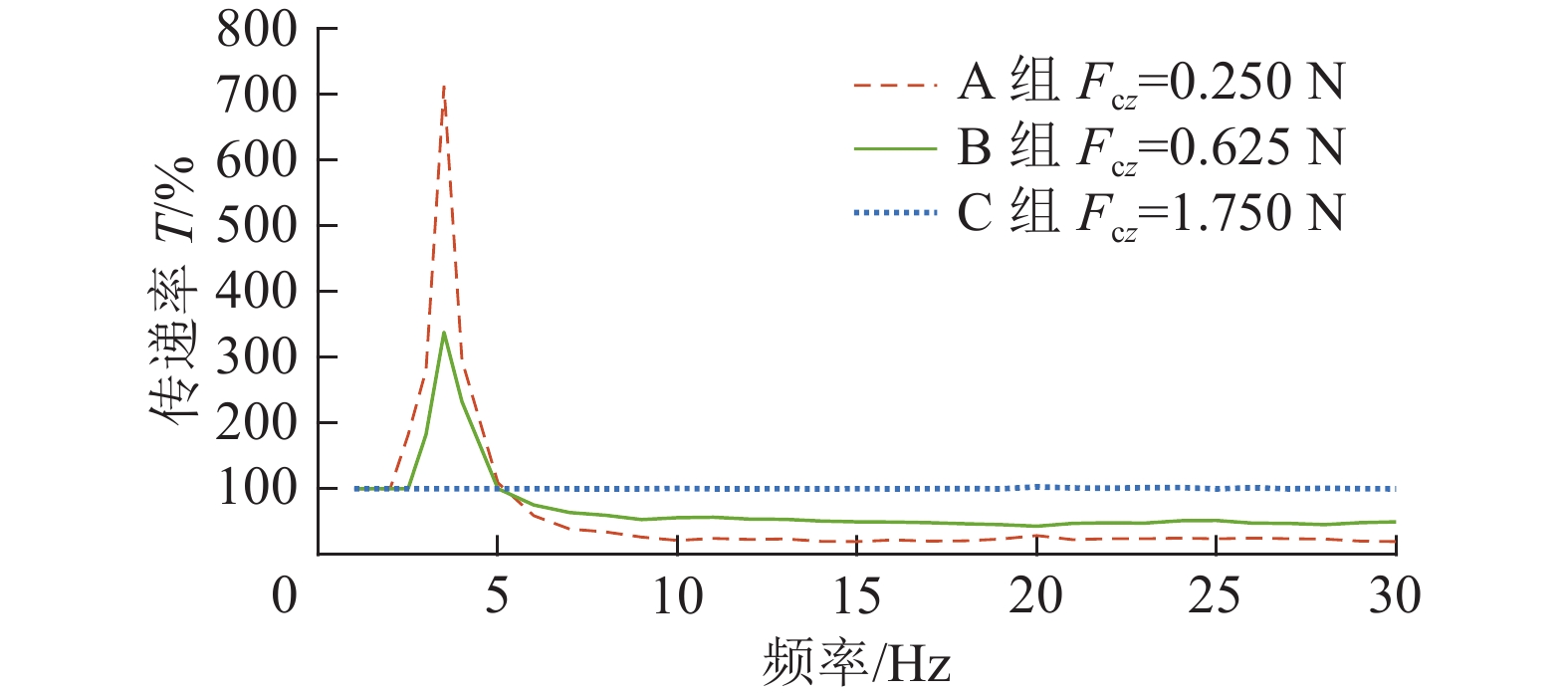

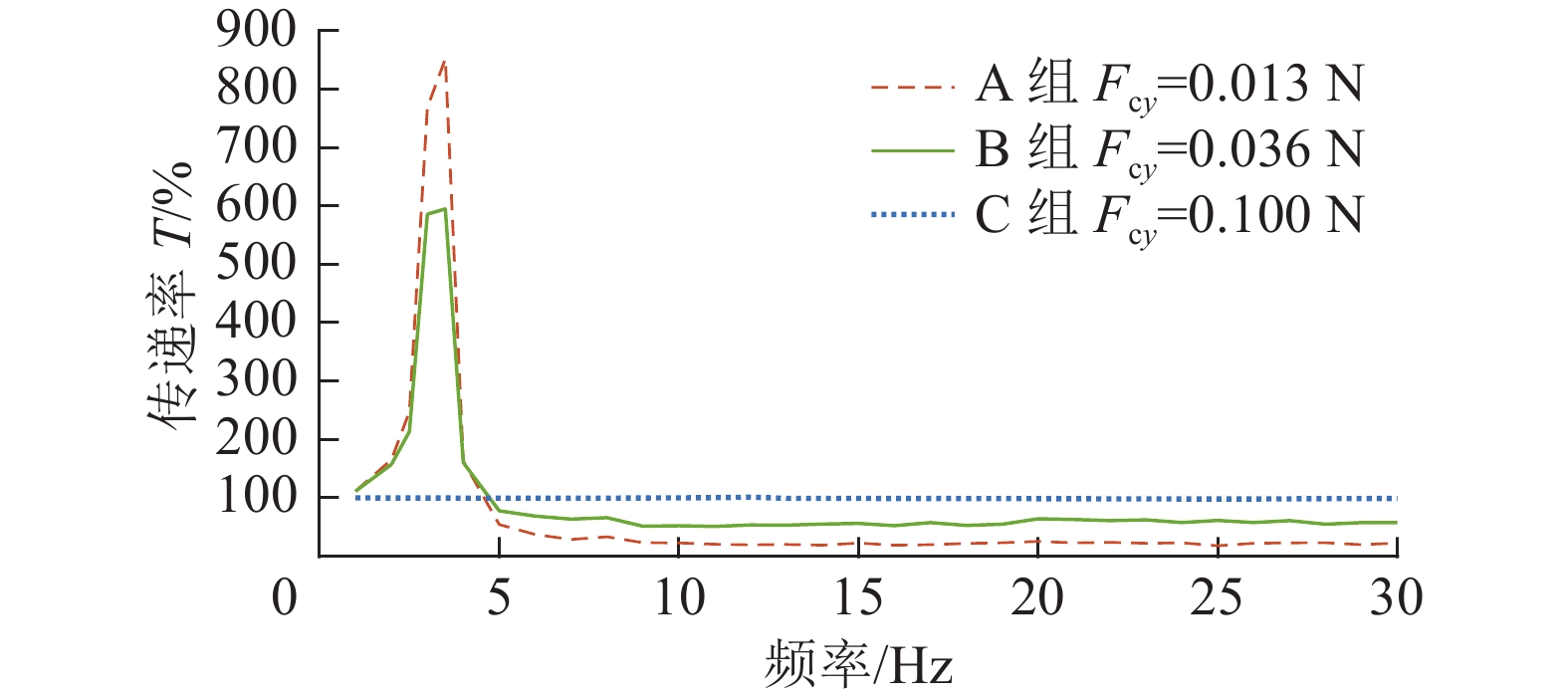

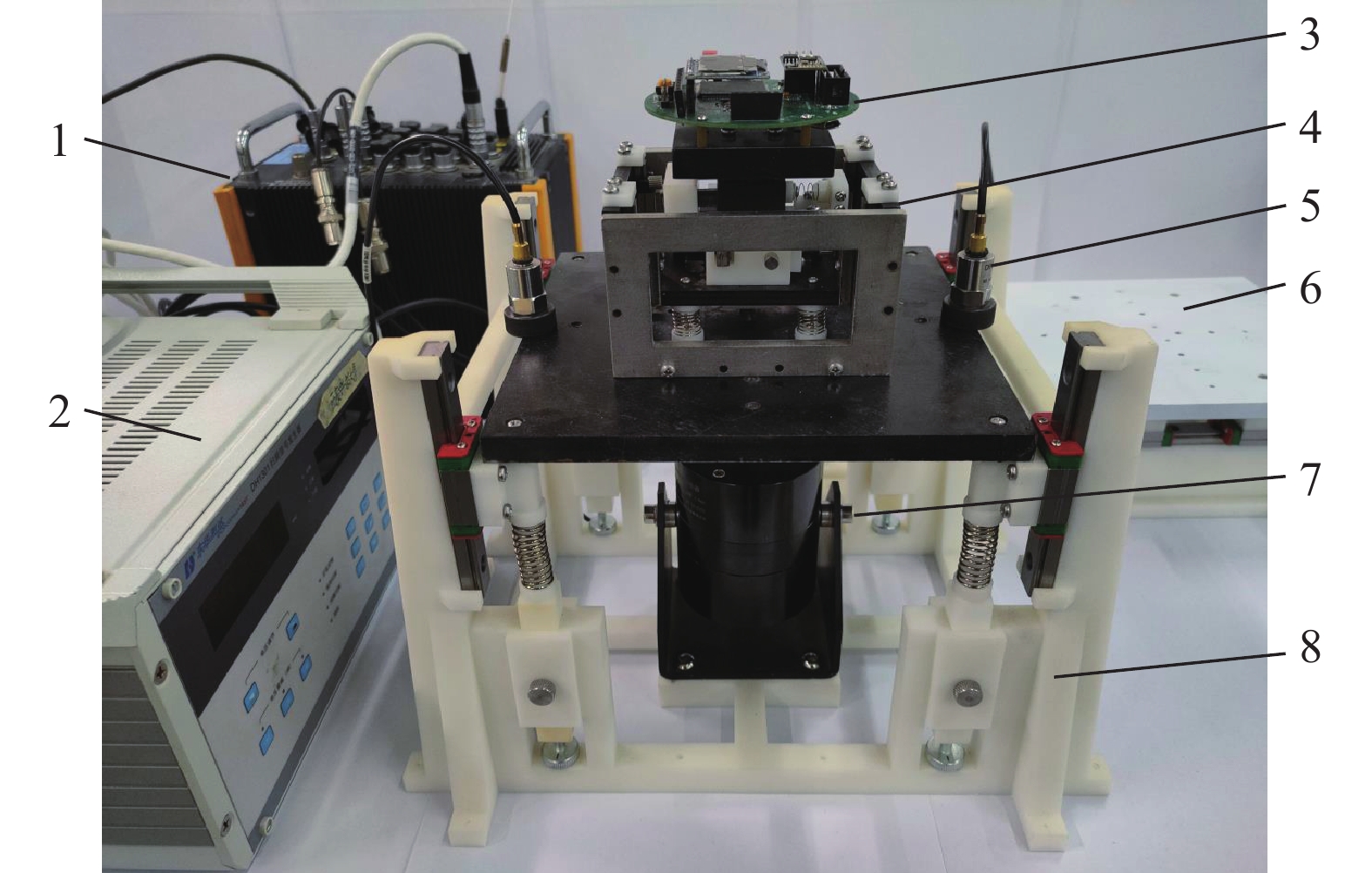

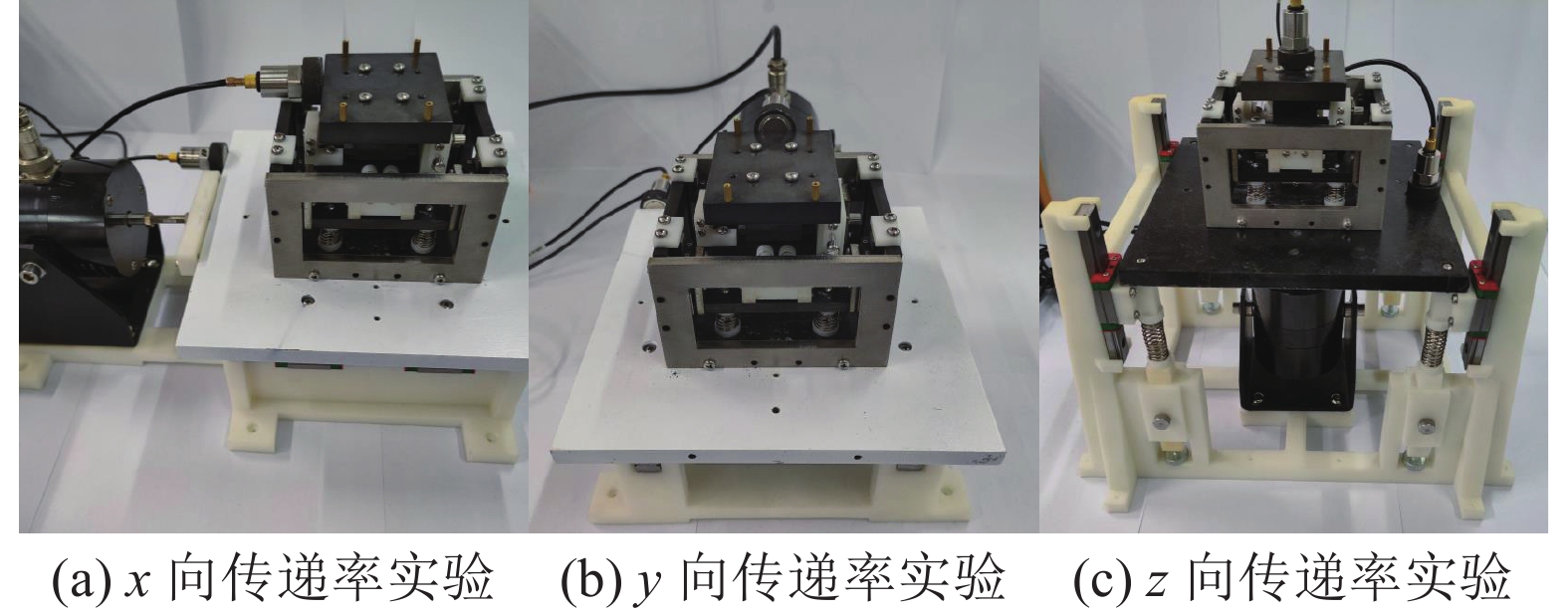

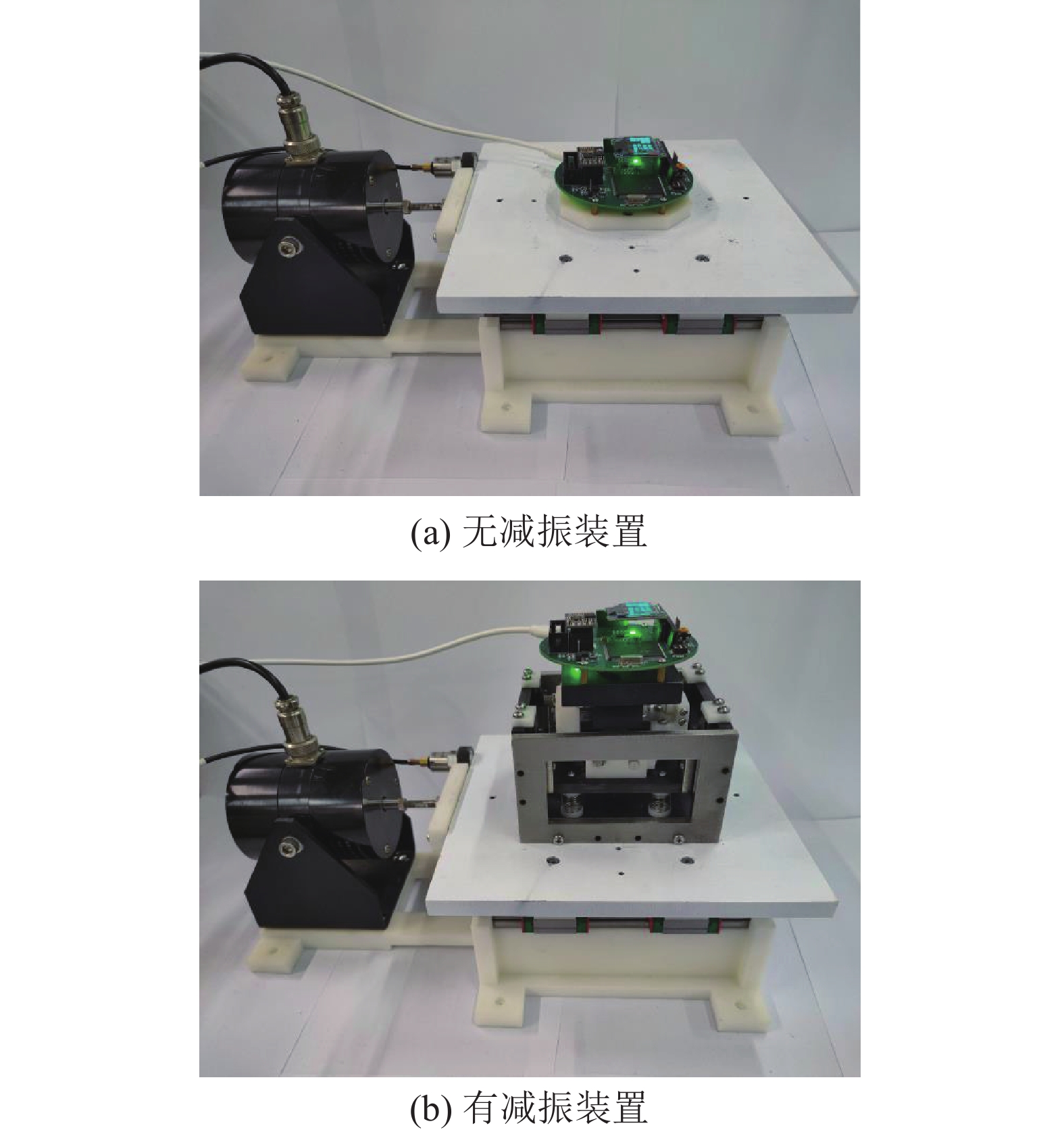

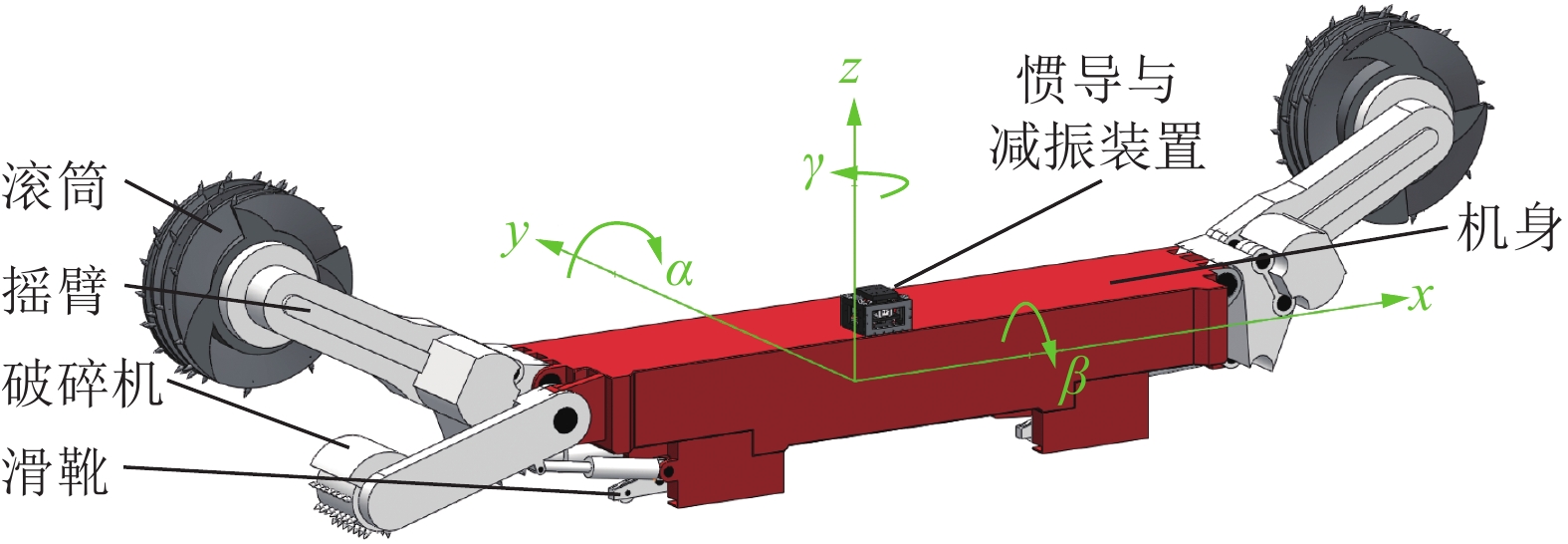

惯性传感器以其鲜明的优点,已成为目前采煤机姿态测量及井下自主导航研究和应用的热点。针对惯性传感器在实际应用中因受采煤机强振动干扰,存在测量稳定性差和精度低等问题,研制了一种金属弹簧-可调摩擦阻尼三向减振装置。首先,介绍了惯性传感器种类和基于惯性传感器的采煤机姿态测量方法。分析MG500/1180WD滚筒式采煤机截割煤层时的振动加速度数据,得到其X、Y、Z三方向主振频率为0~30 Hz,三方向振动加速度范围分别为1~2、0.15~0.20、2~4 m/s2;其次,基于采煤机振动特性,提出了金属弹簧-可调摩擦阻尼单向减振器力学模型,建立了模型传递率方程。结合直线导轨机构设计了金属弹簧−可调摩擦阻尼三向减振装置。采用SolidWorks Motion建立了减振装置的仿真模型,通过仿真分析确定了减振装置的主要参数。最后,对减振装置进行了振动传递率仿真分析和试验测试,并使用惯性传感器验证其减振效果。仿真分析表明:在符合采煤机振动频率范围和振动加速度范围的振动条件下,设置减振装置可调摩擦阻尼为摩擦阻尼最大参考值的0.25~0.5倍,可得到较低的共振放大倍数和较低的振动传递率。试验结果表明:减振装置三方向的共振放大倍数低于4倍,10~30 Hz频率范围的激振下,平均振动传递率维持在45%以下。增加减振装置后可有效降低惯性传感器测量数据的波动量,三方向传感器姿态角标准差平均下降率分别为78.36%、36.96%、66.51%,具有明显的减振作用。

Abstract:Inertial sensor has become a hot spot in the research and application of shearer attitude measurement and underground autonomous navigation due to its distinct advantages. The inertial sensor is disturbed by the strong vibration of the shearer in practical application, and has the problems of poor measurement stability and low accuracy. A metal spring-adjustable friction damping three-way vibration damping device is developed to solve the above problems. Firstly, the types of inertial sensors and the attitude measurement method of shearers based on inertial sensors are introduced. The data of vibration acceleration of MG500/1180WD drum shearer when cutting coal seam are analyzed, the main vibration frequency inX,YandZdirections is 0-30 Hz, and the three-direction vibration acceleration ranges are 1-2 m/s2, 0.15-0.2 m/s2 and 2-4 m/s2, respectively. Secondly, based on the vibration characteristics of the shearer, the mechanical model of the metal spring-adjustable friction damping one-way vibration damper is proposed, and the model transmissibility equation is established. Combined with the linear guide mechanism, a metal spring-adjustable friction damping three-way vibration damping device is designed. SolidWorks Motion is used to establish the simulation model of the vibration reduction device, and the main parameters of the vibration reduction device are determined by the simulation analysis. Finally, the vibration transmittance simulation analysis and experimental test of the vibration isolation device are carried out, and the effect of vibration reduction is verified by using the inertial sensor. The simulation analysis shows that under the vibration conditions that conform to the vibration frequency range and vibration acceleration range of the shearer, the adjustable friction damping of the vibration damper is 0.25-0.5 times of the maximum reference value of the friction damping, and the lower resonance amplification times and the lower vibration transmission rate can be obtained. The experimental results show that the resonance amplification of the vibration damping device in three directions is less than 4 times. Under the excitation of 10-30Hz frequency range, the average vibration transmission rate remains below 45%. Adding vibration damping device can effectively reduce the fluctuation of the measured data of the inertial measuring unit. The average drop rate of attitude angle standard deviation of the three-direction sensors is 78.36%, 36.96% and 66.51% respectively, which has obvious vibration damping effect.

-

Keywords:

- vibration /

- shearer /

- inertial sensor /

- shock absorber

-

-

表 1 MG500/1180WD采煤机三方向振动参数

Table 1 Three-direction vibration parameters of MG500/1180WD shearer

采煤机振动方向 振动加速度范围/(m·s–2) 主振频率/Hz 牵引方向(X向) 1.00~2.00 11.23 截深方向(Y向) 0.15~0.20 11.57 垂直方向(Z向) 2.00~4.00 10.64 表 2 三向减振装置主要参数

Table 2 Main parameters of three-way damping device

减振装

置方向簧载质量/

kg弹性系数/

(N·mm–1)固有频率/

Hz摩擦阻尼

最大参考值/NX向 0.372 0.100 2.610 0.372 Y向 0.475 0.200 3.270 0.095 Z向 0.843 0.400 3.470 1.686 表 3 摩擦阻尼值设定

Table 3 Friction damping value setting

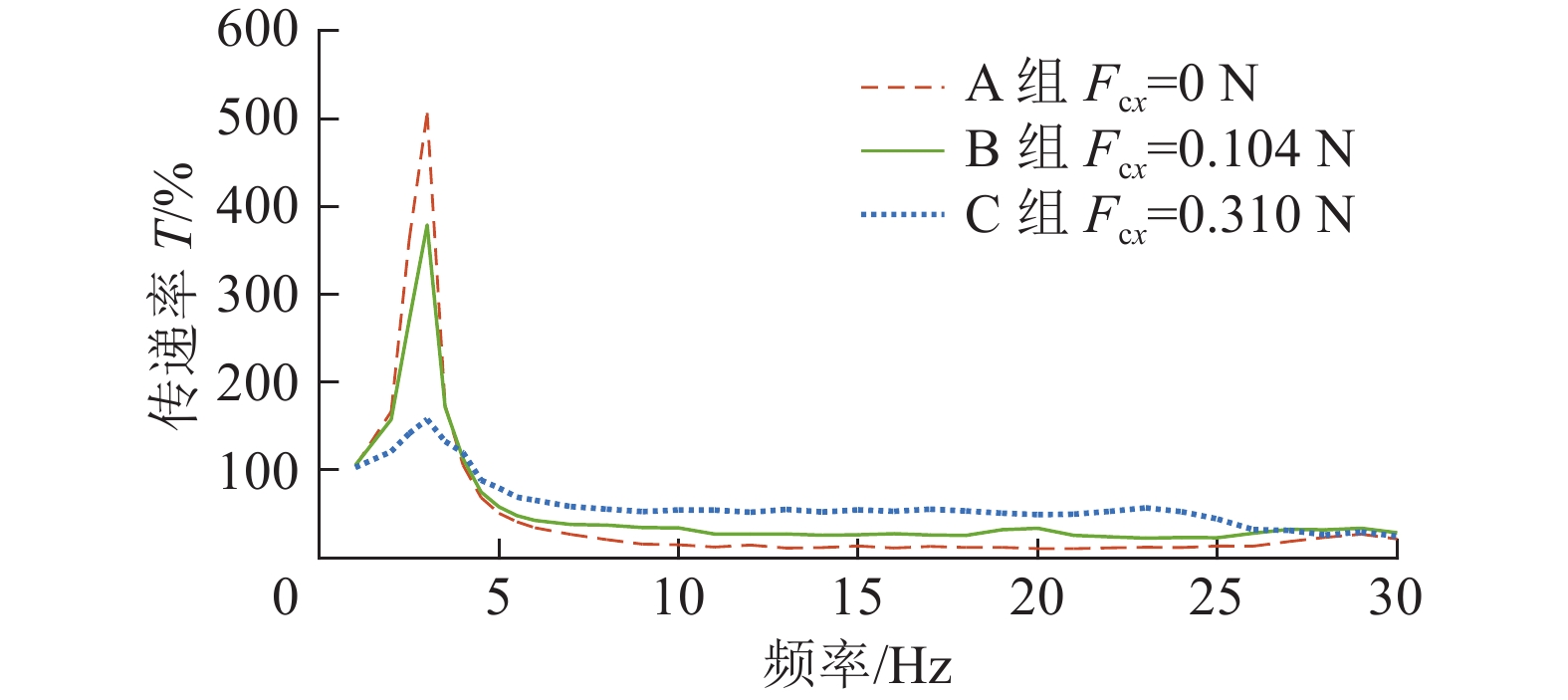

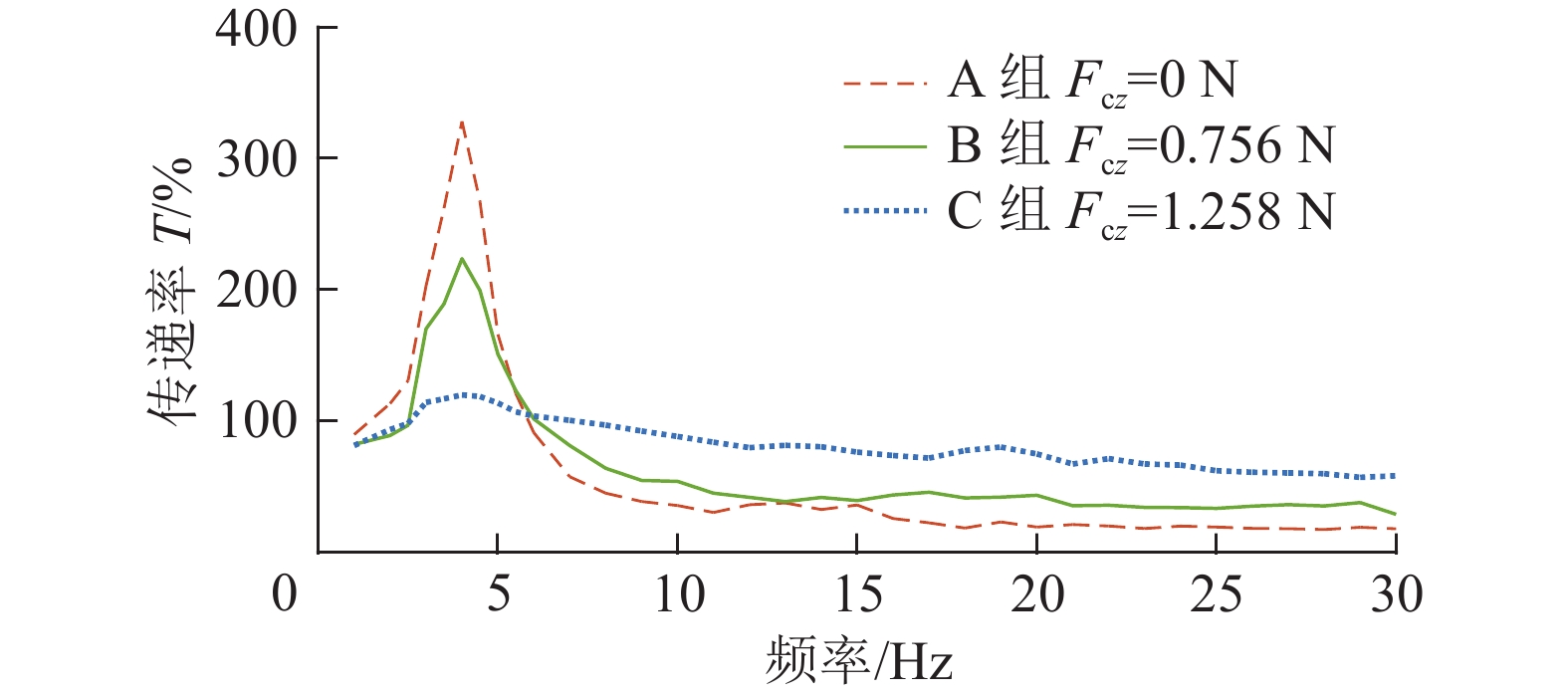

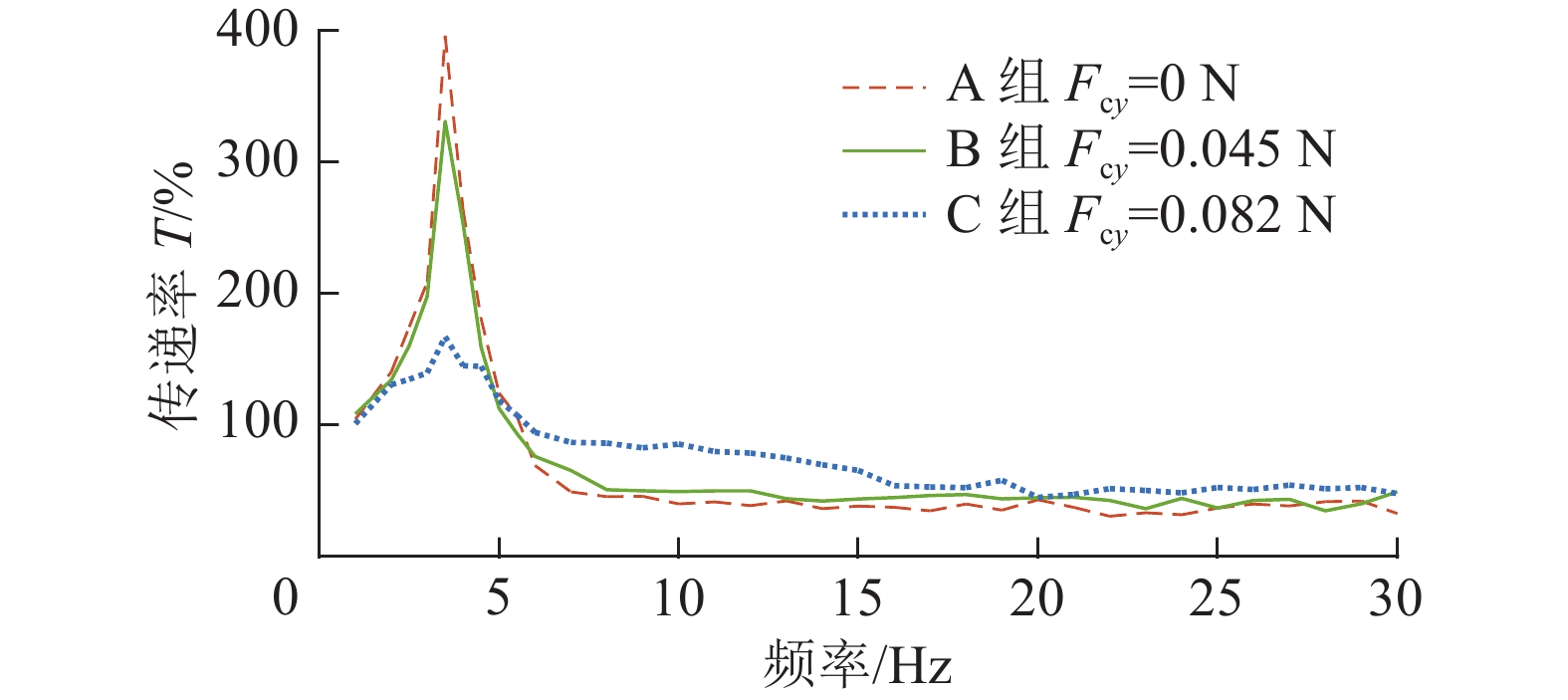

激振方向 摩擦阻尼Fc/N A组 B组 C组 X向 0.063 0.125 0.375 Y向 0.013 0.036 0.100 Z向 0.250 0.625 1.750 表 4 共振放大倍数与平均传递率

Table 4 Resonance amplification and average transmittance

激振方向 共振放大倍数 10~30 Hz平均传递率/% A组 B组 C组 A组 B组 C组 X向 6.019 3.105 1.000 24.44 45.29 102.45 Y向 8.522 5.951 1.000 21.91 57.29 99.19 Z向 7.136 3.383 1.000 22.84 49.48 100.55 表 5 摩擦阻尼值设定

Table 5 Friction damping value setting

激振方向 摩擦阻尼Fc/N A组 B组 C组 X向 0.000 0.104 0.310 Y向 0.000 0.045 0.082 Z向 0.000 0.756 1.258 表 6 共振放大倍数与平均传递率

Table 6 Resonance amplification and average transmittance

激振方向 共振放大倍数 10~30 Hz平均传递率/% A组 B组 C组 A组 B组 C组 X向 5.066 3.790 1.577 14.33 27.94 46.97 Y向 3.965 3.312 1.674 37.85 43.99 58.39 Z向 3.283 2.237 1.200 24.40 39.50 71.64 表 7 姿态角标准差与下降率

Table 7 Attitude angle standard deviation and descent rate

激振方向 姿态角 $ {S_{\mathrm{t}}} $/(°) $ {V_{\mathrm{i}}} $/(°) $ {A_{\mathrm{b}}} $/(°) $ {D_{\mathrm{e}}} $/% $ {D_{{\mathrm{ev}}}} $/% X向 α 0.007 0.325 0.024 94.55 78.36 β 0.010 0.028 0.015 70.95 γ 0.035 0.053 0.041 69.57 Y向 α 0.007 0.009 0.009 2.44 36.96 β 0.009 0.096 0.048 55.48 γ 0.041 0.050 0.045 52.95 Z向 α 0.008 0.010 0.008 65.74 66.51 β 0.010 0.014 0.012 40.69 γ 0.040 0.080 0.043 93.10 -

[1] 王国法,杜毅博,徐亚军,等. 中国煤炭开采技术及装备50年发展与创新实践−纪念《煤炭科学技术》创刊50周年[J]. 煤炭科学技术,2023,51(1):1−18. WANG Guofa,DU Yibo,XU Yajun,et al. Development and innovation practice of China coal mining technology and equipment for 50 years: Commemorate the 50th anniversary of the publication of Coal Science and Technology[J]. Coal Science and Technology,2023,51(1):1−18.

[2] 王国法,任怀伟,庞义辉,等. 煤矿智能化(初级阶段)技术体系研究与工程进展[J]. 煤炭科学技术,2020,48(7):1−27. WANG Guofa,REN Huaiwei,PANG Yihui,et al. Research and engineering progress of intelligent coal mine technical system in early stages[J]. Coal Science and Technology,2020,48(7):1−27.

[3] 王国法,徐亚军,张金虎,等. 煤矿智能化开采新进展[J]. 煤炭科学技术,2021,49(1):1−10. WANG Guofa,XU Yajun,ZHANG Jinghu,et al. New development of intelligent mining in coal mines[J]. Coal Science and Technology,2021,49(1):1−10.

[4] 任怀伟,赵国瑞,周 杰,等. 智能开采装备全位姿测量及虚拟仿真控制技术[J]. 煤炭学报,2020,45(3):956−971. REN Huaiwei,ZHAO Guorui,ZHOU Jie,et al. Key technologies of all position and orientation monitoring and virtual simulation and control for smart mining equipment[J]. Journal of China Coal Society,2020,45(3):956−971.

[5] 李 曼,郑思雨,刘浩东,等. 采煤机滚筒高度测量传感器工作环境磁场仿真与屏蔽研究[J]. 煤炭科学技术,2022,50(8):204−209. LI Man,ZHENG Siyu,LIU Haodong,et al. Study on magnetic field simulation and shielding design of shearer drum height measurement sensor working environment[J]. Coal Science and Technology,2022,50(8):204−209.

[6] 崔 耀,叶 壮. 基于5G+云边端协同技术的采煤机智能调高调速 控制系统设计与应用[J]. 煤炭科学技术,2023,51(6):205−216. doi: 10.13199/j.cnki.cst.2022-1017 CUI Yao,YE Zhuang. Research on cloud-edge-terminal collaborative intelligent control of coal shearer based on 5G communication[J]. Coal Science and Technology,2023,51(6):205−216. doi: 10.13199/j.cnki.cst.2022-1017

[7] 葛世荣,郝雪弟,田 凯,等. 采煤机自主导航截割原理及关键技术[J]. 煤炭学报,2021,46(3):774−788. GE Shirong,HAO Xuedi,TIAN Kai,et al. Principle and key technology of autonomous navigation cutting for deep coal seam[J]. Journal of China Coal Society,2021,46(3):774−788.

[8] 吴 刚. 基于捷联惯导的采煤机运行姿态高精度感知理论与技术研究[D]. 徐州:中国矿业大学,2020:73−86. WU Gang. Research on high precision sensing theory and technology of shearer operating attitude based on SINS[D]. Xuzhou:China University of Mining and Technology,2020:73−86.

[9] 杨盛林,芈小龙,王晓丹,等. 基于橡胶等效动态模量的惯导减振装置设计方法[J]. 中国惯性技术学报,2019,27(5):695−700. YANG Shenglin,MI Xiaolong,WANG Xiaodan,et al. A design method of inertial navigation’s damping device based on rubber equivalent dynamic Young’s Modulus[J]. Journal of Chinese Inertial Technology,2019,27(5):695−700.

[10] 王 平,张广鹏,尉飞等. 无人机惯导减振系统设计及其支架拓扑优化[J]. 机械科学与技术,2018,37(11):1744−1749. WANG Ping,ZHANG Guangpeng,WEI Fei,et al. Vibration isolation design and bracket topology optimization for UAV inertial navigation system[J]. Mechanical Science and Technology for Aerospace Engineering,2018,37(11):1744−1749.

[11] 孙丽艳,张 帅,杨 亮,等. MEMS惯性测量单元减振系统仿真分析[J]. 导航与控制,2016,15(2):36−39,35. SUN Liyan,ZHANG Shuai,YANG Liang,et al. Simulation of an isolation system for MEMS inertial measurement unit[J]. Navigation and Control,2016,15(2):36−39,35.

[12] 屈进红,王 明,姜作喜,等. 航空重力仪两级减振系统设计与研究[J]. 振动与冲击,2022,41(11):97−103. QU Jinhong,WANG Ming,JIANG Zuoxi,et al. Design and study of two-stage vibration reduction system of airborne gravimeter[J]. Journal of Vibration and Shock,2022,41(11):97−103.

[13] 罗 华,肖 凯,余 鲲,等. 惯组减振系统设计及试验研究[J]. 压电与声光,2021,43(3):402−405. LUO Hua,XIAO Kai,YU Kun,et al. Design and experimental study on vibration damping system for IMU[J]. Piezoelectrics and Acoustooptics,2021,43(3):402−405.

[14] 黄 帅. 船用惯性导航设备缓冲系统设计[J]. 机床与液压,2021,49(22):133−136. HUANG Shuai. Design of anti-shocking system for marine inertial navigation equipment[J]. Machine Tool and Hydraulics,2021,49(22):133−136.

[15] 李博恒. 地下掘进机惯导设备减振系统设计与实现[D]. 武汉:华中科技大学,2021:57−65. LI Boheng. Design and implementation of vibration isolation system for inertial navigation equipment of underground roadheader[D]. Wuhan:Huazhong University of Science and Technology,2021:57−65.

[16] ZHANG Xiaoli,YAO Guo,ZHANG Yimin. Nonlinear multi body dynamic modeling and vibration analysis of a double drum coal shearer[J]. Journal of Central South University,2021,28(7):2120−2130. doi: 10.1007/s11771-021-4757-z

[17] 赵丽娟,孙国强. 基于双向耦合的采煤机截割部振动特性研究[J]. 机械设计,2021,38(2):29−34. ZHAO Lijuan,SUN Guoqiang. Research on the vibration characteristics of the shearer’s cutting section based on two-way coupling[J]. Journal of Machine Deign,2021,38(2):29−34.

[18] 白杨溪,陈洪月,陈洪岩,等. 多约束条件下采煤机摇臂横向振动分析及试验验证[J]. 工程设计学报,2020,27(6):707−712. BAI Yangxi,CHEN Hongyue,CHEN Hongyan,et al. Analysis and test verification of transverse vibration of shearer rocker arm under multiple constraints[J]. Chinese Journal of Engineering Design,2020,27(6):707−712.

[19] 中国矿业大学. 综采工作面采煤机定位装置及定位方法[P]. 中国:CN201110053172.1,2011-09-14. China University of Mining and Technology. Positioning device and method of shearer in fully mechanized mining face[P]. China:CN201110053172.1,2011-09-14.

[20] 张建文,谭得健,于 江,等. 电牵引采煤机振动特性分析[J]. 煤矿机电,2006(4):35−37. ZHANG Jianwen,TAN Dejian,YU Jiang,et al. Vibration characteristic analysis of electro-haulage shearer[J]. Colliery Mechanical and Electrical Technology,2006(4):35−37.

[21] 吴 含. 不同采高下对MG300/730-WD型采煤机截割部模态的仿真与分析[D]. 阜新:辽宁工程技术大学,2015:13−14. WU Han. Simulation and analysis on MG300/730-WD shearer cutting unit mode under different mining height[D]. Fuxin:Liaoning Technical University,2015:13−14.

[22] 白杨溪,陈洪月,陈洪岩,等. 基于滚筒载荷的采煤机滑靴振动分析及实验验证[J]. 工程设计学报,2021,28(3):358−366. BAI Yangxi,CHEN Hongyue,CHEN Hongyan,et al. Vibration analysis and experimental verification of shearer sliding shoes based on drum load[J]. Chinese Journal of Engineering Design,2021,28(3):358−366.

[23] 杨辛未. 采煤机整机动力学特性研究[D]. 阜新:辽宁工程技术大学,2019:96−100. YANG Xinwei. Dynamic characteristics research of shearer[D]. Fuxin:Liaoning Technical University,2019:96−100.

[24] 陈洪月,白杨溪,毛 君,等. 多激励下采煤机在行走平面内的非线性振动特性分析[J]. 机械设计与研究,2016,32(2):166−170,174. CHEN Hongyue,BAI yangxi,MAO Jun,et al. Nonlinear vibration of shearer in walk plane under multiple excitation[J]. Machine Design and Research,2016,32(2):166−170,174.

[25] 余慧杰,常 维. 干摩擦阻尼隔振系统等效阻尼确定方法[J]. 农业装备与车辆工程,2018,56(9):41−44. YU Huijie,CHANG Wei. Method to obtain equivalent damping of dry friction vibration isolation system[J]. Agricultural Equipment and Vehicle Engineering,2018,56(9):41−44.

[26] 骆 号,陈建松,颜肖龙. GWF型隔振器性能分析与实验验证[J]. 噪声与振动控制,2012,32(4):178−182. LUO Hao,CHEN Jiansong,YAN Xiaolong. Performance analysis and experimental verification of GWF vibration isolator[J]. Noise and Vibration Control,2012,32(4):178−182.

[27] 宁月光,贾新强. 机载惯导系统减振设计[J]. 现代导航,2015,6(6):497−501. NING Yueguang,JIA Xinqiang. Damping design of airborne inertial navigation system[J]. Modern Navigation,2015,6(6):497−501.

[28] LI Man,ZHENG Siyu,LIU Junqi,et al. Improvement of measurement method and design of intelligent sensor for shearer drum height[J]. IEEE Sensors Journal,2022,22(14):13981−13988. doi: 10.1109/JSEN.2022.3181824

下载:

下载: