Experimental study on characterization hydraulic fracturing coal fracture network and evolution of fracture forming performance

-

摘要:

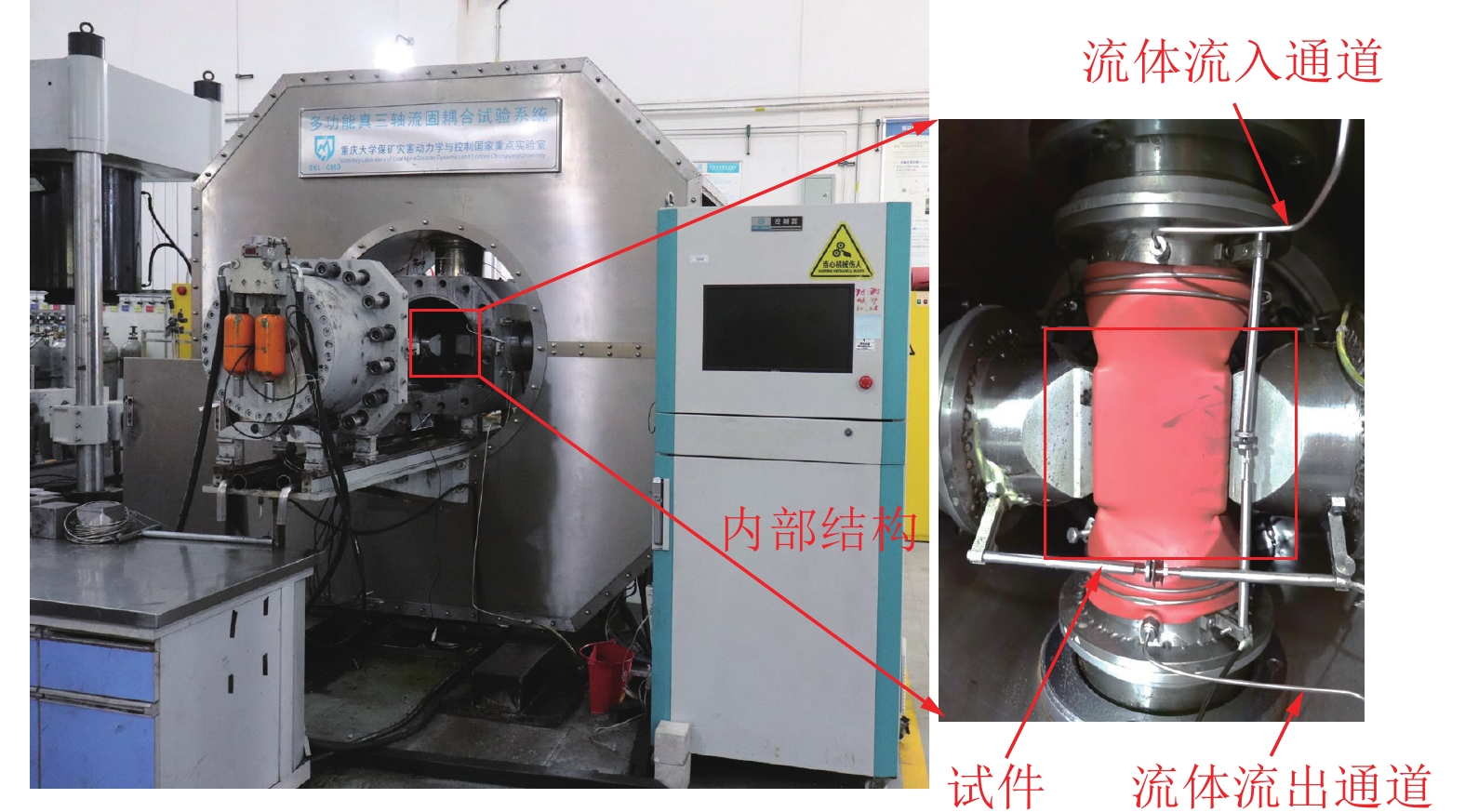

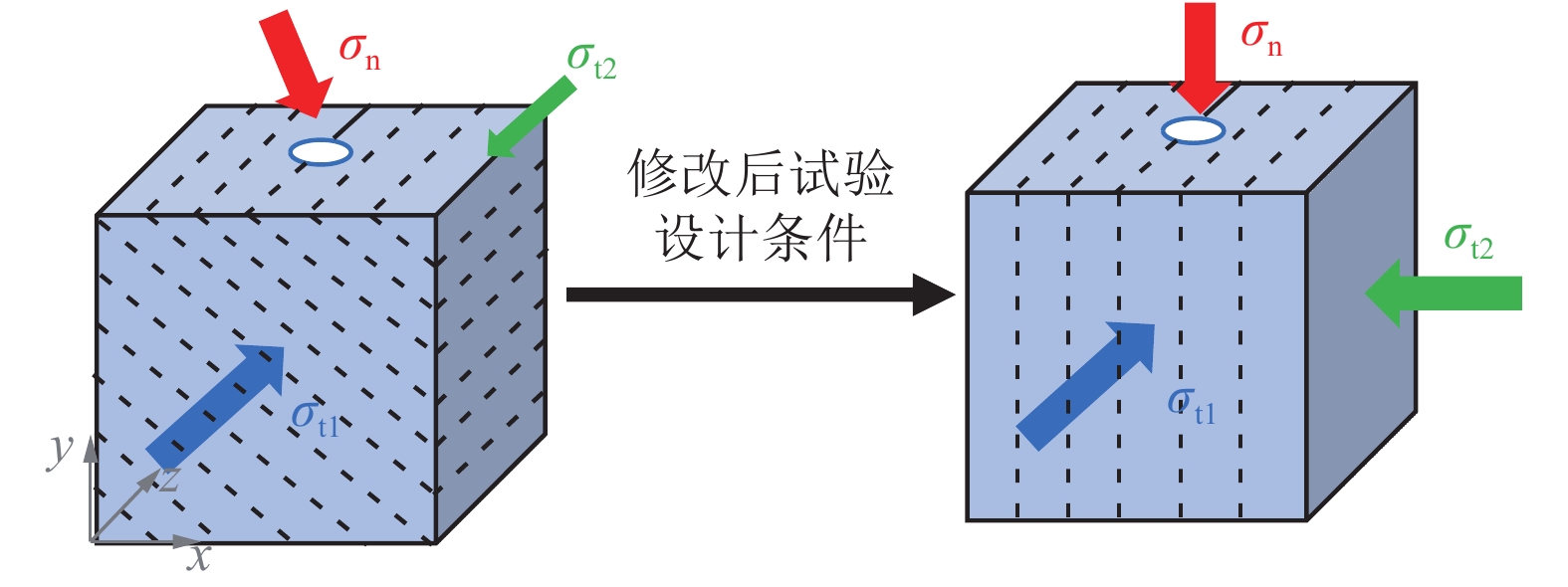

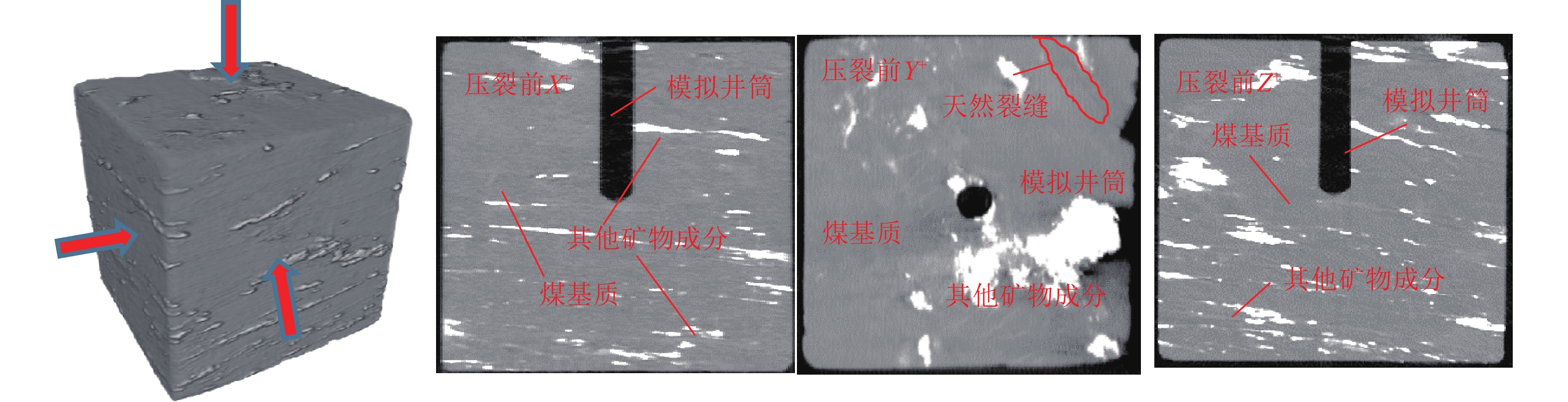

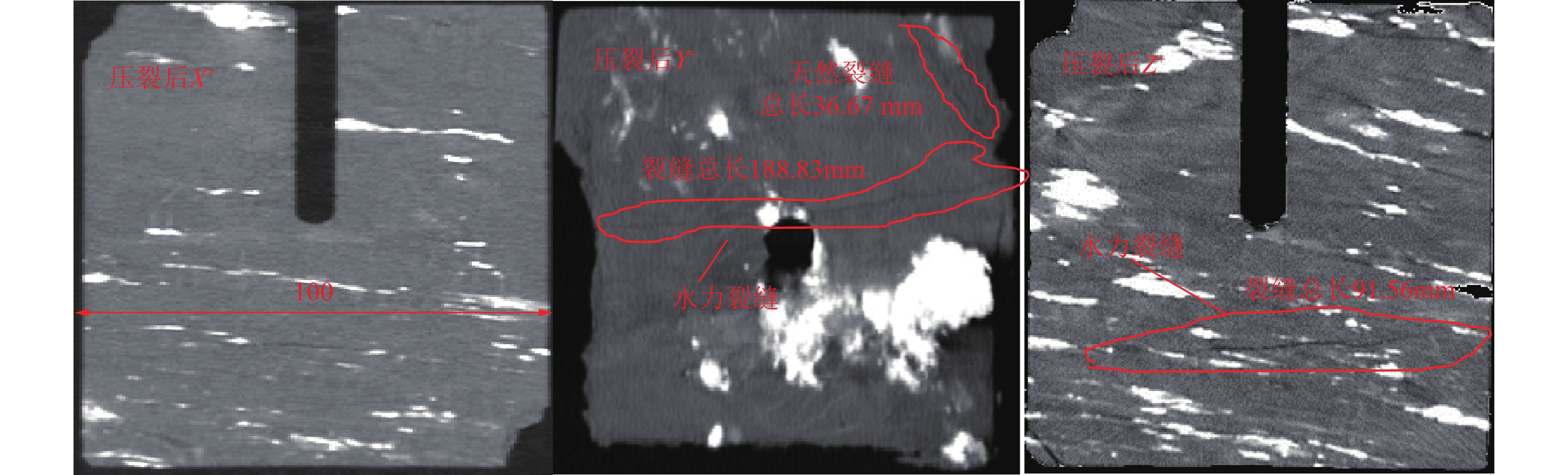

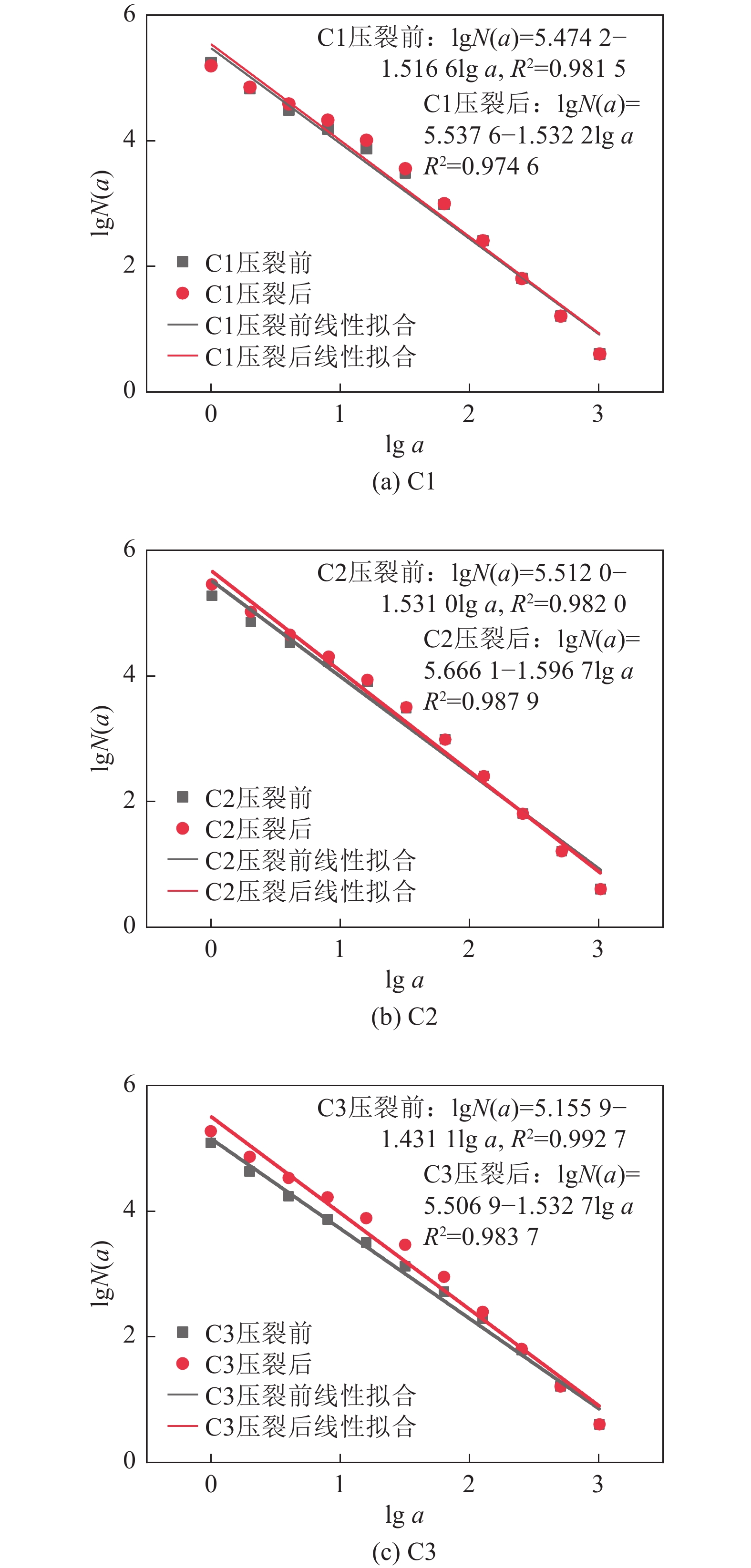

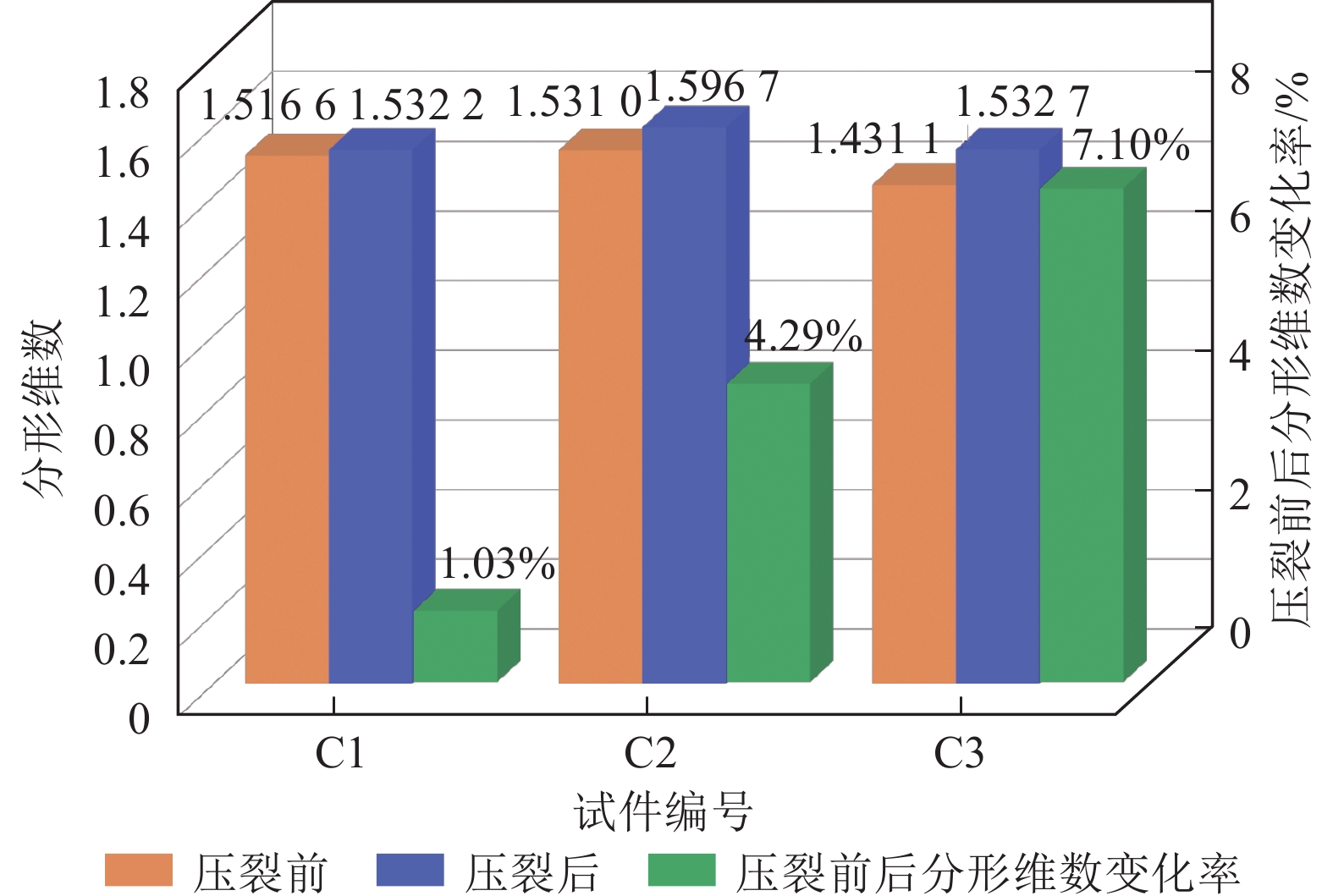

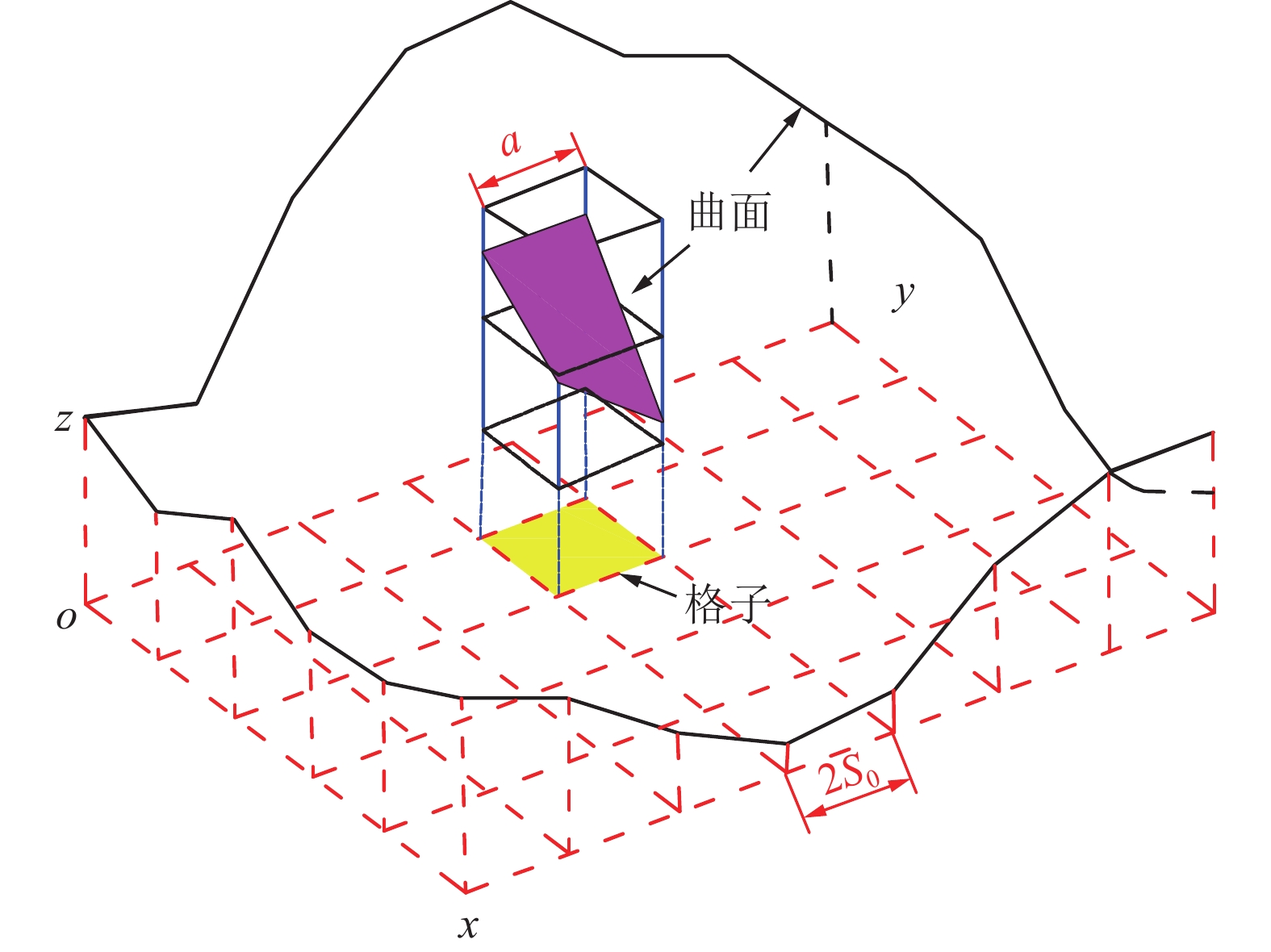

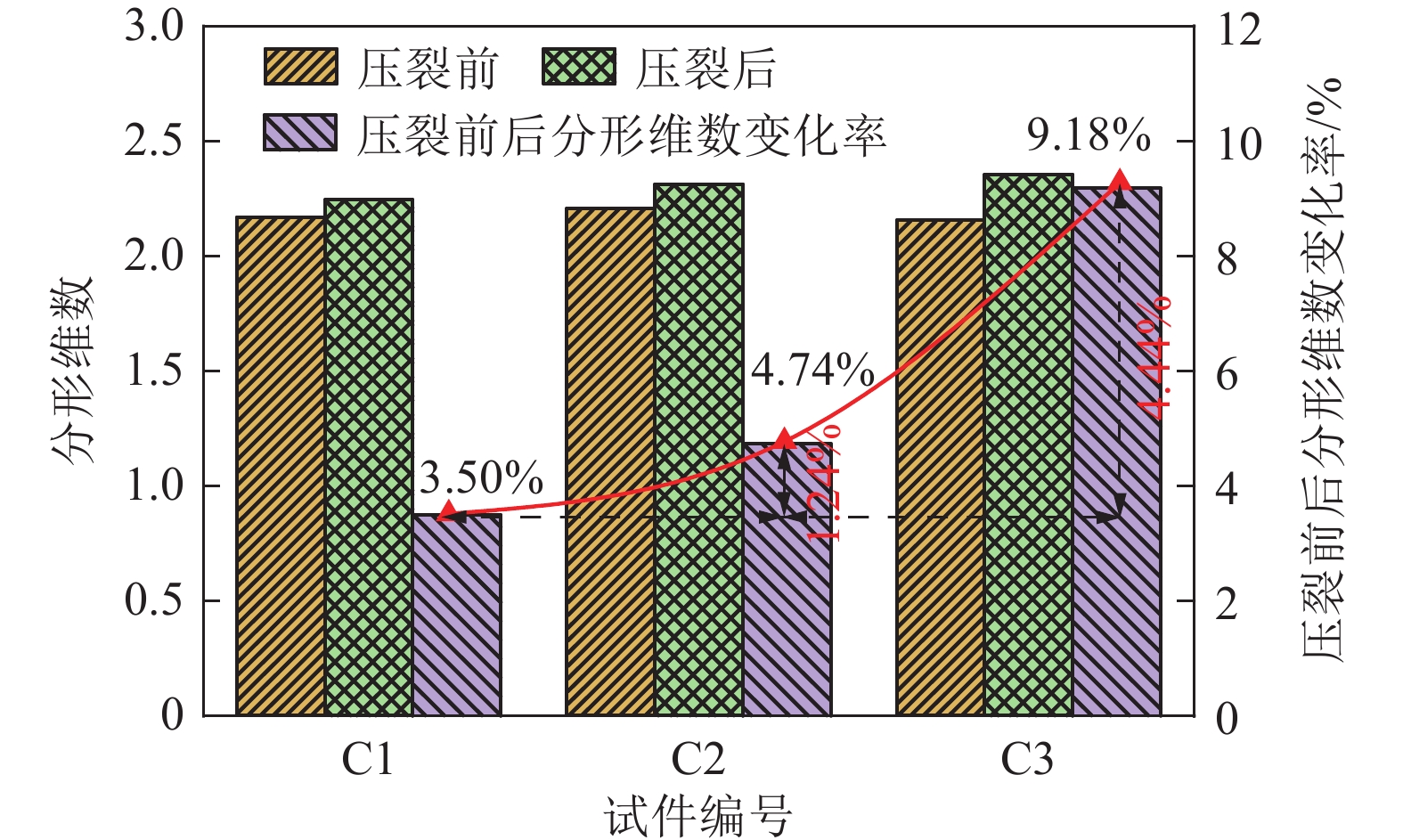

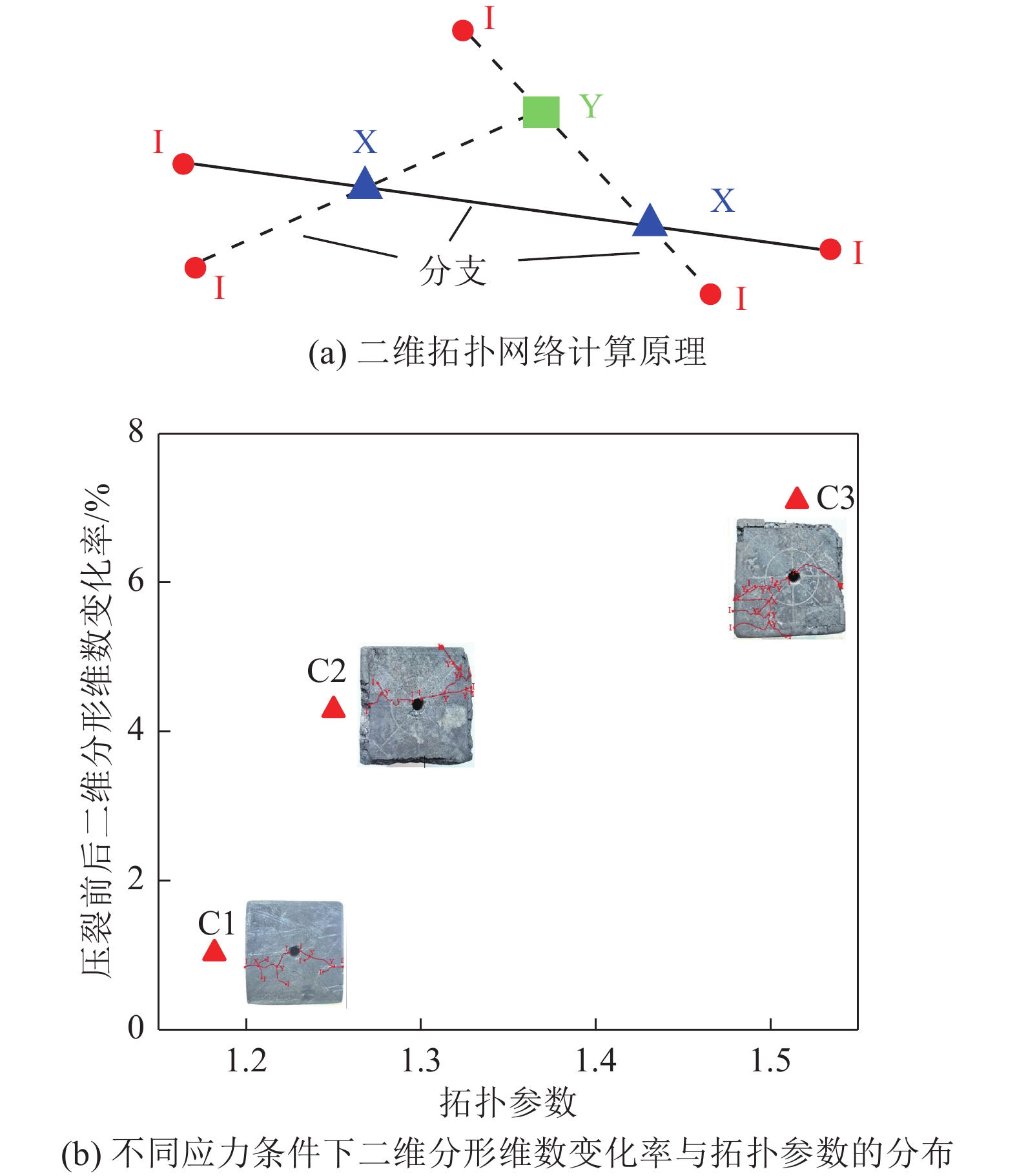

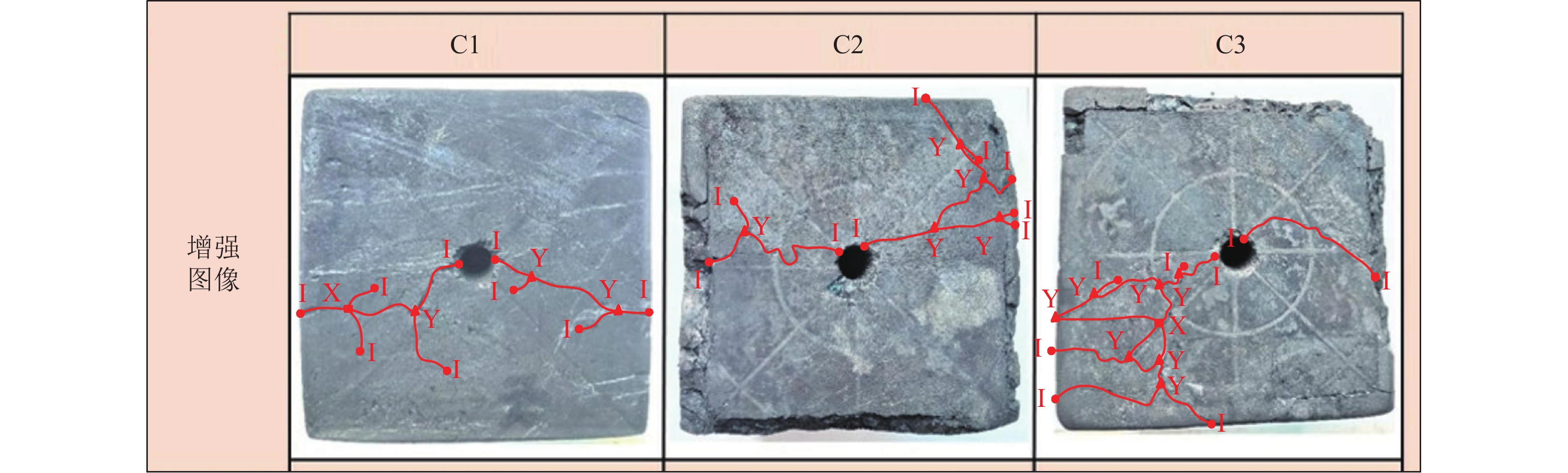

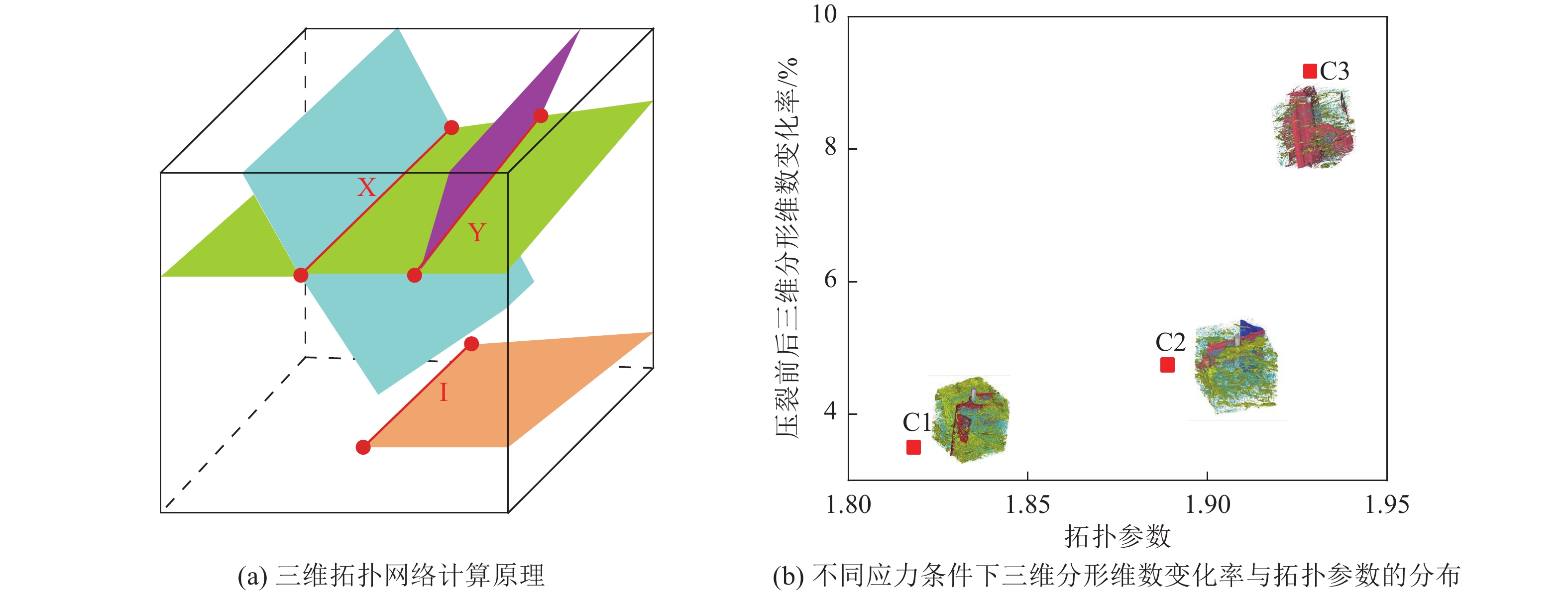

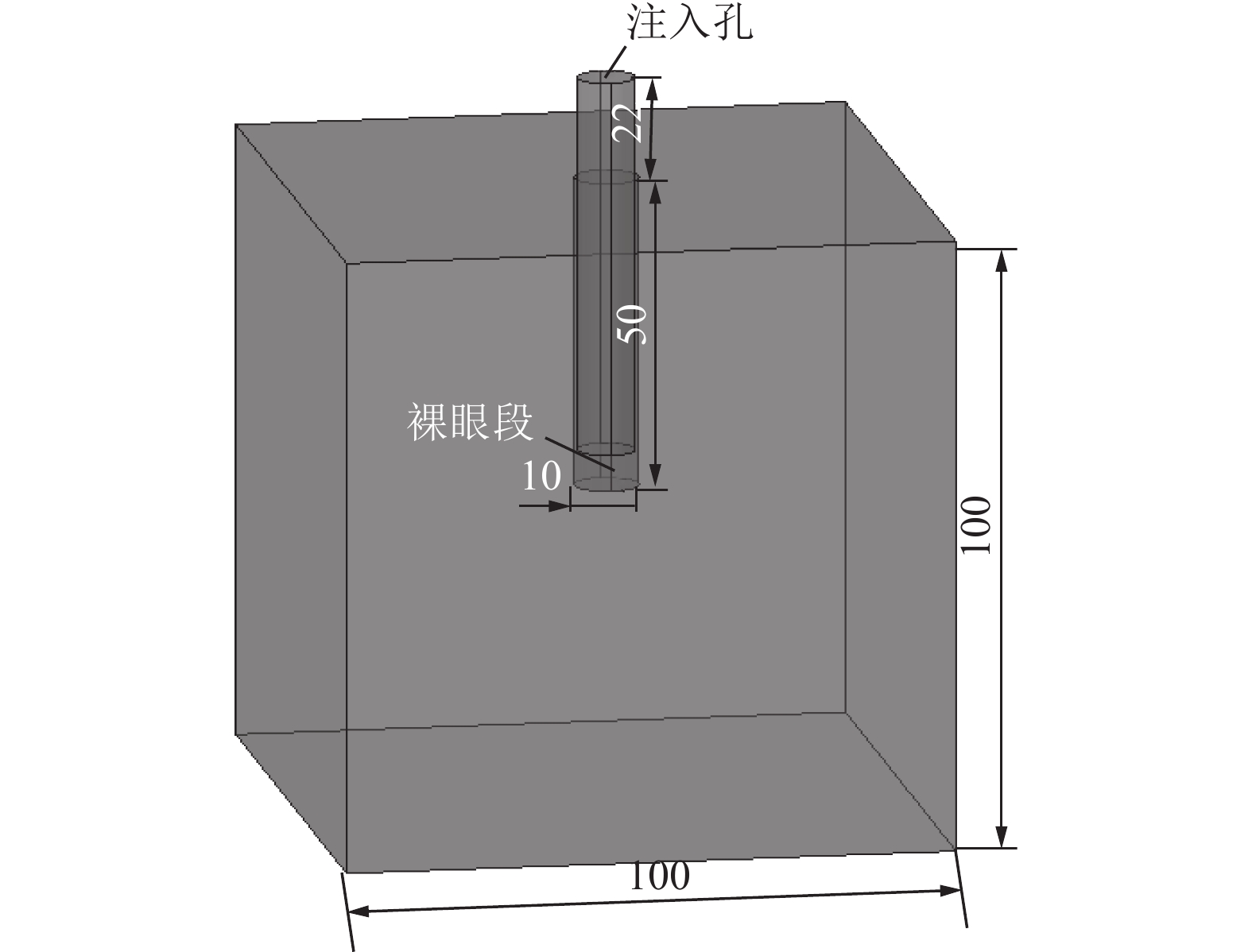

煤裂隙网络的准确表征可以有效评估深部煤层经水力压裂后的压裂效果,为了定量评估煤层经水力压裂后的复杂程度,利用自制的真三轴试验系统进行了煤的水力压裂试验,结合CT扫描,重建了具有拓扑结构的孔裂隙网络,用分形理论和拓扑学定量表征了断裂网络的复杂程度。探究了在真三轴应力条件下,中间主应力对裂缝网络复杂程度的影响。结果表明:压裂后煤样的二维分形维数变化率K为1.03%~7.10%,三维分形维数的变化率为3.50%~9.18%,经过水力压裂后煤样的二维和三维分形维数均显著增大。基于分形理论和拓扑学的方法能有效表征水力压裂的裂缝结构和造缝能力。压裂后煤样的二维拓扑参数为1.18~1.52,与压裂前后煤样的二维分形维数变化率呈正相关关系,二维分形维数变化率的增加速率随着拓扑参数的增大逐渐减小。重构的内部结构和裂缝分布表明,压裂后的三维分形维数比二维分形维数更具优势,压裂后煤样的三维拓扑参数为1.82~1.93,随着三维分形维数变化率的增加而增大,三维分形维数变化率的增加速率随着拓扑参数的增大而增大。中间主应力对煤层的造缝能力存在积极影响。水力压裂前后的分形维数和拓扑参数都随着中间主应力的增大而增大,即随着中间主应力的增大而增大,产生的裂缝网络更复杂,连通性更好,水力压裂的造缝能力更强。

Abstract:The accurate characterization of coal fracture network can effectively evaluate the fracturing effect of the deep coal seam after hydraulic fracturing. In order to quantitatively evaluate the complexity of coal seam after hydraulic fracturing, the hydraulic fracturing test of coal was carried out by using the self-made true triaxial test system, combined with CT scan, the pore network and fracture network with topological structure are reconstructed, and the complexity of the fracture network is quantitatively characterized by fractal theory and topology. The effect of the intermediate principal stress on the complexity of the fracture networks under the condition of true triaxial stress is explored. The results showed that the change rate of the two-dimensional fractal dimension (K) are 1.03% ~ 7.10%, and the change rate of three-dimensional fractal dimension are 3.50% ~ 9.18%, the two-dimensional and three-dimensional fractal dimensions of coal samples after hydraulic fracturing increase significantly. The method based on fractal theory and topology can effectively characterize the fracture structure and fracture forming ability of hydraulic fracturing. The two-dimensional topological parameter of coal samples after fracturing are1.18 ~ 1.52, which is positively correlated with the change rate of two-dimensional fractal dimension.Increasing rate of change rate of two-dimensional fractal dimension decreases with the increase of topological parameters. The reconstructed internal structure and fracture distribution showed that the three-dimensional fractal dimension after fracturing is more advantaged than the two-dimensional fractal dimension. The three-dimensional topological parameters of coal samples after fracturing are 1.82-1.93, increased with the increase of the change rate of three-dimensional fractal dimension. The intermediate principal stress has a positive effect on the seam forming ability of coal seam. The fractal dimension and topological parameters increase with the increase of intermediate principal stress before and after hydraulic fracturing. In other words, Increased with the intermediate principal stress, the resulting fracture network is more complex, the connectivity is better, and the fracture forming ability of hydraulic fracturing is stronger.

-

-

表 1 试样的物理力学性质

Table 1 Physical properties of samples

孔隙率/

%天然密度/

(g·m−3)抗拉强度/

MPa弹性模量/

GPa单轴抗压强度/

MPa6.021 1.756 1.743 5.49 10.43 表 2 真三轴水力压裂试验参数

Table 2 True triaxial hydraulic fracturing test parameters

试件

编号($ {\mathrm{\sigma }}_{\mathrm{t}1}/{\mathrm{\sigma }}_{\mathrm{n}}/{\mathrm{\sigma }}_{\mathrm{t}2} $)/

MPa垂向应力

差异系数水平应力

差异系数水平

应力比注入速度/

(mL·min−1)C1 25/40/20 1 0.25 1.25 60 C2 30/40/20 1 0.50 1.50 C3 35/40/20 1 0.75 1.75 注:垂向地应力差异系数$k_{\mathrm{v} }=\left(\sigma_{\rm{n}}-\sigma_{ {\rm{t} } 2}\right) / \sigma_{ {\rm{t} } 2}$;水平应力差异系数$k_{\mathrm{H}}=\left(\sigma_{{\rm{t}} 1}-\sigma_{{\rm{t}} 2}\right) / \sigma_{{\rm{t}} 2}$。 表 3 煤样裂缝的相关参数

Table 3 Relevant parameters of coal cracks

试件

编号压裂前裂缝数量 压裂后裂缝数量 压裂后裂缝形态 C1 0 7 主裂缝为弧形裂缝 C2 1 7 主裂缝为横向贯穿裂缝 C3 0 8 网状裂缝网络 表 4 压裂前后煤样的三维分形维数

Table 4 Three-dimensional fractal dimension of coal samples before and after hydraulic

试件编号 Da Db K/% 水平应力比 C1 2.167 72 2.24369 3.50 1.25 C2 2.206 16 2.31075 4.74 1.5 C3 2.155 92 2.35386 9.18 1.75 表 5 压裂前后煤样的二维拓扑参数

Table 5 Two dimensional topological parameters of coal samples be-fore and after hydraulic fracturing

试件

编号节点数量 Na Nb NI NX NY C1 9 1 3 11 1.18 C2 9 0 5 12 1.25 C3 8 1 7 16.5 1.52 表 6 压裂前后煤样的三维拓扑参数

Table 6 Three-dimensional topological parameters of coal samples before and after hydraulic

试件

编号节点数量 Na Nb NI NX NY C1 1 1 2 5.5 1.82 C2 1 1 3 7 1.86 C3 1 3 5 14 1.93 -

[1] 何利文. 煤矿回采工作面瓦斯涌出非线性特性分析及预测仿真理论研究[D]. 长沙: 中南大学, 2010. HE liwen. Study on nonlinear characteristic analysis and prediction simulation theory of gas emission in coal mining face[D]. Changsha: Central South University, 2010.

[2] 蒋长宝,余 塘,段敏克,等. 瓦斯压力和应力对裂隙影响下的渗透率模型研究[J]. 煤炭科学技术,2021,49(2):115−121. JIANG Changbao,YU Tang,DUAN Minke,et al. Study on permea-bility model under the influence of gas pressure and stress on fracture[J]. Coal Science and Technology,2021,49(2):115−121.

[3] CAO Yunxing,ZHANG Junsheng,ZHAI Hong,et al. CO2 gas fracturing: a novel reservoir stimulation technology in low permeability gassy coal seams[J]. Fuel,2017,203:197−207. doi: 10.1016/j.fuel.2017.04.053

[4] QIN Lei,ZHAI Cheng,XU Jizhao,et al. Evolution of the pore structure in coal subjected to freeze−thaw using liquid nitrogen to enhance coalbed methane extraction[J]. Journal of Petroleum Science and Engineering,2019,175:129−139. doi: 10.1016/j.petrol.2018.12.037

[5] 张凤婕,吴 宇,茅献彪,等. 煤层气注热开采的热-流-固耦合作用分析[J]. 采矿与安全工程学报,2012,29(4):505−510. ZHANG Fengjie,WU Yu,MAO Xianbiao,et al. Coupled ther-mal-hydrological-mechanical analysis of exploiting coal me-thane by heat injection[J]. Journal of Mining & Safety Engineering,2012,29(4):505−510.

[6] LI Quanshu,XING Huilin,LIU Jianjun,et al. A review on hydraulic fracturing of unconventional reservoir[J]. Petroleum,2015,1(1):8−15. doi: 10.1016/j.petlm.2015.03.008

[7] ALEXANDRINE Gesret, MARK Noble, NICOLAS Desassis, et al. Microseismic monitoring-consequences of velocity model uncertainties on event location uncertainties[C]. //Paper presented at the 75th EAGE Conference & Exhibition incorporating SPE EUROPEC, United Kingdom, 2013.

[8] CRAIG L Cipolla, WENG Xiaowei, MARK Gavin Mack, et al. Integrating microseismic mapping and complex fracture modeling to charac-terize fracture complexity [C]. //Paper presented at the SPE Hy-draulic Fracturing Technology Conference, The Woodlands, Texas, USA, 2011: 1-22.

[9] ANISH Singh Chaudhary. Shale oil production performance from a stim-ulated reservoir volume[D]. Texas A&M University, 2011.

[10] PAVEL Zuloaga-Molerol,YU Wei,XU Yifei,et al. Simulation study of CO2-EOR in tight oil reservoirs with complex fracture geome-tries[J]. Scientific Reports,2016,6(1):1−11. doi: 10.1038/s41598-016-0001-8

[11] 高金栋,周立发,冯 乔,等. 储层构造裂缝识别及预测研究进展[J]. 地质科技情报,2018,37(4):158−166. GAO Jindong,ZHOU Lifa,FENG Qiao,et al. Research progress of reservoir structural fracture identification and prediction[J]. Geological Science and Technology Information,2018,37(4):158−166.

[12] DAVID J. Sanderson, CASEY W. Nixon. The use of topology in fracture network characterization[J]. Journal of Structural Geology,2015,72:55−66. doi: 10.1016/j.jsg.2015.01.005

[13] CARDONA R,JENNER E,DAVIS T L. Fracture network characterization from P- and S-wave data at Weyburn field, Canada[J]. Seg Expanded Ab-stracts,2003(1):370.

[14] 赵海燕,宫伟力. 基于图像分割的煤岩割理CT图像各向异性特征[J]. 煤田地质与勘探,2009,37(6):14−18. ZHAO Haiyan,GONG Weili. Anisotropic characteristics of coal and rock cleat CT image based on image segmentation[J]. Coal Geology & Exploration,2009,37(6):14−18.

[15] 康天合,赵阳升,靳钟铭. 煤体裂隙尺度分布的分形研究[J]. 煤炭学报,1995,20(4):393−398. doi: 10.3321/j.issn:0253-9993.1995.04.019 KANG Tianhe,ZHAO Yangsheng,JIN Zhongming. Fractal study on scale distribution of coal fractures[J]. Journal of China Coal Society,1995,20(4):393−398. doi: 10.3321/j.issn:0253-9993.1995.04.019

[16] FU Xuehai,QIN Yong,ZHANG Wanhong,et al. Fractal classification and natural classification of coal pore structure based on migration of coal bed methane[J]. Chinese Science Bulletin,2005,50:66−71.

[17] CAO Taotao,SONG Zhiguang,WANG Sibo,et al. Characterization of pore structure and fractal dimension of Paleozoic shales from the northeastern Sichuan Basin, China[J]. Journal of Natural Gas Science and Engineering,2016,35:882−895. doi: 10.1016/j.jngse.2016.09.022

[18] XIA Yuxuan,CAI Jianchao,WEI Wei,et al. A new method for calculating fractal dimensions of porous media based on pore size distribu-tion[J]. Fractals,2018,26(1):1850006. doi: 10.1142/S0218348X18500068

[19] 李廷芥,王耀辉,张梅英,等. 岩石裂纹的分形特性及岩爆机理研究[J]. 岩石力学与工程学报,2000,19(1):6−10. LI Tingjie,WANG Yaohui,ZHANG Meiying,et al. Fractal properties of crack in rock and mechanism of rock-burst[J]. Chinese Journal of Rock Mechanics and Engineering,2000,19(1):6−10.

[20] LIU Xianfeng,NIE Baisheng. Fractal characteristics of coal samples utilizing image analysis and gas adsorption[J]. Fuel,2016,182:314−322. doi: 10.1016/j.fuel.2016.05.110

[21] JIANG Changbao,NIU Bingwei,YIN Guangzhi,et al. CT-based 3D re-construction of the geometry and propagation of hydraulic frac-turing in shale[J]. Journal of Petroleum Science and Engineering,2019,179:899−911. doi: 10.1016/j.petrol.2019.04.103

[22] HE Qiang,HE Bo,LI Fengxia,et al. Fractal characterization of complex hydraulic fractures in oil shale via topology[J]. Energies,2021,14(4):1123−1141. doi: 10.3390/en14041123

[23] LIU Peng,JU Yang,GAO Feng,et al. CT identification and fractal char-acterization of 3D propagation and distribution of hydrofracturing cracks in low-permeability heterogeneous rocks[J]. Journal of Geophysical Research:Solid Earth,2018,123(3):2156−2173. doi: 10.1002/2017JB015048

[24] LIU Peng,JU Yang,PATHEGAMA G Ranjith,et al. Experimental investi-gation of the effects of heterogeneity and geostress difference on the 3D growth and distribution of hydrofracturing cracks in uncon-ventional reservoir rocks[J]. Journal of Natural Gas Science and Engineering,2016,35:541−554. doi: 10.1016/j.jngse.2016.08.071

[25] JU Yang,HUANG Yaohui,SU Sun,et al. Three-dimensional numerical reconstruction method for irregular structures of granular geo-materials[J]. Geomechanics and Geophysics for Geo-Energy and Geo-Resources,2018,4:327−341. doi: 10.1007/s40948-018-0089-3

[26] PENG Ruidong,YANG Yancong,JU Yang,et al. Computation of fractal dimension of rock pores based on gray CT images[J]. Chinese Science Bulletin,2011,56(31):3346−3357. doi: 10.1007/s11434-011-4683-9

[27] DUAN Minke,JIANG Changbao,GAN Quan,et al. Study on permeability anisotropy of bedded coal under true triaxial stress and its appli-cation[J]. Transport in Porous Media,2020,131:1007−1035. doi: 10.1007/s11242-019-01375-y

[28] JU Yang,ZHENG Jiangtao,MARCELO Epstein,et al. 3D numerical recon-struction of well-connected porous structure of rock using fractal algorithms[J]. Computer Methods in Applied Mechanics & En-gineering,2014,279:212−226.

[29] ANWAR S Al-Kharusi,MARTIN J Blunt. Network extraction from sandstone and carbonate pore space images[J]. Journal of Petroleum Science and Engineering,2007,56(4):219−231. doi: 10.1016/j.petrol.2006.09.003

[30] LI Minghui,YIN Guangzhi,XU Jiang,et al. A novel true triaxial apparatus to study the geomechanical and fluid flow aspects of energy exploitations in geological formations[J]. Rock Me-chanics and Rock Engineering,2016,49:4647−4659. doi: 10.1007/s00603-016-1060-7

[31] 袁 亮. 深部采动响应与灾害防控研究进展[J]. 煤炭学报,2021,46(3):716−725. YUAN Liang. Research progress of deep mining response and disaster prevention and control[J]. Journal of China Coal Society,2021,46(3):716−725.

[32] JANG Changbao,LIU Xiaodong,WANG Wengsong,et al. Three-dimensional visualization of the evolution of pores and fractures in reservoir rocks under triaxial stress[J]. Powder Technology,2021,378:585−592. doi: 10.1016/j.powtec.2020.10.013

[33] AI Ting,ZHANG Ru,ZHOU Hongwei,et al. Box-counting methods to directly estimate the fractal dimension of a rock surface[J]. Applied Surface Science,2014,314:610−621. doi: 10.1016/j.apsusc.2014.06.152

[34] WU Mingyang,WANG Wensong,SHI Di,et al. Improved box-counting methods to directly estimate the fractal dimension of a rough surface[J]. Measurement,2021,177:109303. doi: 10.1016/j.measurement.2021.109303

[35] CHINMAYA Panigrahy,AYAN Seal,NIHAR Kumar Mahato,et al. Differential box counting methods for estimating fractal dimension of gray-scale images: a survey[J]. Chaos, Solitons and Fractals,2019,126:178−202. doi: 10.1016/j.chaos.2019.06.007

[36] 莫海涛,郝世俊,赵江鹏. 煤矿区地面大直径钻孔成孔关键技术与装备[J]. 煤炭科学技术,2021,49(5):190−197. MO Haitao,HAO Shijun,ZHAO Jiangpeng. Key technology and equipment of hole-forming for surface large diameter borehole in coal mine area[J]. Coal Science and Technology,2021,49(5):190−197.

[37] 李波波,王斌,杨康,等. 煤岩孔裂隙结构分形特征及渗透率模型研究[J]. 煤炭科学技术,2021,49(2):226−231. LI Bobo,WANG Bin,YANG Kang,et al. Study on fractal characteristics of coal and rock pore fissure structure and permeability model[J]. Coal Science and Technology,2021,49(2):226−231.

下载:

下载: