Surface deformation field and fracture propagation mechanism of rock-like specimen with pre-existing fracture

-

摘要:

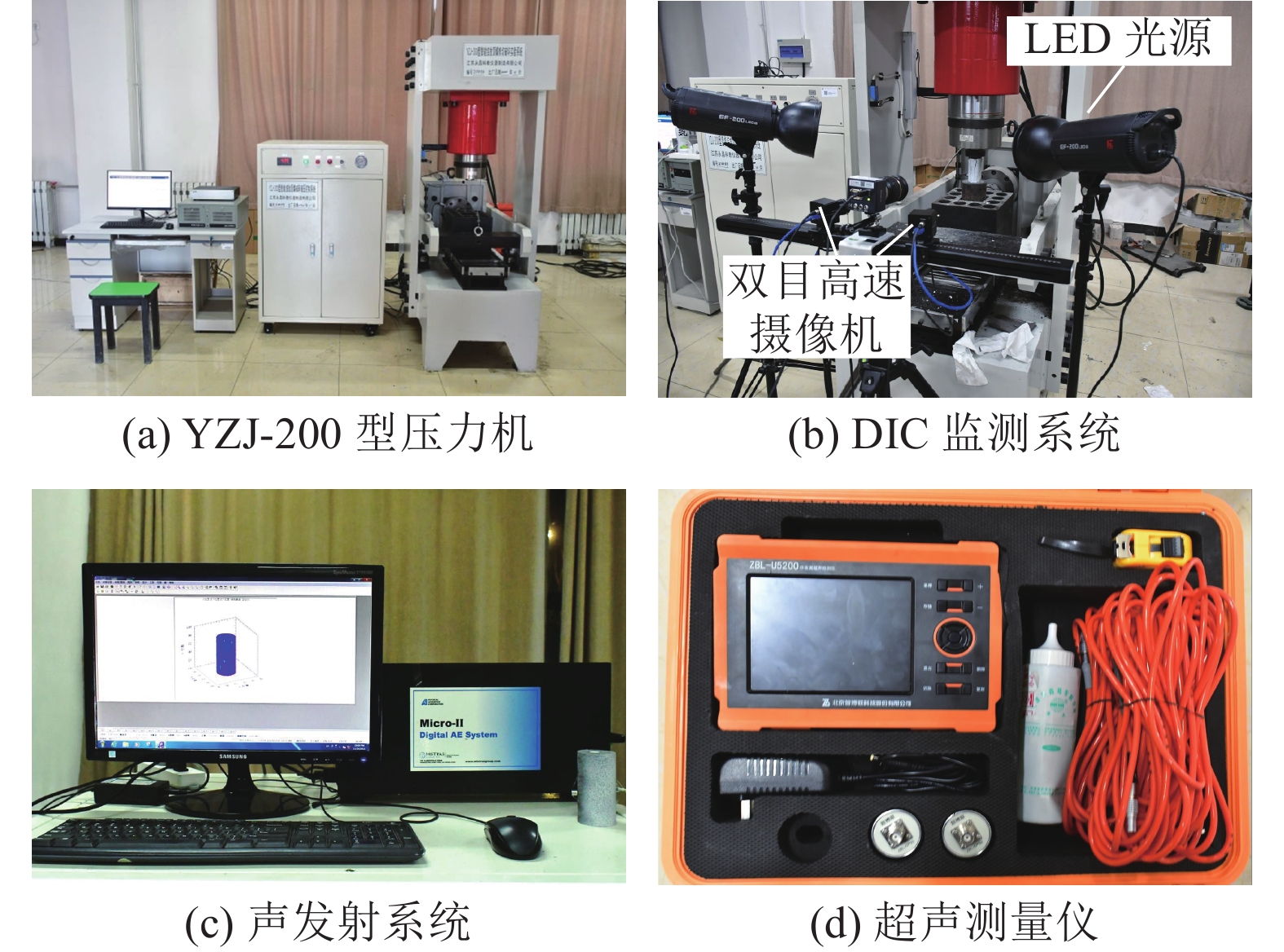

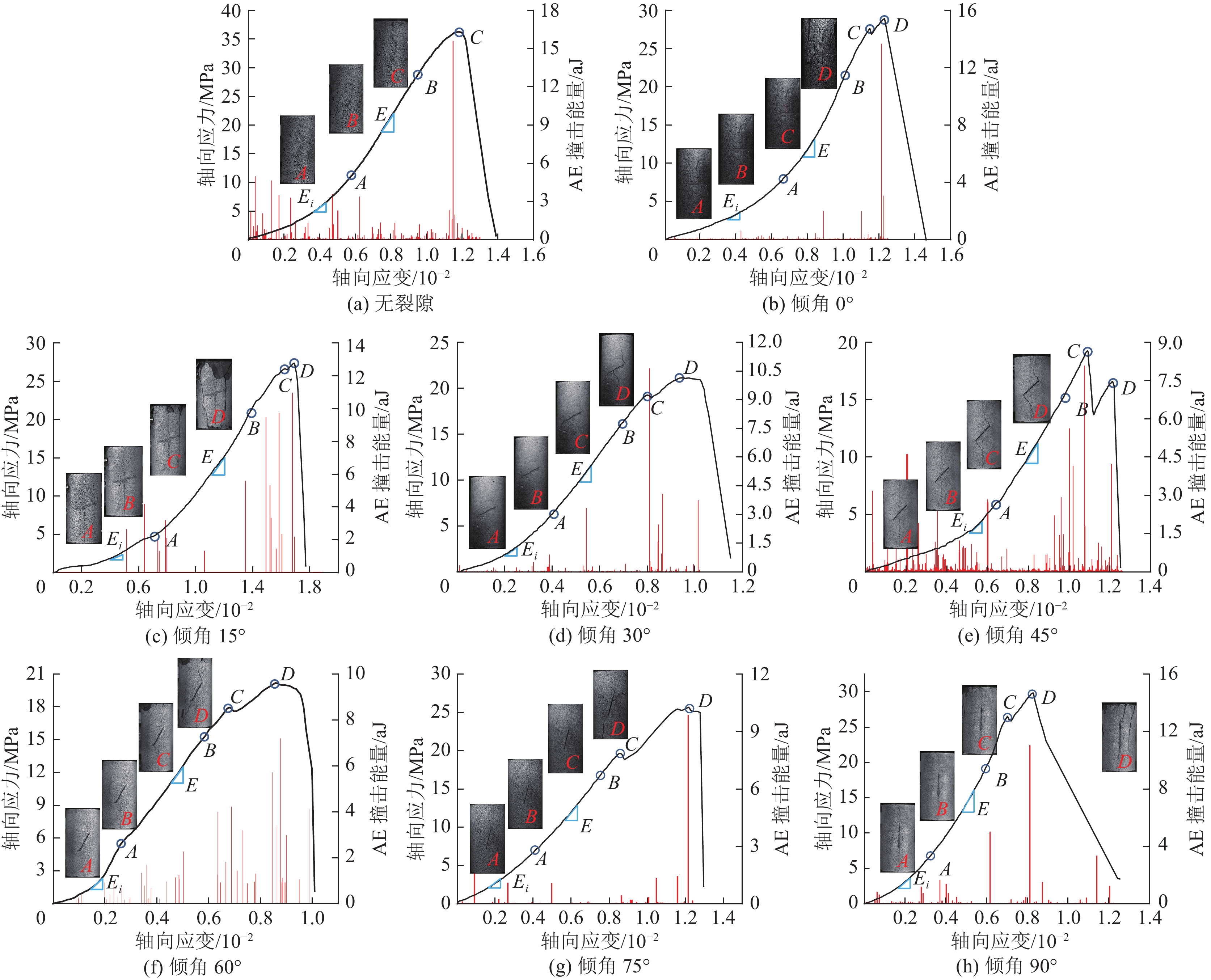

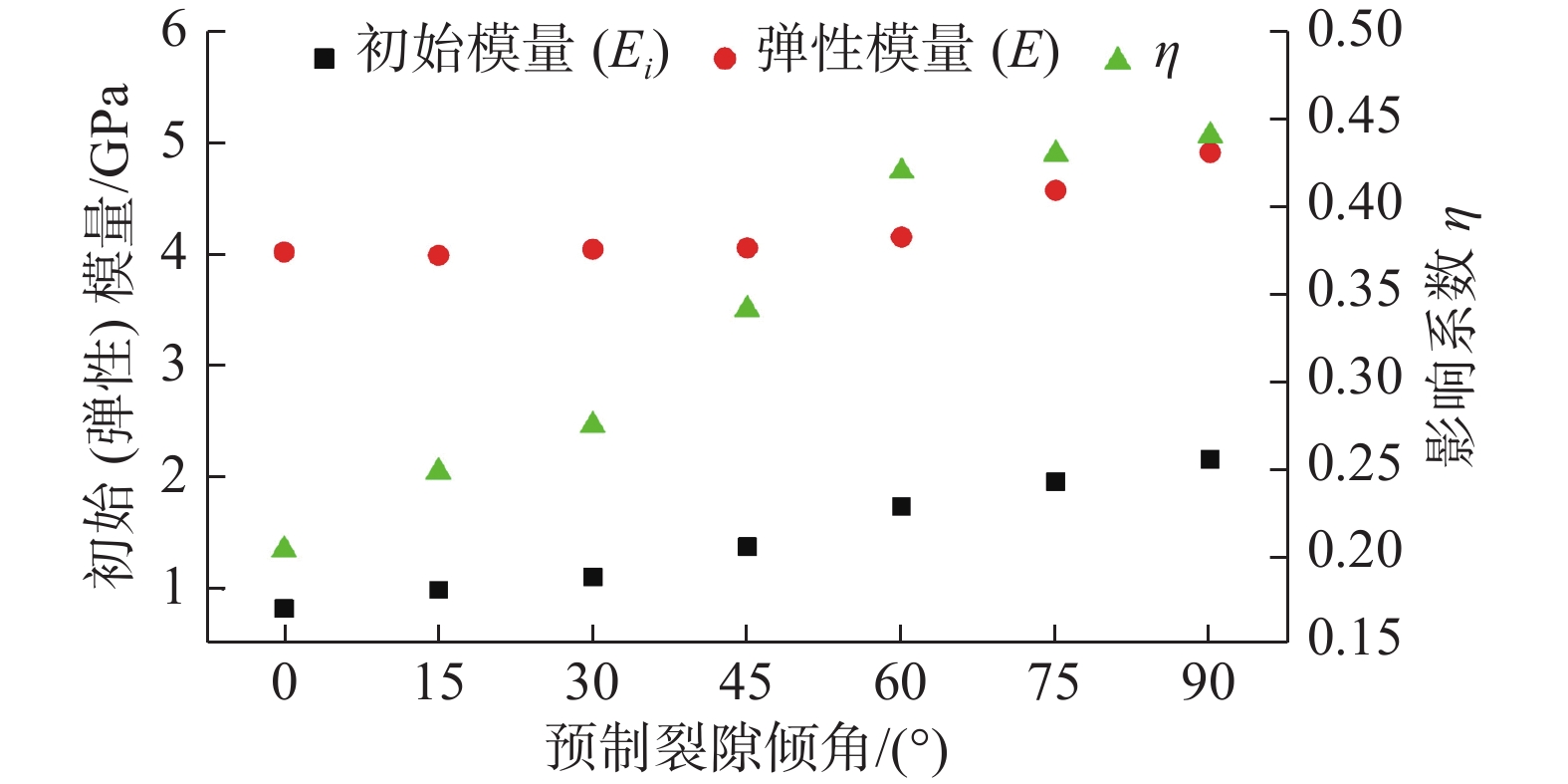

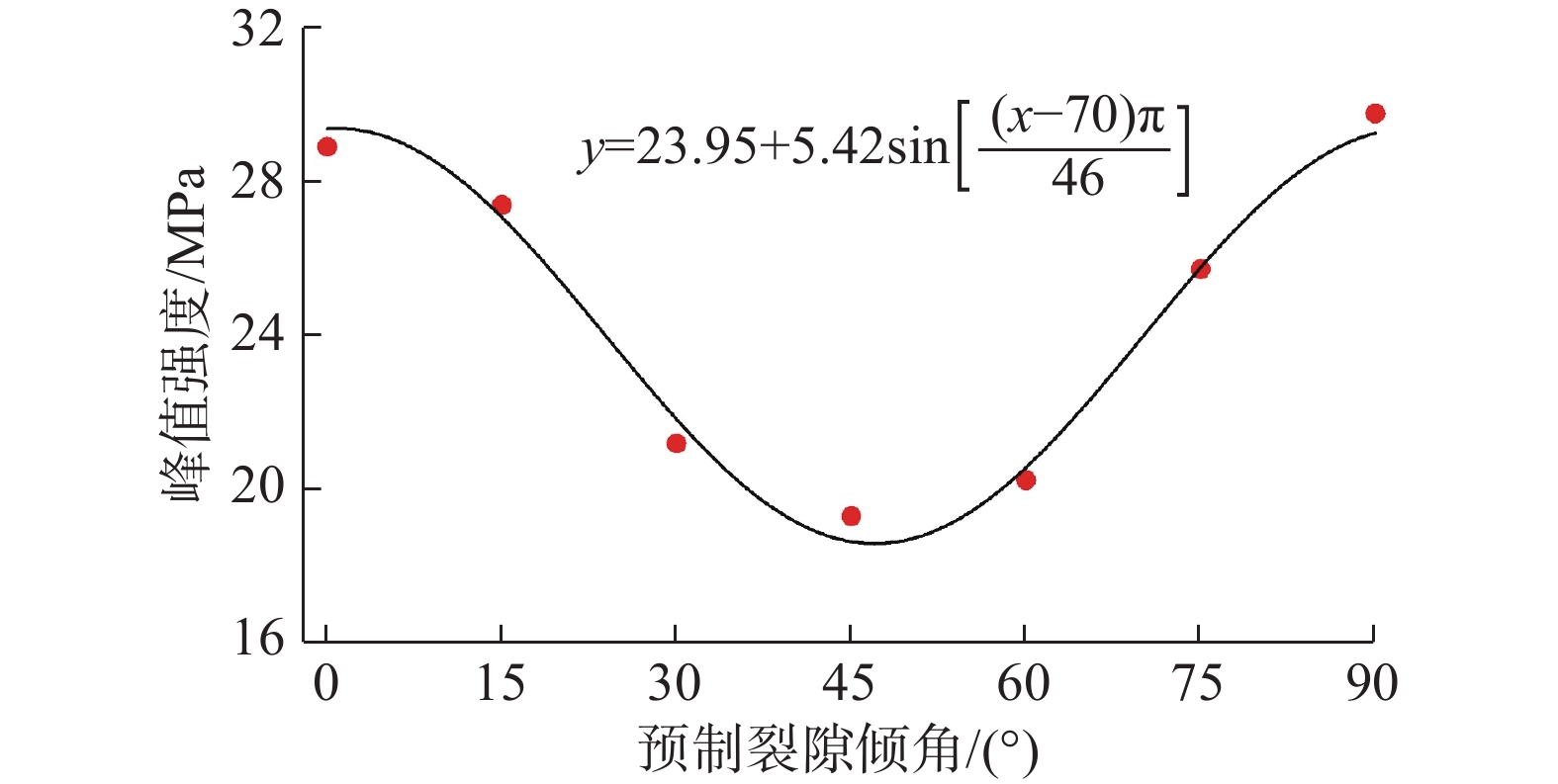

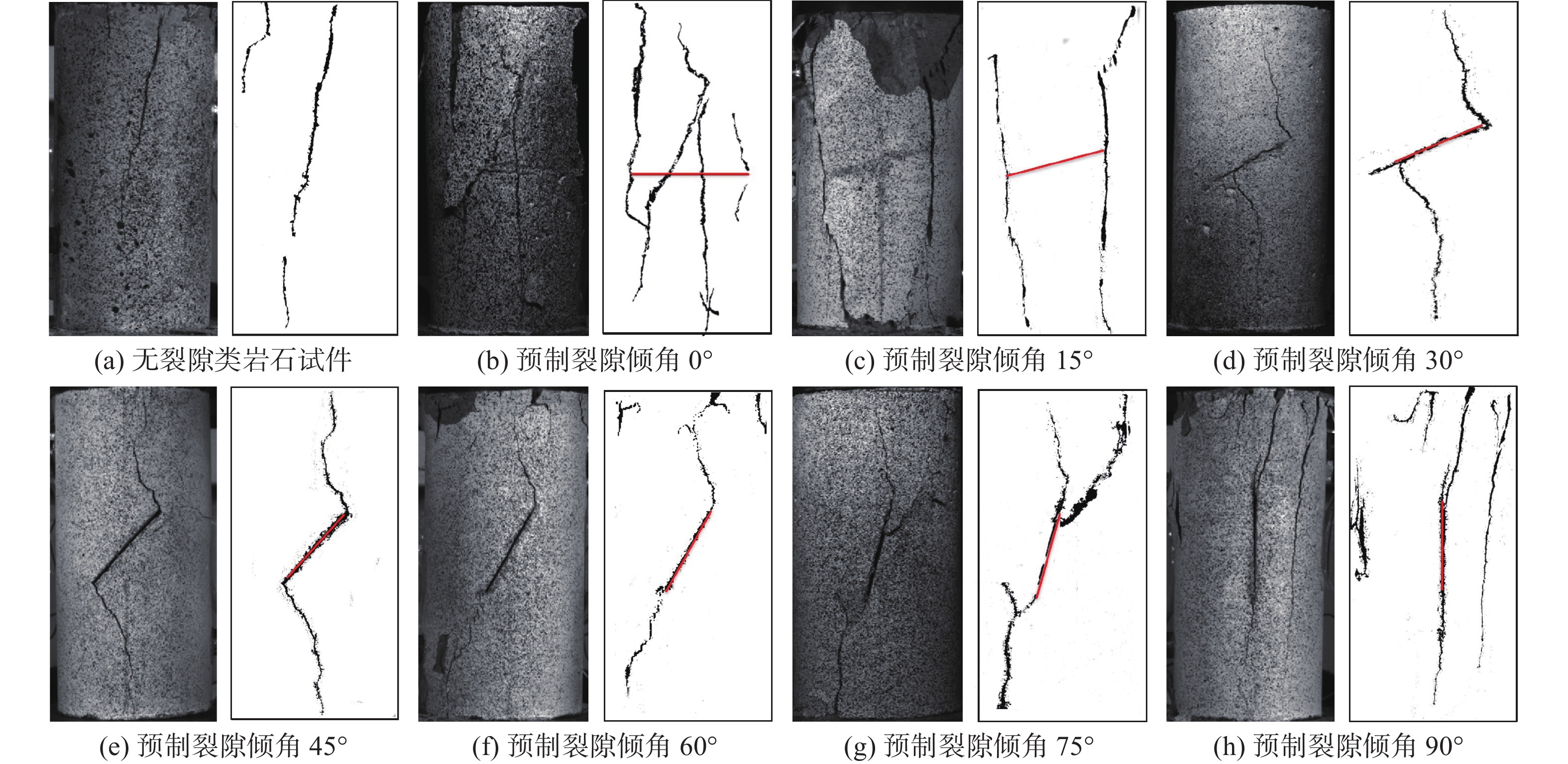

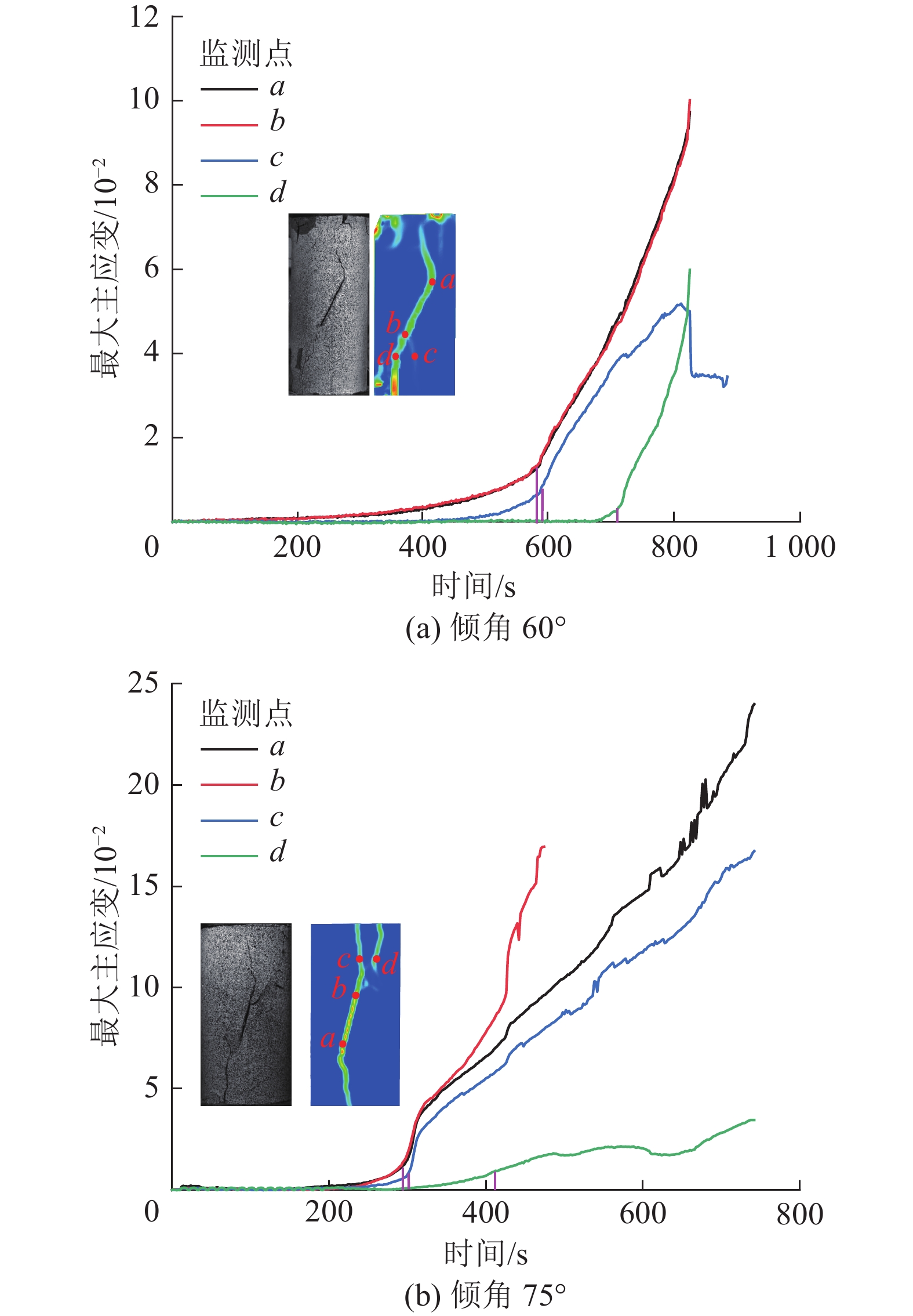

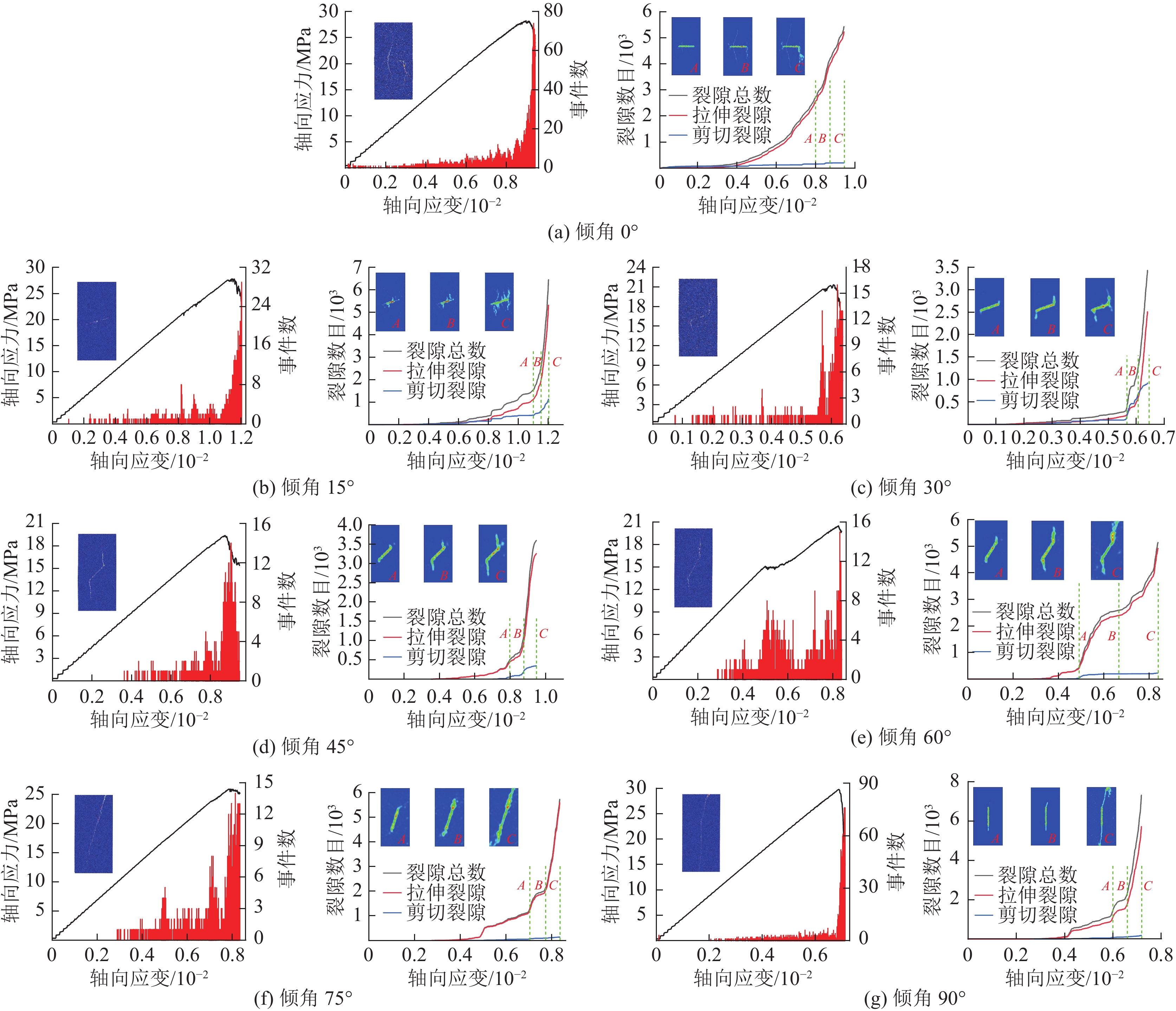

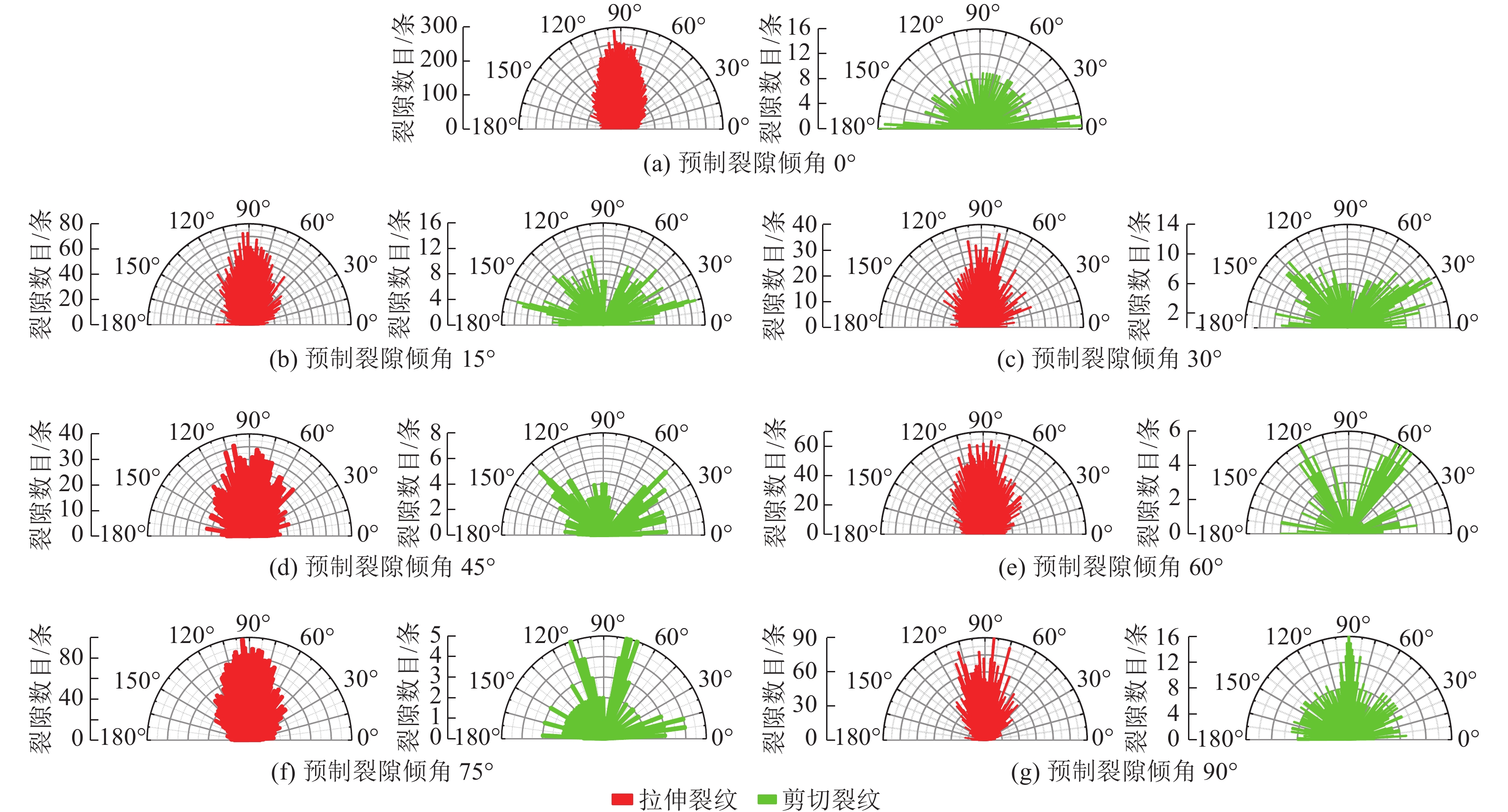

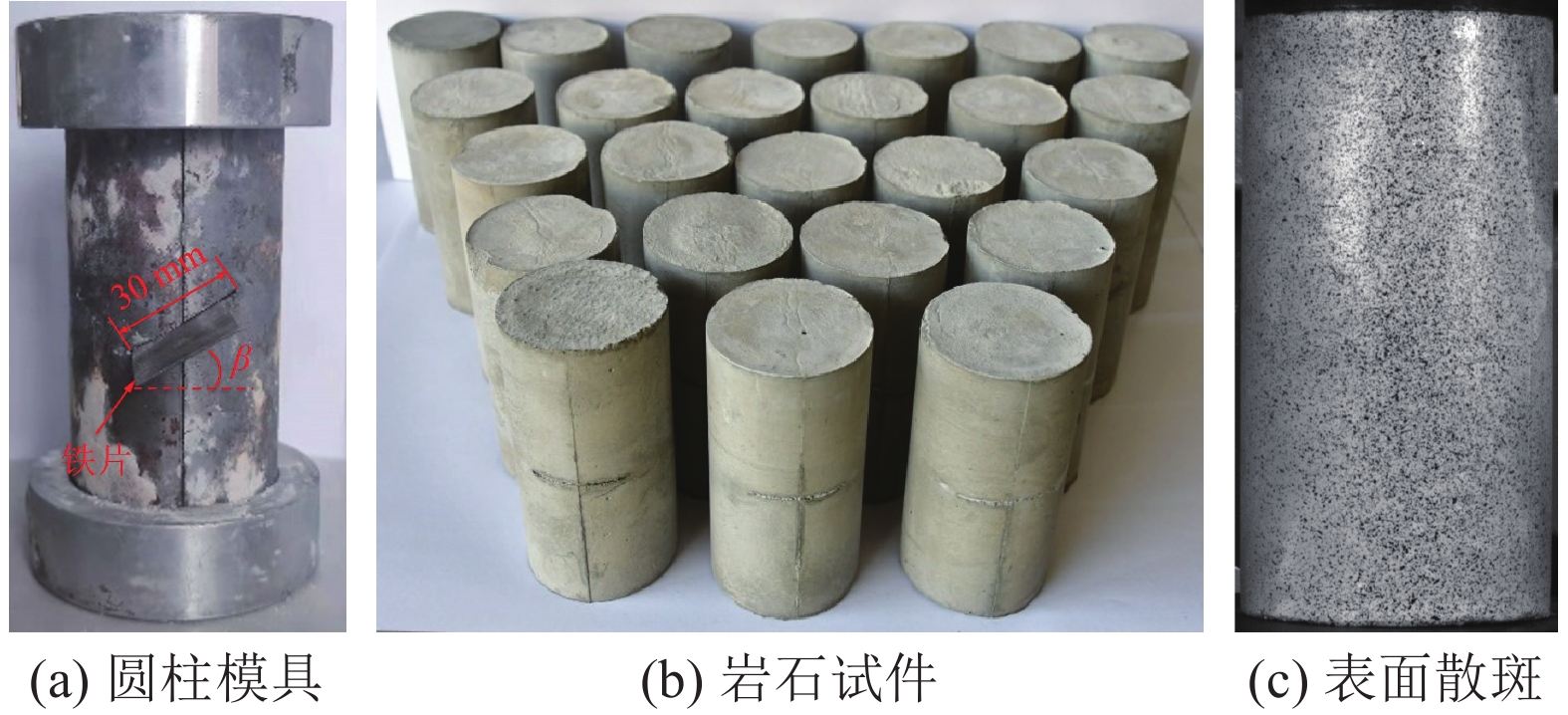

我国东部矿区相继进入深部开采阶段,裂隙发育程度升高,开采扰动效应增强,围岩控制难度增大。为研究含裂隙岩石破坏机理,提高深部围岩控制效果,采用单轴抗压试验结合DIC技术研究了裂隙倾角对类岩石试件力学特性、表面变形场、裂隙扩展路径的影响。结果表明:预制裂隙与翼裂纹产生剪切互锁效应,含裂隙岩石应力−应变曲线呈双峰形态;裂隙倾角增大,岩石弹性模量和损伤程度升高,单轴抗压强度先降低后升高;确定了单轴抗压强度与裂隙倾角的定量关系,定义了含裂隙岩石破坏优势倾角,张开型裂隙优势倾角为45°;含裂隙岩石变形局部化现象始现于裂隙尖端,拉应力主导型启动应力为初始屈服强度的80%,剪应力主导型降至60%;变形集中带扩展路径与表面裂隙一致,应变值达到5.0%时,岩石变形由局部集中向裂隙发育阶段过渡;预制裂隙倾角为60°和75°时,岩石发生拉剪混合破坏,其他角度发生拉伸破坏;拉伸裂隙孕育时间长,两侧特征点水平位移曲线相互分离,剪切裂隙孕育时间短,两侧特征点纵向位移曲线相互分离;构建了预制裂隙类岩石试件GBM模型,岩石内部微裂纹以拉伸型为主,剪切型微裂纹随预制裂隙倾角增大呈先增多后减少趋势;DIC技术可预判岩石起裂位置、时间和裂隙扩展路径,为深部岩石破坏防控提供前兆信息。

Abstract:Eastern coalfield goes into deep mining gradually in China. Fracture development rises greatly in surrounding rocks, increasing the difficulty in ground control under increased mining disturbance. In order to reveal failure mechanism of fractured rocks and improve ground control of deep coal mine, the influence of fracture angle on mechanical behavior, surface strain field and fracture propagation is analyzed by using uniaxial compression test combined with DIC technique. The results show that stress-strain curve of rock specimen with pre-existing fracture presents double-peak shape, induced by shear inter-locking effect between pre-existing and newly-developed fractures. With the growth in fracture angle, elastic modulus and damage degree rise in rock specimen while uniaxial compressive strength (UCS) experiences decreasing and subsequent increasing stages, respectively. Quantitative relationship between the UCS and fracture angle is deduced. Preponderant dip angle is defined for failure of rock with pre-existing fractures and the value is 45° when the fracture belongs to open-type. Deformation localization rock with pre-existing fractures occurs at the fracture tip. The initiation stress reaches 80% of initial yield stress when localization area is dominated by tensile stress, and the percentage decreases to 60% when dominated by shear stress. Propagation path of deformation localization area is consistent with that of surface fracture. Rock deformation stage transits from strain localization to fracture development when strain magnitude reaches 5.0%. Rock specimen fails in tension and shear mixed mode when fracture angle is 60° or 75°. Otherwise, only tension failure is observed in the loading process. It takes longer to form a tensile fracture and horizontal displacement curves of feature points on two sides deviate from each other. It takes shorter to form a shear fracture and vertical displacement curves show deviation trend. Grain based model (GBM) is developed for fractured specimen, which indicates small crack development is dominated by tensile type. Shear crack experiences both rising and subsequent declining stages with the growth in fracture angle. With the DIC technique, failure position, failure time and fracture propagation path can be predicted, which provides valuable precursor for instability prevention of surrounding rock at depth.

-

-

表 1 GBM数值模型细观力学参数

Table 1 Meso-mechanical properties for the GBM model

属性组别 细观参数 取值 基础球体颗粒组 球体半径/mm 0.1~0.2 球体刚度/GPa 1.0 线性黏结刚度比/(kg·m−3) 2.0 线性黏结摩擦因数 0.7 非规则内部颗粒组 平行黏结有效模量/GPa 4.0 平行黏结刚度比 2.0 平行黏结黏聚力/MPa 25.0 平行黏结摩擦角度/(°) 30 平行黏结抗拉强度/MPa 10.0 非规则颗粒边界组 光滑节理法向刚度/GPa 200 光滑节理刚度比 2.0 光滑节理摩擦角度/(°) 30 光滑节理黏聚力/MPa 20 光滑节理抗拉强度/MPa 8.0 预制裂隙组 光滑节理黏聚力/MPa 10 光滑节理抗拉强度/MPa 4.0 表 2 试验与数值模拟结果对比

Table 2 Comparison of testing and numerical results

裂隙倾角/(°) 峰值强度/MPa 弹性模量/GPa 试验 模拟 误差 试验 模拟 误差 0 28.89 28.61 −0.28 4.01 3.64 −0.37 15 27.36 27.79 +0.43 3.98 3.85 −0.13 30 21.14 21.23 +0.09 4.03 3.91 −0.12 45 18.23 18.34 +0.11 4.05 3.76 −0.29 60 20.19 20.28 +0.09 4.14 3.99 −0.15 75 25.68 25.89 +0.21 4.56 4.37 −0.19 90 29.76 29.71 −0.05 4.90 4.53 −0.37 -

[1] 谢和平,高 峰,鞠 杨. 深部岩体力学研究与探索[J]. 岩石力学与工程学报,2015,34(11):2161−2178. doi: 10.13722/j.cnki.jrme.2015.1369 XIE Heping,GAO Feng,JU Yang. Research and development of rock mechanics in deep ground engineering[J]. Chinese Journal of Rock Mechanics and Engineering,2015,34(11):2161−2178. doi: 10.13722/j.cnki.jrme.2015.1369

[2] 王家臣,杨胜利,杨宝贵,等. 深井超长工作面基本顶分区破断模型与支架阻力分布特征[J]. 煤炭学报,2019,44(1):54−63. doi: 10.13225/j.cnki.jccs.2018.5139 WANG Jiachen,YANG Shengli,YANG Baogui,et al. Roof sub-regional fracturing and support resistance distribution in deep longwall face with ultra-large length[J]. Journal of China Coal Society,2019,44(1):54−63. doi: 10.13225/j.cnki.jccs.2018.5139

[3] 王家臣,王兆会,杨 杰,等. 千米深井超长工作面采动应力旋转特征及应用[J]. 煤炭学报,2020,45(3):876−888. doi: 10.13225/j.cnki.jccs.SJ20.0147 WANG Jiachen,WANG Zhaohui,YANG Jie,et al. Mining-induced stress rotation and its application in longwall face with large length in kilometer deep coal mine[J]. Journal of China Coal Society,2020,45(3):876−888. doi: 10.13225/j.cnki.jccs.SJ20.0147

[4] 张俊文,宋治祥,刘金亮,等. 煤矿深部开采冲击地压灾害结构调控技术架构[J]. 煤炭科学技术,2022,50(2):27−36. doi: 10.13199/j.cnki.cst.2021-1273 ZHANG Junwen,SONG Zhixiang,LIU Jinliang,et al. Architecture of structural regulation technology for rock burst disaster in deep mining of coal mine[J]. Coal Science and Technology,2022,50(2):27−36. doi: 10.13199/j.cnki.cst.2021-1273

[5] 王兆会,孙文超,水艳婷,等. 千米深井超长工作面采动应力旋转轨迹及其推进方向效应研究[J]. 煤炭学报,2022,47(2):634−650. WANG Zhaohui,SUN Wenchao,SHUI Yanting,et al. Mining-induced stress rotation trace and its sensitivity to face advance direction in kilometer deep longwall panel with large face length[J]. Journal of China Coal Society,2022,47(2):634−650.

[6] YANG S Q,YIN P F,ZHANG Y C,et al. Failure behavior and crack evolution mechanism of a nonpersistent jointed rock mass containing a circular hole[J]. International Journal of Rock Mechanics and Mining Sciences,2019,114:101−121. doi: 10.1016/j.ijrmms.2018.12.017

[7] 黄彦华,杨圣奇,刘相如. 类岩石材料力学特性的试验及数值模拟研究[J]. 实验力学,2014,29(2):239−249. doi: 10.7520/1001-4888-13-105 HUANG Yanhua,YANG Shengqi,LIU Xiangru. Experimental and Numerical study on the mechanical characteristics of rock-like materials[J]. Journal of Experimental Mechanics,2014,29(2):239−249. doi: 10.7520/1001-4888-13-105

[8] KAKOURIS E,TRIANTAFYLLOU S. Material point method for crack propagation in anisotropic media: a phase field approach[J]. Archive of Applied Mechanics,2018,88(1):287−316.

[9] REIS J M L,NUNES L C S,MATTOS H S D C. Crack propagation analysis of polymer mortars Brazilian disc specimens containing cracks under compressive line loading[J]. Advanced Materials Research,2015,1129:429−437. doi: 10.4028/www.scientific.net/AMR.1129.429

[10] 于利强,姚强岭,徐 强,等. 加载速率影响下裂隙细砂岩裂纹扩展试验及数值模拟研究[J]. 煤炭学报,2021,46(11):3488−3501. doi: 10.13225/j.cnki.jccs.2020.1529 YU Liqiang,YAO Qiangling,XU Qiang,et al. Experimental and numerical simulation study on crack propagation of fractured fine sandstone under the influence of loading rate[J]. Journal of China Coal Society,2021,46(11):3488−3501. doi: 10.13225/j.cnki.jccs.2020.1529

[11] 李建旺. 基于数字图像技术的含双预制裂隙类岩石试样力学特性细观研究[J]. 中国矿业,2020,29(9):168−174. doi: 10.12075/j.issn.1004-4051.2020.09.002 LI Jianwang. Meso research on the mechanical properties of rock specimens with double pre-existing fissures based on digital image correlation[J]. China Mining Magazine,2020,29(9):168−174. doi: 10.12075/j.issn.1004-4051.2020.09.002

[12] 彭守建,冉晓梦,许 江,等. 基于3D-DIC技术的砂岩变形局部化荷载速率效应试验研究[J]. 岩土力学,2020,41(11):3591−3603. PENG Shoujian,RAN Xiaomeng,XU Jiang,et al. Experimental study on loading rate effects of sandstone deformation localization based on 3D-DIC technology[J]. Rock and Soil Mechanics,2020,41(11):3591−3603.

[13] 宋义敏,邢同振,邓琳琳,等. 不同加载速率下岩石变形场演化试验研究[J]. 岩土力学,2017,38(10):2773−2779. SONG Yimin,XING Tongzhen,DENG Linlin,et al. Experimental study of evolution characteristics of rock deformation field at different loading rates[J]. Rock and Soil Mechanics,2017,38(10):2773−2779.

[14] DAUTRIAT J,BORNERT M,GLAND N,et al. Localized deformation induced by heterogeneities in porous carbonate analyzed by multi-scale digital image correlation[J]. Tectonophysics,2011,503(1-2):100−116. doi: 10.1016/j.tecto.2010.09.025

[15] YANG G,CAI Z X,ZHANG X C,et al. An experimental investigation on the damage of granite under uniaxial tension by using a digital image correlation method[J]. Optics and Lasers in Engineering,2015,73(10):46−52.

[16] ALIABADIAN Z,ZHAO G F,RUSSELL A R. Crack development in transversely isotropic sandstone discs subjected to Brazilian tests observed using digital image correlation[J]. International Journal of Rock Mechanics and Mining Sciences,2019,119(7):211−221.

[17] SHARAFIFISAFA M,SHEN L M,XU Q F. Characterization of mechanical behaviour of 3D printed rock-like material with digital image correlation[J]. International Journal of Rock Mechanics and Mining Sciences,2018,112(12):122−138.

[18] WANG ZH,YANG SL,LI LH. A 3D Voronoi clump based model for simulating failure behavior of brittle rock[J]. Engineering Fracture Mechanics,2021,248:107720. doi: 10.1016/j.engfracmech.2021.107720

[19] LI H,MA H L,SHI X L,et al. A 3D grain-based model for simulating the micromechanical behavior of salt rock[J]. Rock Mechanics and Rock Engineering,2020,53:2819−2837. doi: 10.1007/s00603-020-02085-4

[20] HUANG S B, YAO N, YE Y C, et al. Strength and failure characteristics of rocklike material containing a large-opening crack under uniaxial compression: experimental and numerical studies[J]. International Journal of Geomechanics. 2019, 19(8): 04019098.

[21] SARFARAZI V,GHAZVINIAN A,SCHUBERT W,et al. Numerical simulation of the process of fracture of echelon rock joints[J]. Rock Mechanics and Rock Engineering,2014,47(4):1355−1371. doi: 10.1007/s00603-013-0450-3

[22] HOFMANN H,BABADAGLI T,YOON J S,et al. A grain based modeling study of mineralogical factors affecting strength, elastic behavior and micro fracture development during compression tests in granites[J]. Engineering Fracture Mechanics,2015,147:261−275. doi: 10.1016/j.engfracmech.2015.09.008

[23] BAHRANI N,KAISER P K,VALLEY B. Distinct element method simulation of an analogue for a highly interlocked, non-persistently jointed rockmass[J]. International Journal of Rock Mechanics and Mining Sciences,2014,71:117−130. doi: 10.1016/j.ijrmms.2014.07.005

[24] 李 博,朱 强,张丰收,等. 基于矿物晶体模型的非均质性岩石双裂纹扩展规律研究[J]. 岩石力学与工程学报,2021,40(6):1119−1131. doi: 10.13722/j.cnki.jrme.2020.0754 LI Bo,ZHU Qiang,ZHANG Fengshou,et al. Study on crack propagation of heterogeneous rocks with double flaws based on grain based model[J]. Chinese Journal of Rock Mechanics and Engineering,2021,40(6):1119−1131. doi: 10.13722/j.cnki.jrme.2020.0754

[25] JAEGER J C, COOK N G W, ZIMMERMAN R W. Fundamentals of rock mechanics. forth ed[M]. Oxford: Wiley-Blackwell Publishing, 2007.

下载:

下载: