Mechanism and technical system of ground and underground combined drainage of CBM in “four region linkage” in coal mining area

-

摘要:

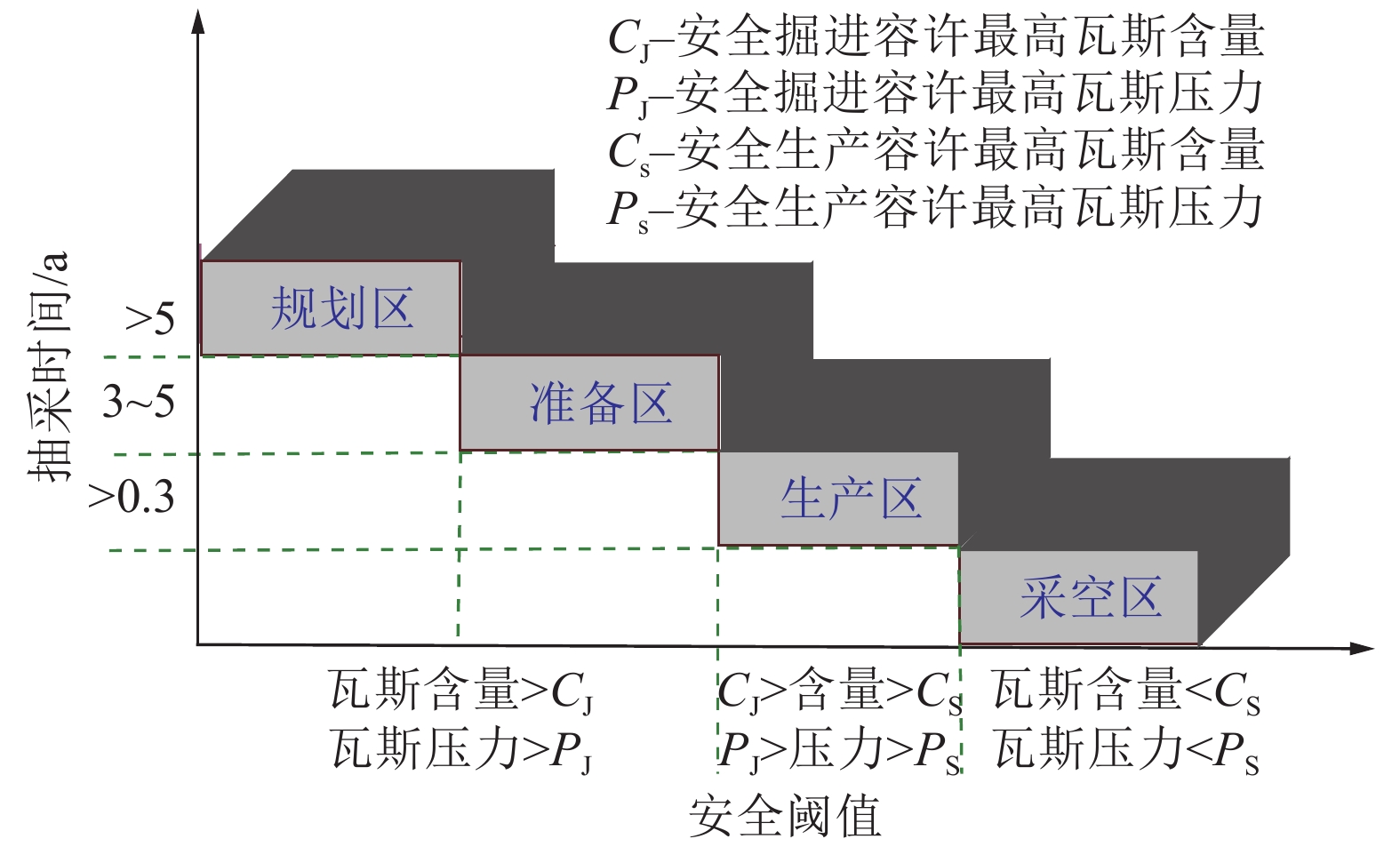

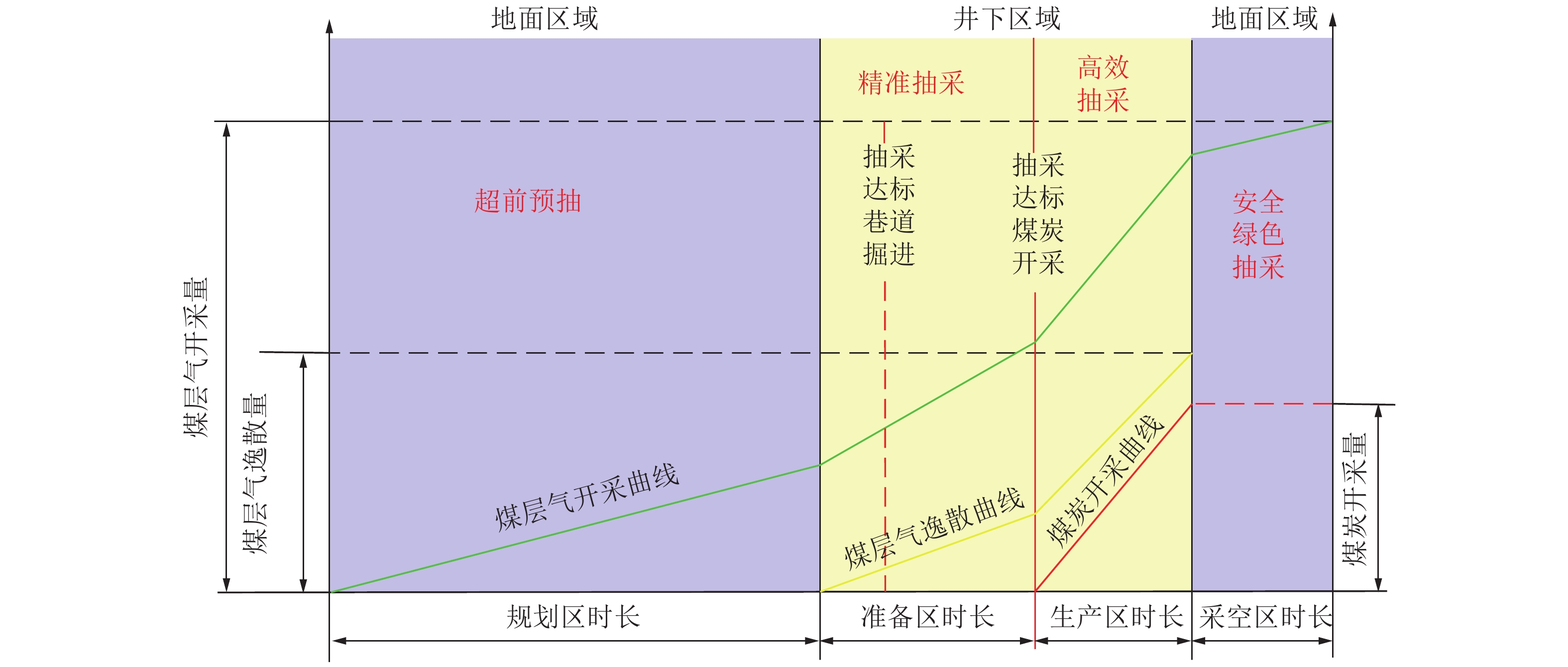

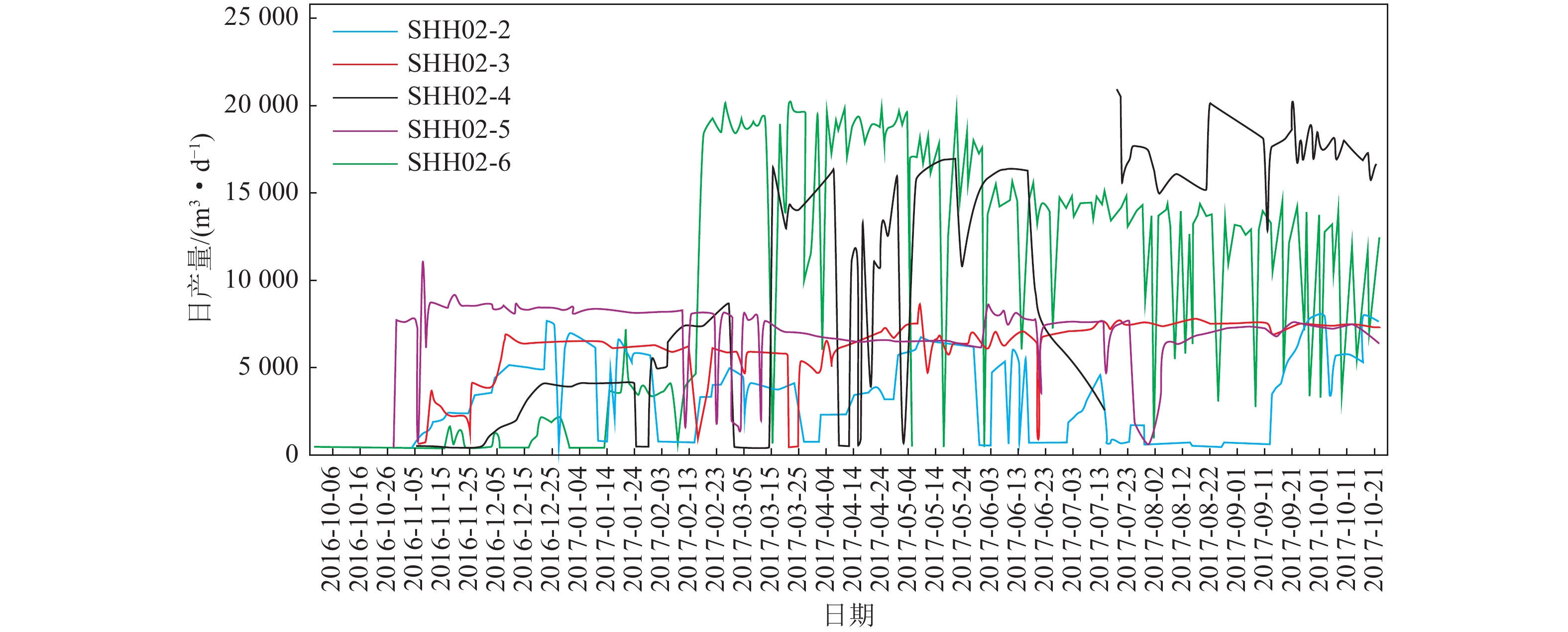

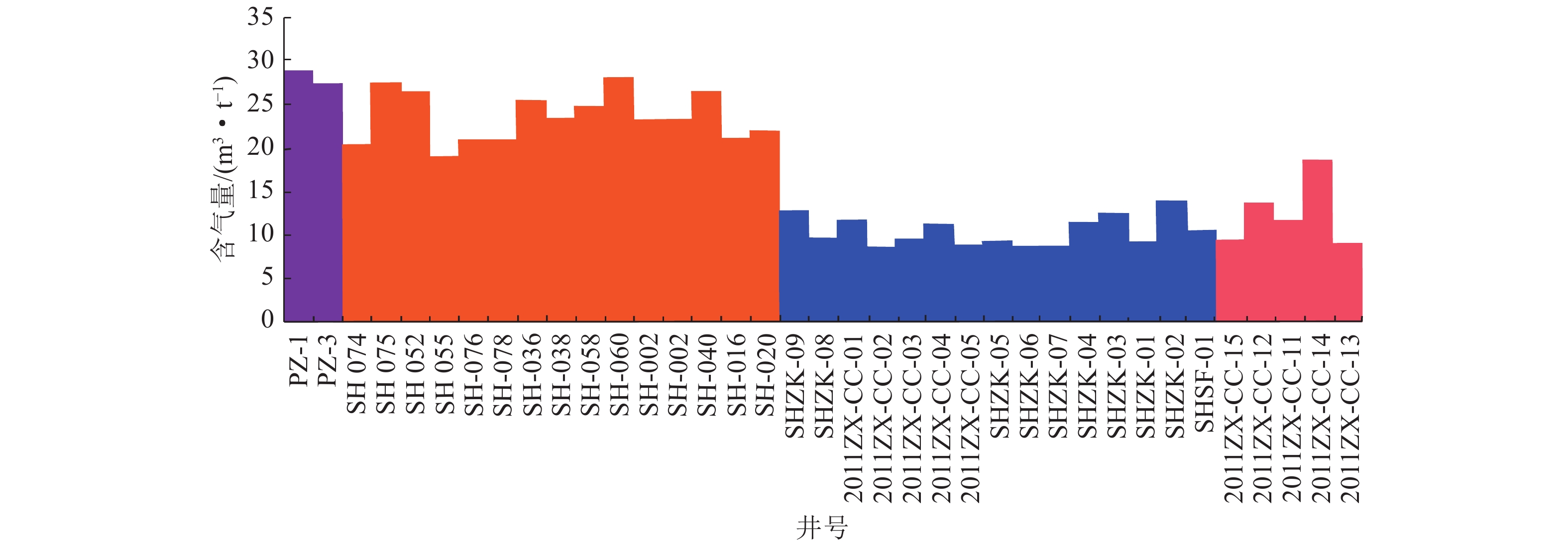

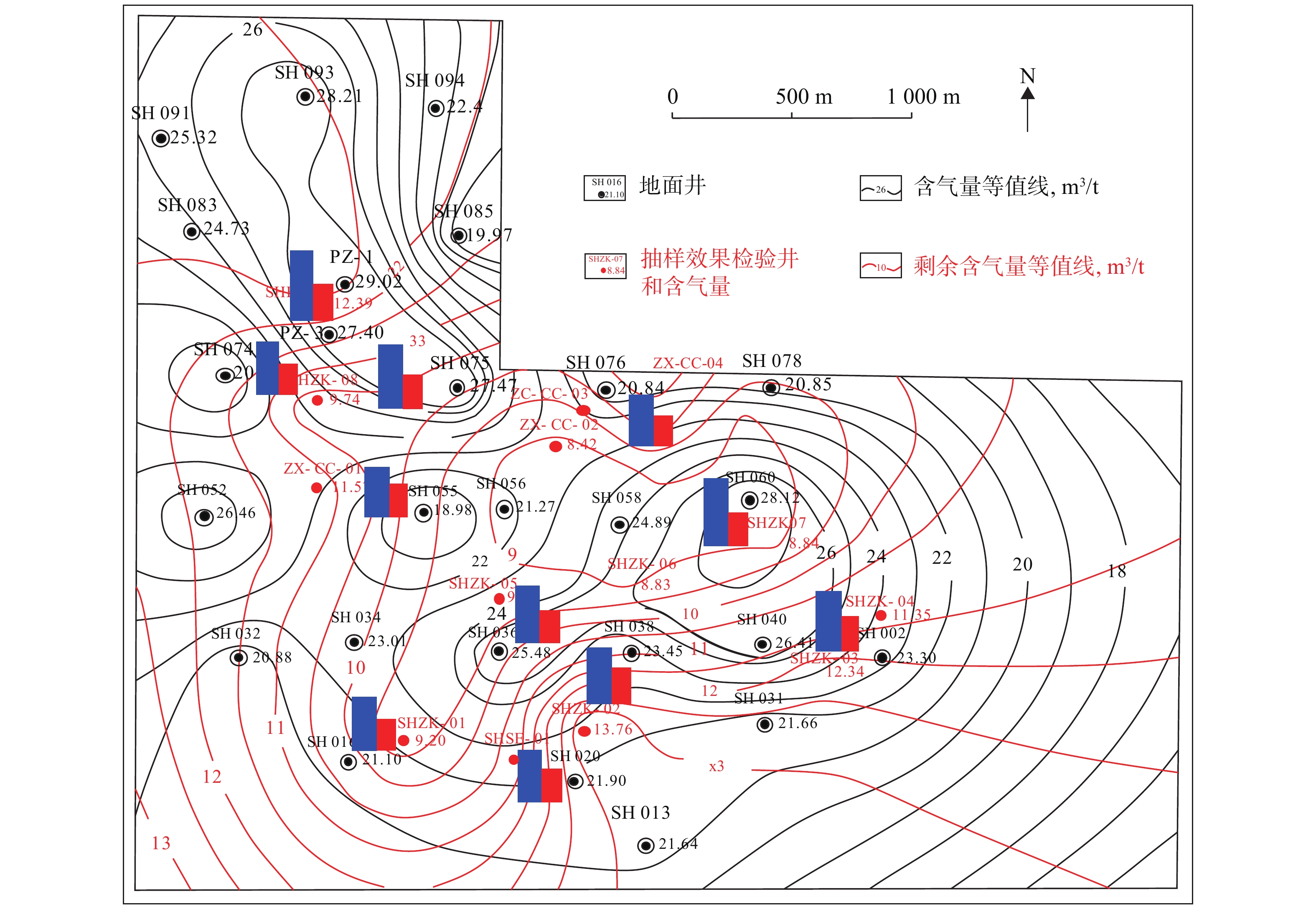

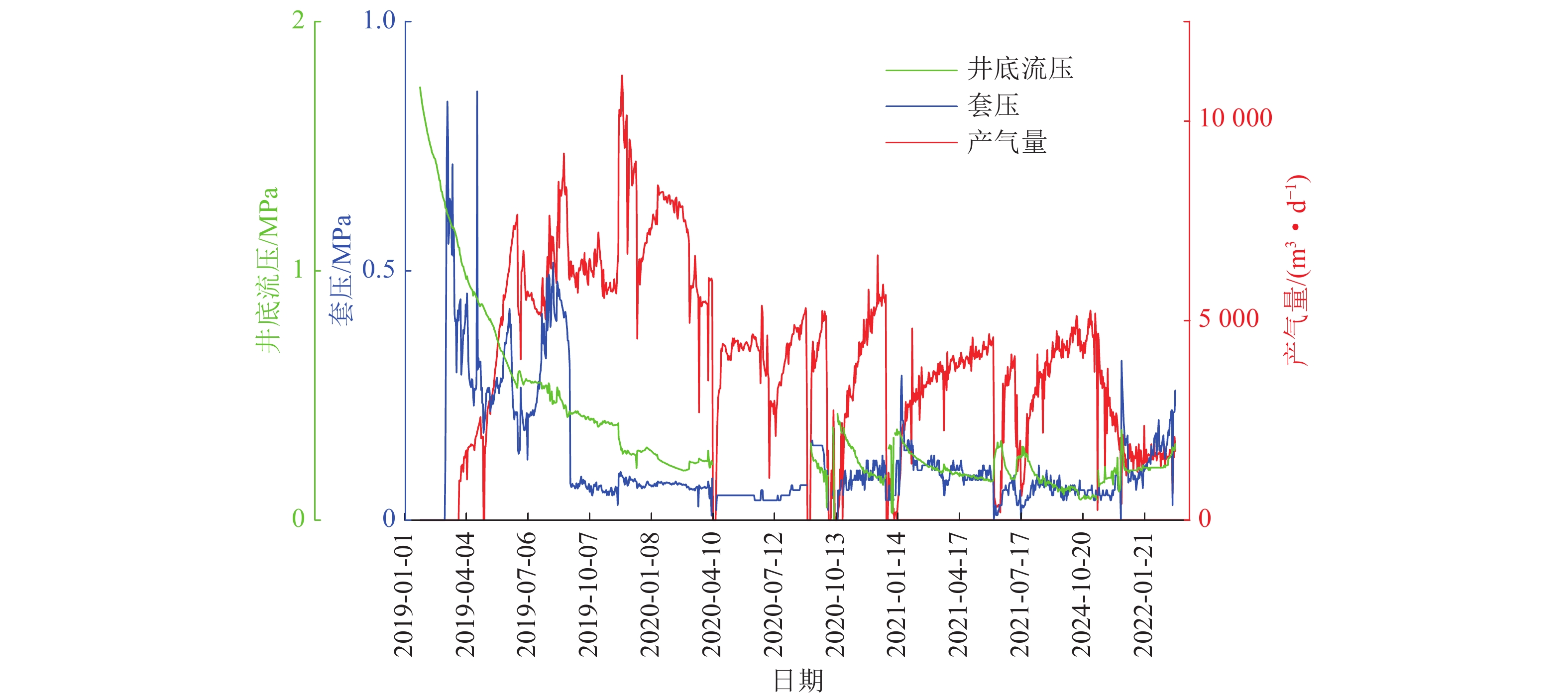

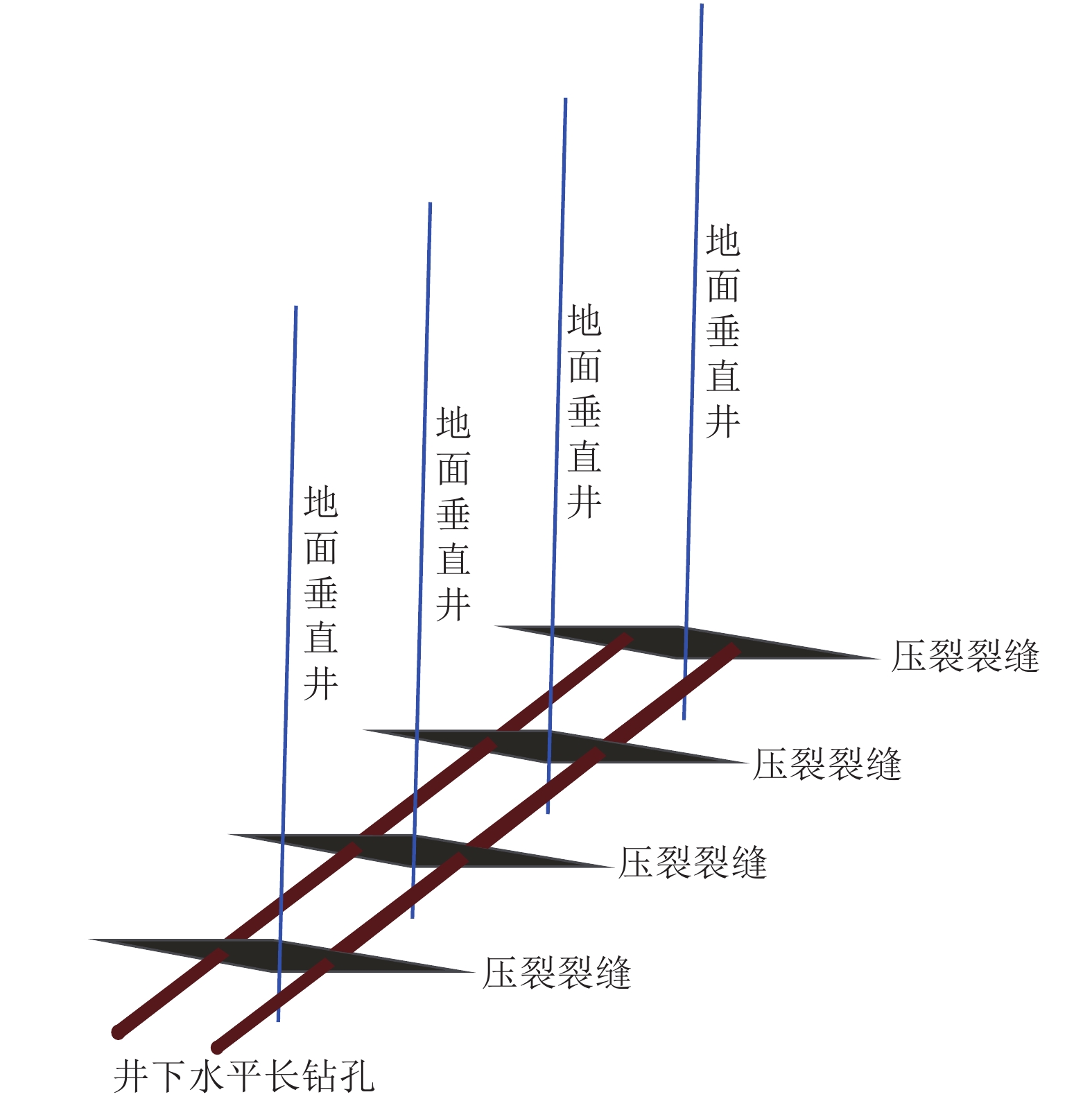

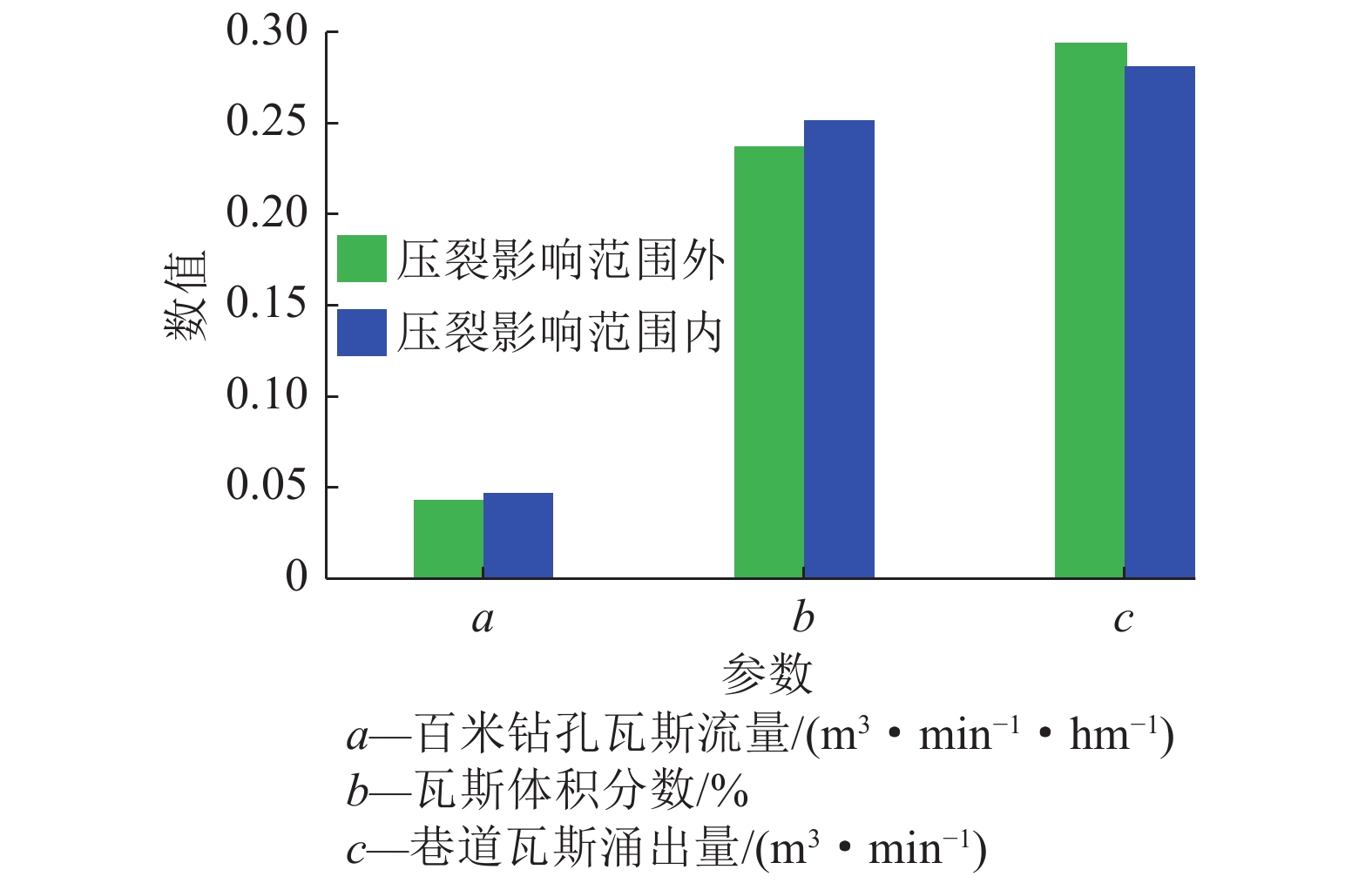

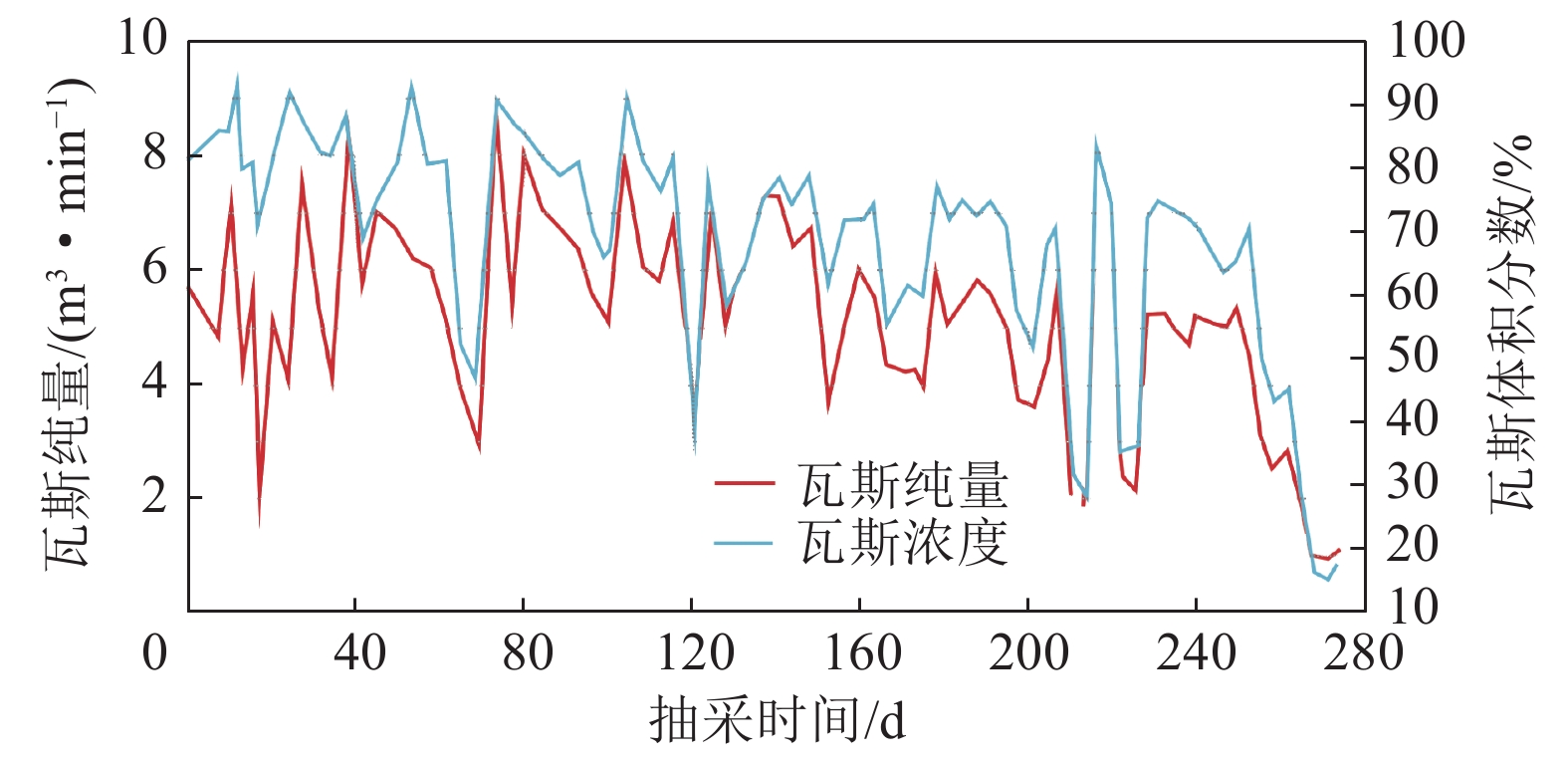

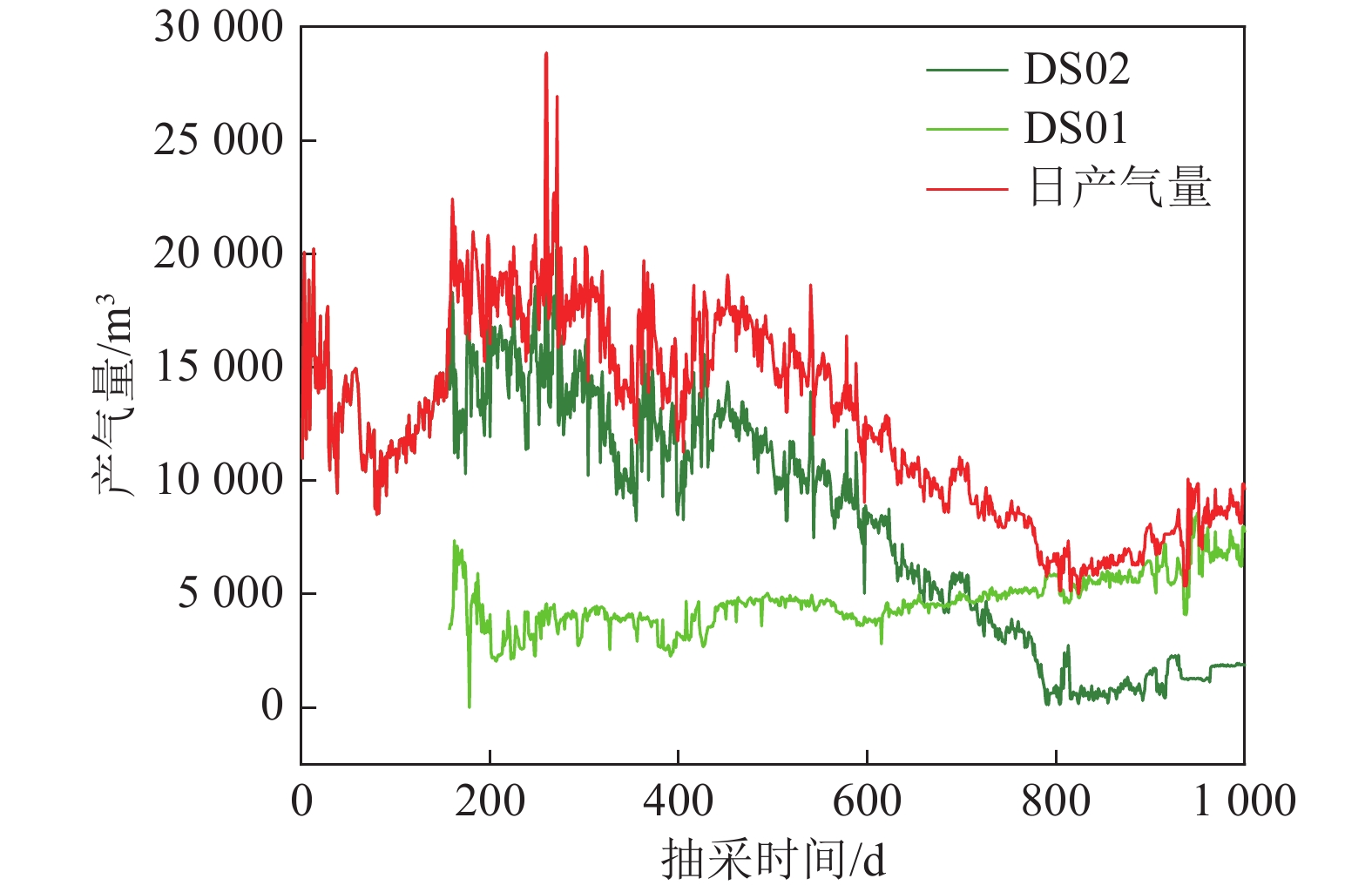

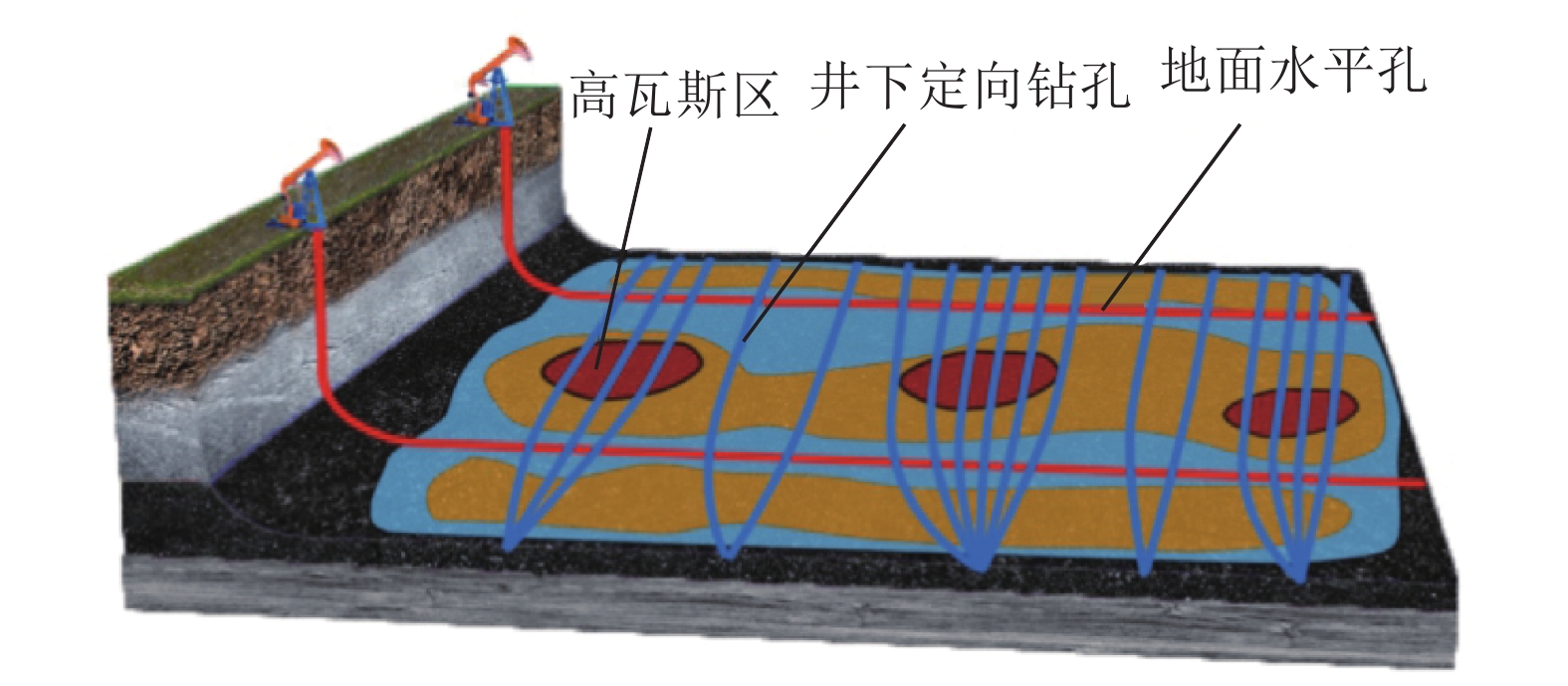

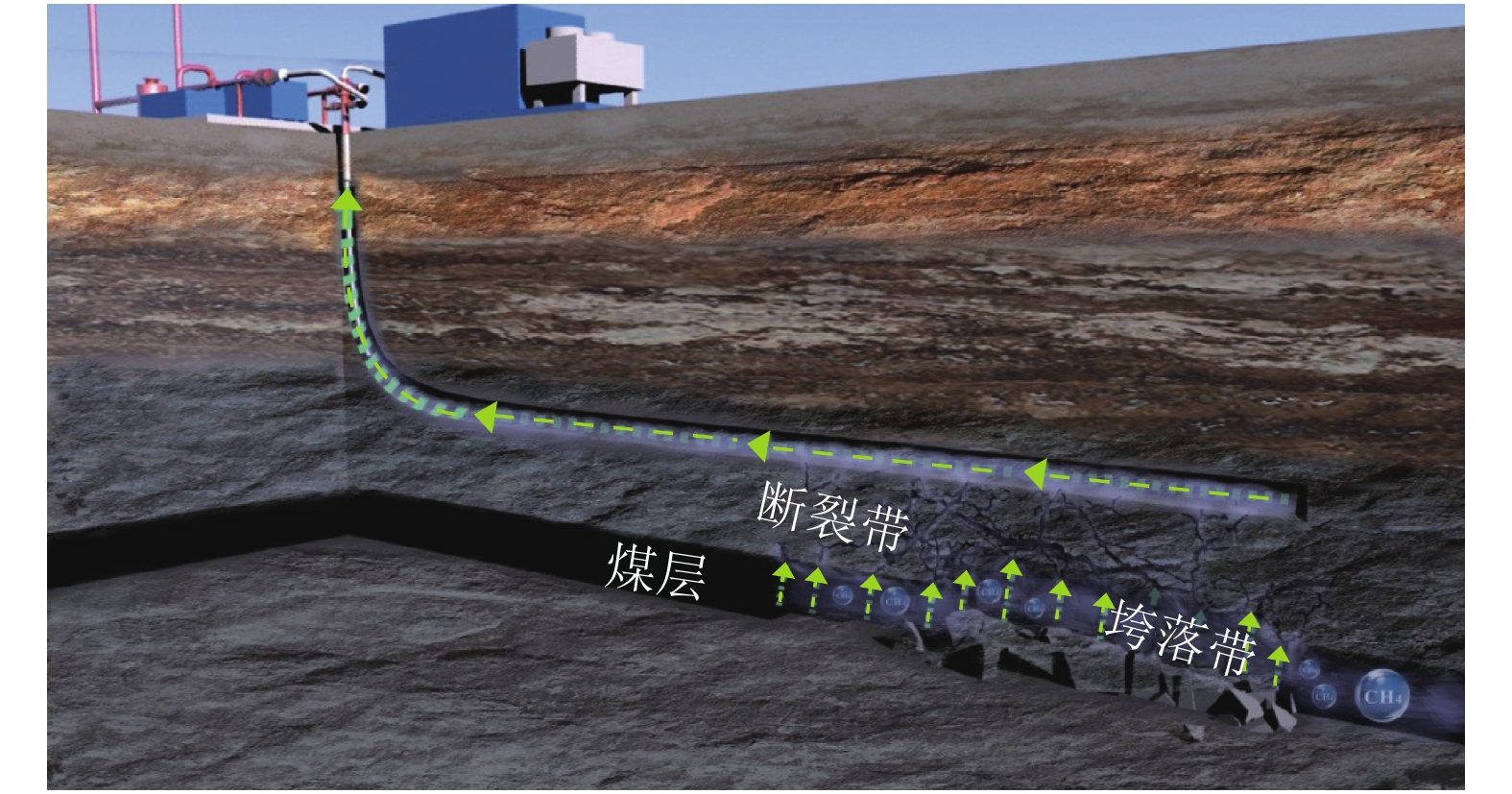

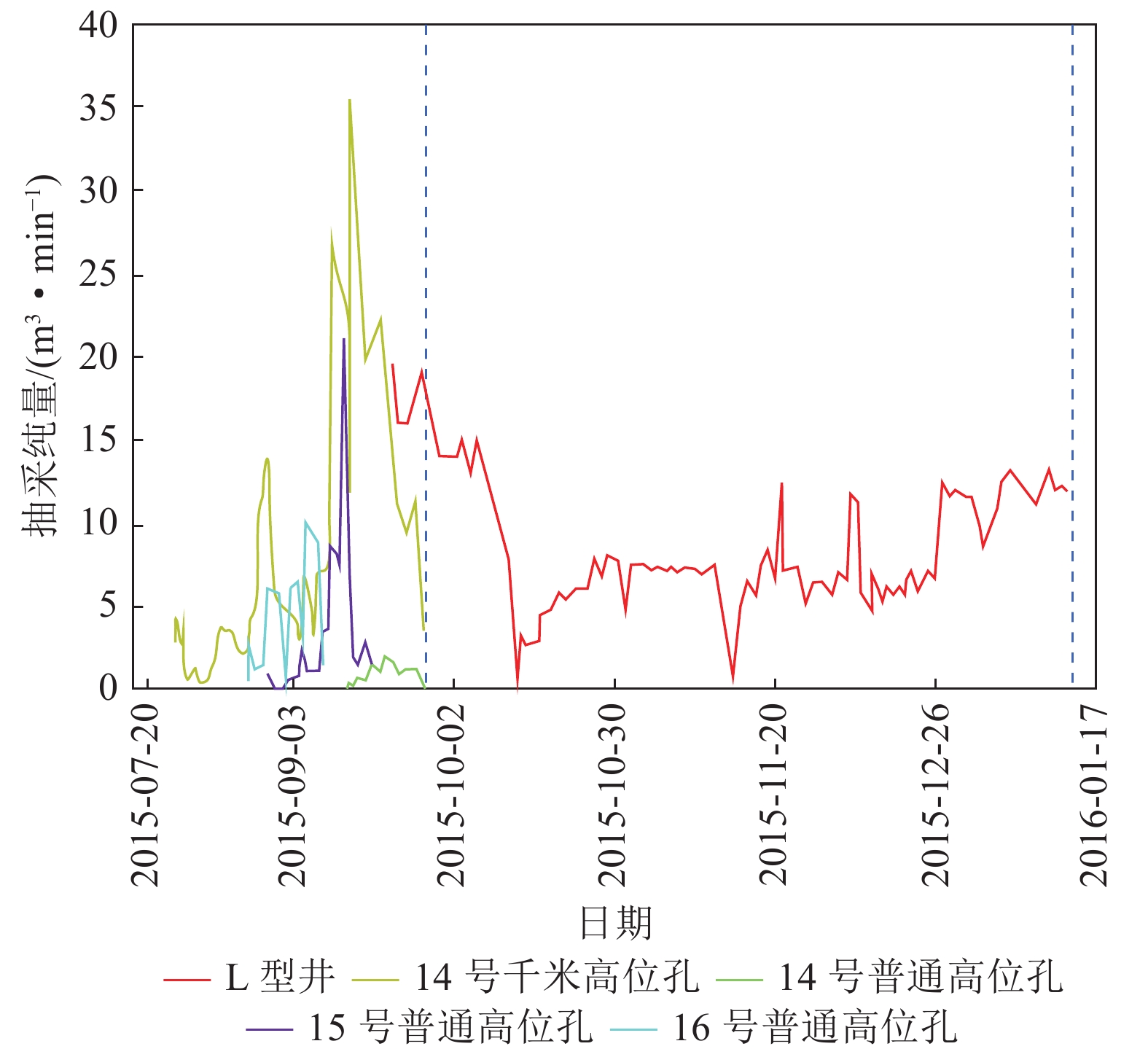

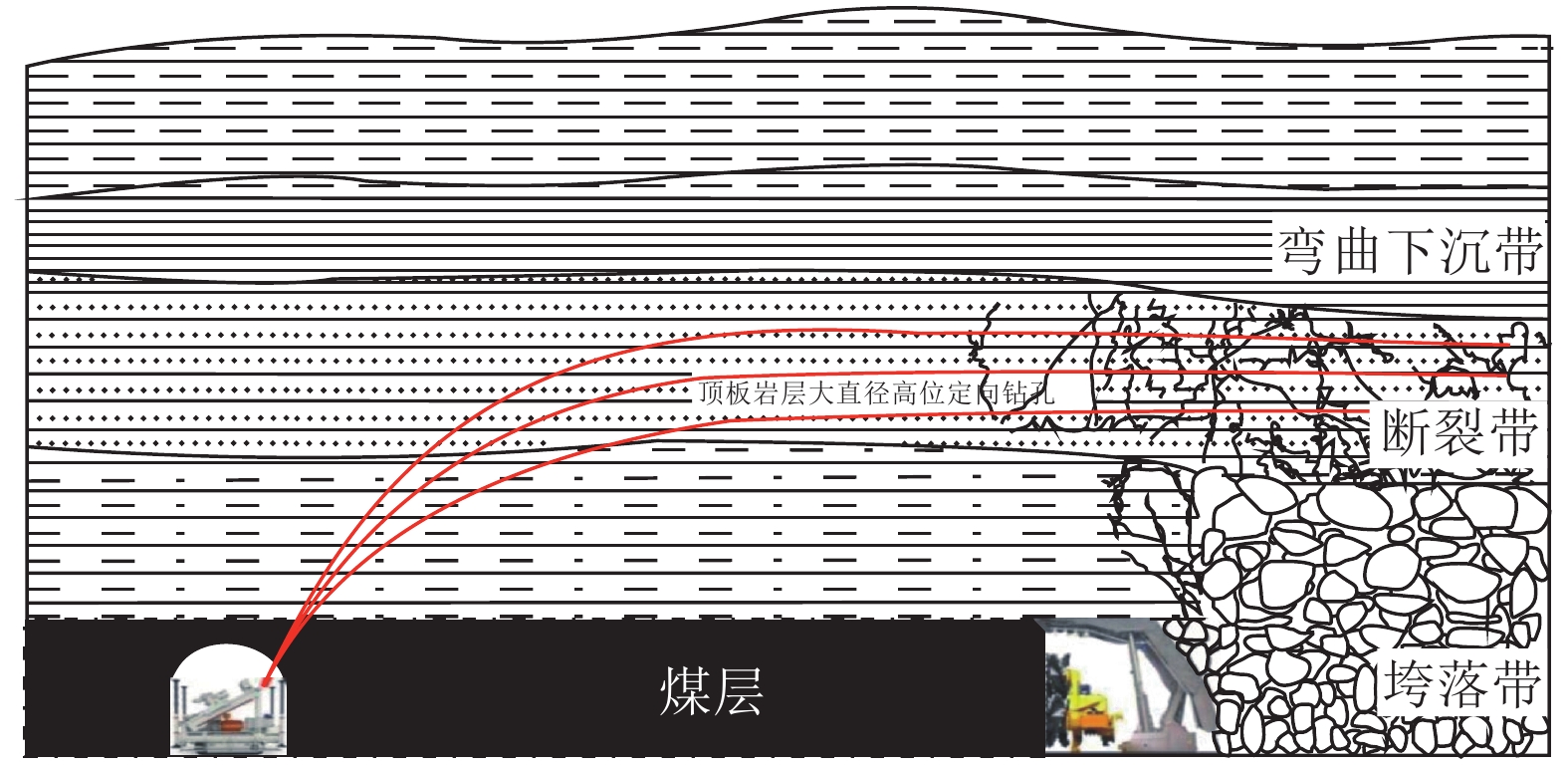

为了更好地实现高瓦斯矿区煤炭与煤层气2种资源的安全高效协调开发,在“十一五”“十二五”研发的煤层气“三区联动”立体抽采模式基础上,依托“十三五”国家科技重大专项持续攻关,并紧密结合山西重点煤矿区生产实际,创新研发了全矿区、全层位、全时段的煤矿区煤层气“四区(规划区、准备区、生产区、采空区)联动”井上下联合抽采模式(新晋城模式)和系列技术体系,在山西重点煤矿区得到广泛应用并取得了良好效果。煤矿规划区煤层气地面抽采技术早期主要采用垂直井、定向井、水平井等技术,现已发展至以分段压裂水平井为主导的井工厂化集约开发模式与技术。经十五年的地面超前预抽,晋能控股寺河矿东五盘区3号煤层平均降幅超过55%,该盘区的5310、5311工作面已顺利完成安全高效采煤,实现了高瓦斯煤层的低瓦斯开采。准备区煤层气井上下联合抽采技术充分利用了压裂影响区渗透率大幅提升和井下开放空间抽采生产压差增大的优势,构建了立体抽采网络,提高了煤层气抽采效率,有效缓解了矿井抽掘采接替紧张,促进了高产高效。基于生产区采动活动剧烈和井下工程全开放特点,运用定向钻机精准完成区域递进式顺层钻孔、穿层钻孔、高位定向长钻孔等,精准均衡抽采生产区煤层气,有效解决了常规钻孔轨迹不可控、易形成抽采盲区、抽采效果差等难题,实现了生产区井下抽采精准达标,确保万无一失。针对煤炭采空区煤层气资源赋存规律不清、资源量评估困难、安全钻采技术缺乏等难题,创建了采空区煤层气资源量计算方法,研发了煤矿采空区地面钻采系列技术,已在晋城、西山、阳泉等山西重点煤矿区完成了129口井的示范推广,累计抽采利用煤层气1.28亿m3,相当于减排二氧化碳192万t。“四区联动”井上下联合抽采模式和系列技术体系在山西重点煤矿区的成功,有效实现了煤层气 “减少温室气体排放、保障煤矿安全生产、补充绿色气体能源”三重功效,为我国煤层气产量由2006年的25.8亿m3提升到2020年的191.7亿m3提供了有力的支撑,同时也为山西重点煤矿区煤炭采深逐年加深、矿井生产条件日趋复杂、生产矿井数量持续减少、煤炭总产量稳步增长提供了有效的保障。

Abstract:In order to better realize the safe and efficient coordinated development of coal and CBM resources in high gassy mining areas, the four regions (planning region, preparation region, production region and coal mined-out region) linkage ground-underground combined drainage mode (new Jincheng mode) and a series of technical systems of CBM in the whole mining area, all stratum layer and all time were innovatively developed. Relying on the “Thirteen Five - Year Plan” national major science and technology projects to continue to tackle key problems, closely combining with the actual production of key coal mining areas in Shanxi Province. This new mode upgraded from the “three regions linkage” three-dimensional extraction mode of CBM developed during the “Eleventh Five-Year” and the “Twelfth Five-Year” Plan and it had been widely used in key coal mining areas of Shanxi Province and achieved good results. The ground pre-drainage technology of CBM in the planning area mainly used vertical wells, directional wells, horizontal wells and other technologies in the early stage. But now it had developed into a well factory intensive development mode and technology dominated by multi-fractured horizontal well. After 15 years of ground pre-drainage, the average reduction of No.3 coal seam in East Fifth Panel of Sihe Mine of Jinneng Holding Group had reached 55%. The No.5310 and No.5311 working faces in this panel had successfully completed safe and efficient coal mining, realizing low gas mining in high gas content coal seam. The ground-underground combined drainage technology of CBM in the preparation region made full use of the advantages of the greatly increased permeability in the fracturing affected area and the increased production pressure difference of underground open space drainage. Which formed a three-dimensional drainage network, improved the drainage efficiency, effectively alleviated the tension in the replacement of mining, and promoted high production and efficiency.Based on the characteristics of intense mining activities in the production area and full opening of underground projects, directional drilling rigs were used to accurately complete regional progressive seam drilling, through hole drilling, and high directional long borehole, and accurately and evenly extract the CBM in the production region. This effectively solved the problems of uncontrollable conventional drilling trajectory, easy to form blind areas for drainage, and poor drainage effect, and realized the accurate standard of underground drainage in the production region, ensuring no risk.In view of the problems such as unclear occurrence law of CBM resources in the coal mined-out region, difficulty in resource assessment, and lack of safe drilling and mining technology, the calculation method of CBM resources in the coal mined-out region was created. And a series of technologies for ground drilling and mining in coal mined-out region were developed. 129 wells had been demonstrated and promoted in Shanxi key coal mine areas such as Jincheng, Xishan, Yangquan, etc., 128 million cubic meters of CBM had been pumped and utilized, and 1.92 million tons of carbon dioxide had been reduced.The success of the ‘four region linkage’ ground-underground combined drainage mode and a series of technical systems in key coal mining areas of Shanxi had effectively achieved the triple effect of CBM “reducing greenhouse gas emissions, ensuring coal mine safety production, and supplementing green gas energy”. Which provided strong support for China’s CBM production to increase from 2.58 billion cubic meters in 2006 to 19.17 billion cubic meters in 2020. At the same time, it also provided an effective guarantee for the deepening of coal mining depth year by year in key coal mining areas of Shanxi Province, the increasingly complex mine production conditions, the continuous reduction of the number of production mines, and the steady growth of the total coal output.

-

-

表 1 煤矿区煤层气“四区联动”抽采技术体系

Table 1 Four region linkage gas drainage technical system of CBM in coal mining area

抽采区域 规划区 生产矿井或在建矿井 准备区 生产区 采空区 抽采条件 原始煤层瓦斯含量高于16 m3/t

时,至少提前8~10 a超前预抽提前3~5 a实施,

先抽后采半开放条件下气相渗流瓦斯含量低于

8 m3/t,瓦斯压力低于0.74 MPa卸压开放条件气相渗流顶底板及其

覆岩被破坏后的采空区抽采顺序 超前预抽 煤与煤层气共采

先抽后采煤与煤层气共采

边抽边采采后抽采 抽采模式 地面抽采 井上下联合抽采、采动区抽采 井下精准抽采和采动区抽采 采空区抽采 表 2 压裂影响区内外抽采效果对比

Table 2 Comparison of fracturing in and out of affected area

井号 百米钻孔流量/

(m³·min−1·hm−1)瓦斯体积分数/% 提高幅度/% 压裂区内 压裂区外 压裂区内 压裂区外 CZYC-07 0.015 0.0090 72 56 28.6 CZYC-08 0.036 0.0270 83 68 22.1 CZYC-09 0.220 0.0126 89 75 18.7 CZYC-10 0.026 0.0120 77 45 71.1 CZYC-11 0.021 — 82 — — -

[1] 新华社. 国家煤矿安监局联手中国航天科技集团推进煤矿智能装备和机器人发展 [EB/OL].[2022-07-05] http://www.gov.cn/xinwen/2019-08/14/content_5421261.htm. [2] 张遂安. 采煤采气一体化理论与实践 [J]. 中国煤层气, 2006, 3(4): 14-16. ZHANG Suian, Theory and practice of integrated coal mining and gas extraction [J]. China Coalbed Methane, 2006, 3(4): 14-16.

[3] 陈志胜. 煤矿区煤层气综合开发与利用存在问题探讨[J]. 煤炭科学技术,2009,37(7):5−8. doi: 10.13199/j.cst.2009.07.10.chenzhsh.027 CHEN Zhisheng. Discussion on problems existing in comprehensive development and utilization of Coal Bed Methane in coal mining area[J]. Coal Science and Technology,2009,37(7):5−8. doi: 10.13199/j.cst.2009.07.10.chenzhsh.027

[4] 雷 毅,申宝宏,刘见中. 煤矿区煤层气与煤炭协调开发模式初探[J]. 煤矿开采,2012,17(3):1−4. doi: 10.3969/j.issn.1006-6225.2012.03.001 Lei Yi,Shen Baohong,Liu Jianzhong. Initial discussion of coalbed methane and coal coordination mining mode[J]. Coal mining Technology,2012,17(3):1−4. doi: 10.3969/j.issn.1006-6225.2012.03.001

[5] 申宝宏,刘见中,雷 毅. 我国煤矿区煤层气开发利用技术现状及展望[J]. 煤炭科学技术,2015,43(2):1−4. doi: 10.13199/j.cnki.cst.2015.02.001 SHEN Baohong,LIU Jianzhong,LEI Yi. Present status and prospect of coalbed methane development and utilization technology of coal mine area in China[J]. Coal Science and Technology,2015,43(2):1−4. doi: 10.13199/j.cnki.cst.2015.02.001

[6] 张学超. 煤与煤层气协调开发煤层气井下抽采安全性评价[J]. 煤矿安全,2015,46(12):174−178. doi: 10.13347/j.cnki.mkaq.2015.12.050 ZHANG Xuechao. Evaluation of underground gas extraction safety based on coordinative development of coal and coalbed methane[J]. Safety in Coal Mines,2015,46(12):174−178. doi: 10.13347/j.cnki.mkaq.2015.12.050

[7] 武华太. 煤矿区瓦斯三区联动立体抽采技术的研究和实践[J]. 煤炭学报,2011,36(8):1312−1316. doi: 10.13225/j.cnki.jccs.2011.08.022 WU Huatai. Study and practice on technology of three-zones linkage 3D coalbed methane drainage in coal mining area[J]. Journal of China Coal Society,2011,36(8):1312−1316. doi: 10.13225/j.cnki.jccs.2011.08.022

[8] 李国富,何 辉,刘 刚,等. 煤矿区煤层气三区联动立体抽采理论与模式[J]. 煤炭科学技术,2012,40(10):7−11. doi: 10.13199/j.cst.2012.10.13.ligf.008 LI Guofu,HE Hui,LIU Gang,et al. Three region linkage three-dimensional gas drainage theory and mode of coal bed methane in coal mining area[J]. Coal Science and Technology,2012,40(10):7−11. doi: 10.13199/j.cst.2012.10.13.ligf.008

[9] 李国富,李 波,焦海滨,等. 晋城矿区煤层气三区联动立体抽采模式[J]. 中国煤层气,2014,11(1):3−7. doi: 10.3969/j.issn.1672-3074.2014.01.001 LI Guofu,LI Bo,JIAO Haibin,et al. Three-region integrated CBM stereo-extraction in Jincheng mining area[J]. China Coalbed Methane,2014,11(1):3−7. doi: 10.3969/j.issn.1672-3074.2014.01.001

[10] 孙景来. 煤与煤层气协调开发机制研究[J]. 煤炭科学技术,2014,42(10):62−65. doi: 10.13199/j.cnki.cst.2014.10.015 SUN Jinglai. Study on coordinative development mechanism of coal and coalbed methane[J]. Coal Science and Technology,2014,42(10):62−65. doi: 10.13199/j.cnki.cst.2014.10.015

[11] 范喜生,张 浪,汪 东. 煤与煤层气协调开采的含义及关键问题定量分析[J]. 安全与环境学报,2016,16(2):123−127. doi: 10.13637/j.issn.1009-6094.2016.02.025 FAN Xisheng,ZHANG Lang,WANG Dong. Implication of the coordinative mining of coal and coal-bed methane and a quantitative analysis of the key problems involved[J]. Journal of Safety and Environment,2016,16(2):123−127. doi: 10.13637/j.issn.1009-6094.2016.02.025

[12] 刘见中,沈春明,雷 毅,等. 煤矿区煤层气与煤炭协调开发模式与评价方法[J]. 煤炭学报,2017,42(5):1221−1229. LIU Jianzhong,SHEN Chunming,LEI Yi. Coordinated development mode and evaluation method of coalbed methane and coal in coal mine area in China[J]. Journal of China Coal Society,2017,42(5):1221−1229.

[13] 刘彦青,赵 灿,李国富,等. 晋城矿区煤与煤层气协调开发模式优化决策方法[J]. 煤炭学报,2020,45(7):2575−2589. LIU Yanqing,ZHAO Can,LI Guofu,et al. Optimized decision method of coordinated development mode of coal and coalbed methane in Jincheng mining area[J]. Journal of China Coal Society,2020,45(7):2575−2589.

[14] 李希建,徐明智. 近年我国煤与瓦斯突出事故统计分析及其防治措施[J]. 矿山机械,2010,38(10):13−16. doi: 10.16816/j.cnki.ksjx.2010.10.004 LI Xijian,XU Mingzhi. Statistics and analysis of domestic coal and gas outburst accidents in recent years and prevention measures[J]. Mining & Processing Equipment,2010,38(10):13−16. doi: 10.16816/j.cnki.ksjx.2010.10.004

[15] 国家矿山安监局 [OL]. https://www.chinacoal-safety.gov.cn/xw/mkaqjcxw/202101/t20210108_376767.shtml. [16] 国家矿山安全监察局. 防治煤与瓦斯突出细则 [M]. 北京 : 煤炭工业出版社, 2019. [17] 刘见中,孙海涛,雷 毅,等. 煤矿区煤层气开发利用新技术现状及发展趋势[J]. 煤炭学报,2020,45(1):258−267. doi: 10.13225/j.cnki.jccs.YG19.1757 LIU Jianzhong,SUN Haitao,LEI Yi,et al. Current situation and development trend of coalbed methane development and utilization technology in coal mine area[J]. Journal of China Coal Society,2020,45(1):258−267. doi: 10.13225/j.cnki.jccs.YG19.1757

[18] 王保玉,白建平,郝春生,等. 煤层气地面井压裂-井下长钻孔抽采技术效果分析[J]. 煤炭科学技术,2015,43(2):100−103. doi: 10.13199/j.cnki.cst.2015.02.023 WANG Baoyu,BAI Jianping,HAO Chunsheng,et al. Effect analysis on fracturing of coalbed methane surface well and long distance bore-hole gas drainage technology in underground mine[J]. Coal Science and Technology,2015,43(2):100−103. doi: 10.13199/j.cnki.cst.2015.02.023

[19] 陈召英,郝海金,郝春生,等. 煤层气井地面压裂和井下长钻孔联合抽采技术研究[J]. 煤炭科学技术,2019,47(8):142−146. doi: 10.13199/j.cnki.cst.2019.08.018 CHEN Zhaoying,HAO Haijin,HAO Chunsheng,et al. Study on combined extraction technology of underground long borehole and CBM ground-well fracturing[J]. Coal Science and Technology,2019,47(8):142−146. doi: 10.13199/j.cnki.cst.2019.08.018

[20] 袁 亮,杨 科. 再论废弃矿井利用面临的科学问题与对策[J]. 煤炭学报,2021,46(1):16−24. doi: 10.13225/j.cnki.jccs.yg20.1966 YUAN Liang,YANG Ke. Further discussion on the scientific problems and countermeasures in the utilization of abandoned mines[J]. Journal of China Coal Society,2021,46(1):16−24. doi: 10.13225/j.cnki.jccs.yg20.1966

[21] 孟召平,李国富,田永东,等. 晋城矿区废弃矿井采空区煤层气地面抽采研究进展[J]. 煤炭科学技术,2022,50(1):204−211. doi: 10.3969/j.issn.0253-2336.2022.1.mtkxjs202201020 MENG Zhaoping,LI Guofu,TIAN Yongdong,et al. Research progress on surface drainage of coalbed methanein abandoned mine gobs of Jincheng mining area[J]. Coal Science and Technology,2022,50(1):204−211. doi: 10.3969/j.issn.0253-2336.2022.1.mtkxjs202201020

[22] 孟召平,李国富,杨 宇,等. 晋城寺河井区煤矿采空区煤层气地面抽采关键技术研究[J]. 煤炭科学技术,2021,49(1):240−247. doi: 10.13199/j.cnki.cst.2021.01.020 MENG Zhaoping,LI Guofu,YANG Yu,et al. Study on key technology for surface extraction of coalbed methane in coal mine goaf from Sihe Wells Area, Jincheng[J]. Coal Science and Technology,2021,49(1):240−247. doi: 10.13199/j.cnki.cst.2021.01.020

下载:

下载: