摘要:

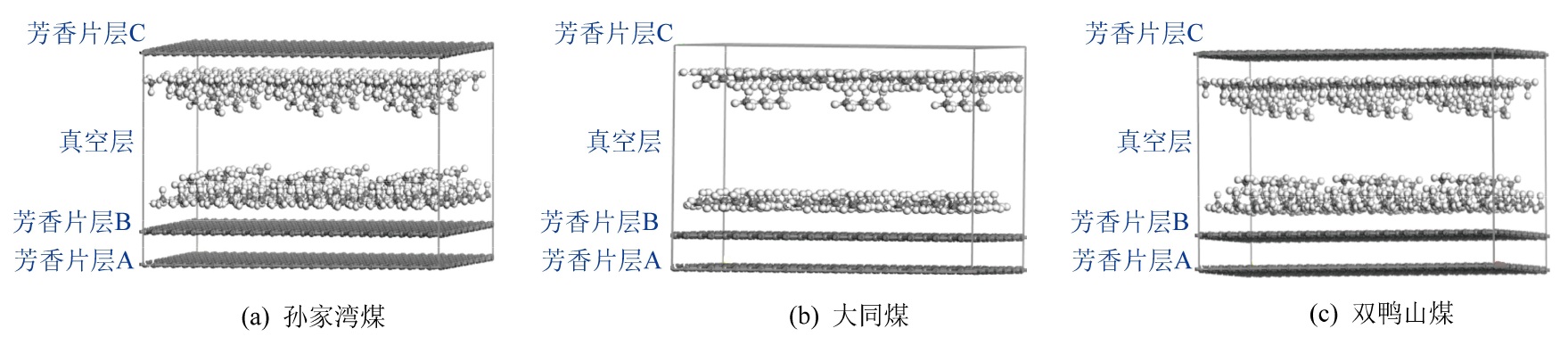

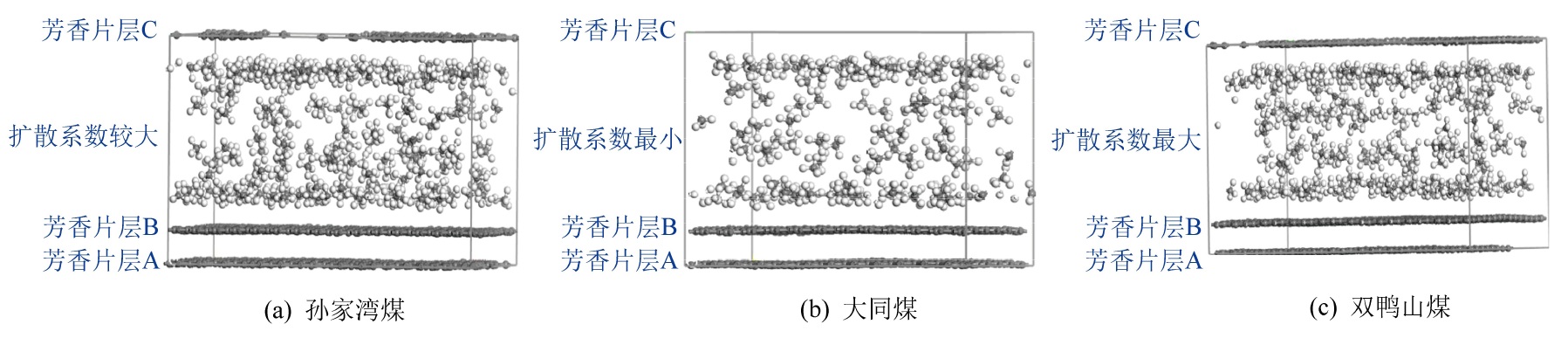

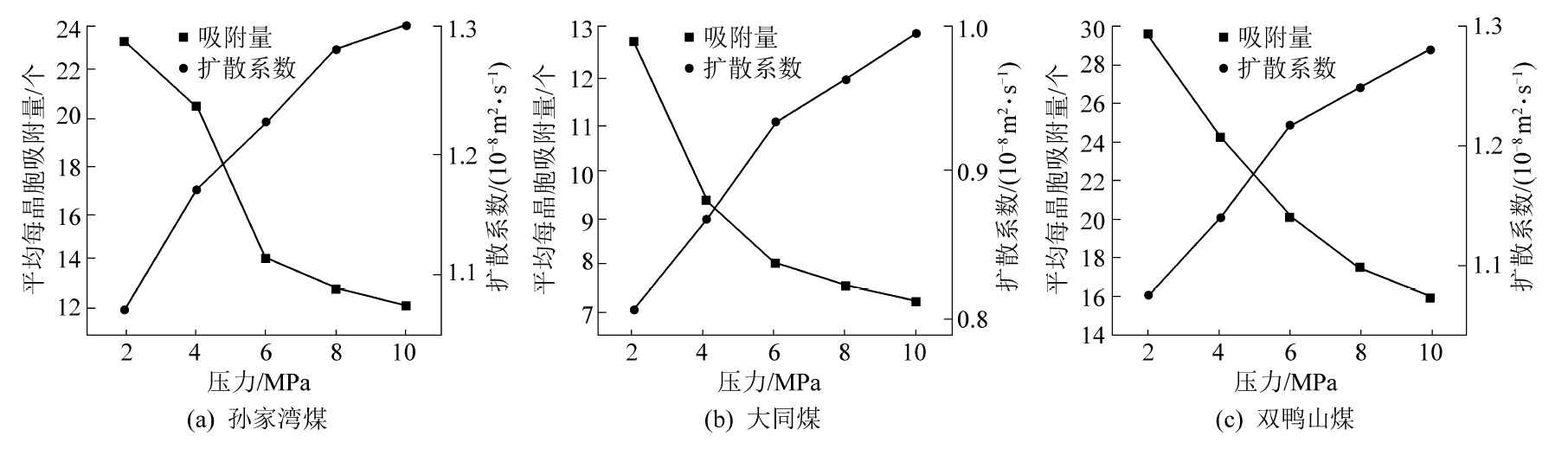

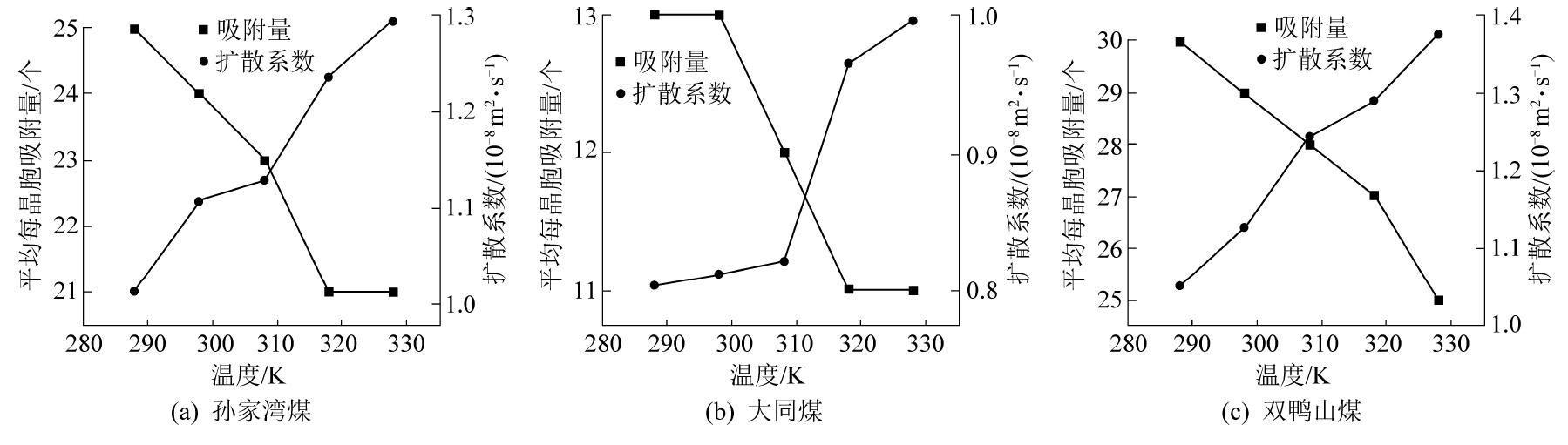

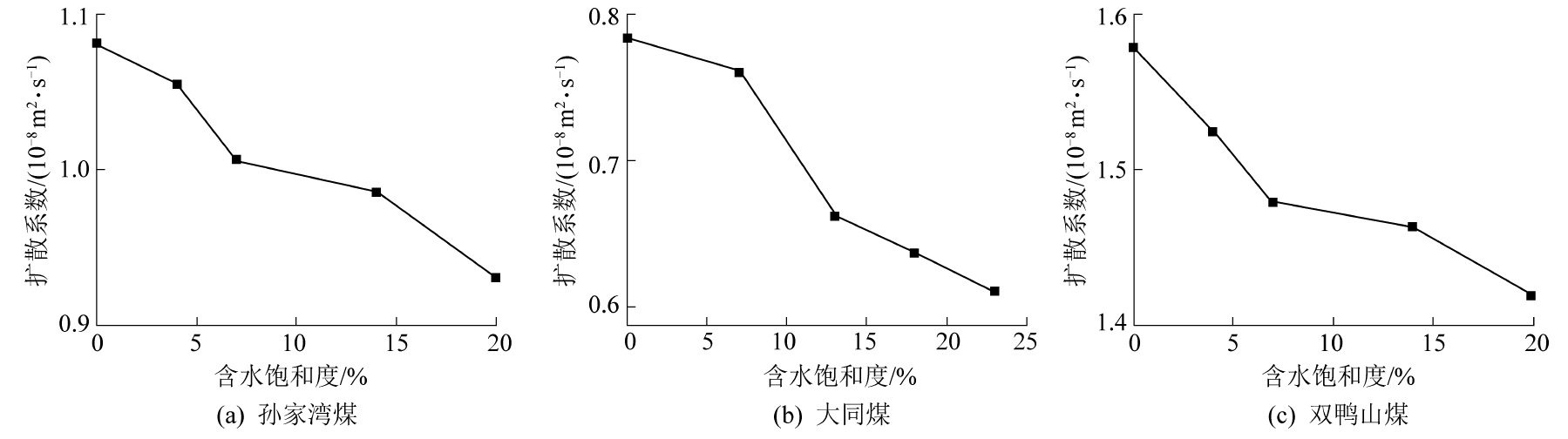

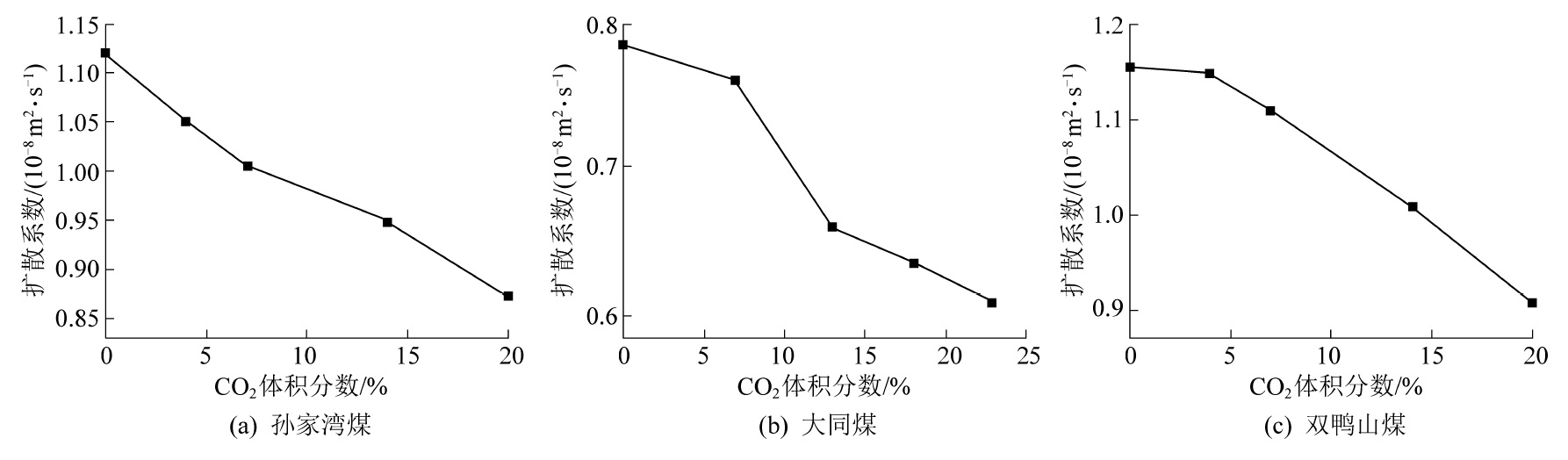

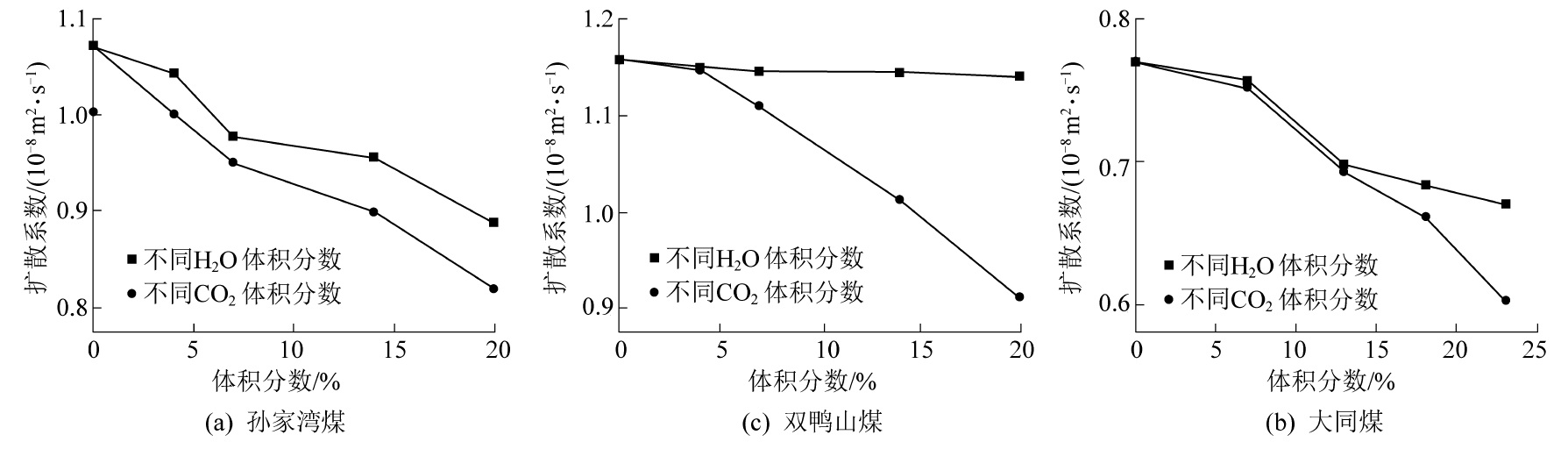

为从微观角度分析煤中甲烷扩散影响因素,以孙家湾、大同、双鸭山3种煤样为研究对象,基于XRD衍射试验结果,构建3种煤大分子结构模型,采用分子动力学模拟方法,研究压力、温度、CO2、H2O对CH4分子在煤中扩散的影响,揭示了不同影响因素下煤中CH4扩散系数变化规律。研究结果表明:压力增加,CH4分子在3种煤中扩散系数先减小后趋于稳定,当压力增大到一定值后孙家湾、大同、双鸭山3种煤中CH4分子扩散系数将分别稳定于1.084×10 -8、0.770×10 -8、1.137×10 -8 m2/s;相同压力条件下,3种煤中CH4分子扩散速率由大到小顺序为双鸭山煤、孙家湾煤、大同煤。温度升高,CH4分子在3种煤中的均方位移均增大,有利于其扩散,不利于其吸附;温度变化对CH4分子在3种煤中扩散速率影响程度由大到小为孙家湾煤、双鸭山煤、大同煤。在一定范围内,水体积分数增加对CH4分子扩散具有阻碍作用,含水饱和度增加对孙家湾与大同煤中CH4分子扩散速率影响较大,对双鸭山煤中CH4分子扩散速率影响较小,注水采气法对孙家湾煤矿与大同煤矿更有效。随CO2体积分数增加,CH4分子扩散系数减小。CO2对煤中CH4分子扩散抑制作用由强到弱为大同煤、孙家湾煤、双鸭山煤。与H2O相比,CO2对CH4分子在煤层中的扩散抑制作用更强,从分子动力学扩散系数角度表明煤层注CO2采气法更有效。

关键词:

-

甲烷

/

-

分子动力学

/

-

煤

/

-

吸附

/

-

扩散系数

Abstract:

In order to analyze the influence factors of methane diffusion in coal from the microscopic point of view.Taking three kinds of coal samples from Sunjiawan, Datong and Shuangyashan as the research objects.Based on the XRD results, three kinds of coal macromolecular structure models were constructed.The effects of pressure, temperature, CO2 and H2O on the diffusion of CH4 molecules in coal were studied by molecular dynamics simulation.The change law of CH4 diffusion coefficient in coal under different influence factors is given.The results show that with the increase of pressure, the diffusion coefficient of CH4 molecules in the three coals decreases first and then tends to be stable. When the pressure increases to a certain value, the diffusion coefficient of CH4 molecules in the three coals from Sunjiawan, Datong and Shuangyashan will be stable at 1.084×10 -8, 0.770×10 -8 and 1.137×10 -8 m 2/s, respectively. Under the same pressure condition, the order of CH4 molecular diffusion rate from large to small is Shuangyashan coal,Sunjiawan coal,Datong coal. With the increase of temperature, the mean orientation shift of CH4 in the three kinds of coal increases, which is conducive to the diffusion of CH4 molecules, but not conducive to its adsorption. The effect of temperature change on the diffusion rate of CH4 molecules in three kinds of coal is from the largest to the least as Sunjiawan coal, Shuangyashan coal,Datong coal. Within a certain range, the increase of H2O content has a hindrance to the diffusion of CH4 molecules. The increase of H2O content has a greater effect on the diffusion rate of CH4 molecules in Sunjiawan and Datong coals, but a smaller effect on the diffusion rate of CH4 molecules in Shuangyashan coals. H2O gas injection method is more effective in Sunjiawan and Datong coals. The molecular diffusion coefficient of CH4 decreases with the increase of CO2 content. The inhibition effect of CO2 on the diffusion of CH4 molecules in coal is stronger to weaker than that in Datong coal,Sunjiawan coal,Suangyashan coal. Compared with H2O, CO2 has a stronger inhibition effect on the diffusion of CH4 molecules in coal seam. From the perspective of molecular dynamics diffusion coefficient, the coal seam CO2 injection gas recovery method is more effective.

百度学术

百度学术

百度学术

百度学术

本站查看

本站查看

百度学术

百度学术

百度学术

百度学术

百度学术

百度学术

下载:

下载: