Coal mining equipment lifecycle management system architecture and key technology

-

摘要:

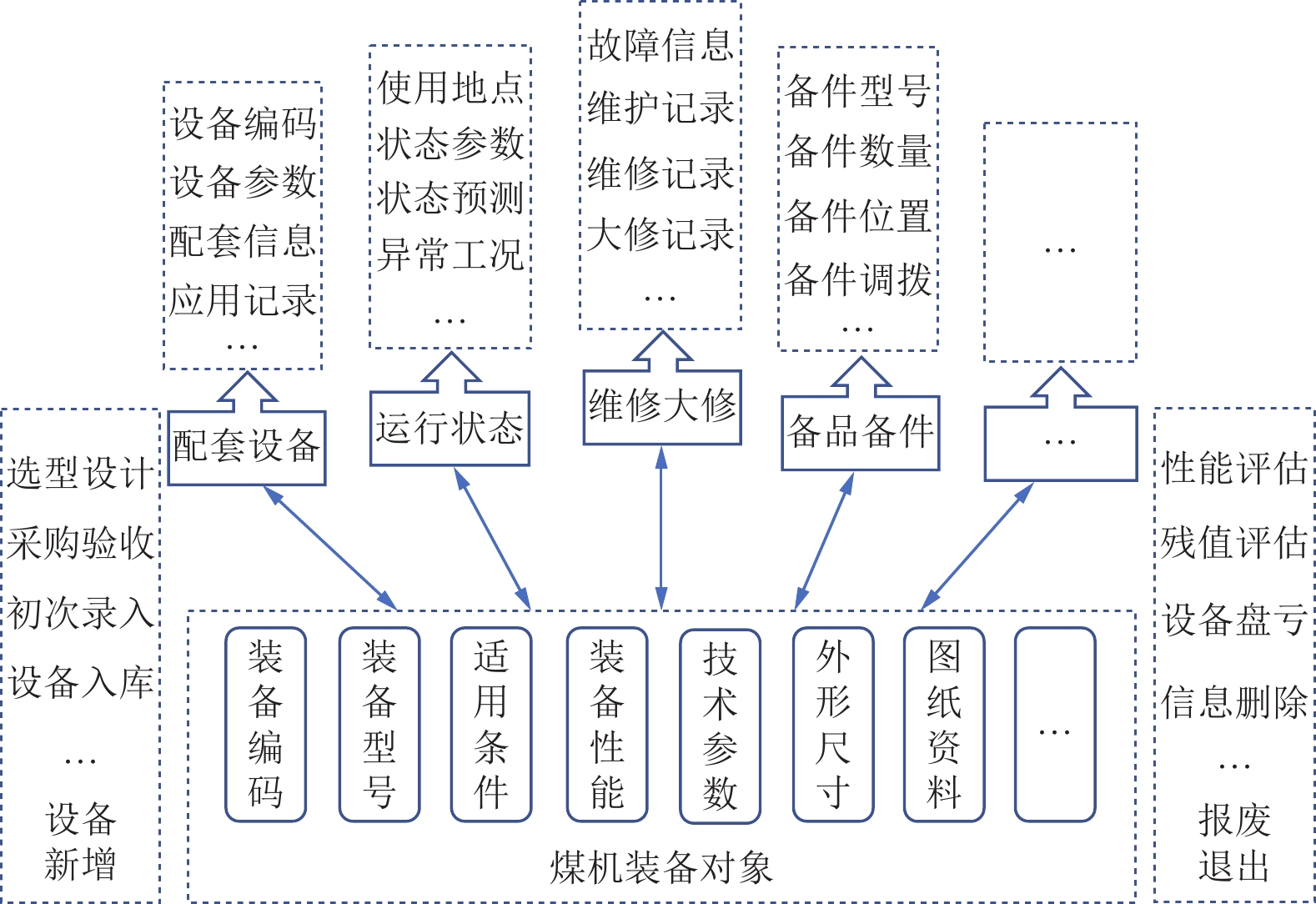

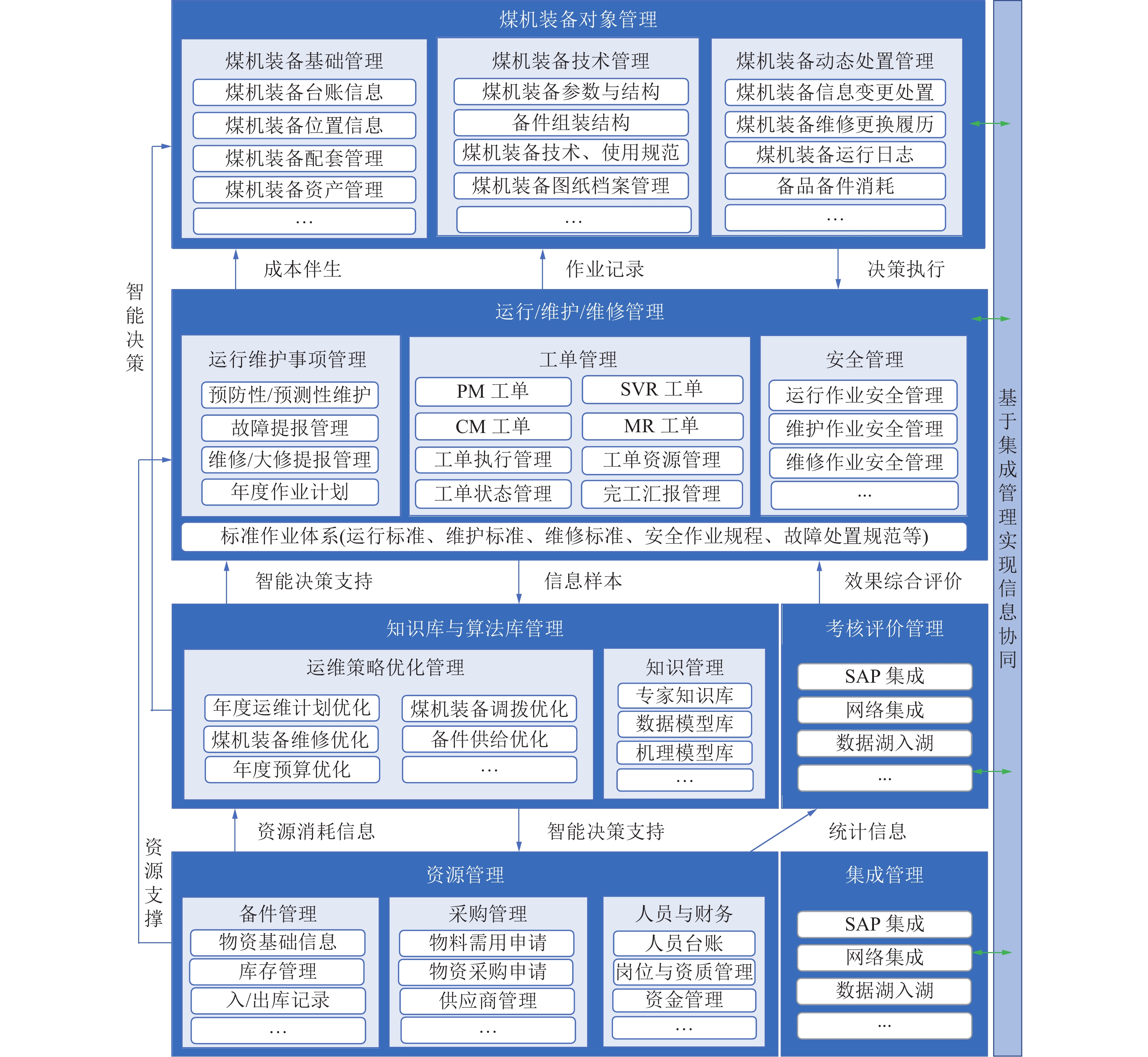

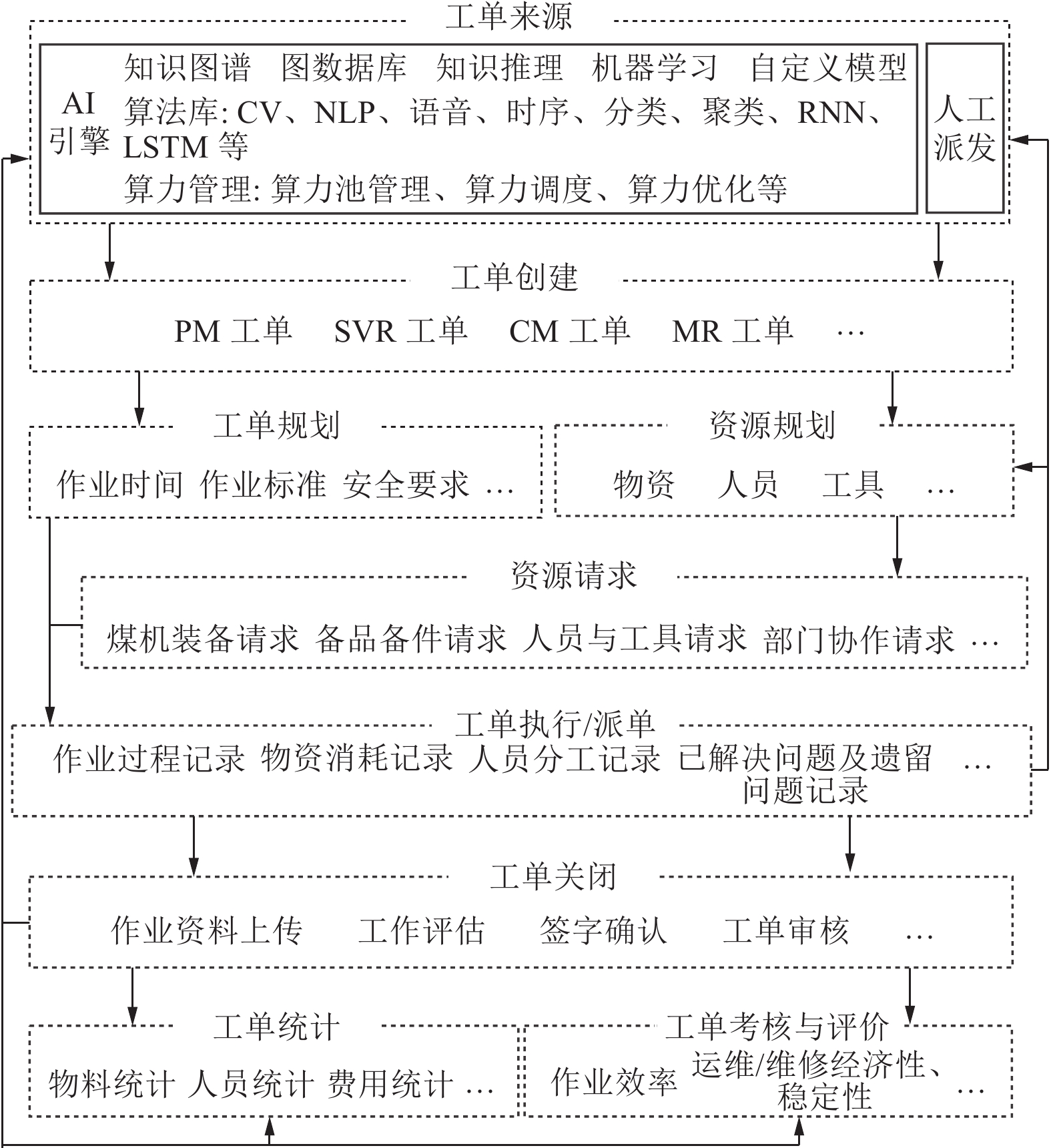

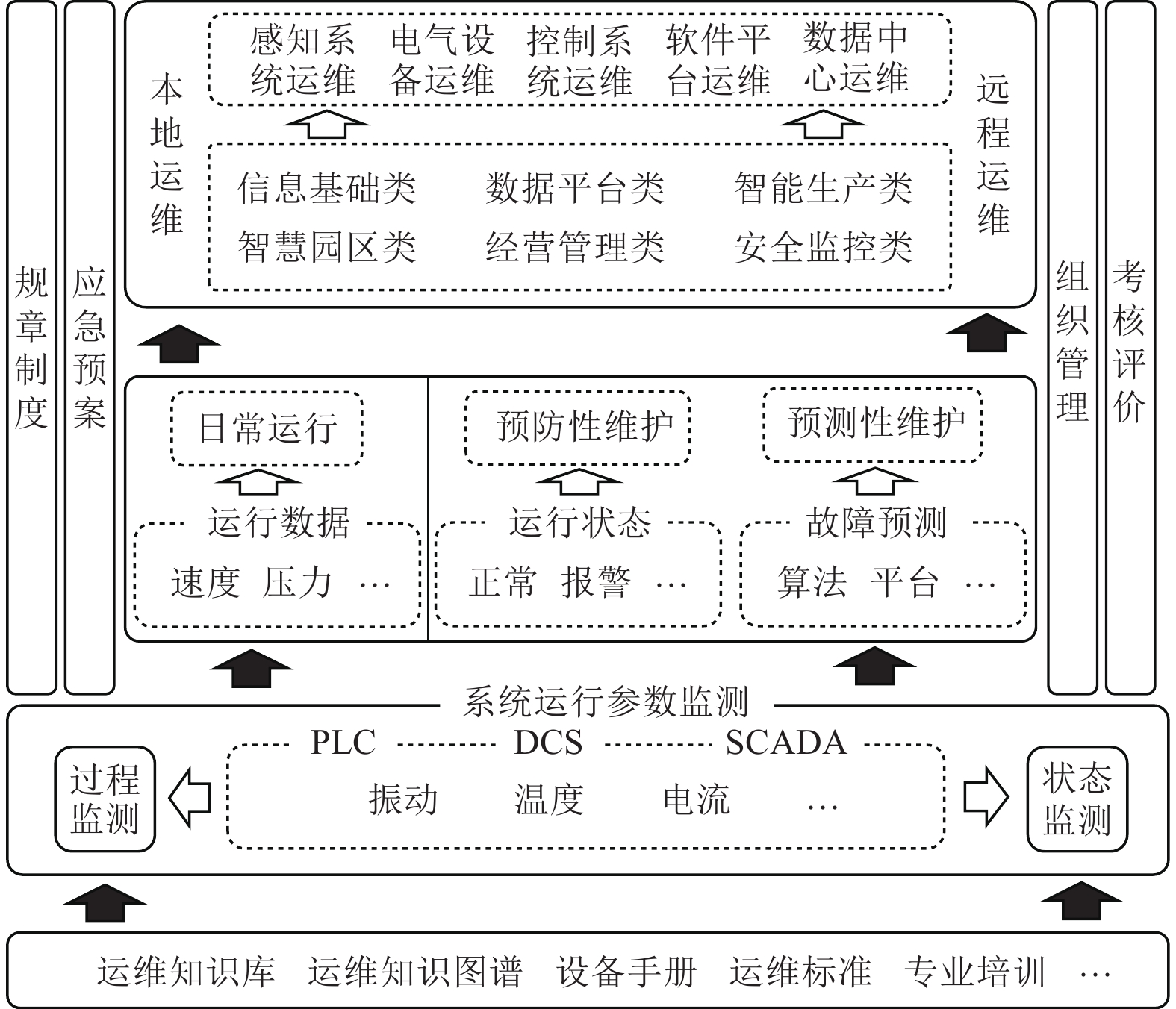

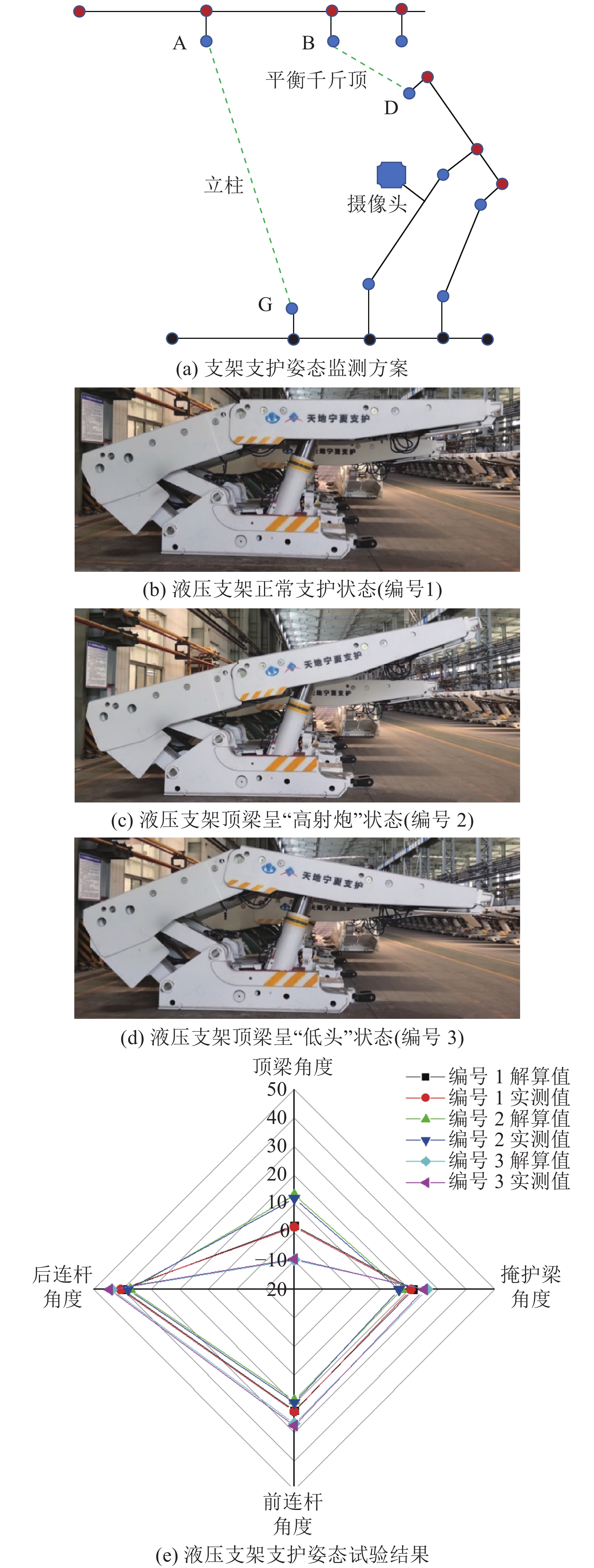

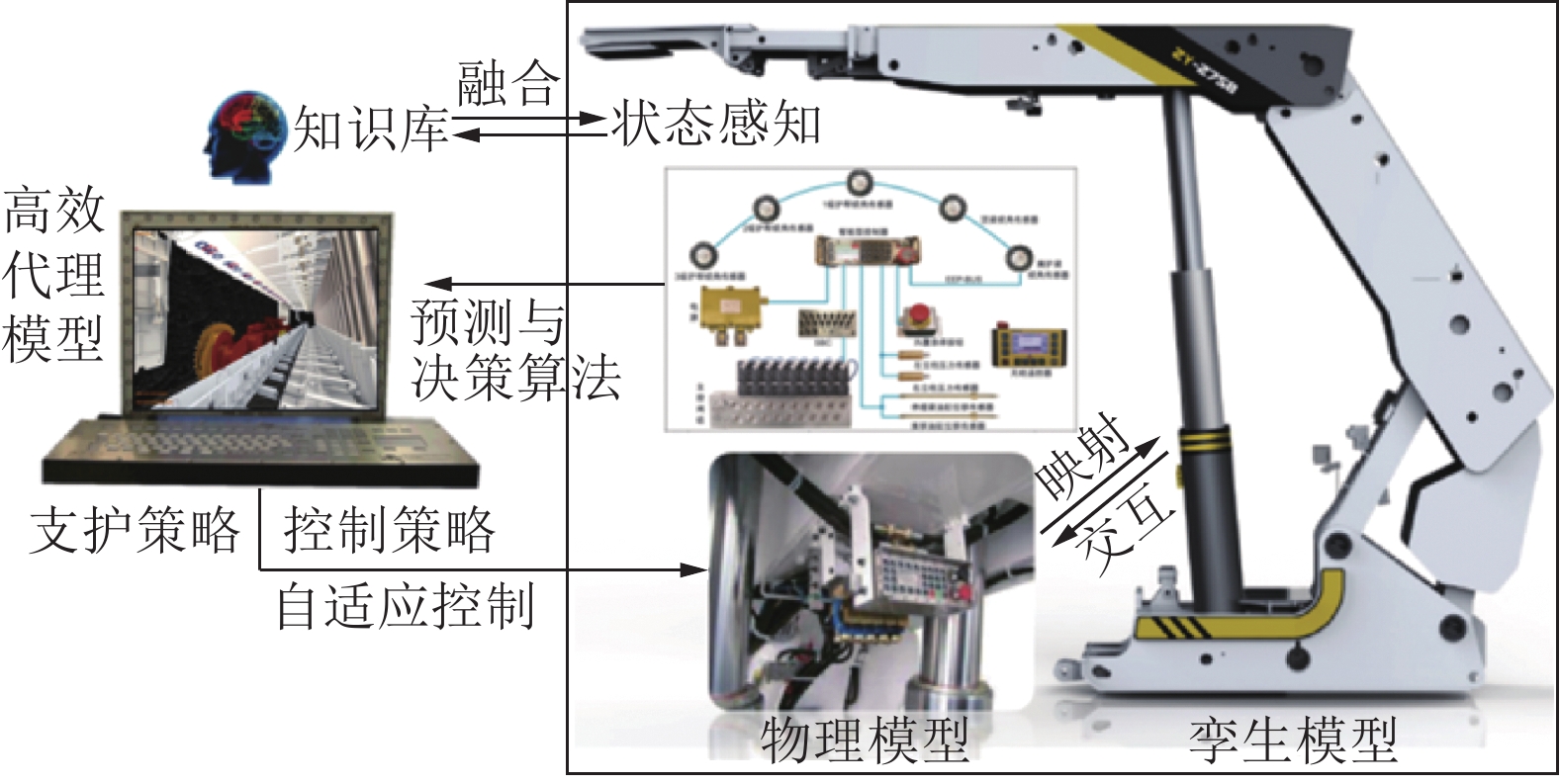

针对煤机装备实现全生命周期数智化综合管理技术难题,将我国煤机装备全生命周期管理技术发展历程划分为3个阶段,从煤机装备管理标准体系建设、设备台账流程管理、智能运维管理及系统平台建设等方面分析了现阶段我国煤机装备管理存在的痛点。研究了煤机装备前期、中期、后期管理目标、业务流程及实施主体,提出了煤机装备全生命周期数智化管理系统总体架构。分析了煤机装备选型优化设计主要影响因素,研究得出了综采设备选型优化计算方法,开发了综采设备选型优化算法及软件平台,提出了煤机装备系列型谱与编码体系构建方法。将煤机装备管理划分为6个业务域,阐明了不同业务域之间的关联关系;研究了工单管理流程不同阶段的业务分工,提出了基于AI赋能的工单精细化管理流程。分析了不同运维模式之间的差异,基于区域集中运维模式提出了煤机装备运维管理技术框架。分析了煤机装备状态感知技术现状及存在的问题,研究了基于非接触式传感技术的间接感知方法,在提高解算精度的前提下降低了安装与运维成本。研究了基于数字孪生技术对实体模型进行远程运维作业的技术路径,提出了几何模型+机理模型+数据模型融合驱动的运行控制与维护策略,展望了煤机装备全生命周期数智化综合管理技术及系统平台研发方向。

Abstract:In response to the technical challenges of achieving intelligent comprehensive management of the entire lifecycle of coal mining equipment, the development process of China’s coal mining equipment lifecycle management technology is divided into three stages. The pain points in China’s current coal mining equipment management are analyzed from the aspects of standard system construction, equipment ledger process management, intelligent operation and maintenance management, and system platform construction. We have studied the management objectives, business processes, and implementation entities of coal mining equipment in the early, middle, and later stages, and proposed the overall architecture of a digitalized management system for the entire lifecycle of coal mining equipment. The main influencing factors of coal mining equipment selection optimization design were analyzed, and a calculation method for comprehensive mining equipment selection optimization was studied. An optimization algorithm and software platform for comprehensive mining equipment selection were developed, and a method for constructing a series spectrum and coding system for coal mining equipment was proposed. Dividing coal mining equipment management into six business domains and clarifying the interrelationships between different business domains; We studied the business division of labor in different stages of the work order management process and proposed a refined work order management process based on AI empowerment. Analyzed the differences between different operation and maintenance modes, and proposed a technical framework for coal machine equipment operation and maintenance management based on the regional centralized operation and maintenance mode. Analyzed the current status and existing problems of coal mining equipment state perception technology, studied indirect perception methods based on non-contact sensing technology, and reduced installation and operation costs while improving solution accuracy. We studied the technical path of remote operation and maintenance of physical models based on digital twin technology, proposed a geometric-mechanism-data model fusion driven operation control and maintenance strategy, and looked forward to the development direction of intelligent comprehensive management technology and system platform for the entire life cycle of coal mining equipment.

-

0. 引 言

氟元素是人类必不可少的微量元素之一,然而过量甚至少量的氟化物都是有害的,比如过量摄入氟化物会导致牙齿或氟骨症、甲状腺和内分泌系统功能受损或发育神经毒性[1-4]。在过去的百年间,由于含氟化合物在技术和生活中的重要性日益增加,导致向生物圈排放的氟化物大量增加[5]。在煤炭资源开采领域,由于资源的大量消耗,近年来开采深度逐渐加深,煤炭开采产生的矿井水中氟化物含量逐年升高,特别是神东矿区矿井水中的氟化物超标趋势尤为突出[6-8]。

神东矿区地处黄河中游,煤炭资源非常丰富,然而生态环境脆弱,水资源相对短缺。近年来,神东矿区作为黄河流域生态保护的重点矿区,将矿井水储存于地下水库中,处理后作为生产、生态、生活用水循环利用[9-12]。然而,随着煤矿开采深度的增加,在多个矿区检测出高氟矿井水,比如布尔台矿区矿井水中F-质量浓度高达13 mg/L,远超过GB3838—2002《地表水环境质量标准》中III类水质中氟化物浓度(1.0 mg/L),高氟污染已成为威胁矿井水资源化循环利用的关键问题。研究认为,矿井水中的氟化物超标问题主要与人类活动污染、地下含氟矿物释放以及氟的富集有关[13-15]。人类生产生活产生的可溶性氟,随雨水进入土壤、地下水,导致地下水氟化物超标。地层中含氟矿物特别是富氟矿物[14-15],主要有萤石(CaF2)、冰晶石(Na3AlFPO6)、氟磷灰石(Ca3(PO)2Ca(FCl)2)等,煤炭资源的开采破坏了地下含水层的结构,地下水流经含氟富氟矿物,由于水流的物理、化学、生物等作用,导致氟化物溶解到矿井水中形成含氟矿井水[15-16]。国外相关研究表明[17-19],富氟矿井水的形成是由于含水层岩石风化或溶解、以及蒸发作用,而萤石(CaF2)的溶解平衡是控制地下水中F−浓度的基本因素。Simona等研究阿鲁托火山地区的氟化物迁移规律时发现,氟化物容易从浮石和沉积物中浸出,但很难从固结岩石中浸出[20]。此外,由于降水量小或pH较高等因素造成氟元素富集,也会导致矿井水中氟化物浓度上升[21-22]。

当前对矿井水中氟化物来源的解析,多局限于利用统计学、数值模拟等方法进行推测计算。张伟等[23]研究内蒙古布尔台煤矿高氟矿井水特征及成因分析,通过SPSS、pHREEQC等软件进行统计分析和模拟,认为萤石等含氟矿物是矿井水中氟的主要来源,方解石、白云石等含钙矿石的沉淀作用影响萤石的溶解平衡,蒸发浓缩、阳离子交换作用和HCO3-的竞争吸附作用会直接或间接的促进氟的富集。郭洋楠等[24]通过氢氧同位素分析、水化学等方法推测矿井水中F−浓度的升高与水岩作用过程中Na+和Ca2+的变化有关系。还有一些研究学者认为[16,25-26],在碱性矿井水中,F−和OH−半径非常接近,在水岩作用过程中,黏土矿物和云母矿物中以吸附态和以类质同象形式呈离子态存在于矿物晶格中的氟,有可能被分解或置换出来,导致水体氟浓度增大。

因此,通过展开相关试验研究天然矿物中氟化物的浸出规律以及不同深度的天然矿物对矿井水中F−浓度的影响,对厘清矿井水中的氟化物来源具有重要的意义。以神东典型矿区不同深度的天然矿物为研究对象,采用模拟水岩浸出试验和对比试验的方式,讨论了不同深度天然矿物的氟化物富存规律,并对典型的天然含氟矿物进行了F−浸出试验,分析了天然含氟矿物在水中的F−浸出规律,验证了改变水岩作用条件可以提高天然含氟矿物在水中的F−浸出溶度。试验证明,在一定的水岩作用环境下,神东矿区的天然含氟矿物可以导致矿井水中氟化物超标(大于1.0 mg/L),有力证明了天然含氟或富氟矿物是矿井水中氟化物的主要来源。

1. 样品采集与测试分析

由于神东矿区不同煤矿的地理位置相近,水文地质条件相似[27-29],为研究神东矿区不同开采深度的矿井水氟超标情况,分别在寸草塔一矿、哈拉沟矿、石圪台、柳塔矿、布尔台矿、石圪台矿的井下不同位置采集了矿井水样10组,包含埋深40~360 m的采水点,主要取自水仓、煤顶板渗水、采空区进出水。水样采集后,采样方法按国标,测试所用试剂均为分析纯[23],具体采集的矿井水信息见表1。

表 1 神东矿区矿井水采样信息Table 1. Rock mining area samples in Shendong Mining Area序号 地点 埋深/m 采集位置 1 寸草塔一 40 2−2煤中央水仓 2 石圪台 70 1−2煤顶板渗水 3 哈拉沟 80 水仓 4 柳塔矿 120 1−2煤采空区净化出水 5 柳塔矿 130 2−2煤采空区进水水仓水 6 柳塔矿 140 2−2煤顶板渗水 7 寸草塔一 160 水仓 8 寸草塔一 171 2−2煤矿矿井水、采空区进水 9 布尔台 256 4−2煤矿矿井水、采空区进水 10 布尔台 340 4−2煤矿矿井水、采空区出水 11 布尔台 360 2−2煤中央水仓 为进一步分析神东矿区天然矿物中的氟化物情况,在哈拉沟矿区、布尔台矿区进行了钻孔取样,采集到了不同深度的黄土、岩石、煤样等样品。所有固体样品研磨至粒径小于100目(0.150 mm),在115 ℃以上烘干6 h后压片,进行X射线荧光(XRF)测试,可得到不同样品的氟含量。

选取部分固体样品进行了水中氟化物的浸出试验。所有样品溶液用0.45 μm的微孔过滤器进行过滤后,分成3份。采用离子色谱法(IC)测定

${\rm{SO}}_4^{2-} $ ,Cl−,F−和${\rm{NO}}_3^{-} $ 的浓度;其中一份用HNO3酸化至pH<2,使用电感耦合等离子发射光谱法测定Na+、Ca2+、Mg2+和K+等阳离子的浓度;其中一份使用pH计对矿井水样品进行了pH测试。为验证不同水岩作用条件下天然矿物中氟化物在水中的浸出情况,将一定比例的岩石样品浸泡于超纯水或矿井水中,采用静态试验、恒温震荡、超声波震荡等方式加速氟离子的浸出速度,采用离子色谱法进行水中阴离子的检测。

2. 结果分析

2.1 矿井水成分分析

GB3838—2002《地表水环境质量标准》中规定地表III类水质标准中氟化物标准为1.0 mg/L,分析神东矿区不同取样深度的矿井水(图1a和表2),在80 m处,哈拉沟水仓氟化物含量为0.46 mg/L,在120 m处,柳塔矿采空区净化出水的氟化物含量为1.60 mg/L,超过地表III类排放标准。

表 2 神东矿区矿井水成分Table 2. Rock mining area samples in Shendong Mining Area序号 pH 埋深/m 各成分质量浓度/(mg·L−1) 氟化物 氯化物 硫酸盐 硝酸盐 碳酸氢根 钠 镁 钾 钙 1 7.00 40 0.81 113.34 296.25 22.54 325.80 112.00 20.07 2.5 15.49 2 6.20 70 0.95 43.45 272.74 1.74 412.50 117.12 9.32 3.76 14.84 3 8.30 83 0.46 7.18 970.00 0.02 210 666 110 14 7.86 4 7.02 120 1.60 30.06 166.42 0.66 538.20 116.11 0.44 0.33 0.93 5 6.25 120 2.48 89.10 187.81 0.23 496.70 168.34 1.14 1.74 3.37 6 7.09 140 4.40 73.49 150.66 1.86 527.20 173.99 0.72 1.89 1.02 7 7.12 160 13.98 317.29 3.65 <0.15 497.90 208.97 0.48 0.91 1.09 8 7.10 171 9.24 319.49 77.40 1.63 690.70 240.53 1.92 5.34 2.58 9 7.12 256 7.82 277.14 79.17 2.33 881.10 258.68 1.25 2.99 0.78 10 7.05 340 6.80 292.10 59.50 2.51 983.60 265.25 1.32 2.91 0.83 11 7.10 360 6.31 281.78 30.24 0.21 1 444.90 301.30 1.20 2.49 1.08 注:pH限值为6~9,氟化物、氯化物、硫酸盐、硝酸盐的限值分别为1.000、250.00、250.00、10.00 mg/L。 图1b中,Cl−浓度在160 m处为317.29 mg/L,远大于地表III类排放标准,并且在深度大于170 m后,逐渐降低,与F−浓度变化一致。对不同深度的矿井水中的离子成分进行分析发现,深度0~160 m,F−浓度随埋深深度的增大而增大,在大于160 m后,F−浓度随深度增大而降低,但是F−浓度依旧严重超标,这是由于开采过程中地层结构破坏导致地下水渗流的路径变化或是地下水渗流过程中天然矿物的净化作用[17,30-32],导致同一深度的采水点样品可能来自不同的埋深含水层。

如图1c和1d,分析矿井水中阳离子浓变化,发现Ca2+浓度随埋深增大呈现缓慢减小,Na+浓度随埋深增大呈现缓慢增大。在较浅的40 、70 和83 m处矿井水Ca2+的浓度高于120 m以上其他矿井水,而F−浓度低于1.0 mg/L,氟化物浸出较少。随着埋深增大,在120 m以上,Ca2+的浓度降低,Na+浓度增大,360 m处Ca2+的浓度为0.93 mg/L,Na+浓度为301.30 mg/L,F−浓度大于6.31 mg/L,说明随着深度的加深,矿井水逐渐由Ca型水向Na型水转变,Na型水具有较高的氟化物[24]。

根据上文,矿井水中F−浓度的升高与埋深深度和天然含氟矿物有很大的关系。当地下水中Na+与Cl−的摩尔浓度比接近于1∶1时,表明岩盐溶解是矿井水中Na+和Cl−的主要来源[24]。如图2所示,Na+与Cl−的摩尔浓度比明显远离1∶1线,然而Na+与Cl−的摩尔浓度具有很好的相关性(R2=0.7432),表明矿井水中的Na+除来源于岩盐溶解,还可能来源于地下水中的阳离子交换吸附作用。

通过矿井水中的阴阳离子变化分析,在长期的水岩作用下,天然矿物中的部分氟化物发生了浸出,导致矿井水中的离子浓度改变,推测F−浓度较高的原因是在120 m下,含氟或富氟矿物层较多,导致随着开采深度的加深,矿井水中氟化物超标严重,个别地区可能由于靠近地下水的排泄区,受到的蒸发作用较强,出现高氟矿井水[32]。

2.2 天然矿物成分分析

高氟矿井水的产生可能来自于不同深度的含水层,为进一步探索高氟矿井水与开采深度及天然矿物氟化物的关系,选择对神东哈拉沟(矿井水氟浓度较低)、布尔台矿区(矿井水氟浓度较高)进行钻孔取样,得到了两批次不同深度不同岩层的样品,对其进行XRF测试后,在多个样品中检测到了氟元素。假设1 g样品浸泡于100 mL水中,含氟矿物全部浸出时的水溶液中的F−浓度为天然矿物的F−理想浸出浓度,具体见表3和图3。

表 3 矿区天然矿物的氟含量Table 3. Fluorine content of natural minerals in mining area矿区 编号 深度/

m氟元素

质量分数F−理想浸出浓度/

(mg·L−1)编号 深度/

m氟元素

质量分数F−理想浸出浓度/

(mg·L−1)编号 深度/

m氟元素

质量分数F−理想浸出浓度/

(mg·L−1)哈拉沟 H1 0.5 0.0433 4.33 H10 220 0.1045 10.45 H19 316 — — H2 18 — — H11 236 — — H20 316 H3 64 — — H12 238 0.0628 6.28 H21 340 — — H4 85 — — H13 243 — — H22 390 0.1055 10.55 H5 120 — — H14 250 0.0901 9.01 H23 430 0.0367 3.67 H6 142 — — H15 253 0.0591 5.91 H24 443 0.0814 8.14 H7 157 0.1115 11.15 H16 290 0.0372 3.72 H25 466 — — H8 160 0.1004 10.04 H17 295 0.0680 6.8 — — — — H9 207 0.0428 4.28 H18 310 0.1208 12.08 — — — — 布尔台 B1 0.5 — — B14 455 0.0545 5.45 B27 569 — — B2 9.5 0.1423 14.23 B15 475 0.0614 5.64 B28 580 — — B3 46 — — B16 483 — — B29 585 — — B4 56 — — B17 493 — — B30 592 0.0450 4.5 B5 129 — — B18 503 0.0510 5.1 B31 598 0.0415 4.15 B6 240 — — B19 506 0.0559 5.59 B32 610 0.0776 7.76 B7 290 — — B20 510 — — B33 616 0.1208 12.08 B8 320 — — B21 516 — — B34 621 0.0678 6.78 B9 350 0.0829 8.29 B22 527 — — B35 631 0.0540 5.4 B10 380 — — B23 538 — — B36 633 — — B11 397 0.0614 6.14 B24 540 0.0825 8.25 B37 647 — — B12 410 0.0614 6.14 B25 546 0.0666 6.66 B38 652 — — B13 436 — — B26 556 — — — — — — 表2中,哈拉沟和布尔台矿不同深度的63个天然矿物中,有30个样品的F−理想浸出浓度大于1 mg/L,含氟矿物占比接近50%。如图3a所示,哈拉沟矿发现在40 m左右的黄土样品H1检测到了氟元素,分析认为主要由于农业化肥、大气降尘、农业灌溉等人为因素的影响。在80~100 m深度监测的岩石样品中,未检测到F元素,结果与矿井水监测结果(表1)相吻合。随着开采深度的增大,在157 m深度的安定组再次检测到了F元素,F元素含量为0.11%,F−理想浸出浓度高达11.15 mg/L,远超地表环境III类标准的F−浓度(1.0 mg/L)。在大于120 m的20个样品中,13个样品的F−浓度大于1.0 mg/L,F−浓度超标的概率为65 %。

如图3b所示,在布尔台矿区的样品中,F−浓度超标的样品主要集中在深度350~700 m,在30个样品中,有15个样品的F−理想浸出浓度大于1.0 mg/L,含氟样品的占比为50%。因此,矿井水中氟含量超标不仅是生活生产污染排放的结果,矿井水F−浓度的累积是由于煤炭开采破坏了地下水原有的渗流路径,导致地下水经过这些含氟的岩石和煤层,最终造成煤炭开采形成的矿井水氟化物浓度超标[29,32]。

2.3 天然矿物浸出结果分析

地层水岩作用是一个复杂的反应过程,可能受到人为开采活动、环境温度、pH、矿物溶解等多种或一种因素的影响[29]。为证明天然含氟矿物的溶解是矿井水中氟化物的主要来源,探索天然含氟矿物的氟化物浸出规律具有重要的理论参考价值。试验通过恒温震荡、超声震荡模拟不同水岩作用强度,改变不同岩水配比模拟水岩接触面积,通过调节pH模拟地下pH环境。为提高氟化物浸出效果,所有的固态样品研磨至颗粒尺寸为100目(0.149 mm)。本试验中的模拟水岩作用只能替代或部分替代实际水岩作用的一部分,但试验结果对证明天然含氟矿物是矿井水中氟化物主要来源具有重要的意义。

2.3.1 天然含氟矿物在不同水岩作用强度下的离子浸出

1)恒温震荡条件。为验证天然含氟矿物中的氟化物浸出效果,在恒温震荡条件下选取2种典型天然含氟矿物进行超纯水或矿井水中的浸出测试。样品选取含氟矿物直罗组H9和延安组H12,见表3,样品H9和H12的F−理想浸出浓度分别为4.28 mg/L和6.28 mg/L。为模拟水岩作用强度,将岩样和水的比例定为1∶100,在室温(25 ℃)下以150 r/min的速度将溶液恒温振荡1 d后,如图4a所示,样品H9在超纯水中的F−浓度为0.03 mg/L,恒温振荡3 d后,F−浓度增大到0.05 mg/L,溶液中Cl−和

${\rm{SO}}_4^{2-} $ 升高;样品H12在超纯水中的离子浸出情况与H9类似(图4c)。如图4b和图4d,当H9和H12岩样在矿井水中的整体变化规律与超纯水中相似,但对比发现,在矿井水中,岩样中浸出的Cl−和${\rm{SO}}_4^{2-} $ 浓度都显著高于超纯水中Cl−和${\rm{SO}}_4^{2-} $ 浓度,而F浓度没有明显差异。分析认为,在岩水比(1∶100)及恒温震荡的条件下,直罗组岩样H9和延安组岩样H12中F−浸出浓度已达到最大值,说明含氟矿物在水中的氟化物浸出量较低,远低于理想浸出浓度。然而为探索实际高氟矿井水的源头,需改变水岩作用条件进一步分析天然含氟矿物在矿井水中的氟浸出情况。2)超声震荡。为进一步探索在剧烈的水岩作用条件下,天然含氟矿物中的氟化物在水中的浸出情况,分别选取哈拉沟和布尔台矿区不同深度的含氟矿物进行在含氟矿井水和超纯水中的超声浸泡试验,岩样和水的比例为1∶100。

通过哈拉沟天然矿物H9、H12、H16、H18、H22、H23及H24样品的超声浸泡试验结果发现,这7个样品的F−理想浸出浓度分别为4.28、6.28、3.72、12.08、10.55、3.67、8.14 mg/L。试验超声10 min后,不同样品的F−浓度有显著的差异,大部分样品的F−质量浓度低于0.10 mg/L,样品H22的F−质量浓度为0.20 mg/L,这是由于样品H22的理想F−浸出质量浓度为10.55 mg/L。随着超声时间增大,各样品F−质量浓度不断增大,超声70 min后,各样品F−浓度达到最大值,样品H22的F−浸出浓度最高,为0.40 mg/L,但远低于地表环境III类氟化物标准1.0 mg/L。同时分析溶液中的Cl−和

${\rm{SO}}_4^{2-} $ 浓度,如图5b—图5c所示,多数样品的Cl−浓度随超声时间增大缓慢升高,但升高趋势与F−浓度变化相似,${\rm{SO}}_4^{2-} $ 的浓度随超声时间增大有缓慢的升高或降低,但是各样品的变化较小;在图5d中,在30 min后,各样品的pH趋向稳定,说明超声70 min后,天然含氟矿物的水溶液中离子达到平衡态[33-34],各溶液中的F−浓度基本稳定。在布尔台天然含氟矿物中,选取B12、B32、B33及B34进行超声浸泡试验,岩水比为1∶100,4个样品的F−理想浸出质量浓度分别为6.14、7.16、12.08、6.78 mg/L,浸泡水选取了超纯水、布尔台高氟矿井水及哈拉沟低氟矿井水。如图6a—图6c所示,在超纯水中,超声60 min后,不同样品中的F−、Cl−、

${\rm{SO}}_4^{2-}$ 浓度基本不再变化,这与上文所述哈拉沟矿岩样试验结果相似。在布尔台含氟矿井水中,如图6d—图6f所示,超声60~120 min后,不同样品中的F−、Cl−、${\rm{SO}}_4^{2-} $ 浓度变化很小,原布尔台含氟矿井水F−质量浓度为4.40 mg/L,超声后B34样品的F−质量浓度最高为4.60 mg/L,实际天然矿物浸出的F−质量浓度仅为0.20 mg/L。类似的,在哈拉沟矿井水中,原矿井水中F−质量浓度为0.33 mg/L,超声后B34样品的F−质量浓度最高为0.52 mg/L,说明在哈拉沟矿井水实际天然矿物浸出的F−质量浓度仅为0.2 mg/L。通过模拟典型岩石样品在不同强度的水岩作用条件下的离子浸出情况,说明天然含氟矿物中的氟化物浸出浓度,除了与水岩作用条件有关,还与原生水化学成分密切相关[35]。当吸附性氟化物在岩石中占比较高时,在短时间内可以有较多的氟化物溶解到水中[22-33],而较强的水岩作用强度可以加速岩样中的F−浸出。

2.3.2 天然含氟矿物在不同岩水比条件下的离子浸出

在岩、水质量比为1∶100条件下,采用哈拉沟和布尔台矿的典型样品进行超声氟浸出实验,F−浸出规律相似,可见天然矿物中的氟化物浸出与矿区的选择没有关系。

因此进一步优化氟浸出试验,在表3中选择哈拉沟H7、H9、H19及H22四个含氟量较高的岩石,进行不同岩水比例的超声浸出试验,这4个样品的F−理想浸出浓度均大于10 mg/L。将H7样品不同的岩水比标记为S1-1(1∶50),S1-2(1∶100),S1-3(1∶200);H9、H19和H22样品分别标记为S2、S3和S4。如图7所示,岩水比为1∶50条件下,超声70 min后,S1-1样品F−质量浓度为0.96 mg/L,S2-1样品F−质量浓度为1.01 mg/L,S3-1样品F−质量浓度为0.44 mg/L,S4-1样品F−质量浓度为0.54 mg/L;岩水比为1∶100条件下,超声60 min后,S1-2样品F−质量浓度为0.26 mg/L,S2-2样品F−质量浓度为0.21 mg/L,S3-2样品F−质量浓度为0.20 mg/L,S4-2样品F−质量浓度为0.30 mg/L;岩水比为1∶200条件下,超声60 min后,S1-3样品F−质量浓度为0.14 mg/L,S2-3样品F−质量浓度为0.19 mg/L,S3-3样品F−质量浓度为0.11 mg/L,S4-3样品F−质量浓度为0.15 mg/L。

结果显示,高的岩水比(1∶50)条件下的F−浸出浓度高于岩石水(1∶200)条件下的F−浸出浓度,如S1-1样品的F−浸出浓度为1 mg/L,S2-1样品的F−浸出浓度大于1 mg/L。试验证明,在高的岩水比条件下,含氟矿物的氟化物浸出可以造成矿井水中的氟超标现象。

2.3.3 天然含氟矿物在不同pH条件的F−浸出规律

实际矿井水在地下运移过程中的水岩作用条件非常复杂,例如不同位置甚至相同位置的岩石样品的氟化物含量存在差异;不同岩性的岩石含水率不同,直接影响氟化物的浸出时间;水岩作用的强度等受地质条件、地下水净流量、流速、接触面与接触时间、采煤方式等因素影响[36-39]。

在上述试验结果的基础上,尝试通过调节pH的方式,加速岩石样品中氟化物的浸出。如图8所示,加入HCl后,调节pH到3.5~4,7 d后S1-1的F−质量浓度高达2.19 mg/L,S1-2和S1-3的F−质量浓度分别为1.49 mg/L和0.91 mg/L;7 d后S2-1的F−质量浓度高达1.67 mg/L,S2-2和S2-3的F−质量浓度分别为1.25 mg/L和0.79 mg/L。如图8a所示,对比岩样所在水中的pH值,发现超纯水中加入岩样后,水样pH值呈碱性,由于水溶性氟与pH是正相关关系[34],因此随着pH的增大,水溶性氟不断溶解,造成初始水溶液中的F−浓度增大,比如S2-1的初始F−浓度大于1.0 mg/L。当加入HCl调节pH值为酸性,稳定一段时间后,pH值有一定程度的上升,证明岩样中离子溶解成碱性,有利于水溶性氟的浸出。加入HCl后,部分岩样在超纯水中F−浓度显著增大,S1-1的F−浓度由初始的0.91 mg/L上升到2.19 mg/L,说明酸性条件下天然矿物组成中其他氟化物的浸出对矿井水中的F−浓度贡献很大。

另外,通过加入NaOH,调节水样pH到11~11.5,由于岩水质量比为1∶200的样品在酸性条件下中浸出浓度远小于1.0 mg/L,因此试验中增加岩水比为1∶25的样品S1-0(1∶25),S2-0(1∶25),S3-0(1∶25),S4-0(1∶25)。如图8b所示,岩水比为1∶25的样品S1-0和S4-0在静置1 h后,F−浓度分别为0.62 mg/L和0.72 mg/L,说明在岩水比较大的情况下,F−会产生富集,浓度增大。超声1 h后,S1-0、S2-0、S3-0及S4-0样品中F−浓度分别为0.92 、0.97 、0.94 和1.31 mg/L,证明大的岩水比和剧烈水岩作用有利于天然矿物中F−的浸出和富集。加入NaOH调节溶液pH>11后,S1-0和S2-0样品的中F−浓度大于1 mg/L,S3-0的F−浓度不变,S4-0的F−浓度大于1.31 mg/L,其他样品的F−浓度出现了小幅下降或不变。由于天然矿物中的氟化物成分较复杂[20,34],矿井水溶液本身呈现碱性(pH=7~9),在碱性条件下易溶的水溶性氟化物已经全部或部分溶解,因此加入NaOH后,溶液中的F−浓度不变或变化幅度较小。

通过天然含氟矿物在不同pH条件的F−浸出试验,发现天然矿物在酸性条件下更有利于F−浸出,究其原因,矿物中的氟多以难溶化合物形式存在,比如CaF2、Na3AlFPO6以及AlF3(s)和FeF3(s)等,当pH>5时,这些难溶化合物反而更稳定[32,40]。当pH<5时,矿物-水溶液的溶解平衡被打破,导致部分难溶化合物发生溶解,F−浸出。同时发现,样品S3和S4,F−浓度变化较小,这是由于不同岩石中的氟元素存在形式差异较大,比如CaF2不溶于盐酸,因此样品S3、S4含CaF2成分较多[20]。而相关研究论文中对矿井水氟来源的分析认为,碱性条件下F−和OH−半径接近,更易于置换,有利于F−浸出[41-42]。究其原因,二者结论并不冲突,矿井水中的氟来源研究主要集中于已形成的碱性高氟矿井水的检测分析和理论推断,而本实验分析不同pH条件含氟矿井水的形成过程,在酸性条件下难溶氟化物发生了化学反应造成溶液中的F−浓度增大,pH也会相应增加,可能导致最终形成的高氟矿井水呈碱性。

通过分析不同天然含氟矿物在不同水岩作用条件下的浸出结果,总结了天然含氟矿物中F−浸出规律,如图9所示,高的岩水比(1∶50)条件下,较多含氟矿物与矿井水接触,更有利于氟化物的浸出,造成矿井水中F−浓度增大;在较强的水岩作用条件下,天然矿物中氟化物更易发生浸出和富集,实际F−浸出浓度与原生水化学成分及氟化物的组成密切相关,当吸附性氟化物在岩石中占比较高时,在短时间内可以有较多的氟化物溶解到水中;另外,在酸性或碱性条件下,天然含氟矿物中的部分难溶化合物或大量的水溶性氟化物会发生浸出反应,导致矿井水中的F−浓度增大。

3. 结 论

1)神东矿区矿井水氟化物主要来源于地层120 m以下深度的含氟天然矿物中,随着开采深度的加深,天然矿物中的含氟矿物出现的概率较大,煤炭开采过程中发生矿井水氟化物超标的概率显著提高。

2)利用实地采样、模拟试验的方法证明在复杂的水岩作用条件下天然含氟矿物中的氟化物浸出可以造成矿井水中F−浓度超标,证明天然含氟矿物是矿井水中氟化物的主要来源。

3)由于天然矿物中氟化物组成成分复杂,矿井水中氟化物浸出浓度受岩水比例、水岩作用强度、水岩作用时间、酸碱性等因素的影响,通过超声、提高岩水比例、增大水岩作用时间、调节酸碱度等方式可有效促进天然矿物中的氟化物浸出,提高矿井水中的氟化物浓度。

通过改变水岩作用条件,含氟天然矿物在矿井水中的F−浸出浓度会不断增大,证明天然矿物中的氟化物是矿井水中的主要来源。另外,试验中最终浸出的F−质量浓度低于实际矿井水F−质量浓度,证明矿井水中氟化物污染是长期地质和水化学作用的结果,高氟矿井水的形成还与地下水实际赋存条件、长时间的融浸以及在不同层位的多级融浸等因素相关。在此研究基础上,为精准判断天然含氟矿物的浸出源头,还需要进行下一步研究,比如厘清不同岩层的天然含氟矿物的氟化物组分,进一步研究易溶解、可溶解、难溶解及不溶解氟化物在含氟岩层的占比,以及探讨不同环境条件下天然含氟矿物的氟化物最大浸出值及浸出机理等。

-

-

[1] 李伟,孙希奎. 深地煤炭资源安全高效智能化开采关键技术与实践[J]. 煤炭科学技术,2024,52(1):52−64. doi: 10.12438/cst.2023-1794 LI Wei,SUN Xikui. Key technologies and practices for safe,efficient,and intelligent mining of deep coal resources[J]. Coal Science and Technology,2024,52(1):52−64. doi: 10.12438/cst.2023-1794

[2] 王国法. 煤矿智能化最新技术进展与问题探讨[J]. 煤炭科学技术,2022,50(1):1−27. doi: 10.3969/j.issn.0253-2336.2022.1.mtkxjs202201001 WANG Guofa. New technological progress of coal mine intelligence and its problems[J]. Coal Science and Technology,2022,50(1):1−27. doi: 10.3969/j.issn.0253-2336.2022.1.mtkxjs202201001

[3] 丁恩杰,俞啸,廖玉波,等. 基于物联网的矿山机械设备状态智能感知与诊断[J]. 煤炭学报,2020,45(6):2308−2319. DING Enjie,YU Xiao,LIAO Yubo,et al. Key technology of mine equipment state perception and online diagnosis under Internet of Things[J]. Journal of China Coal Society,2020,45(6):2308−2319.

[4] 吴劲松,徐辉,阚磊,等. 麻地梁煤矿综放设备全生命周期管理研究与实践[J]. 中国煤炭,2022,48(7):41−44. doi: 10.3969/j.issn.1006-530X.2022.07.007 WU Jinsong,XU Hui,KAN Lei,et al. Research and practice on lifecycle management of fully mechanized top-coal caving equipment in Madiliang Coal Mine[J]. China Coal,2022,48(7):41−44. doi: 10.3969/j.issn.1006-530X.2022.07.007

[5] 王铁军. 煤矿设备全生命周期健康诊断系统[J]. 工矿自动化,2022,48(S1):101−104. WANG Tiejun. State-of-the-art occurrence mechanism and hazard control of mining tremors and their challenges in Chinese coal mines[J]. Journal of China Coal Society,2023,48(5):1894−1918.

[6] 崔亚仲,白明亮,李波. 智能矿山大数据关键技术与发展研究[J]. 煤炭科学技术,2019,47(3):66−74. CUI Yazhong,BAI Mingliang,LI Bo. Key technology and development research on big data of intelligent mine[J]. Coal Science and Technology,2019,47(3):66−74.

[7] CARTER R A. Smart mining needs high IQ monitoring systems[J]. Engineering and Mining Journal,2020,221(9):38−44.

[8] 马宏伟,吴少杰,曹现刚,等. 煤矿综采设备运行状态大数据清洗建模[J]. 工矿自动化,2018,44(11):80−83. MA Hongwei,WU Shaojie,CAO Xiangang,et al. Big data cleaning modeling of operation status of coal mine fully-mechanized coal mining equipment[J]. Industry and Mine Automation,2018,44(11):80−83.

[9] 李福兴,李璐燨. 面向煤炭开采的大数据处理平台构建关键技术[J]. 煤炭学报,2019,44(S1):362−369. LI Fuxing,LI Luxi. Key technologies of big data processing platform construction for coal mining[J]. Journal of China Coal Society,2019,44(S1):362−369.

[10] 刘旭南,赵丽娟,付东波,等. 采煤机截割部传动系统故障信号小波包分解方法研究[J]. 振动与冲击,2019,38(14):169−175,253. LIU Xunan,ZHAO Lijuan,FU Dongbo,et al. Study on wavelet packet decomposition method for fault signal of shearer cutting unit transmission system[J]. Journal of Vibration and Shock,2019,38(14):169−175,253.

[11] XU J,REN C F,LIU Y X,et al. Noise elimination for coalcutter vibration signal based on ensemble empirical mode decomposition and an improved Harris Hawks optimization algorithm[J]. Symmetry,2022,14(10):1978. doi: 10.3390/sym14101978

[12] 王浩任,黄亦翔,赵帅,等. 基于小波包和拉普拉斯特征值映射的柱塞泵健康评估方法[J]. 振动与冲击,2017,36(22):45−50. WANG Haoren,HUANG Yixiang,ZHAO Shuai,et al. Health assessment for a piston pump based on WPD and LE[J]. Journal of Vibration and Shock,2017,36(22):45−50.

[13] 吉晓冬. 振动数据驱动的掘进机关键部件健康状态评估研究[D]. 北京:中国矿业大学(北京),2022. JI Xiaodong. Research on health status evaluation method of roadheader key components data-driven by vibration[J]. Beijing:China University of Mining & Technology-Beijing,2022.

[14] 马旭东,王跃龙,田慕琴,等. 液压支架健康评估与寿命预测模型研究[J]. 煤炭科学技术,2021,49(3):141−148. MA Xudong,WANG Yuelong,TIAN Muqin,et al. Health assessment and life prediction model of hydraulic support[J]. Coal Science and Technology,2021,49(3):141−148.

[15] 罗璇. 数据驱动的采煤机摇臂寿命预测方法研究[D]. 西安:西安科技大学,2020. LUO Xuan. Research on life prediction method of shearer rocker arm driven by data[D]. Xi’an:Xi’an University of Science and Technology,2020.

[16] 张一辙. 煤矿主扇风机故障诊断系统研究[D]. 阜新:辽宁工程技术大学,2020. ZHANG Yizhe. Research on fault diagnosis system of main fan in coal mine[D]. Fuxin:Liaoning Technical University,2020.

[17] 李红岩,杨朝旭,荣相,等. 矿用逆变器功率器件故障预测与健康管理技术现状及展望[J]. 工矿自动化,2022,48(5):15−20. LI Hongyan,YANG Chaoxu,RONG Xiang,et al. Research status and prospect of prognostics health management technology for mine inverter power devices[J]. Journal of Mine Automation,2022,48(5):15−20.

[18] 庞义辉,刘新华,王泓博,等. 基于千斤顶行程驱动的液压支架支护姿态与高度解析方法[J]. 采矿与安全工程学报,2023,40(6):1231−1242. PANG Yihui,LIU Xinhua,WANG Hongbo,et al. Analytical method of support posture and height of hydraulic support based on jack stroke drive[J]. China Industrial Economics,2023,40(6):1231−1242.

[19] 李曼,潘楠楠,段雍,等. 煤矿旋转机械健康指标构建及状态评估[J]. 工矿自动化,2022,48(9):33−41. LI Man,PAN Nannan,DUAN Yong,et al. Construction of health index and condition assessment of coal mine rotating machinery[J]. Industry and Mine Automation,2022,48(9):33−41.

[20] 丁华,杨亮亮,杨兆建,等. 数字孪生与深度学习融合驱动的采煤机健康状态预测[J]. 中国机械工程,2020,31(7):815−823. doi: 10.3969/j.issn.1004-132X.2020.07.007 DING Hua,YANG Liangliang,YANG Zhaojian,et al. Health prediction of shearers driven by digital twin and deep learning[J]. China Mechanical Engineering,2020,31(7):815−823. doi: 10.3969/j.issn.1004-132X.2020.07.007

[21] 秦一帆. 面向煤矿产业的智能算法开发管理平台的设计与实现[D]. 西安:西安电子科技大学,2022. QIN Yifan. Design and implementation of intelligent algorithm development and management platform for coal mine industry[D]. Xi’an:Xidian University,2022.

[22] 曹现刚,宫钰蓉,罗璇,等. 考虑机会维护的煤矿综采设备群维护决策优化研究[J]. 煤炭工程,2020,52(6):164−169. CAO Xiangang,GONG Yurong,LUO Xuan,et al. Research on maintenance decision optimization of coal mine fully mechanized mining equipment based on genetic algorithm[J]. Coal Engineering,2020,52(6):164−169.

[23] 王国法,庞义辉. 综采成套技术与装备集成配套设计创新与实践[J]. 煤炭工程,2018,50(5):1−5,9. WANG Guofa,PANG Yihui. Integrated matching design innovation and practice of fully mechanized mining technology and equipment[J]. Coal Engineering,2018,50(5):1−5,9.

[24] 张彦禄,王步康,张小峰,等. 我国连续采煤机短壁机械化开采技术发展40 a与展望[J]. 煤炭学报,2021,46(1):86−99. ZHANG Yanlu,WANG Bukang,ZHANG Xiaofeng,et al. Forty years’ development and future prospect on mechanized short-wall mining technology with continuous miner in China[J]. Journal of China Coal Society,2021,46(1):86−99.

[25] 焦阳,郭东芝,曹峰. 王坡煤矿“互联网+精益管理” 模式研究与实践[J]. 中国煤炭,2016,42(1):114−117. doi: 10.3969/j.issn.1006-530X.2016.01.029 JIAO Yang,GUO Dongzhi,CAO Feng. Research and practice on Internet plus lean management mode in Wangpo Coal Mine[J]. China Coal,2016,42(1):114−117. doi: 10.3969/j.issn.1006-530X.2016.01.029

[26] 秦翥. 矿用装备全生命周期服务系统的研究与应用[J]. 煤炭科学技术,2019,47(4):44−49. QIN Zhu. Research and application of life cycle service system of mining equipment[J]. Coal Science and Technology,2019,47(4):44−49.

[27] 金智新,闫志蕊,王宏伟,等. 新一代信息技术赋能煤矿装备数智化转型升级[J]. 工矿自动化,2023,49(6):19−31. JIN Zhixin,YAN Zhirui,WANG Hongwei,et al. The new generation of information technology empowers the digital and intelligent transformation and upgrading of coal mining equipment[J]. Industry and Mine Automation,2023,49(6):19−31.

[28] 刘具,秦坤,王海燕,等. 煤炭企业数字化转型建设路径研究[J]. 煤炭工程,2023,56(6):203−210. LIU Ju,QIN Kun,WANG Haiyan,et al. Thoughts on digital transformation path of coal enterprises[J]. Coal Engineering,2023,56(6):203−210.

[29] 王国法,庞义辉,任怀伟,等. 智慧矿山系统工程及关键技术研究与实践[J]. 煤炭学报,2024,49(1):181−202. WANG Guofa,PANG Yihui,REN Huaiwei,et al. System engineering and key technologies research and practice of smart mine[J]. Journal of China Coal Society,2024,49(1):181−202.

[30] 王学文,刘曙光,王雪松,等. 面向多人−多机复杂协作任务的煤矿XR智能运维系统[J]. 煤炭学报,2024,49(4):2124−2140. WANG Xuewen,LIU Shuguang,WANG Xuesong,et al. Research on coal mine XR intelligent operation and maintenance system for complex collaborative tasks involving multiple humans and multiple robots[J]. Journal of China Coal Society,2024,49(4):2124−2140.

[31] 庞义辉,胡相捧,刘新华. 采场围岩失稳与液压支架智能自适应控制[M]. 北京:应急管理出版社,2024. [32] 王国法,杜毅博,徐亚军,等. 中国煤炭开采技术及装备50年发展与创新实践:纪念《煤炭科学技术》创刊50周年[J]. 煤炭科学技术,2023,51(1):1−18. WANG Guofa,DU Yibo,XU Yajun,et al. Development and innovation practice of China coal mining technology and equip-ment for 50 years:Commemorate the 50th anniversary of the publication of Coal Science and Technology[J]. Coal Science and Technology,2023,51(1):1−18.

-

期刊类型引用(3)

1. 焦华喆,陈曦,张铁岗,杨柳华,陈新明,HONAKER Rick,马俊伟,余洋. 黄河流域煤炭开发区地下水污染成因分析及防治建议. 中国地质. 2024(01): 143-156 .  百度学术

百度学术

2. 梁煌,胡潭楸. 煤矿含氟矿井水除氟技术研究进展. 环保科技. 2024(06): 55-59 .  百度学术

百度学术

3. 唐佳伟,张锁,刘兆峰,张海琴,包一翔,侯福林,郭强,曹志国,李井峰. 吸附法去除矿井水中F~-研究进展. 煤炭科学技术. 2023(05): 269-283 .  本站查看

本站查看

其他类型引用(0)

下载:

下载: